VOCs elimination catalyst and preparation method thereof

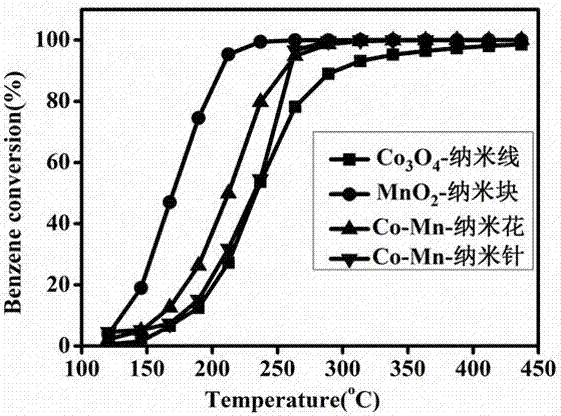

A catalyst and oxide technology, applied in the nano field, can solve the problems of limiting the wide application of noble metal-based catalysts, and achieve the effects of obvious industrial application value, convenient operation, and high benzene catalytic oxidation activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

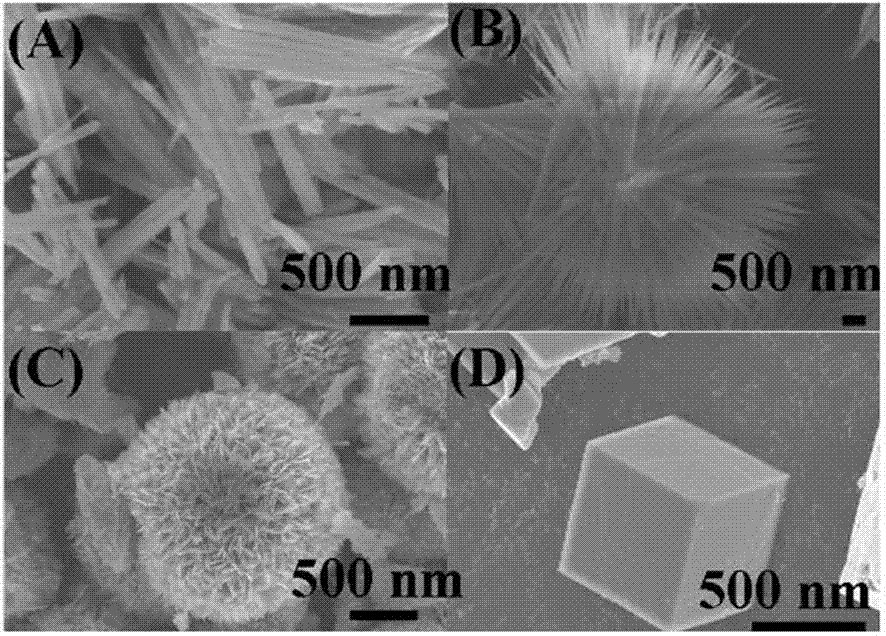

[0023] With Co 3 o 4 Taking nanowires as an example, the raw materials are cobalt nitrate, urea, ethanol and HCl. Specifically: Weigh: 100 mg Co(NO 3 ) 2 ·6H 2 O (molecular weight 291.0), 100 mg urea (molecular weight 60), and then add 35 mL water and 15 mL ethanol mixed solvent, and add 1 mL HCl (3M) to the above solution, stir at room temperature for 1 h, turn to into the water heating kettle, 140 o C, reacted for 10 h, centrifuged, washed with ethanol and water 5-6 times. Put in -46 o Under vacuum freezing for 10 h at 120 o C drying for 24h, then into the muffle furnace roasting, with 1 o C / min heating rate rises to 400 o C, at 400 o C for 4 h. The samples synthesized through the above steps are marked as Co 3 o 4 Nanowires, the synthesized nanowires are 20-30 nm in diameter and 3-12 in length mu m (such as figure 1 in A).

Embodiment 2

[0025] With Co 5 mn 1 O nanoneedles as an example, the raw materials are cobalt nitrate and manganese nitrate, urea, ethanol and HCl. Specifically: Weighing: 85.28 mg Co(NO 3 ) 2 ·6H 2 O (molecular weight 291.0), 14.71 mg Mn(NO 3 ) 2 4H 2 O (molecular weight 251.01), 100 mg urea (molecular weight 60), then add 35 mL of water and 15 mL of ethanol mixed solvent, add 1 mL of HCl (3M) to the above solution, stir at room temperature for 1 h, transfer to Water heating kettle, 140 o C, reacted for 10 h, centrifuged, washed with ethanol and water 5-6 times. Put in -46 o Under vacuum freezing for 10 h at 120 o C drying for 24 h and then into the muffle furnace roasting, with 1 o C / min heating rate rises to 400 o C, at 400 o C for 4 h. The samples synthesized through the above steps are marked as Co 5 mn 1 O nanoneedles, the synthesized nanoneedles have a diameter of 210 nm and a length of 3-12 mu between m (such as figure 1 in B).

Embodiment 3

[0027] With Co 1 mn 1 O nanoflowers as an example, the raw materials are cobalt nitrate and manganese nitrate, urea, ethanol and HCl. Specifically: Weighing: 53.69 mg Co(NO 3 ) 2 ·6H 2 O (molecular weight 291.0), 46.30 mg Mn (NO 3 ) 2 4H 2 O (molecular weight 251.01), 100 mg urea (molecular weight 60), and then add 35 mL of water and 15 mL of ethanol mixed solvent, add 1 mL of HCl (3M) to the above solution, stir at room temperature for 1 h, transfer to into the water heating kettle, 140 o C, reacted for 10 h, centrifuged, washed with ethanol and water 5-6 times. Put in -46 o Under vacuum freezing for 10 h at 120 o C drying for 24 h and then into the muffle furnace roasting, with 1 o C / min heating rate rises to 400 o C, at 400 o C for 4 h. The samples synthesized through the above steps are marked as Co 1 mn 1 O Hollow spheres, hollow spheres are composed of uniform nanoribbons with a diameter of about 400 nm (such as figure 1 in C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com