Patents

Literature

48results about How to "Specific performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

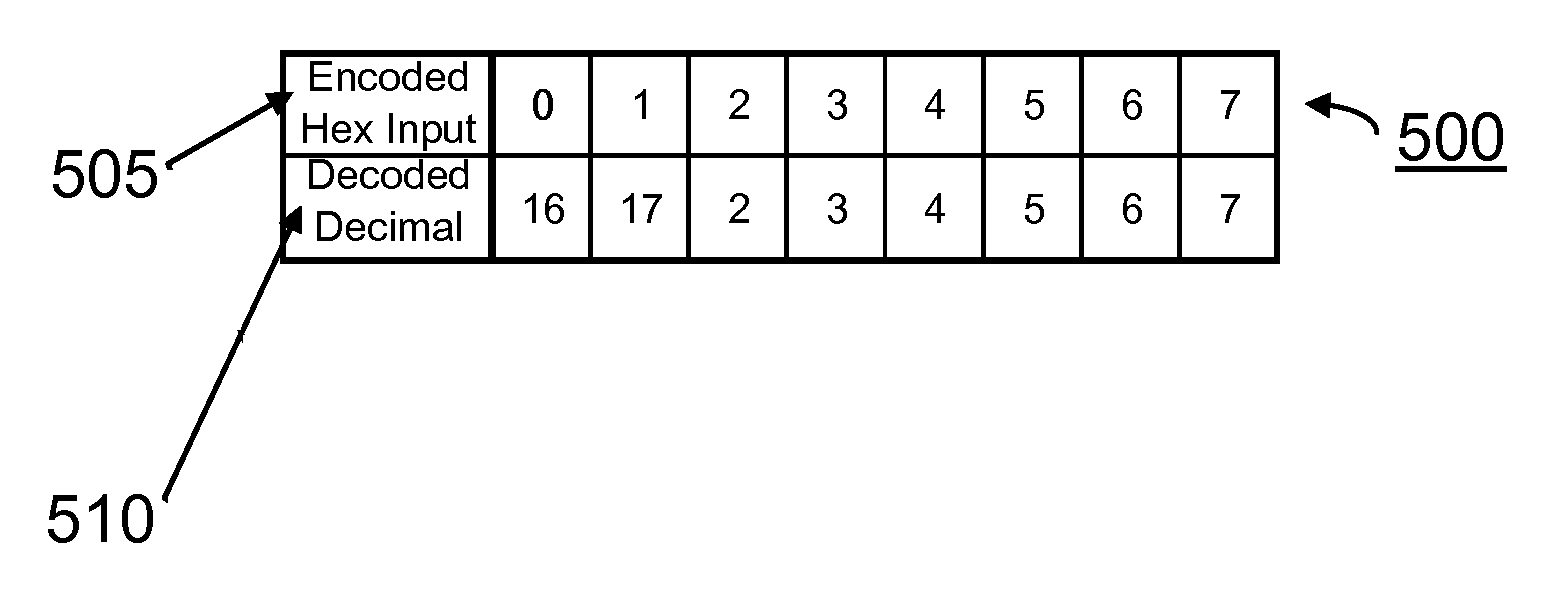

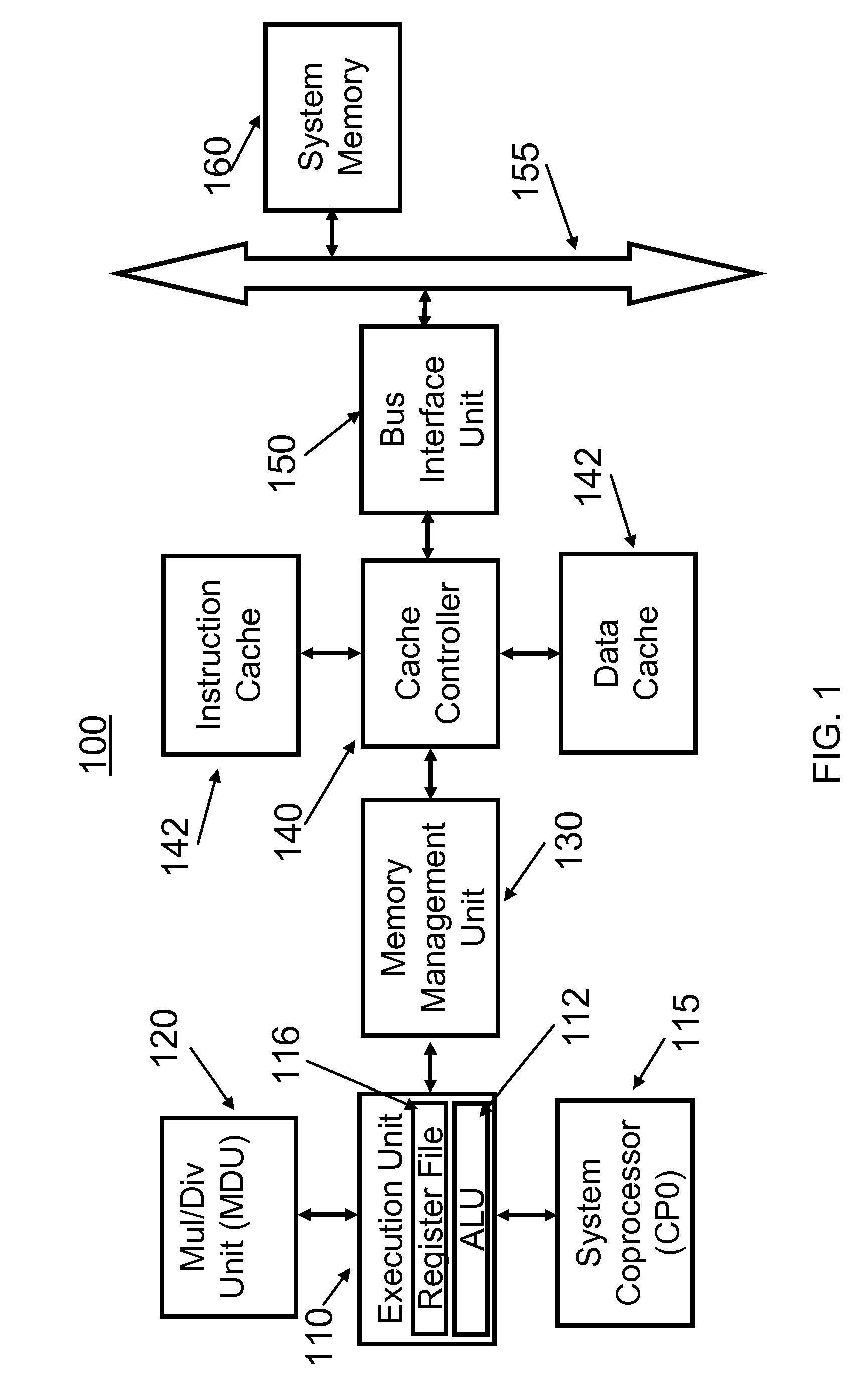

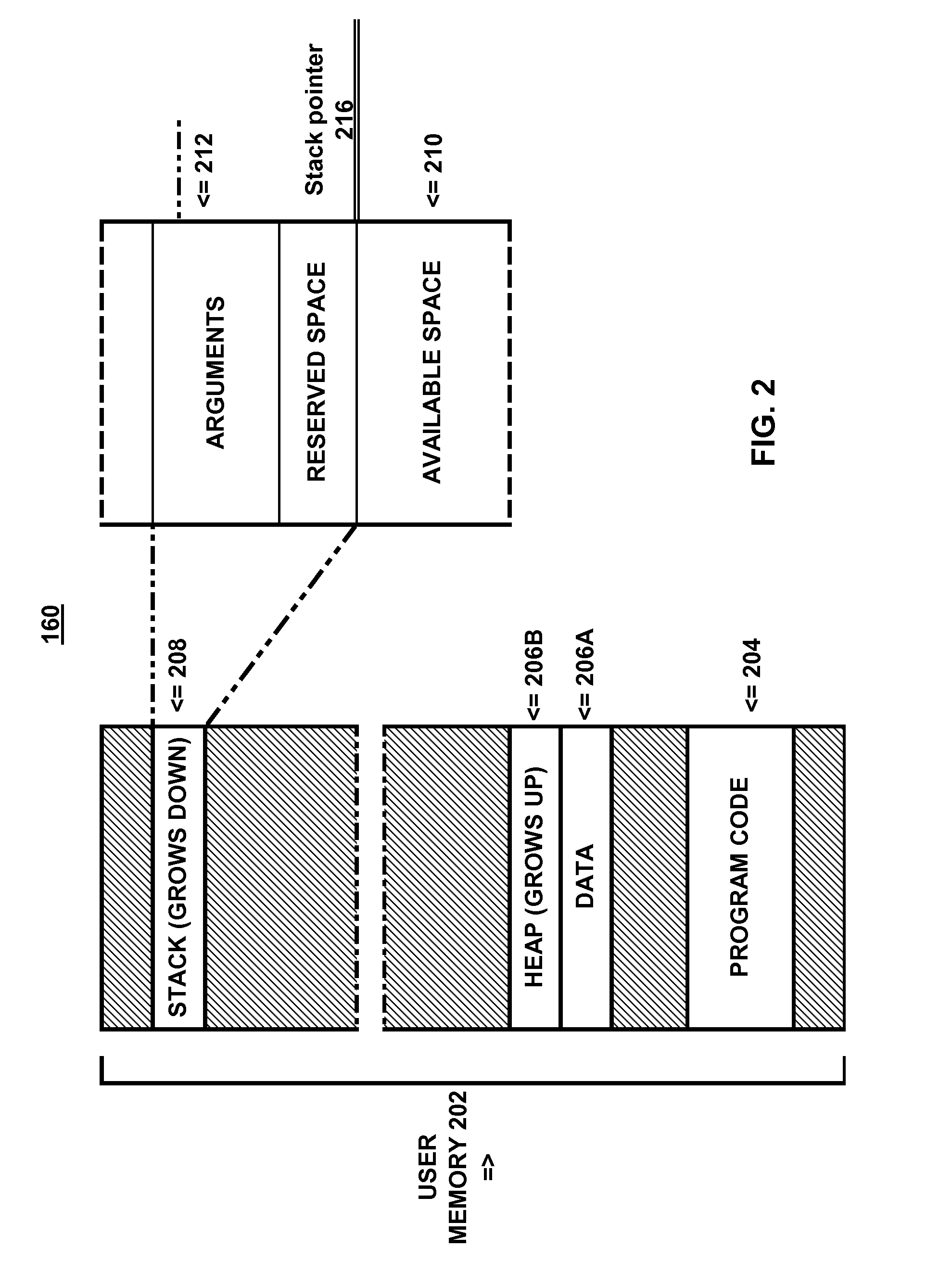

Variable register and immediate field encoding in an instruction set architecture

ActiveUS20100287359A1Suppresses increase in code sizeSpecific costInstruction analysisDigital computer detailsOperation modeApplication software

A method and apparatus provide means for compressing instruction code size. An Instruction Set Architecture (ISA) encodes instructions compact, usual or extended bit lengths. Commonly used instructions are encoded having both compact and usual bit lengths, with compact or usual bit length instructions chosen based on power, performance or code size requirements. Instructions of the ISA can be used in both privileged and non-privileged operating modes of a microprocessor. The instruction encodings can be used interchangeably in software applications. Instructions from the ISA may be executed on any programmable device enabled for the ISA, including a single instruction set architecture processor or a multi-instruction set architecture processor.

Owner:ARM FINANCE OVERSEAS LTD

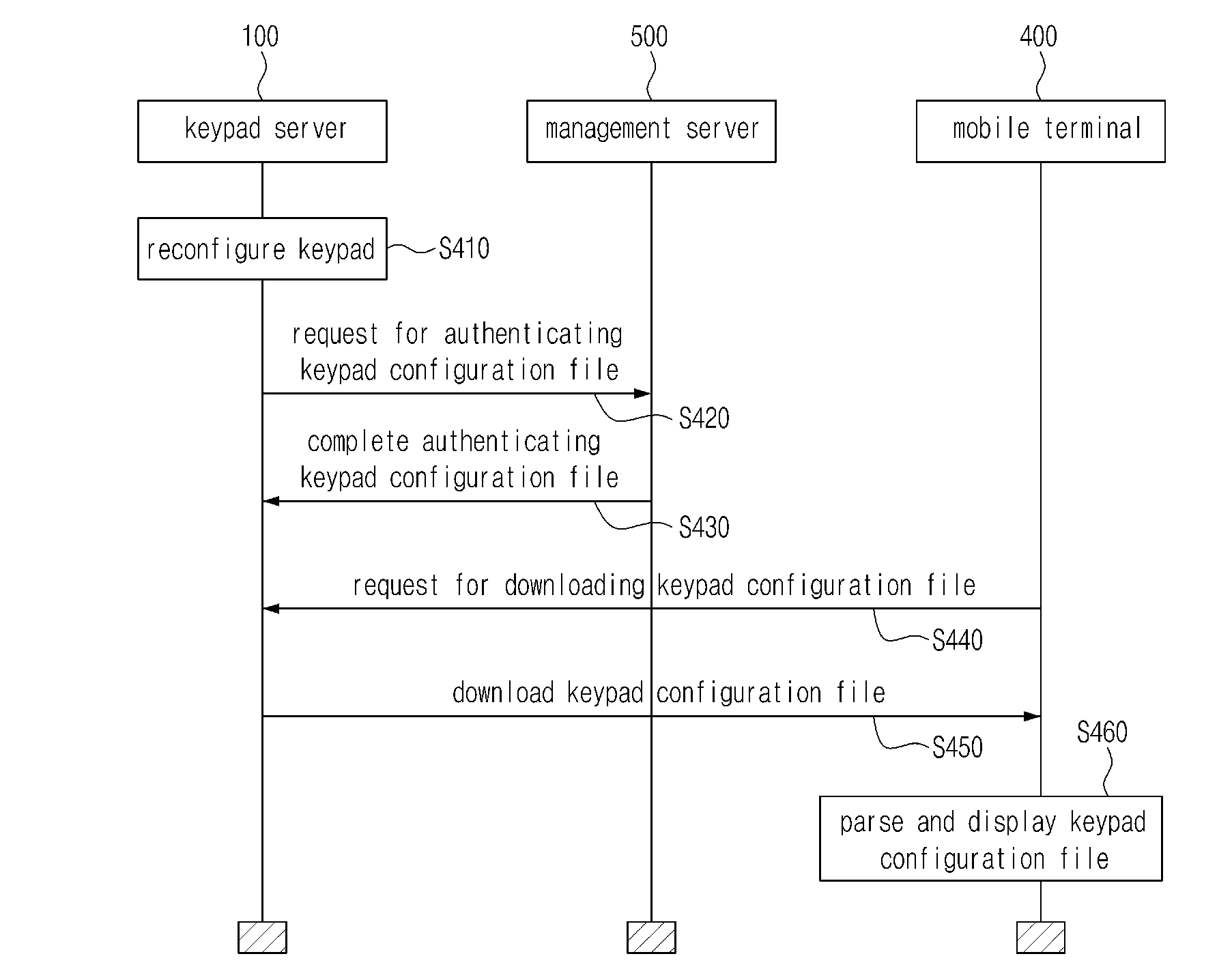

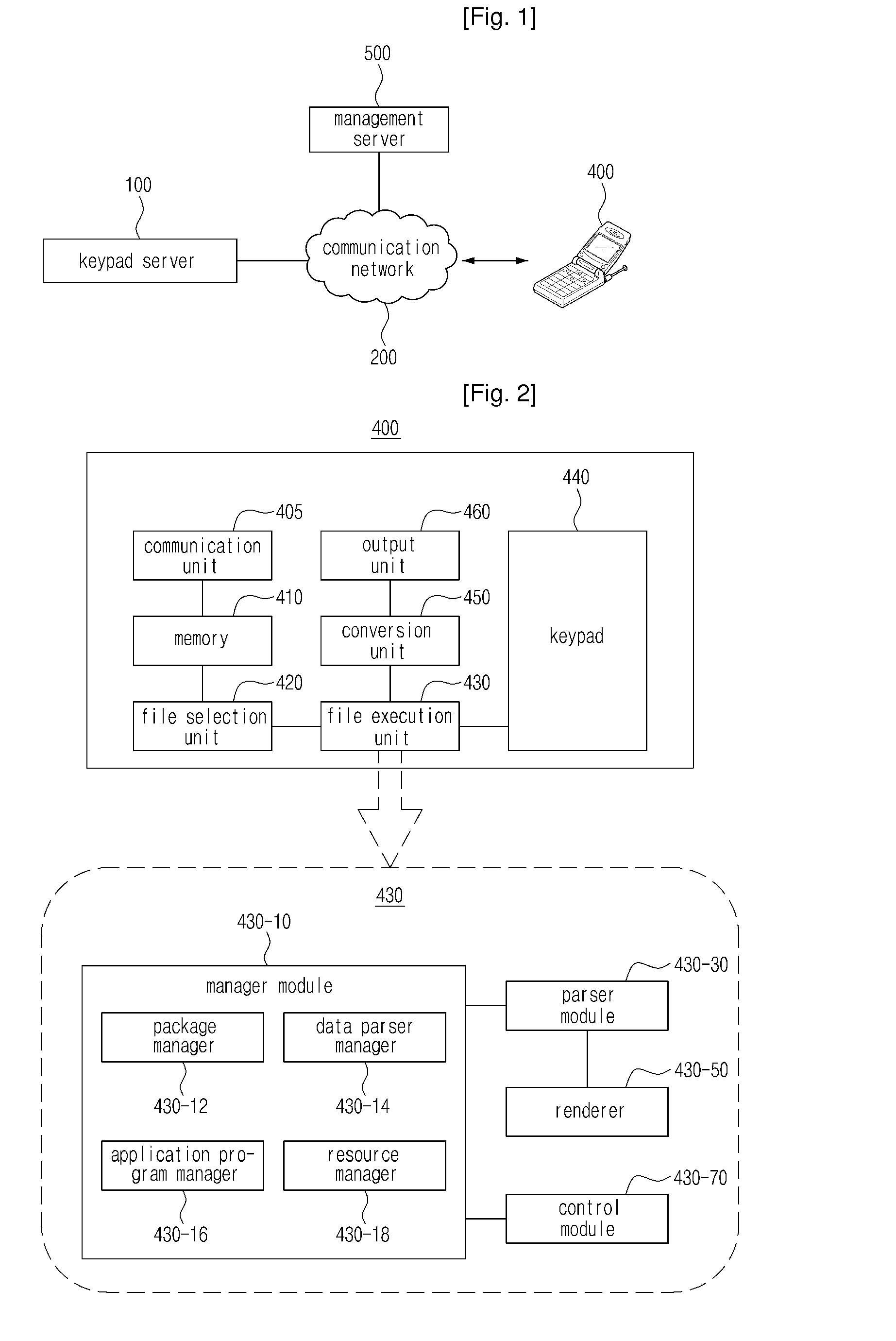

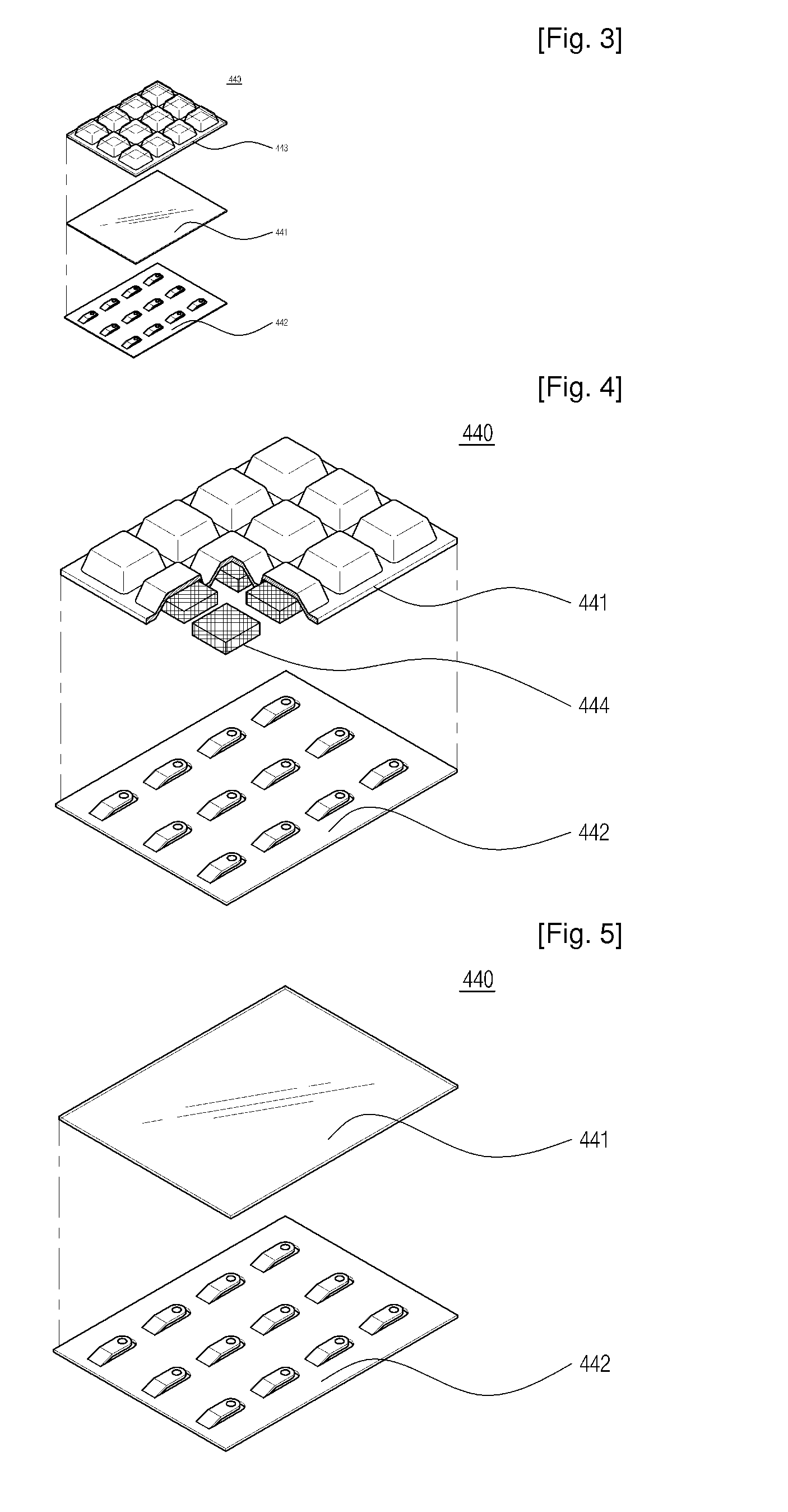

Method for configurating keypad of terminal and the terminal and system including the terminal and the keypad capable of reconfiguration

InactiveUS20090270078A1Good serviceSpecific performanceInput/output for user-computer interactionSpecial service for subscribersComputer terminalEmbedded system

Disclosed are a method of configuring a keypad of a terminal, a terminal configured thereby, a system including such a terminal, and a reconfigurable keypad. A keypad server includes keypad configuration files according to various applications implemented in a terminal, and provides the keypad configuration file to the terminal. The terminal receives the keypad configuration file from the keypad server through a wired or wireless network, and includes a keypad area on which a keypad configuration according to the keypad configuration file is displayed. In this way, various types of keypads can be implemented.

Owner:SK PLANET CO LTD

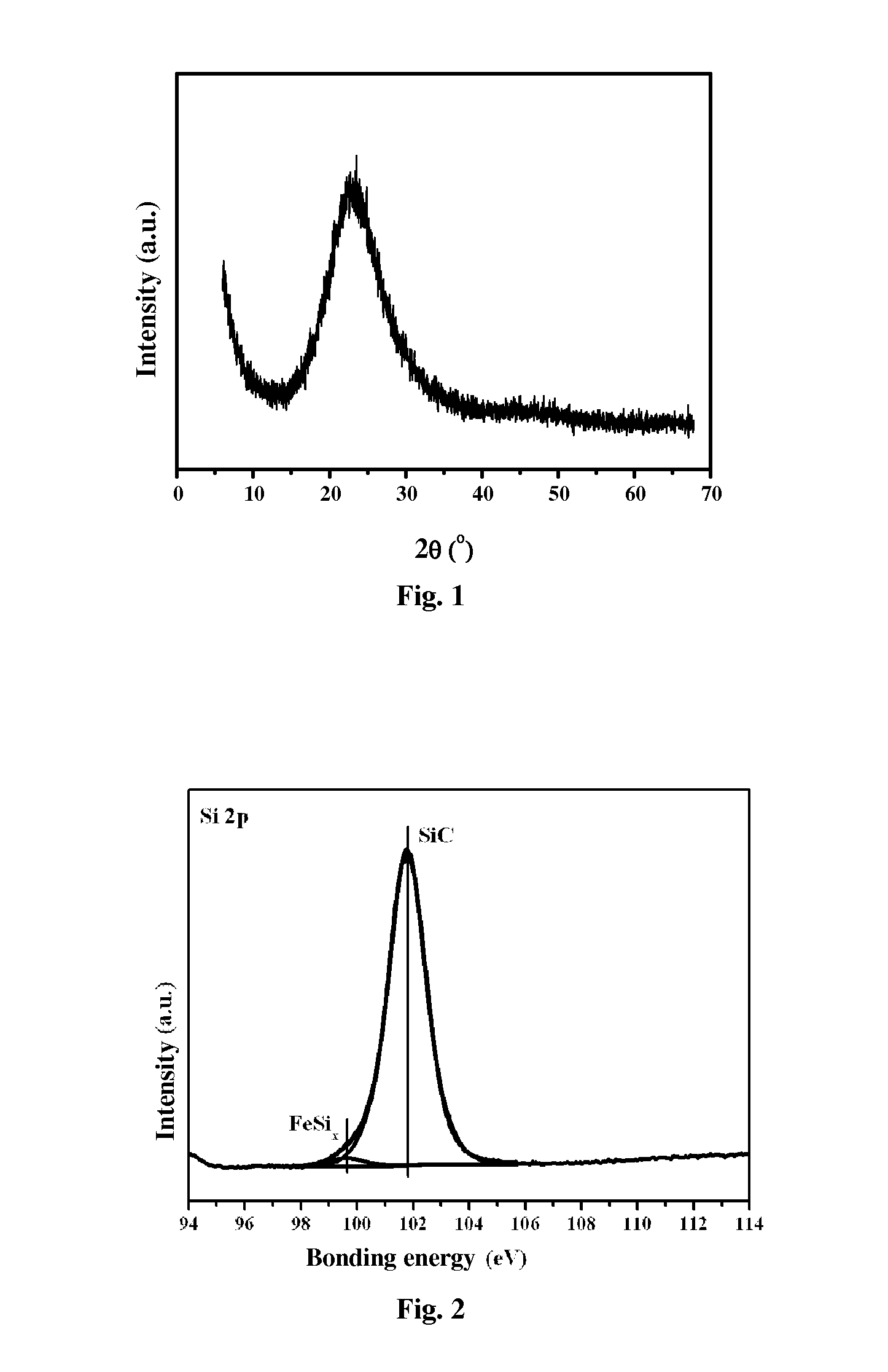

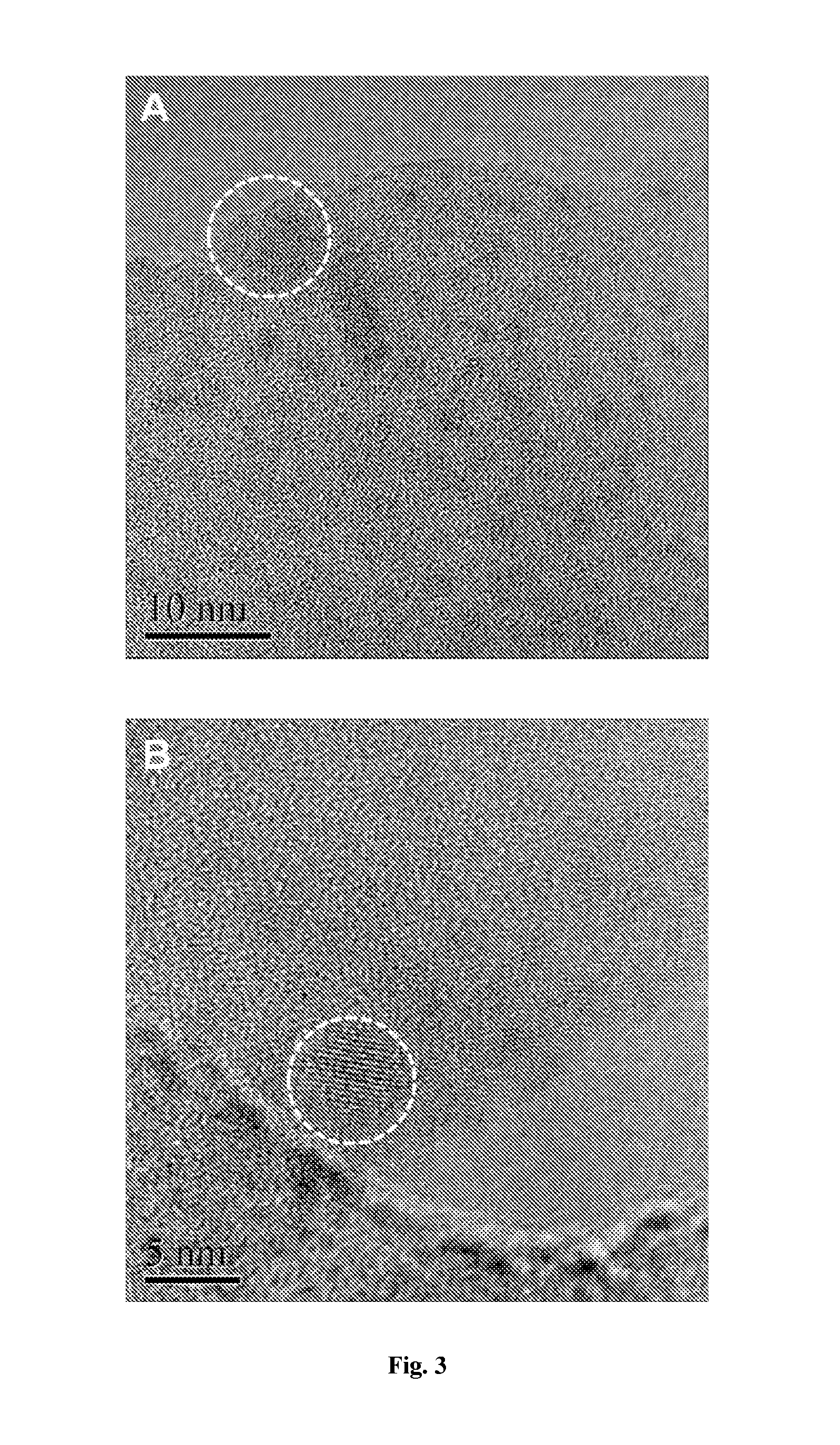

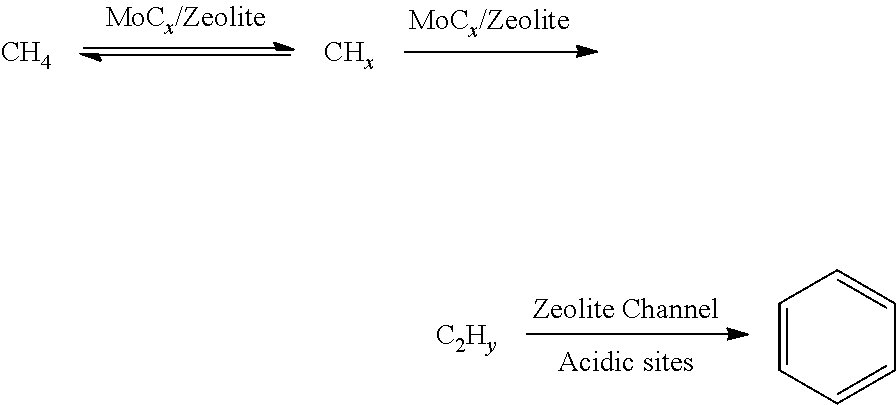

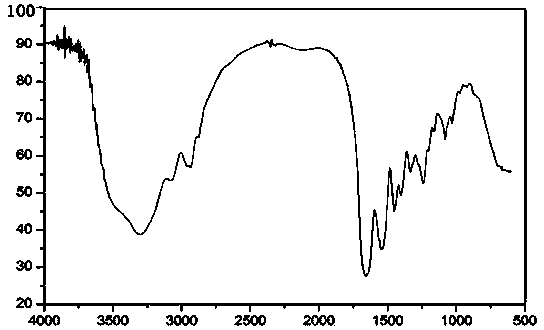

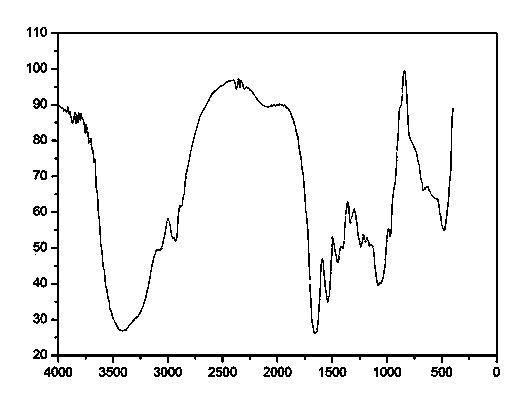

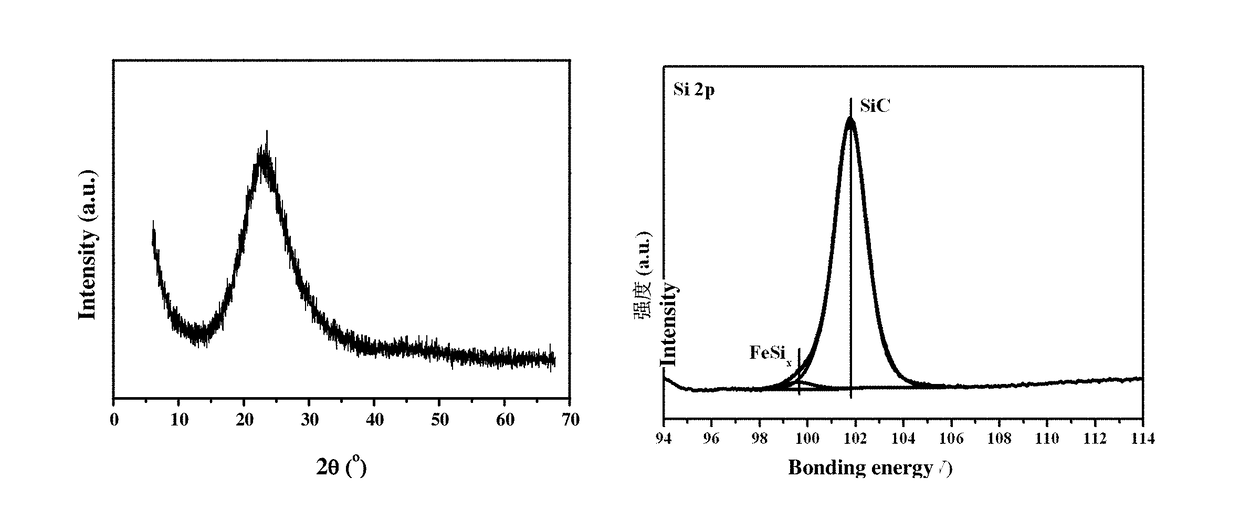

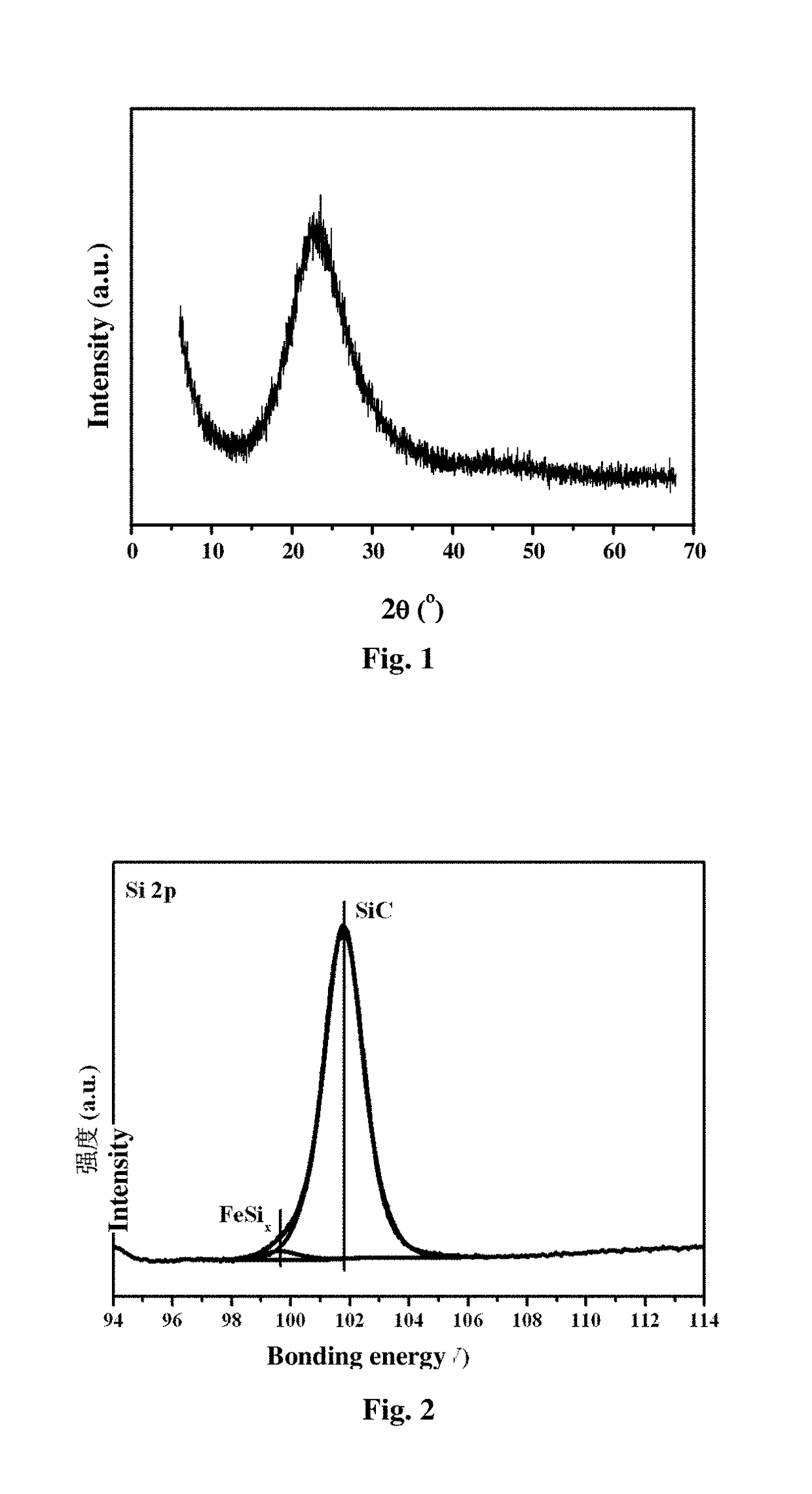

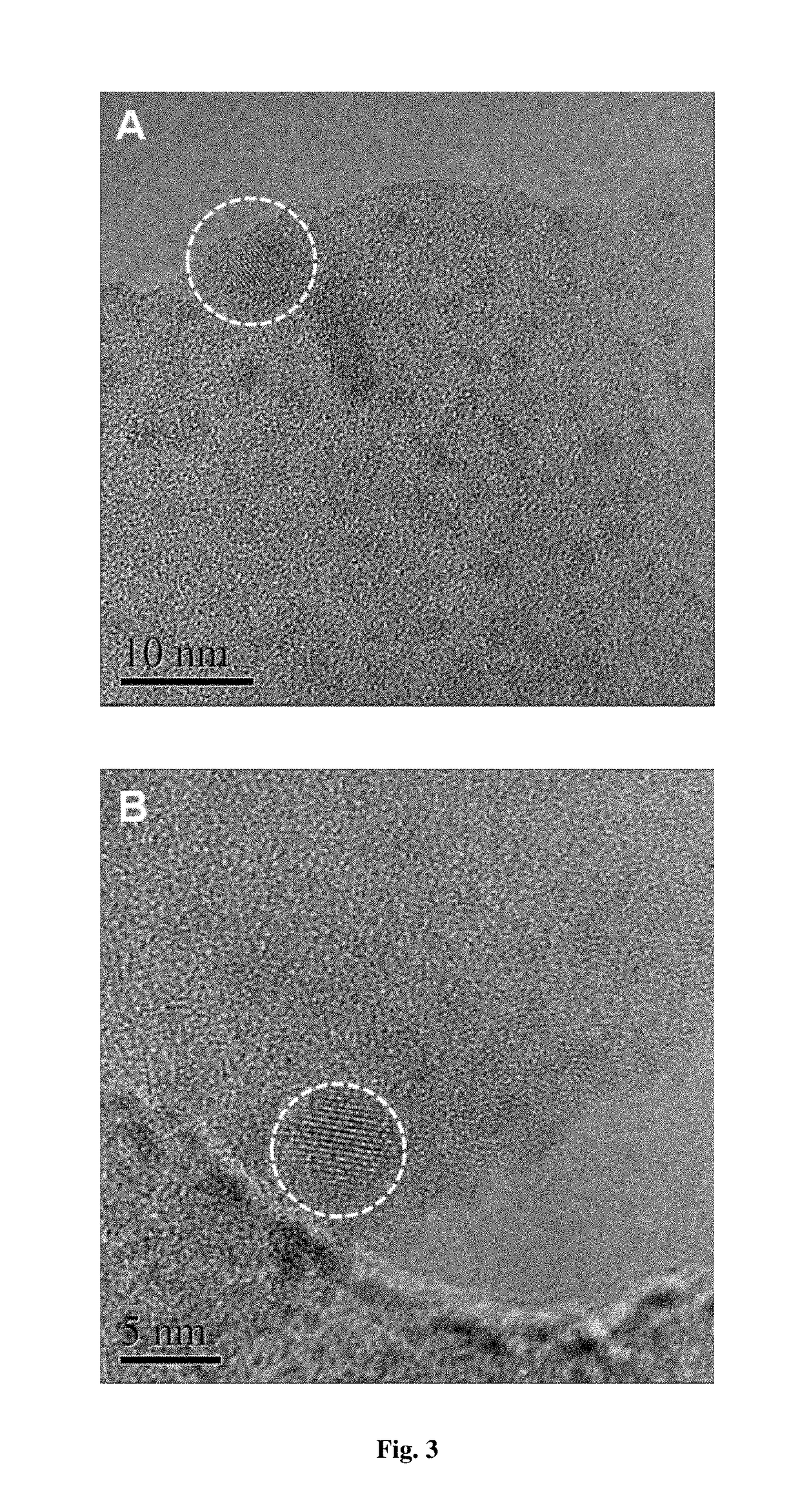

Synthesis of olefins from oxygen-free direct conversion of methane and catalysts thereof

ActiveUS20140336432A1Specific performanceGood dispersionOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPtru catalystFixed bed

The present invention is related to the preparation of a metal lattice-doping catalyst in an amorphous molten state, and the process of catalyzing methane to make olefins, aromatics, and hydrogen using the catalyst under oxygen-free, continuous flowing conditions. Such a process has little coke deposition and realizes atom-economic conversion. Under the conditions encountered in a fixed bed reactor (i.e. reaction temperature: 750˜1200° C.; reaction pressure: atmospheric pressure; the weight hourly space velocity of feed gas: 1000˜30000 ml / g / h; and fixed bed), conversion of methane is 8-50%. The selectivity of olefins is 30˜90%. And selectivity of aromatics is 10˜70%. There is no coking. The reaction process has many advantages, including a long catalyst life (>100 hrs), high stability of redox and hydrothermal properties under high temperature, high selectivity towards target products, zero coke deposition, easy separation of products, good reproducibility, safe and reliable operation, etc., all of which are very desirable for industrial application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

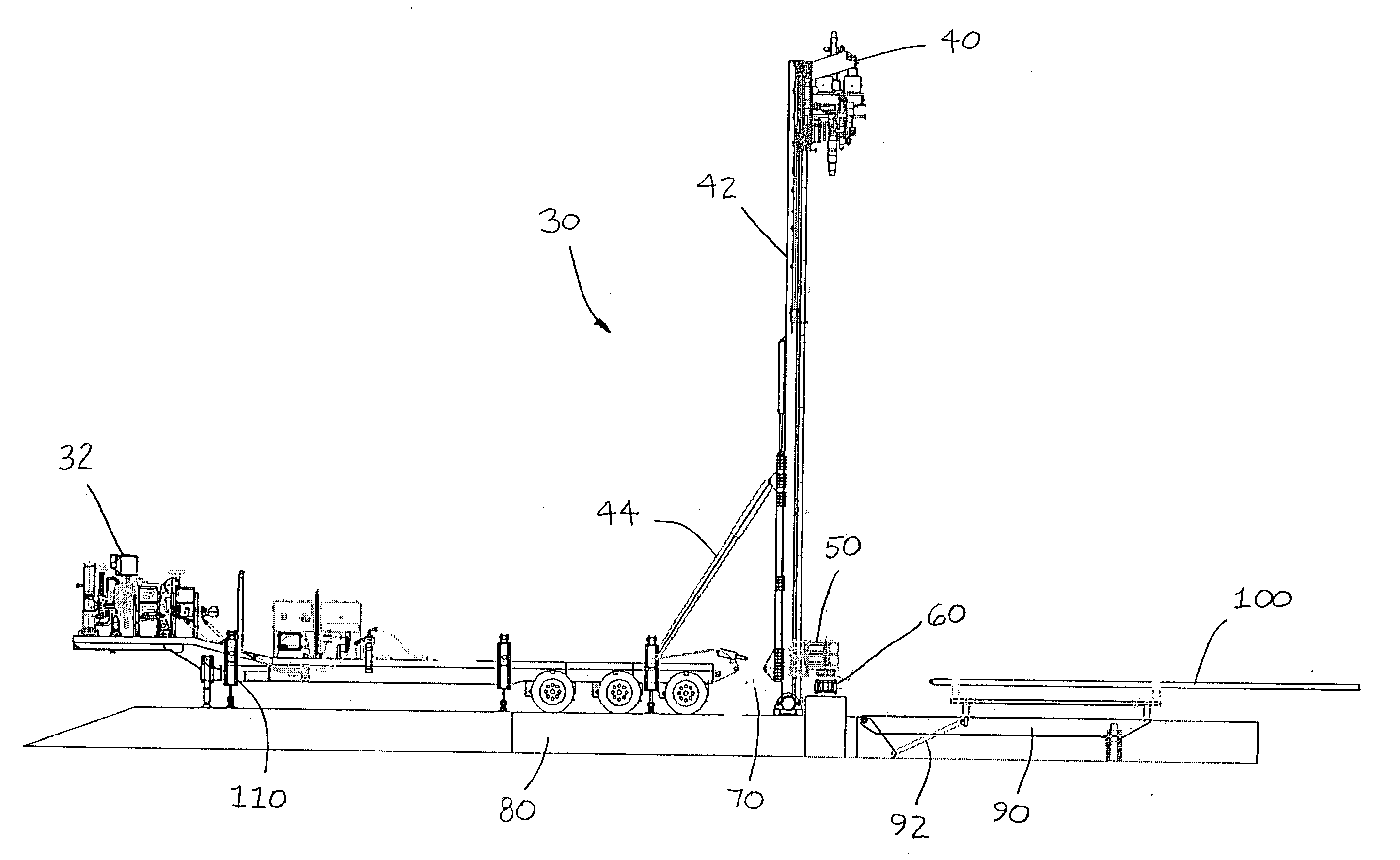

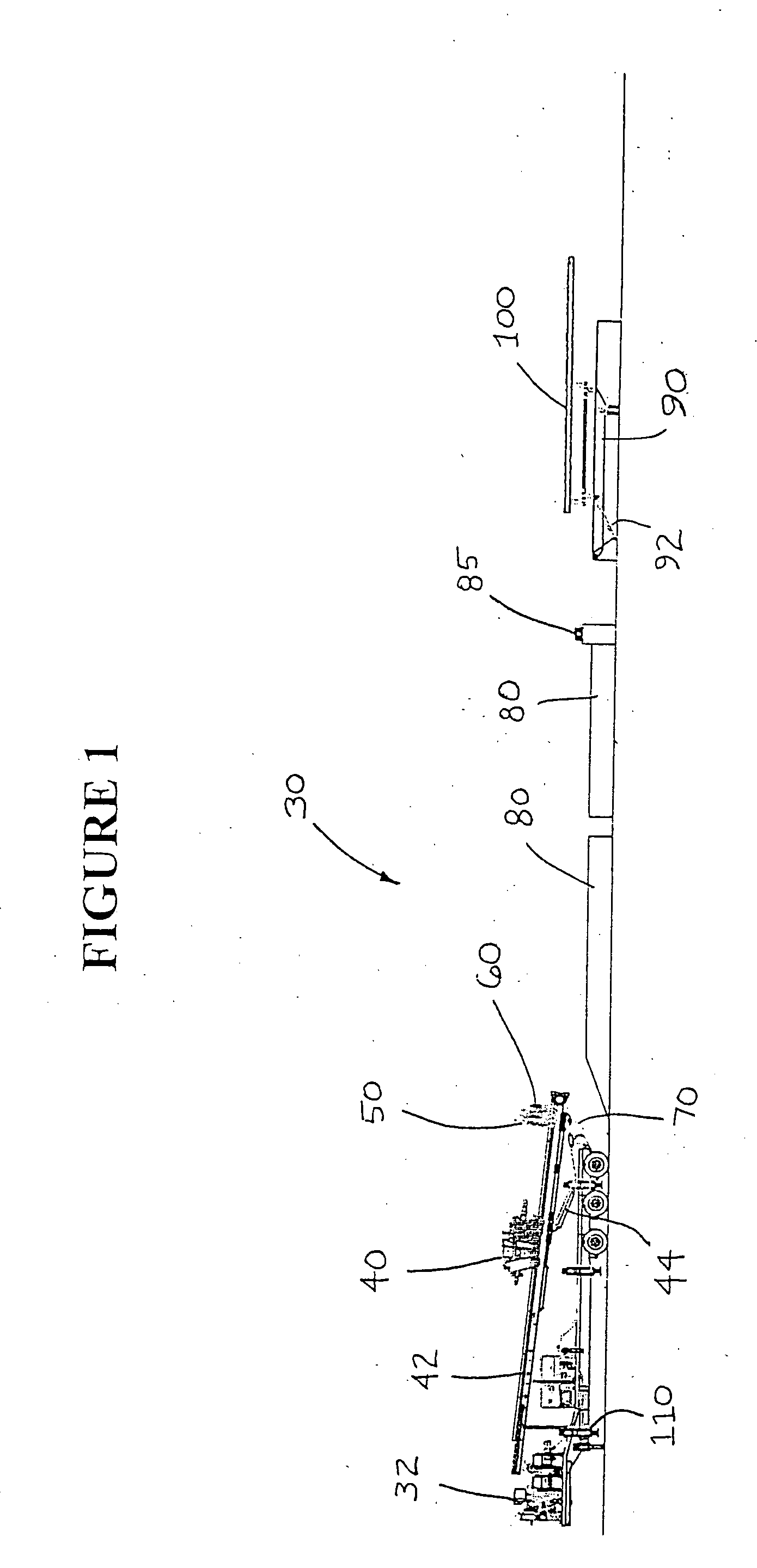

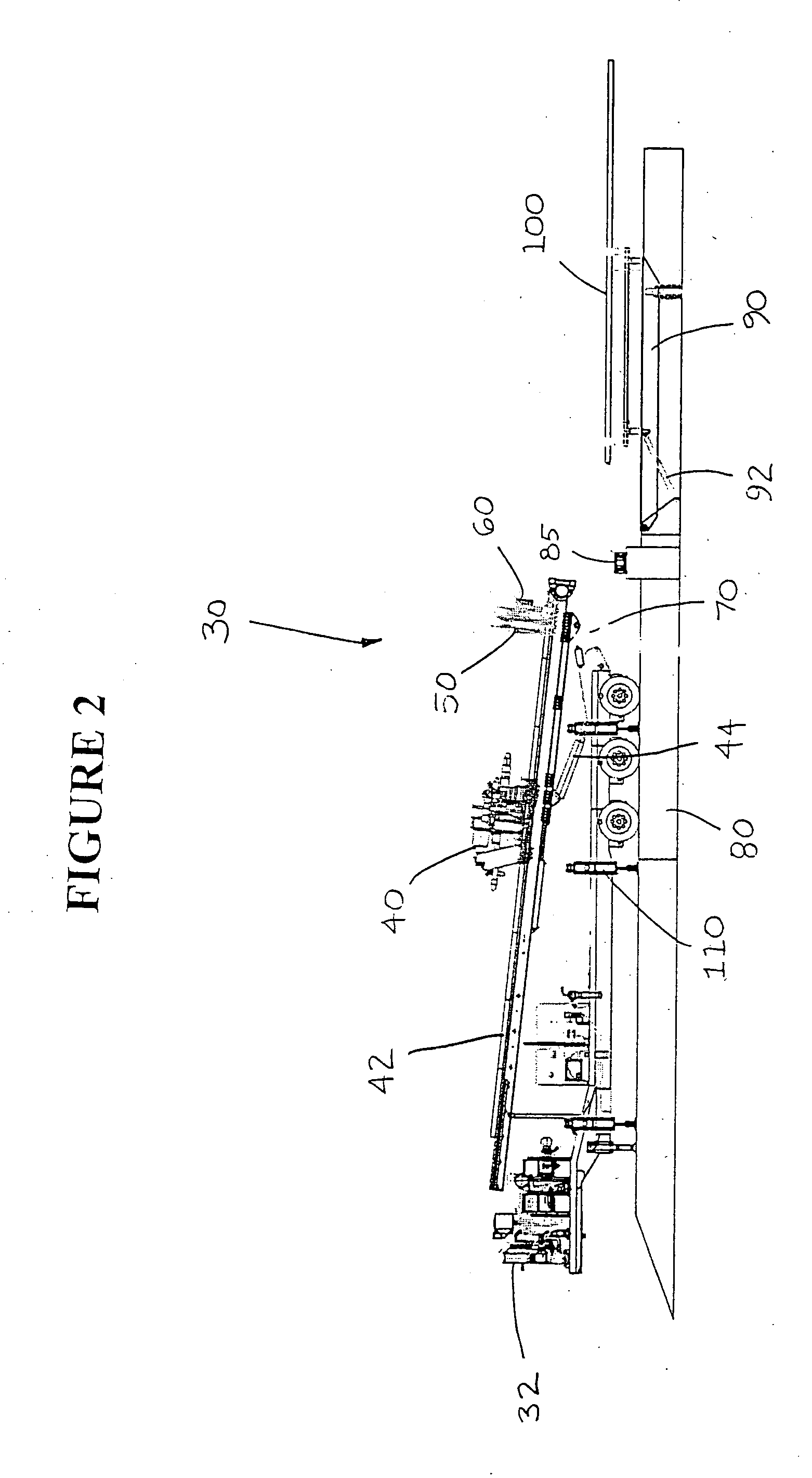

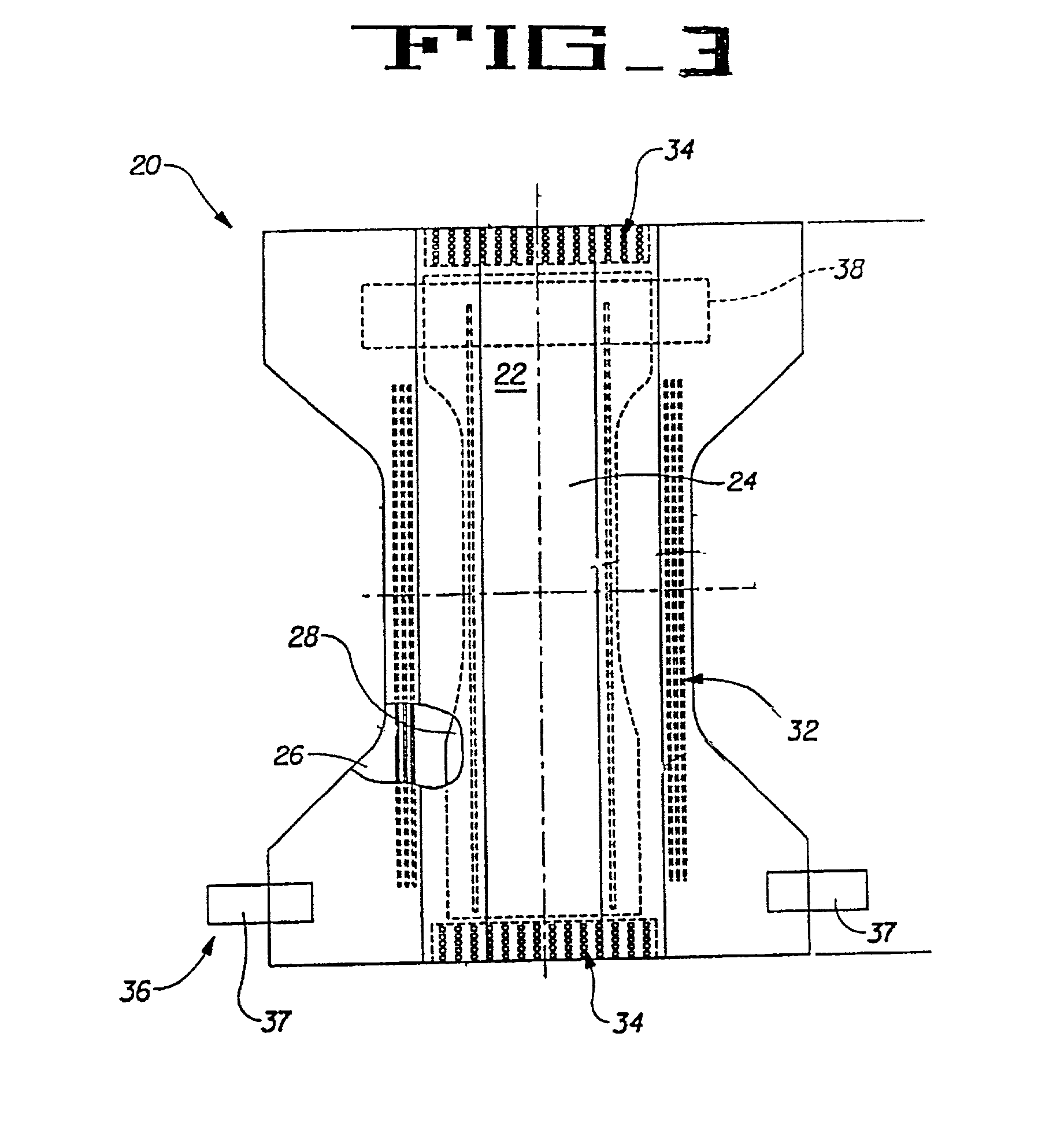

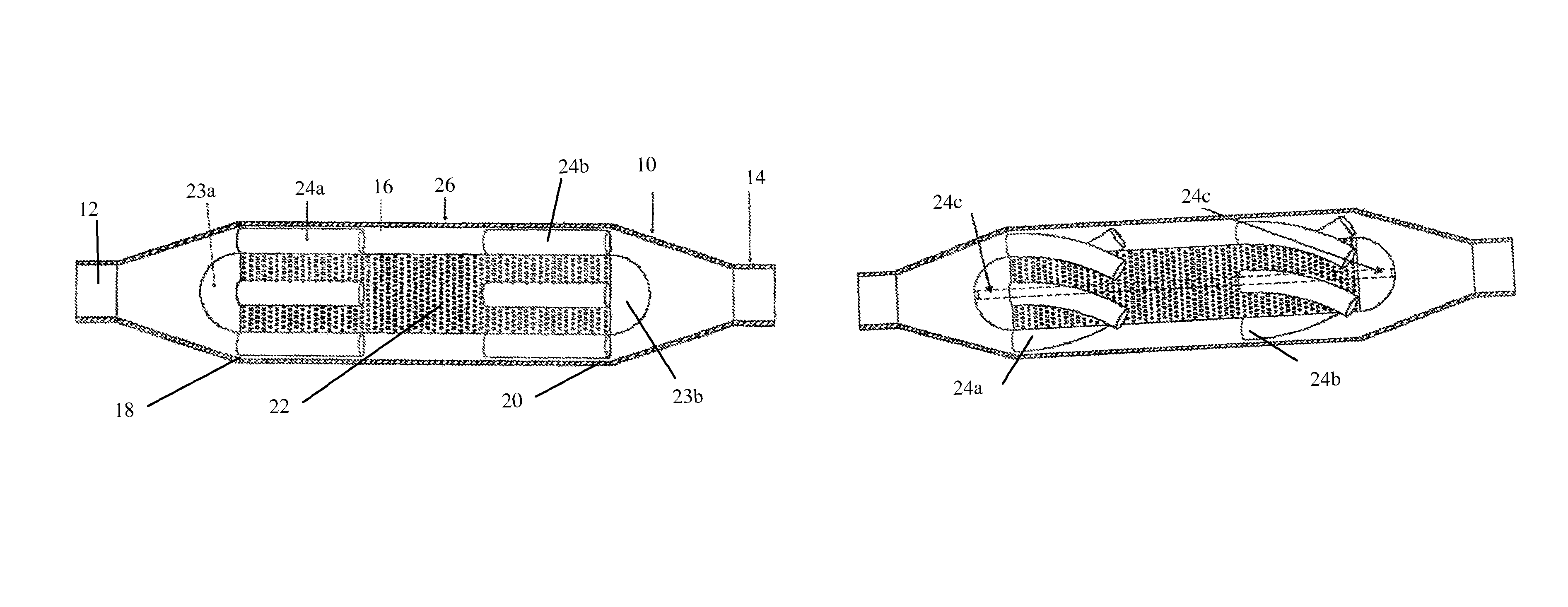

Apparatus and method for modified horizontal directional drilling assembly

InactiveUS20060243490A1Increase capacityLarge diameterDrilling rodsDerricks/mastsPower unitDirectional drilling

An apparatus and method for a modified horizontal directional drilling assembly for drilling pipe into a drilling surface. The drilling assembly comprises a power unit for supplying power to the assembly, a thrust frame adapted to be moved between a position substantially parallel to the drilling surface and a position substantially perpendicular to the drilling surface and a means for moving the thrust frame. The drilling assembly further comprises a rotary and carriage assembly mounted on the thrust frame. The rotary and carriage assembly is adapted to apply rotational, thrust and pull-back forces to the drill pipe. The drilling assembly is adapted to drill pipe into the drilling surface at any angle relative to the drilling surface between substantially parallel to the drilling surface and substantially perpendicular to the drilling surface. The method includes the steps of placing a drill pipe onto the drilling assembly, moving the thrust frame to a desired drilling angle, moving the rotary and carriage assembly into direct contact with the drill pipe, applying rotational, thrust and pull-back forces to the drill pipe, and drilling the pipe into the drilling surface.

Owner:ASTEC INDS

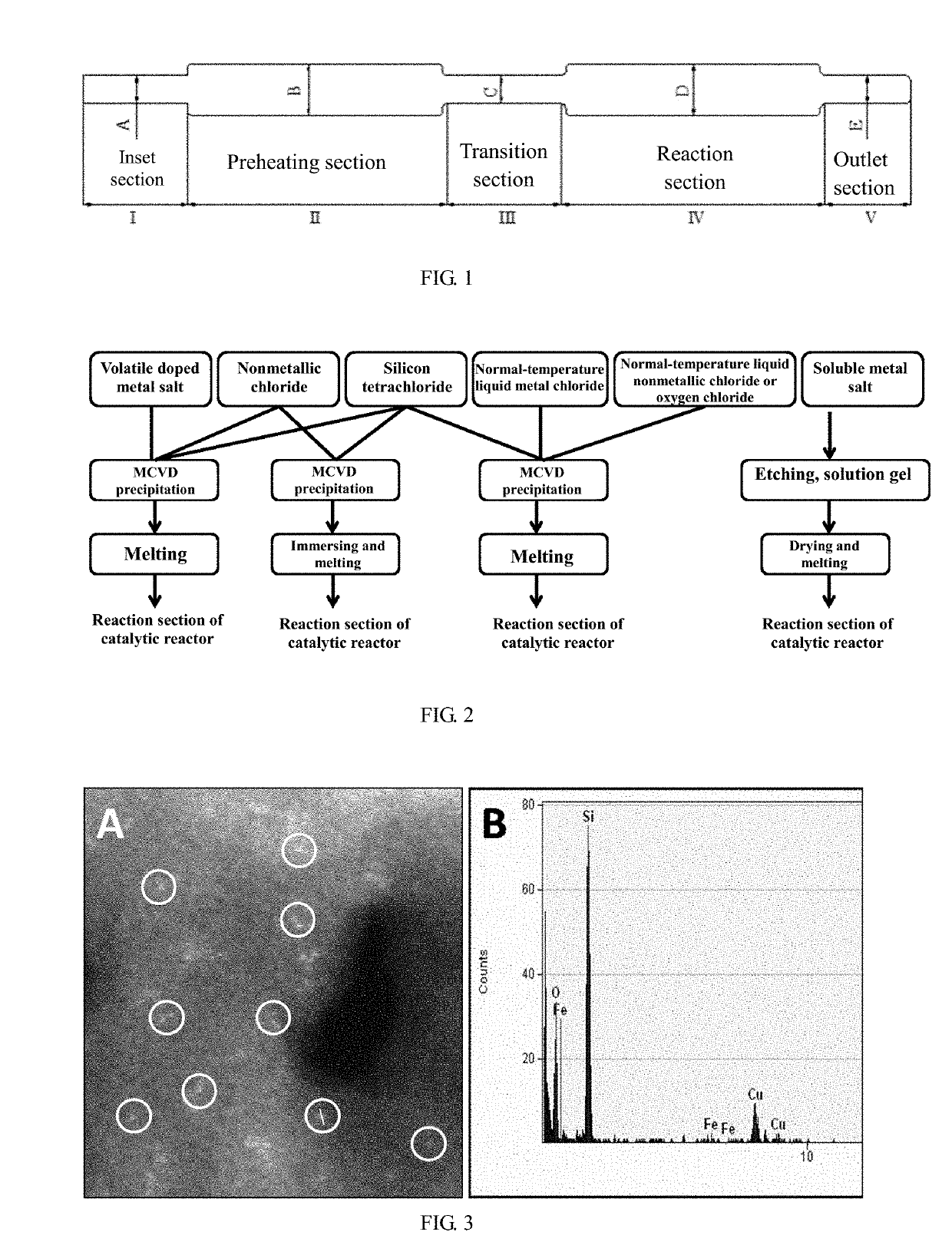

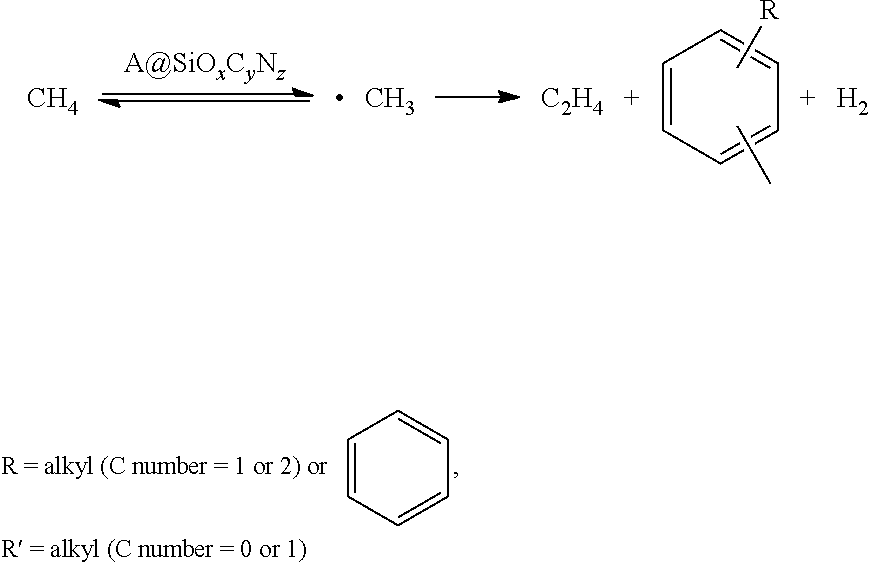

Catalytic reactor configuration, preparation and method of direct synthesis of ethylene through oxygen-free catalysis of methane

ActiveUS20190143288A1High stability of redoxHigh conversion rateCatalytic gas-gas reactionGaseous chemical processesHigh selectivityCoke deposition

A reactor configuration comprises an inlet section I, a preheating section II, a transition section III, a reaction section IV and an outlet section V; except for the preheating section II and the reaction section IV, the existence of the inlet section I, the transition section III and the outlet section V depends on reaction conditions; and the process realizes no coke deposition synthesis of methane and high selectivity synthesis of ethylene. The methane conversion rate is 20-90%; ethylene selectivity is 65-95%; propylene and butylene selectivity is 5-25%; aromatic hydrocarbon selectivity is 0-30%; and coke deposition is zero.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Composite metal oxide adsorbent for fluoride removal

ActiveUS20090270253A1Specific performanceStrong affinityOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsOxideSorbent

The invention provides a composite metal oxide adsorbent for fluoride removal and the preparation method thereof. Said composite metal oxide adsorbent for fluoride removal comprises: 0.05-0.15 molar parts of transition metal, 0.2-0.6 molar parts of Al and / or Mg, and 0.05-0.15 molar parts of rare earth metal. The composite metal oxide adsorbent for fluoride removal has a saturation adsorption capacity on fluorine in water of up to 229 mg / g, under a neutral condition.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

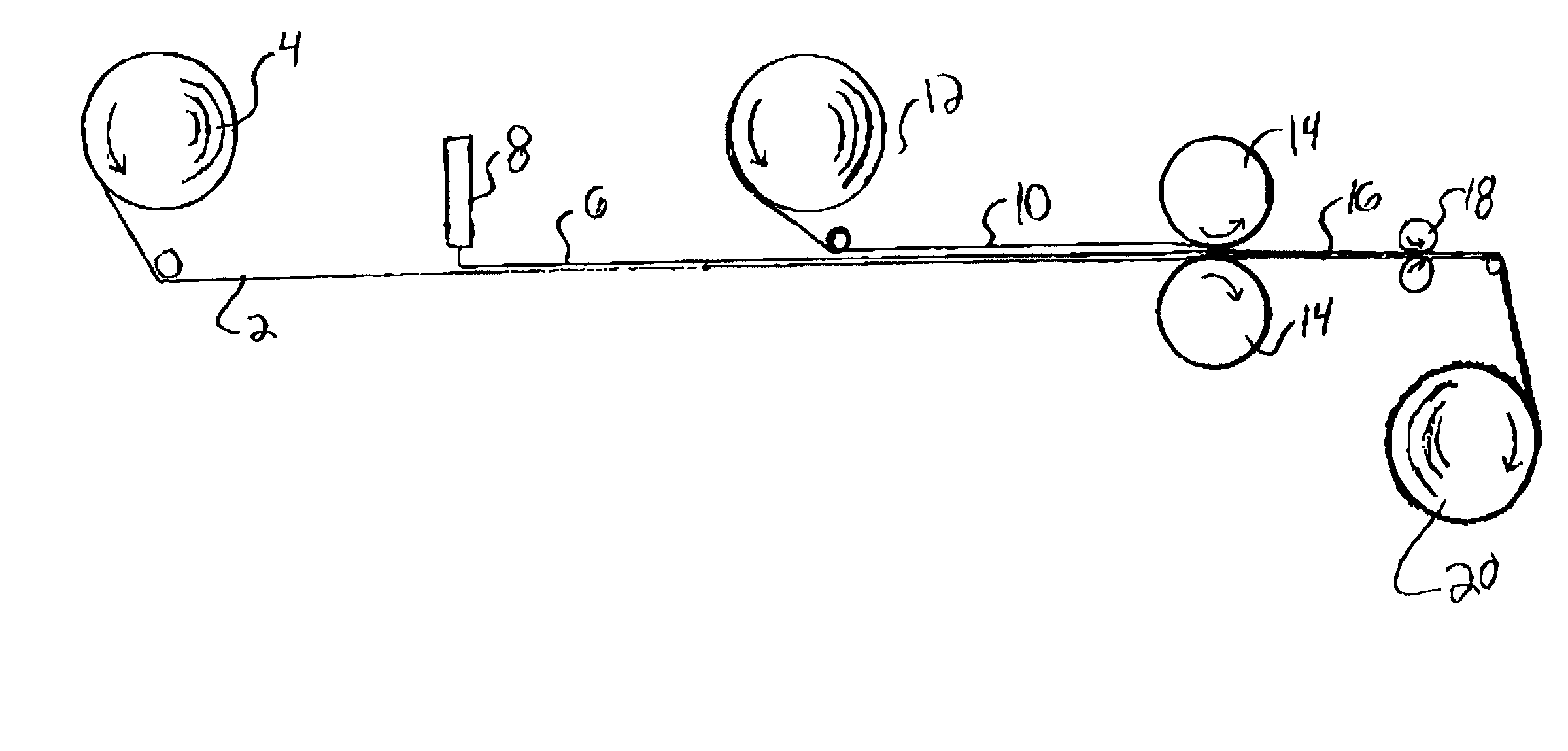

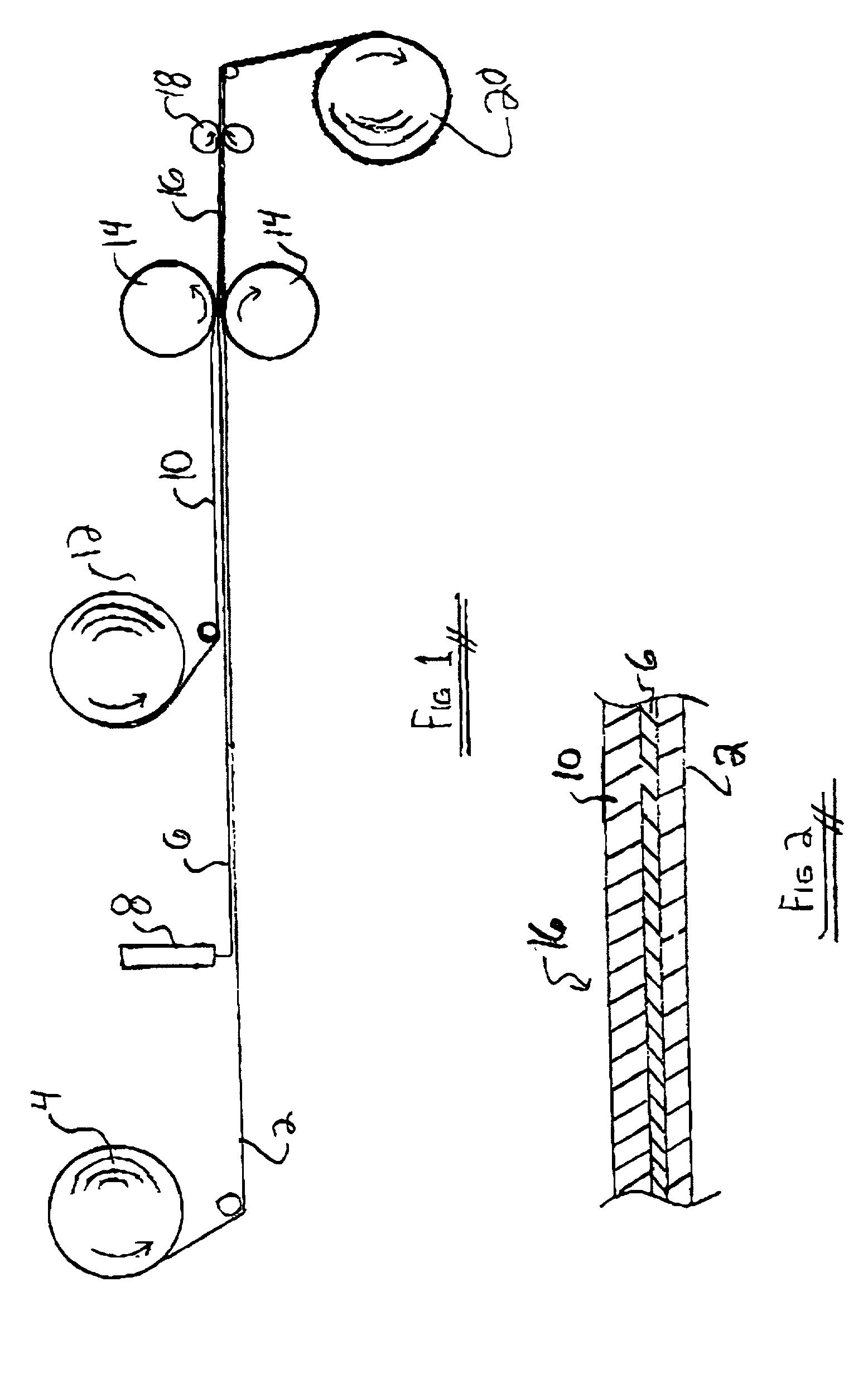

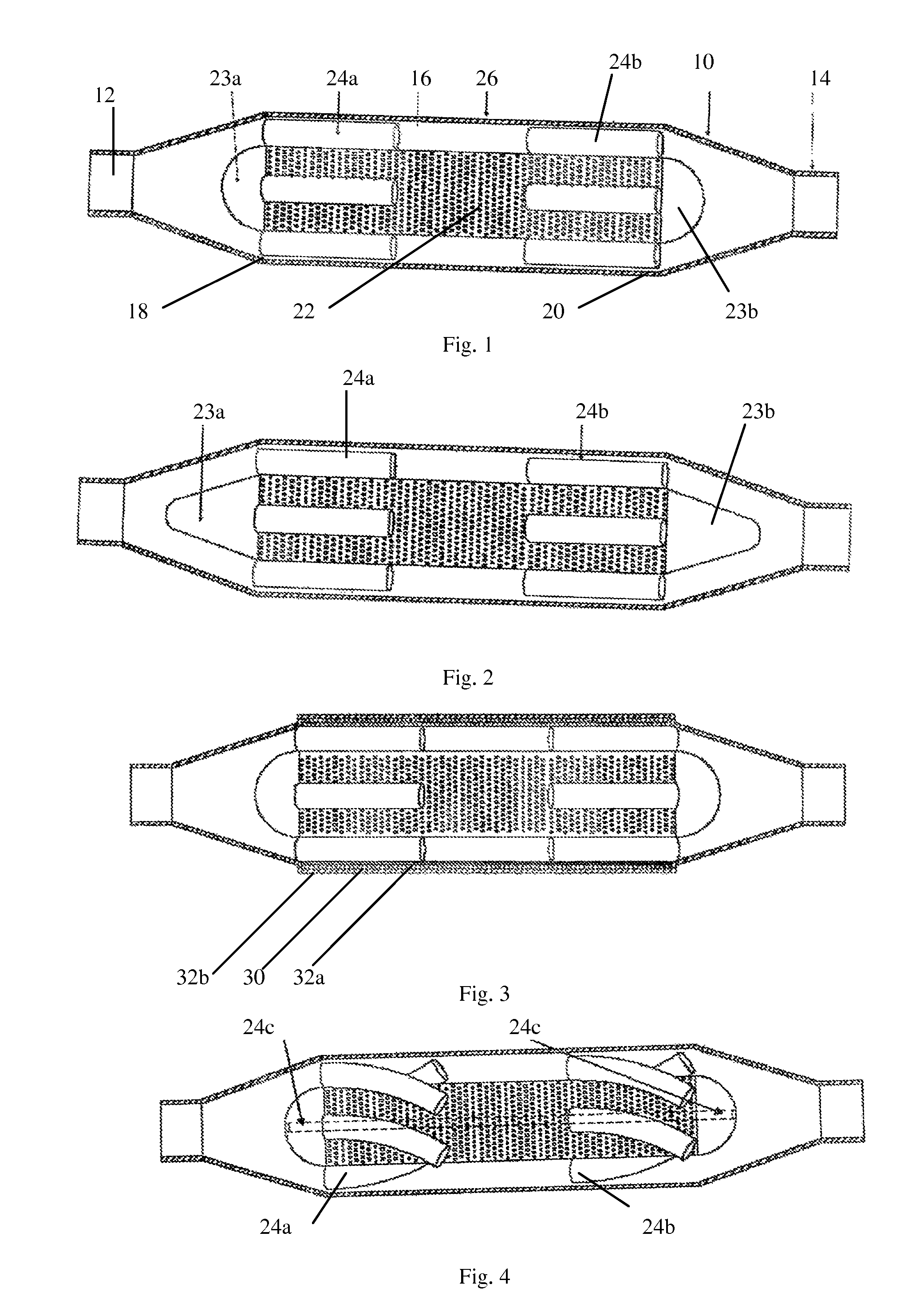

Thermocalendered non-woven elastic laminate

InactiveUS20020056510A1High elongationReduce stretchDecorative surface effectsBaby linensEngineeringIsoprene

An elastic laminate fabric useful for applications including apparel, sanitary products, and the like has an elastic vinylidene isoprene polymer film sandwiched between two outer non-woven layers. The laminate elastic fabric has CD elongation of at least 120%, and has recovery of at least 85% after several cycles of 100% elongation. A method of making the non-woven elastic laminate fabric includes extrusion coating a non-woven web having CD elongation of at least 120% with a vinylidene isoprene polymer film, and then thermocalendaring a second non-woven layer having a CD elongation of at least 120% to the exposed film surface. The mode of thermocalendering includes the use of an engraved calender roll having a discontinuous roll pattern and a land area no greater than 15%.

Owner:AVINTIV SPECIALTY MATERIALS INC

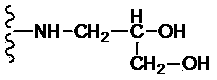

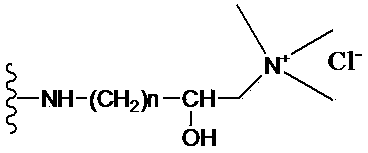

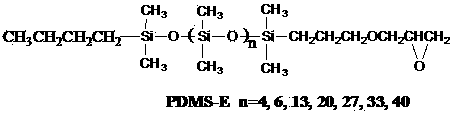

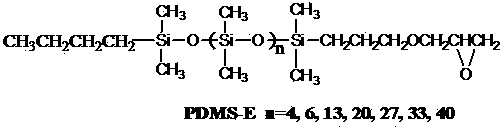

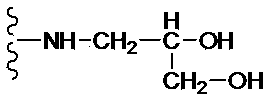

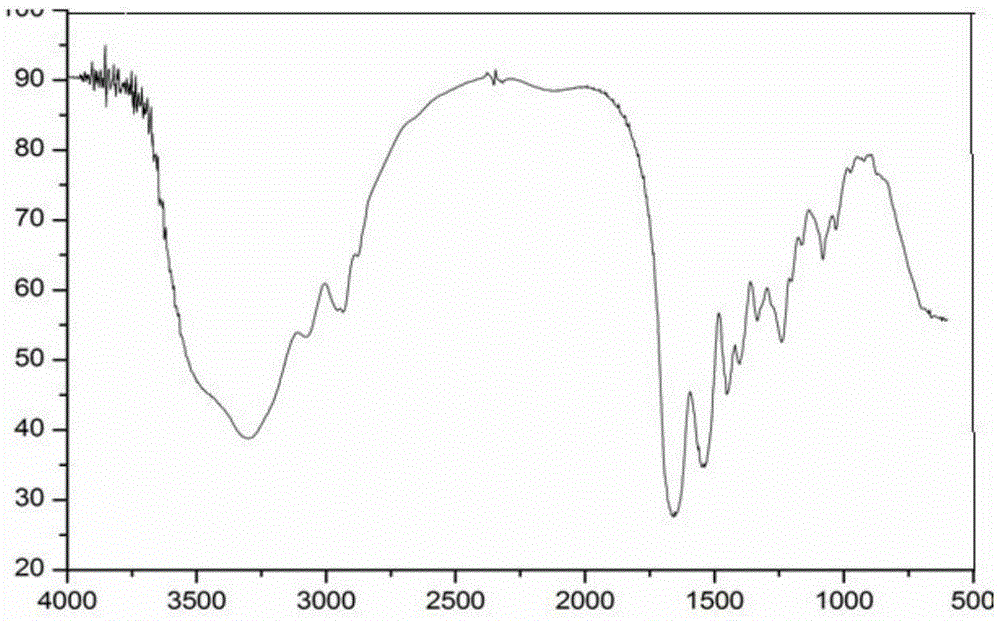

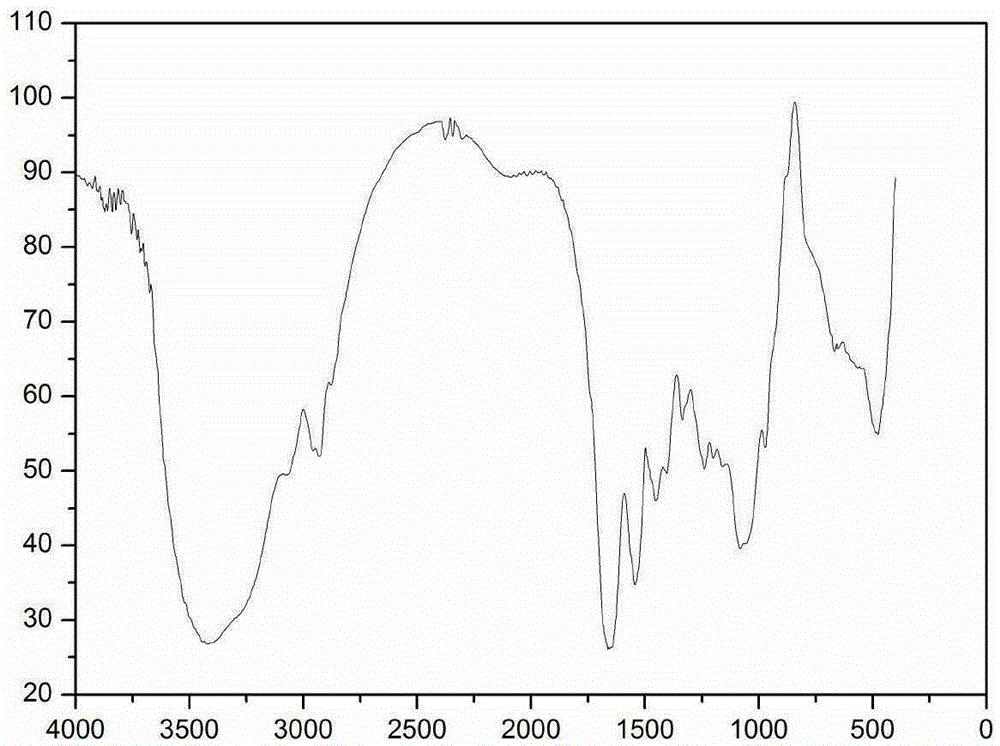

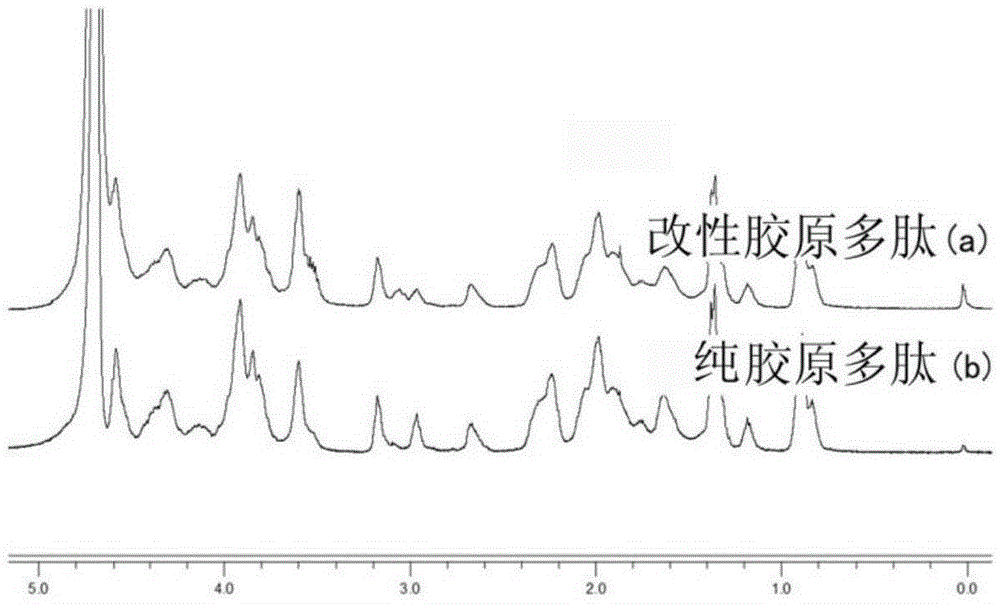

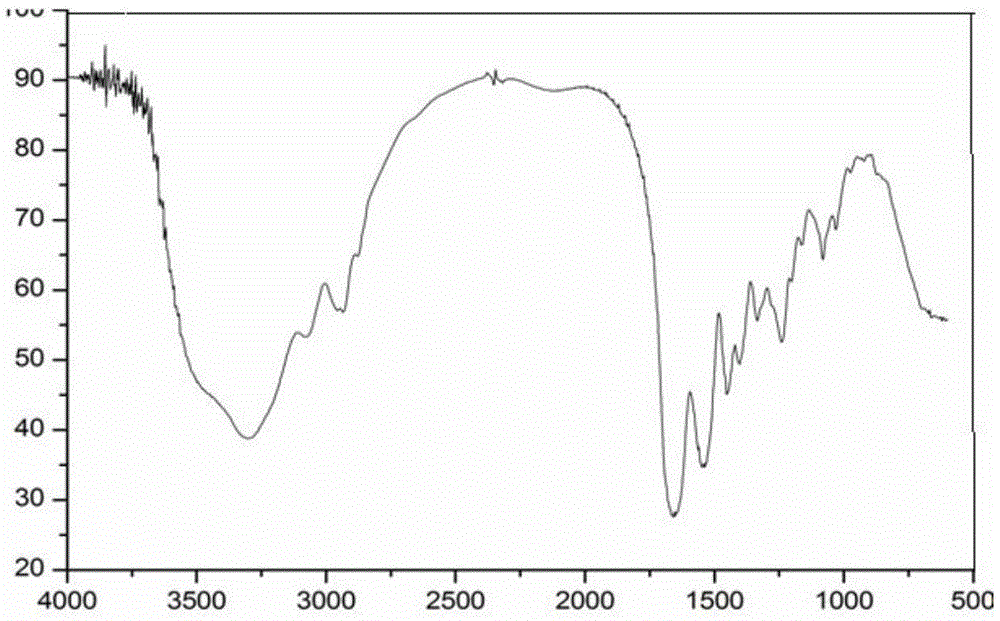

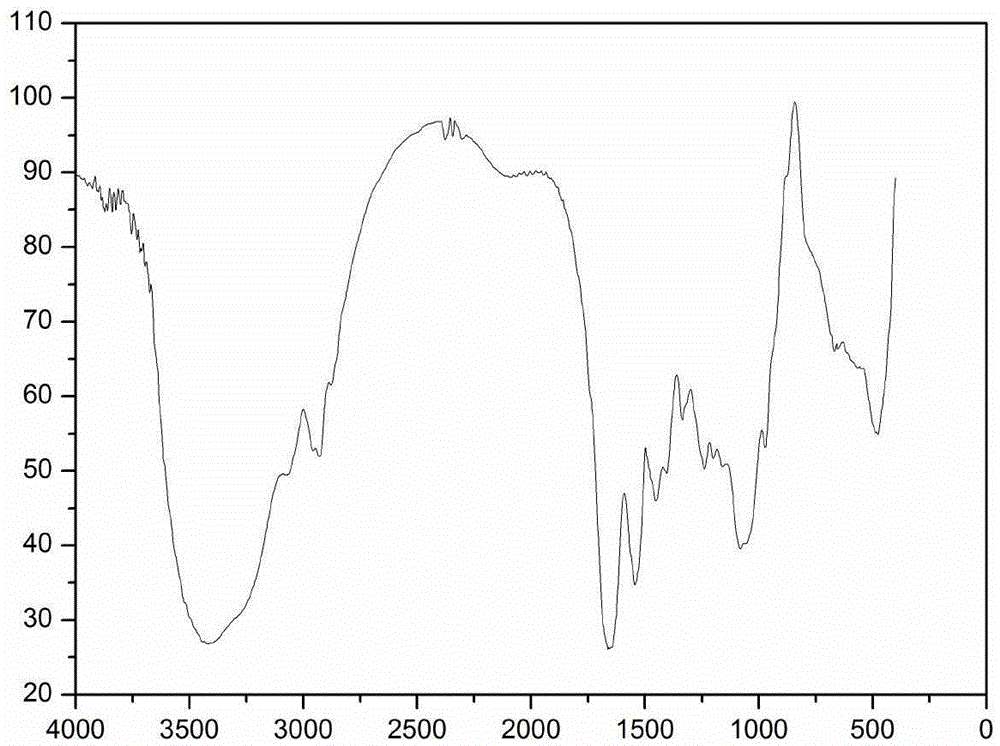

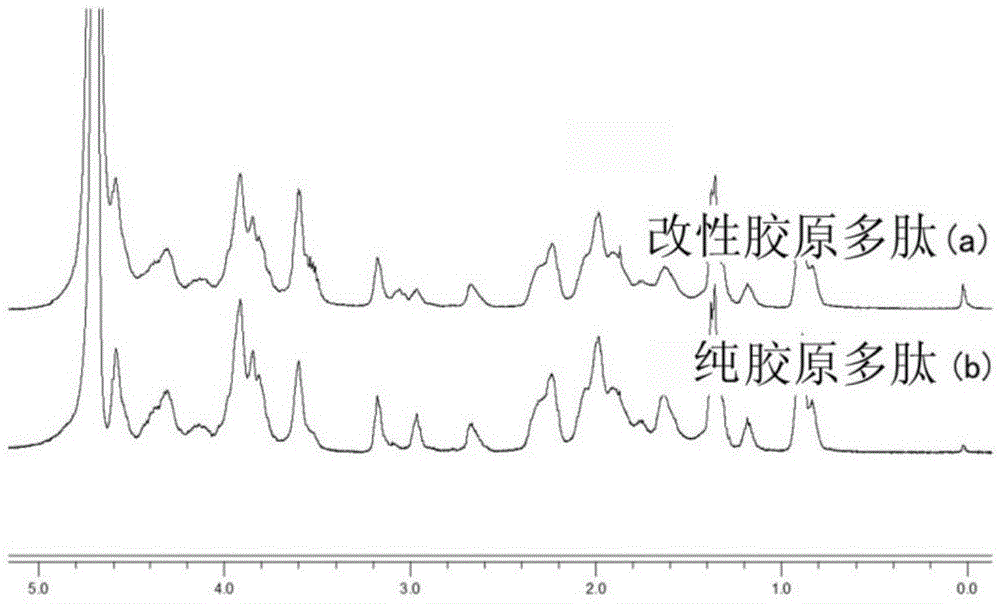

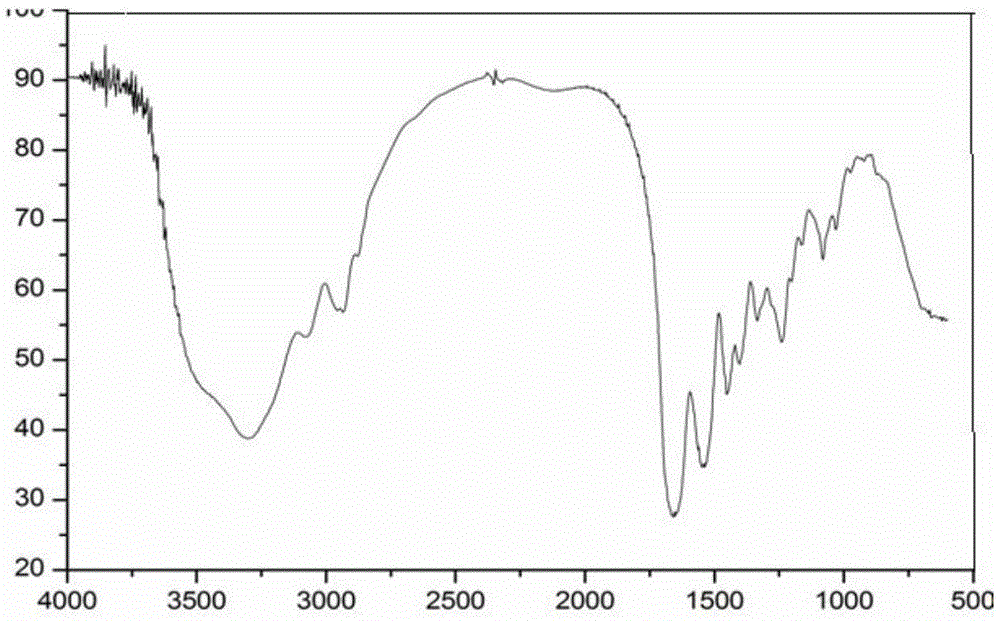

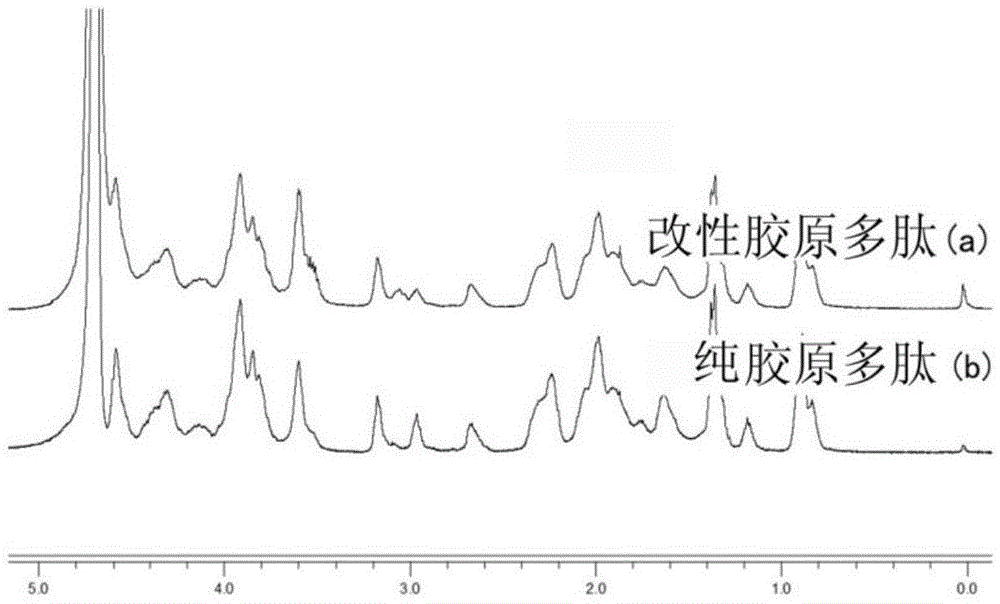

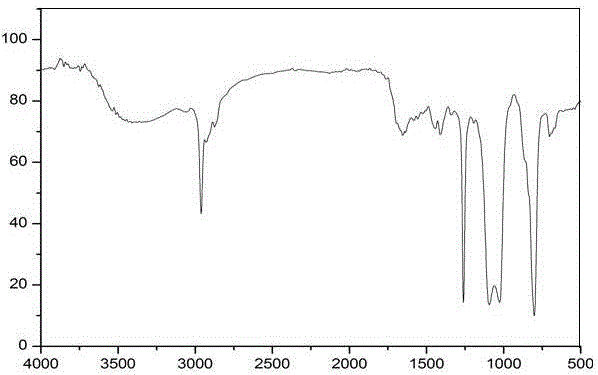

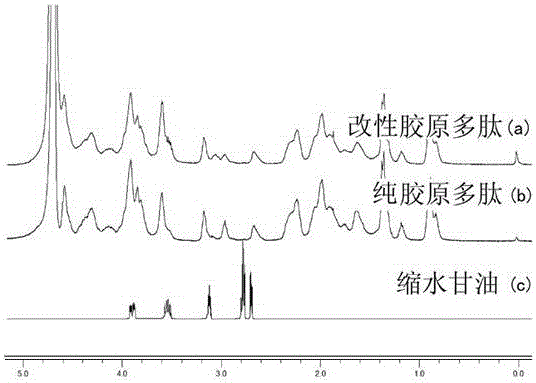

Polysiloxane, glycidol and quaternary ammonium salt-containing multifunctional gelatin leather finishing agent and preparation method

ActiveCN103436167AImprove anti-corrosion and anti-bacterial abilitySpecific performanceAntifouling/underwater paintsFibre treatmentActive agentPolytetrafluoroethylene

The invention relates to a polysiloxane, glycidol and quaternary ammonium salt-containing multifunctional gelatin leather finishing agent and a preparation method. The preparation method comprises the following steps: dissolving gelatin in water to prepare aqueous solution with mass concentration of 2-20 percent; adding epoxy quaternary ammonium salt into a first reaction flask under the conditions of temperature of 40-70 DEG C and pH of 6-12 to obtain solution 1; adding glycidol into a second reaction flask to obtain solution 2; adding a surfactant into a third reaction flask, and meanwhile adding Si-O-Si repetitive unit-containing epoxypolysiloxane in batches or continuously to obtain solution 3; mixing the solution 1, the solution 2 and the solution 3 in different proportions, weighing 15-20 g of the mixed solution to be placed in a mold of polytetrafluoroethylene, adding 5-10 mL of one or three or four of ethanol, tetrahydrofuran, acetone and methanol and drying in a normal pressure drying oven at the temperature of 40-80 DEG C to obtain the multifunctional gelatin leather finishing agent. The finishing agent has the characteristics of strong hydrophobicity, flexible film, antibacterial property, high heat stability, organic solvent resistance, wet scrubbing resistance and the like.

Owner:山东山科美谷科技发展有限公司

Polysiloxane and glycidol-containing strong-hydrophobicity gelatin leather finishing agent and preparation method

ActiveCN103436168APlay a plasticizing roleImprove performanceFibre treatmentProtein coatingsActive agentPolytetrafluoroethylene

The invention relates to a polysiloxane and glycidol-containing strong-hydrophobicity gelatin leather finishing agent and a preparation method. The preparation method comprises the following steps: dissolving gelatin in water to prepare aqueous solution with mass concentration of 2-20 percent; adding glycidol into a first reaction flask under the conditions of temperature of 40-70 DEG C and pH of 6-12 to obtain solution 1; adding a surfactant into a second reaction flask, continuously stirring, and meanwhile adding Si-O-Si repetitive unit-containing epoxypolysiloxane in batches or continuously to obtain solution 2, wherein the using amount of the surfactant is 0.5-20 percent of the mass of the gelatin; mixing the solution 1 and the solution 2 in different proportions, weighing 15-20 g of the mixed solution to be placed in a mold of polytetrafluoroethylene, adding 5-10 mL of one or two or three of ethanol, tetrahydrofuran and methanol and drying in a normal pressure drying oven at the temperature of 40-80 DEG C to obtain the gelatin leather finishing agent with a superior function. The finishing agent has the characteristics of strong hydrophobicity, super extensibility, heat resistance, oxidation resistance, wet scrubbing resistance and the like.

Owner:QILU UNIV OF TECH

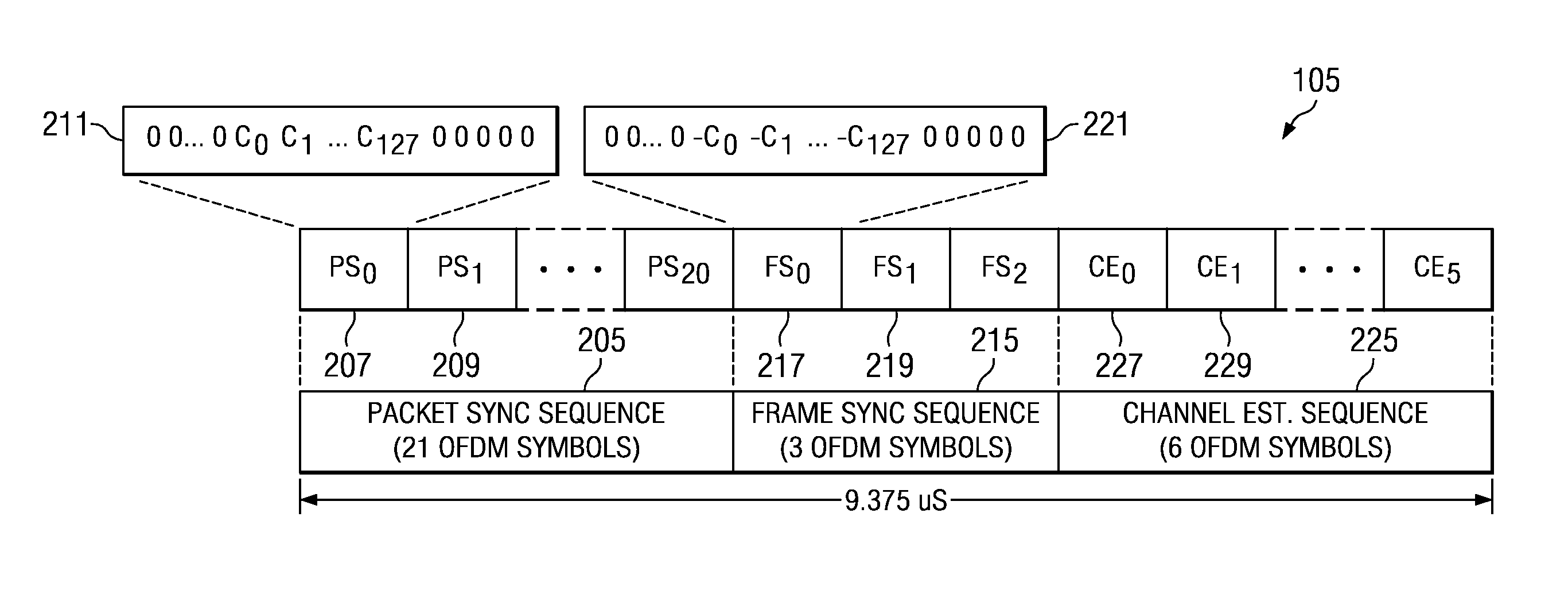

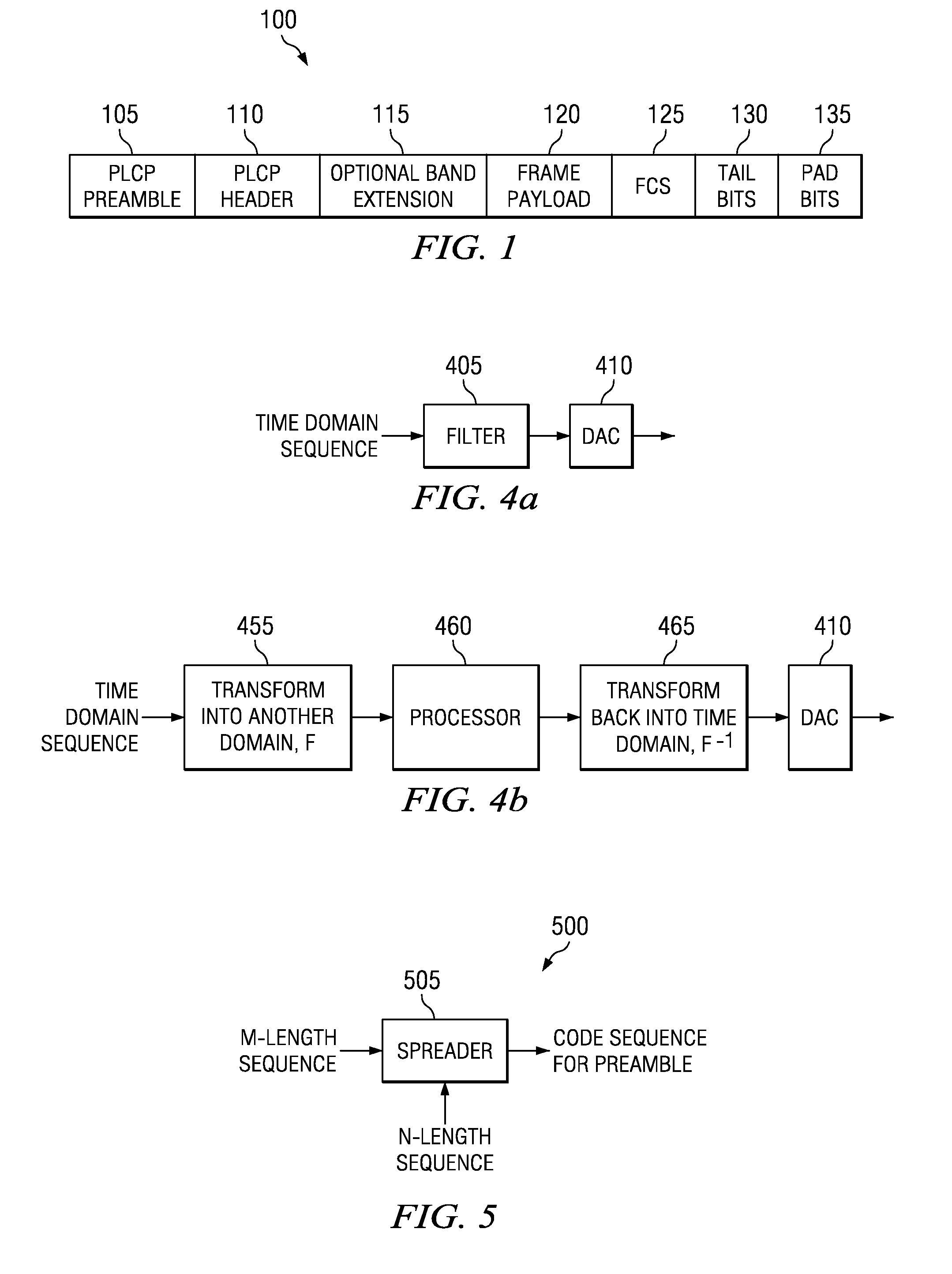

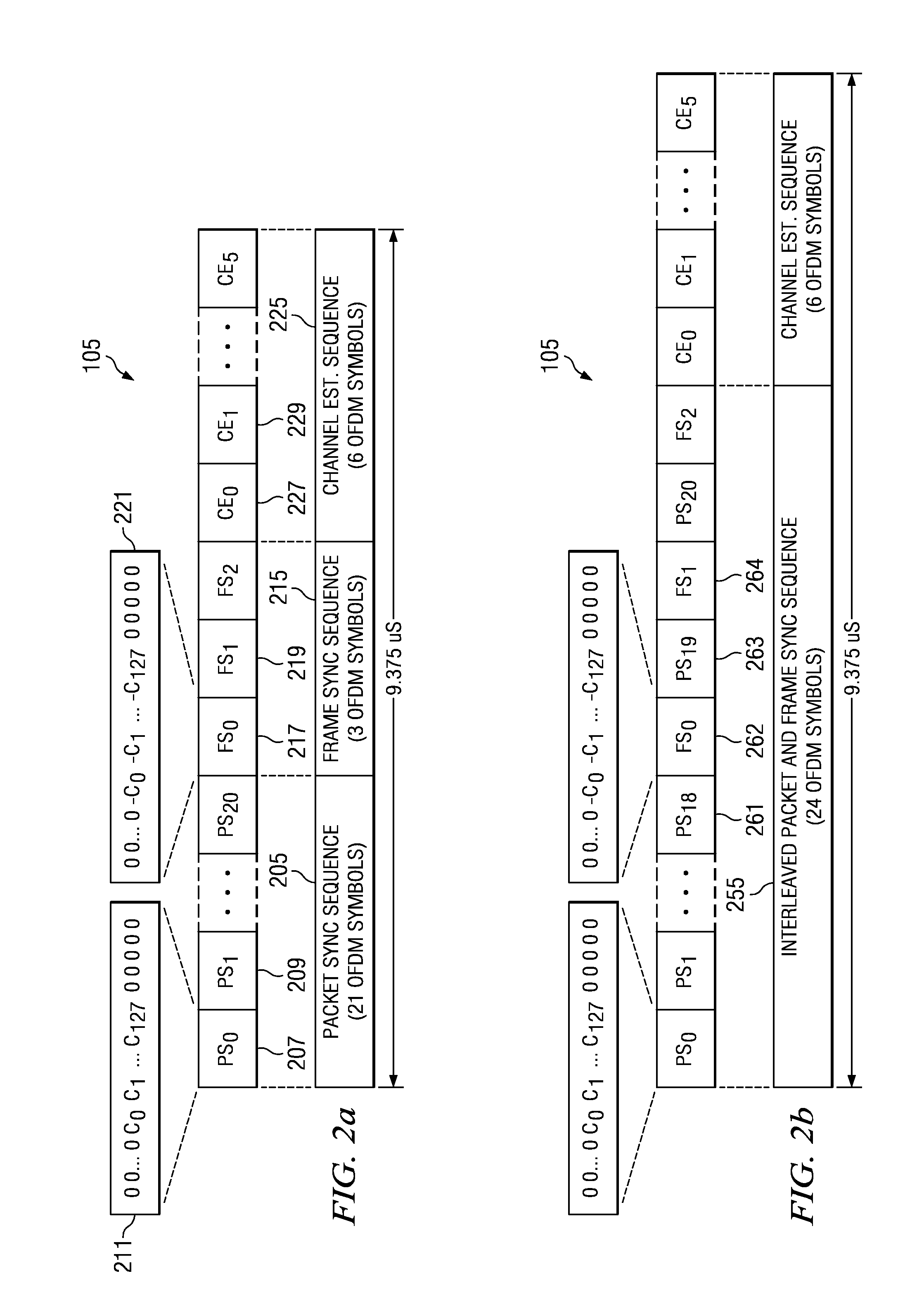

Preamble for a TFI-OFDM communications system

ActiveUS7634020B2Simplifying preamble detectionReduce power consumptionFrequency-division multiplexMulti-frequency code systemsTime domainCommunications system

System and method for simplifying preamble detection and reducing power consumption in receivers. A preferred embodiment comprises a preamble made up of two sequences, a first sequence that is specified in the time domain and a second sequence that is specified in the frequency domain. The first sequence which comprises multiple copies of a time domain code sequence can allow easy detection of the preamble while the second sequence comprises multiple copies of a frequency domain code sequence and allows easy determination of the frequency response of the communications channel. A hierarchical sequence can be used to allow multi-stage correlation. This can result in a less complex correlator, hence lower power consumption. Piconets can use different code sequences to allow rapid determination of the source of a transmission without requiring the receiver to decode the entire transmission.

Owner:TEXAS INSTR INC

Polysiloxane and quaternary ammonium salt-containing antibacterial gelatin leather finishing agent and preparation method

InactiveCN103436169AAntibacterialImprove antibacterial propertiesAntifouling/underwater paintsFibre treatmentPolymer scienceActive agent

The invention relates to a polysiloxane and quaternary ammonium salt-containing antibacterial gelatin leather finishing agent and a preparation method thereof. The preparation method comprises the following steps: dissolving gelatin in water to prepare aqueous solution with mass concentration of 2-20 percent; adding epoxy quaternary ammonium salt into a first reaction flask under the conditions of temperature of 40-70 DEG C and pH of 6-12 to obtain solution 1; adding a surfactant into a second reaction flask, continuously stirring, and meanwhile adding Si-O-Si repetitive unit-containing epoxypolysiloxane in batches or continuously to obtain solution 2, wherein the using amount of the surfactant is 2-20 percent of the mass of the gelatin; mixing the solution 1 and the solution 2 in different proportions, weighing 15-20 g of the mixed solution to be placed in a mold of polytetrafluoroethylene, adding 5-10 mL of one or two or three of ethanol, tetrahydrofuran and methanol and drying in a normal pressure drying oven at the temperature of 40-80 DEG C to obtain the multifunctional gelatin leather finishing agent. The finishing agent has the characteristics of antibacterial property, adjustable hydrophilia and hydrophobicity, flexible film, strong anti-oxidant capacity and the like.

Owner:QILU UNIV OF TECH

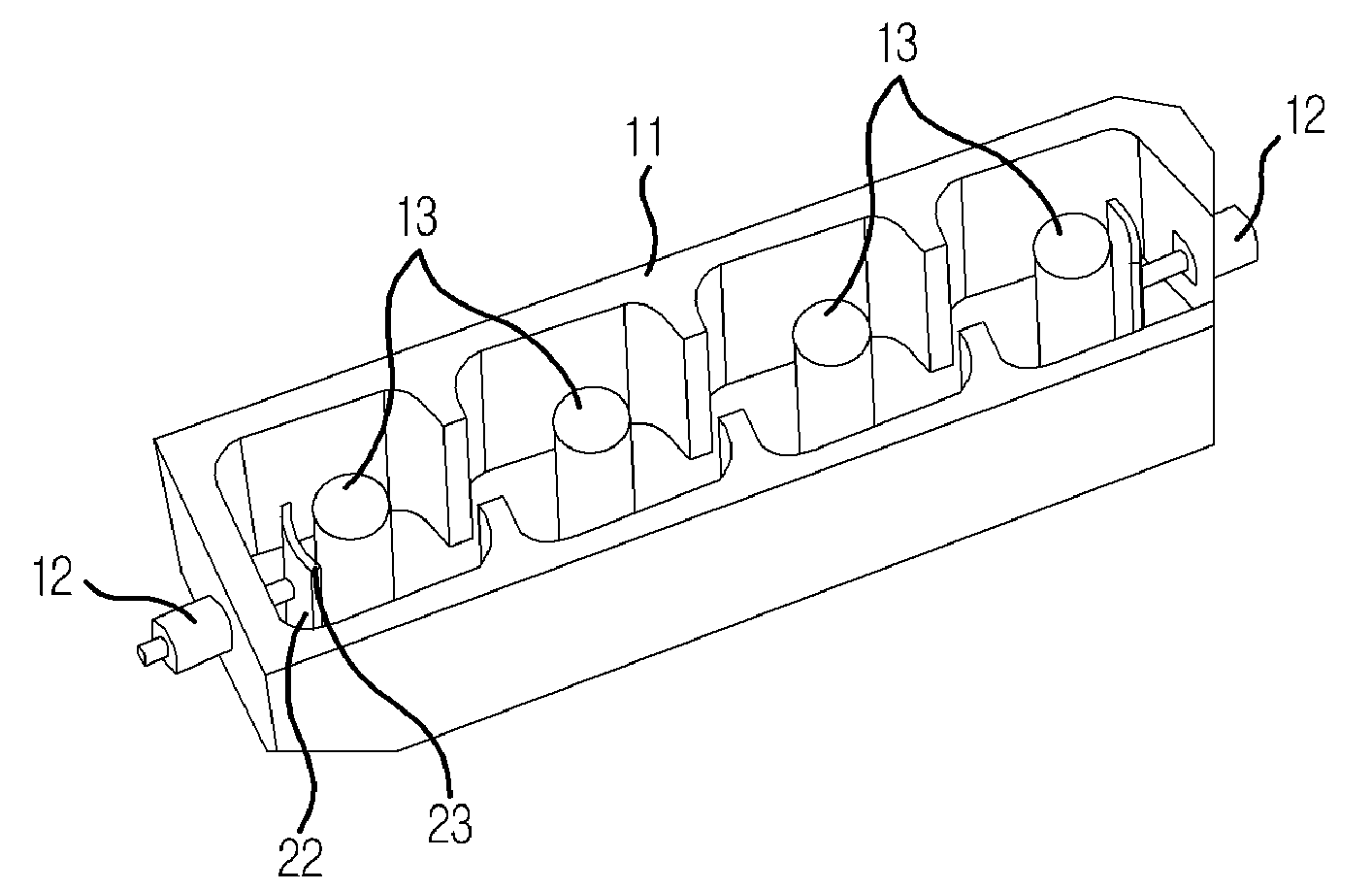

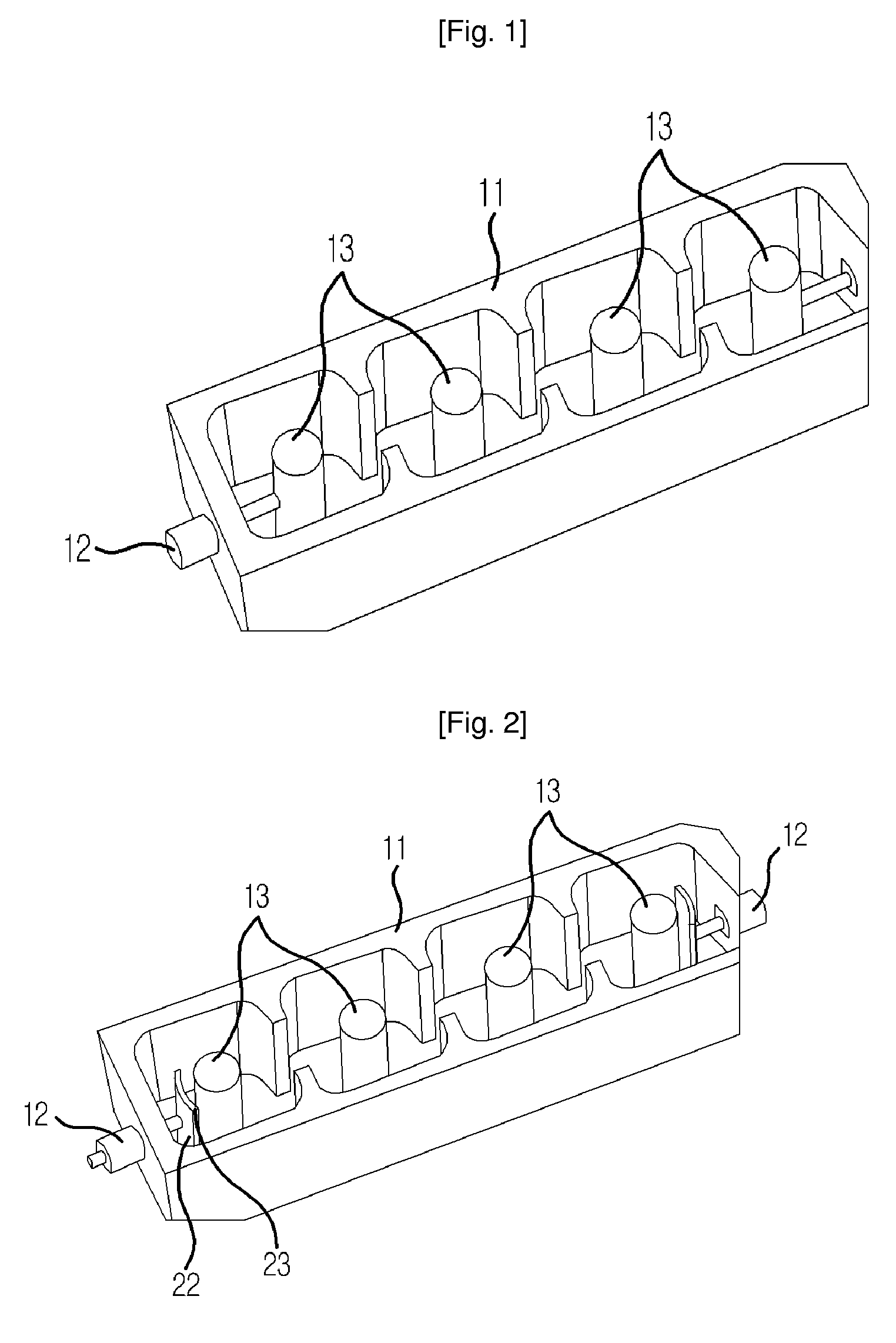

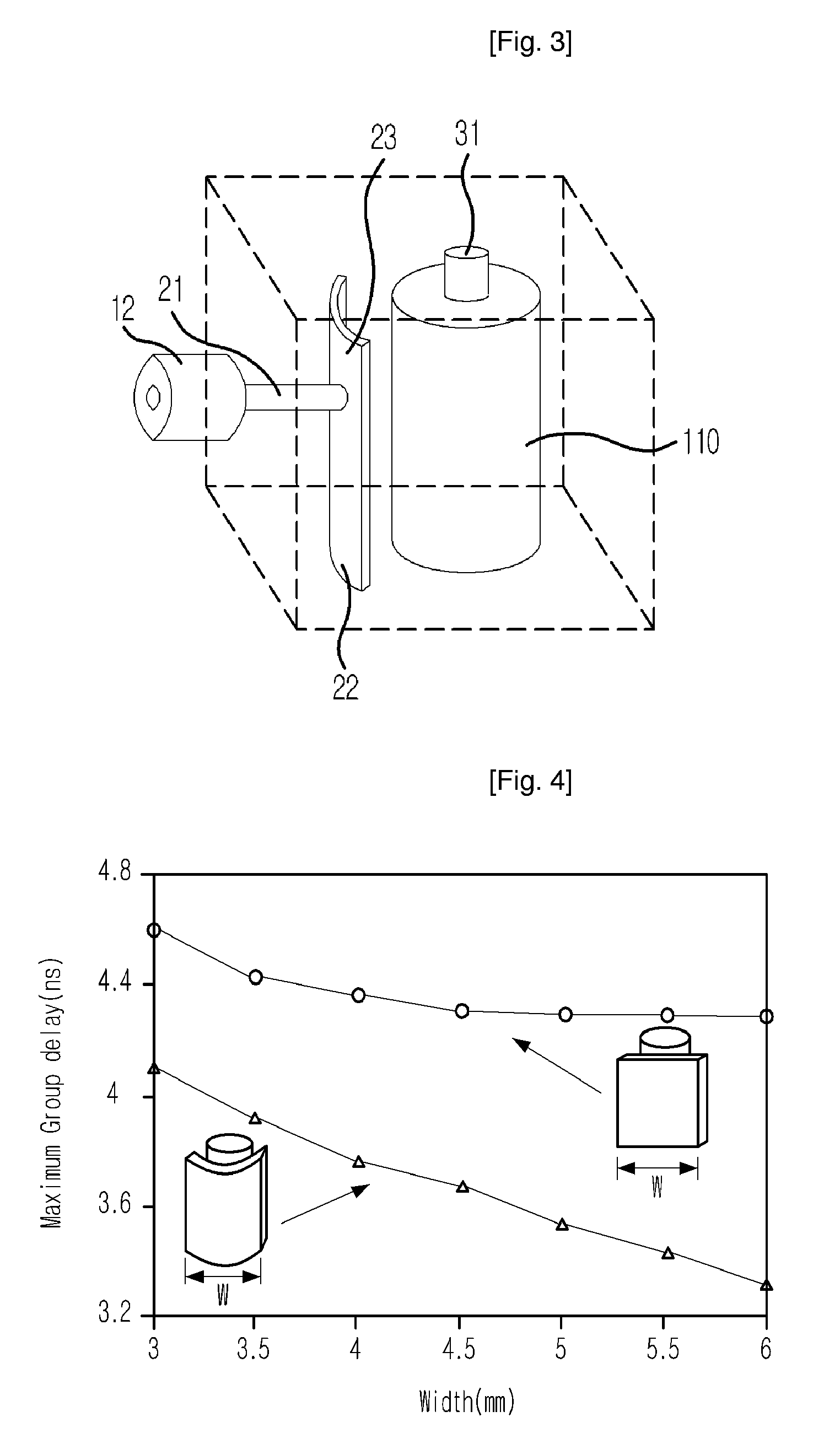

Filter Coupled by Conductive Plates Having Curved Surface

Provided is a resonator filter using conductive plates having a curved surface to connect an input / output coaxial connector to a resonator. The resonator filter includes: a plurality of resonators for resonating; an input / output coaxial connector; an input / output supporting unit formed between the input coaxial connector and one of the resonators and / or between an output supporting unit formed between the output coaxial connector and other resonator for electrically and mechanically supporting the input / output coupling; and a connecting unit for connecting the input / output supporting unit and the input / output coaxial connector, wherein the input / output supporting unit is a conductive plate with a curved surface having a center axis similar to the resonators.

Owner:ELECTRONICS & TELECOMM RES INST

Exhaust filter

ActiveUS8627921B2Easy to tuneHigh speedInternal combustion piston enginesSilencing apparatusEngineeringExpansion chamber

Owner:VORTEX PERFORMANCE EXHAUSTS

Low-density polyethylene (LDPE) resin for cable insulant having voltage level of above 110kV, and preparation method thereof

InactiveCN102382222ASpecific performanceEasy to processPlastic/resin/waxes insulatorsPolymer scienceInsulation layer

The invention discloses a low-density polyethylene (LDPE) resin for a cable insulant having a voltage level of above 110kV, and a preparation method thereof, and belongs to the field of LDPE resins. The LDPE resin is the characterized in that a melt flow rate is in a range of 0.1 to 10g / 10min; density is in a range of 0.910 to 0.940kg / cm<3>; a degree of crystallization is in a range of 30 to 60%; molecular weight distribution Mw / Mn determined by a gel permeation chromatography is in a range of 2 to 7; fracture elongation is above 500%; a dielectric constant is below 4; a dielectric loss factor is below 6*10<-4>; volume resistivity is above 1.0*10<15>Omega.cm; and a maximum impurity size representing cleanliness is below 0.5mm. The preparation method of the LDPE resin comprises the following steps that 1, raw materials and a conditioning agent are subjected to compression boosting; 2, an initiator-peroxide solution is injected into the mixture obtained by the step 1 and undergoes a polymerization reaction; and 3, the polymerization system obtained by the step 2 is controlled and adjusted. The LDPE resin has specific performances, stable processing performances and physicochemical performances, and high cleanliness, and thus satisfying ultrahigh voltage cable insulation layer production requirements. The preparation method has relatively simple processes and adopts LDPE production equipment. Reaction conditions needed by the preparation method are easy to be satisfied.

Owner:BASF YPC

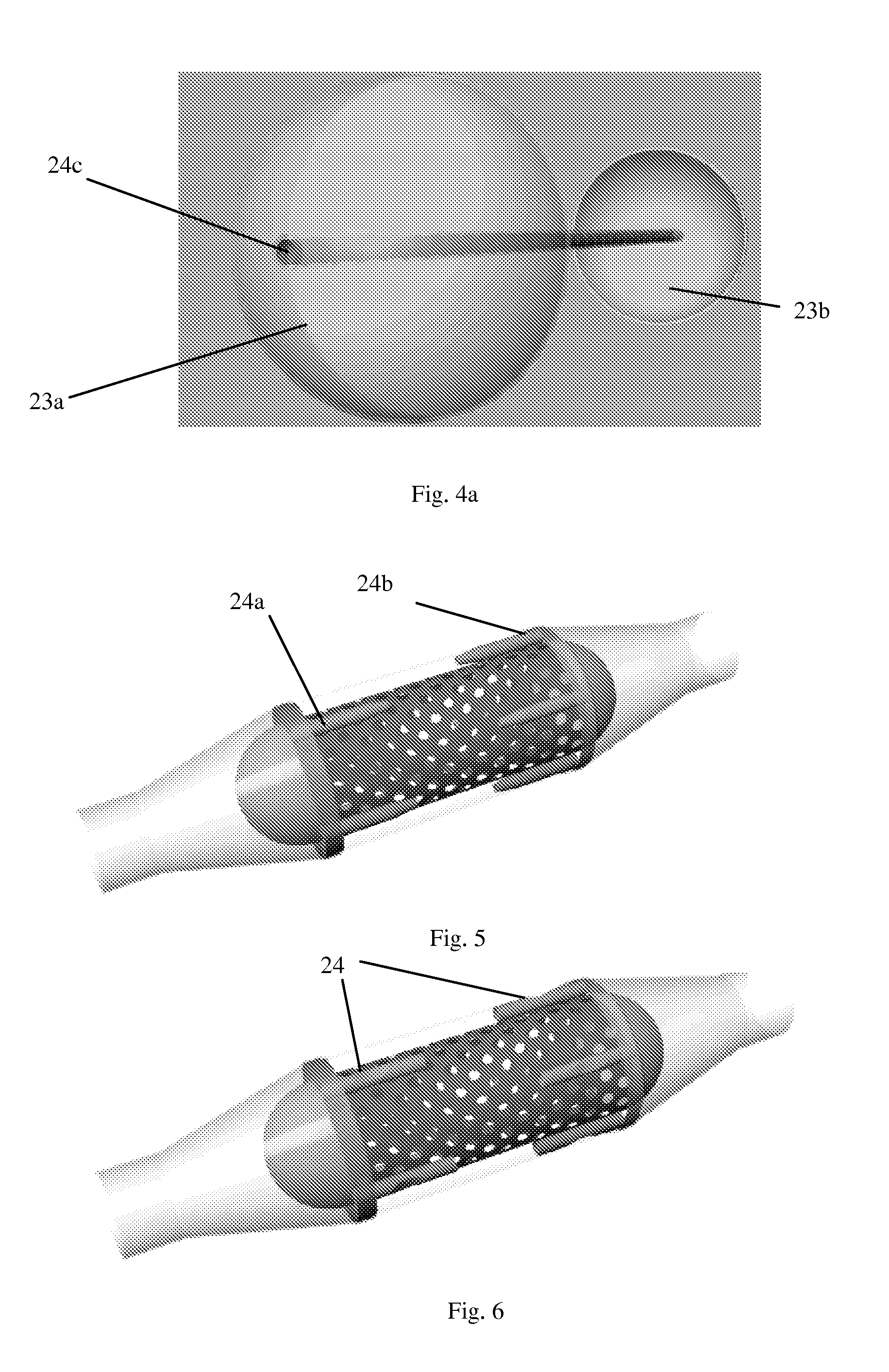

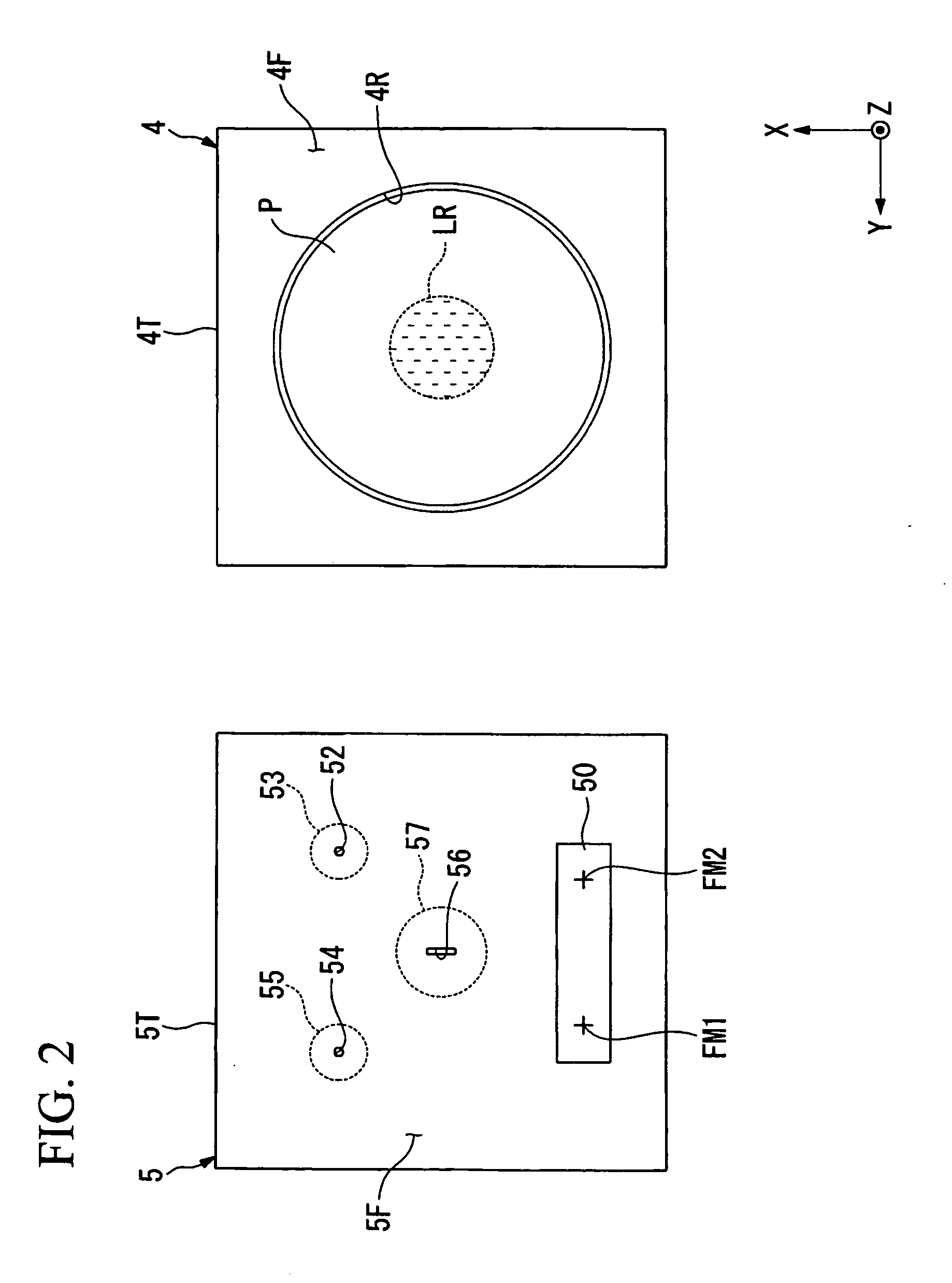

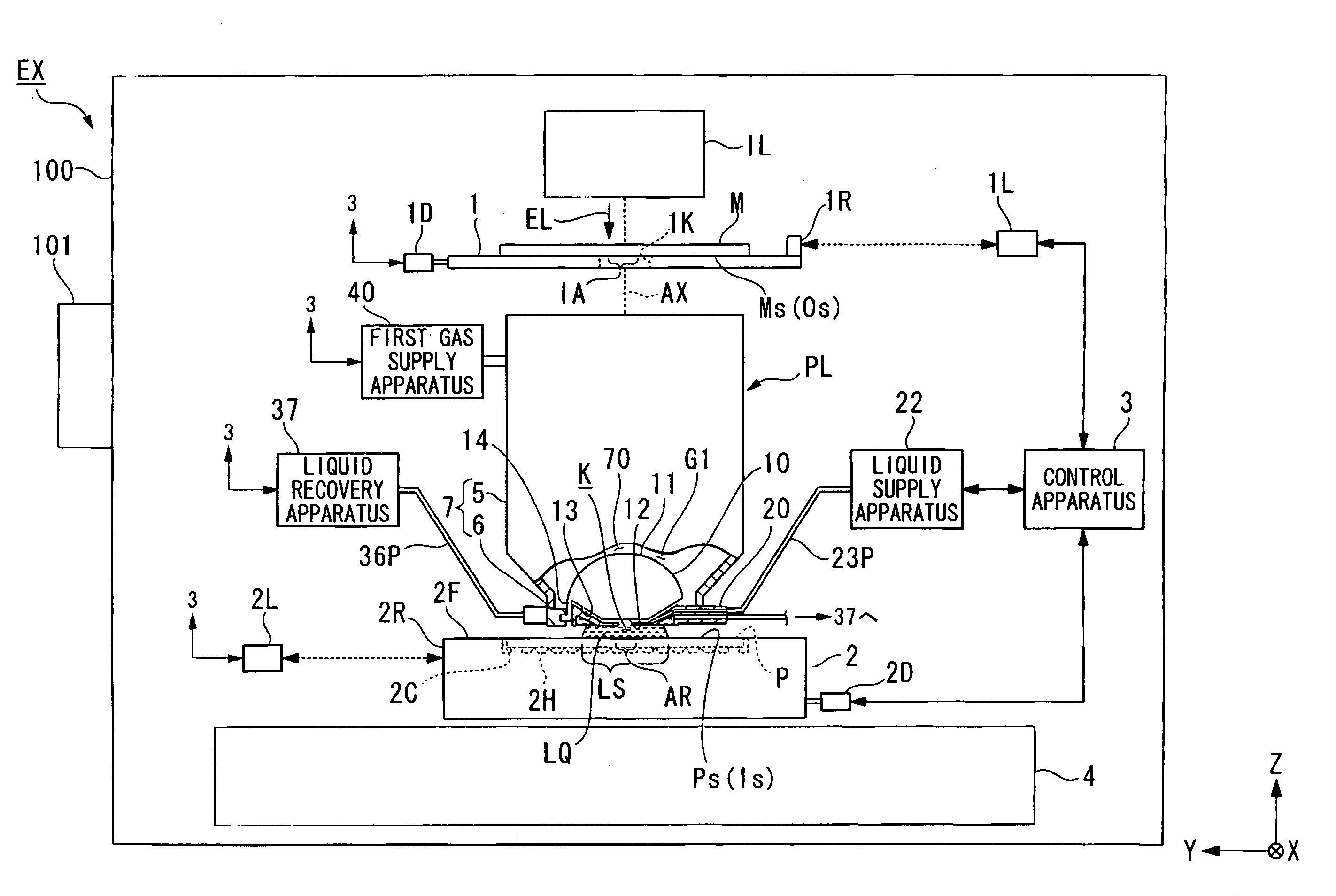

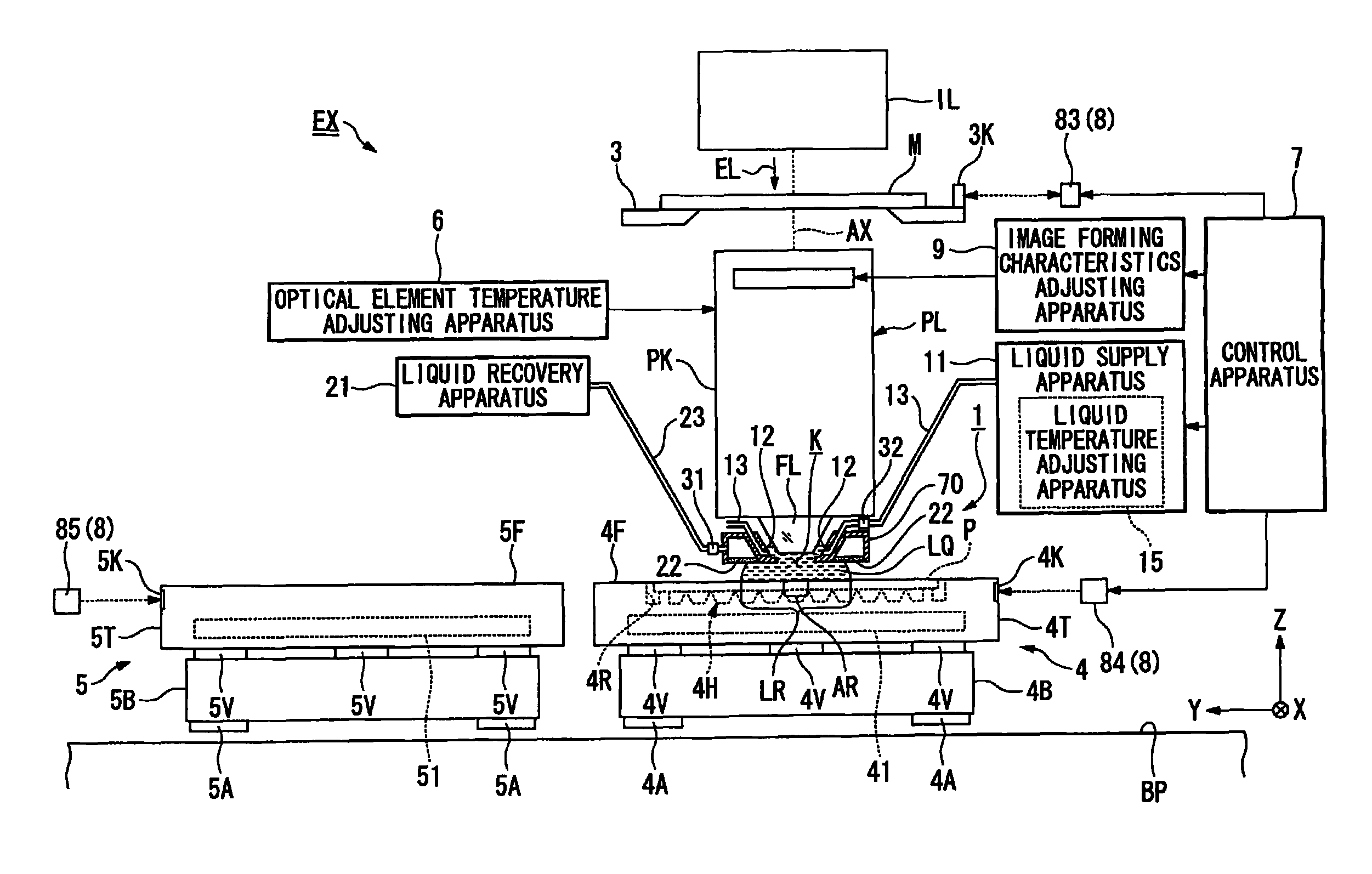

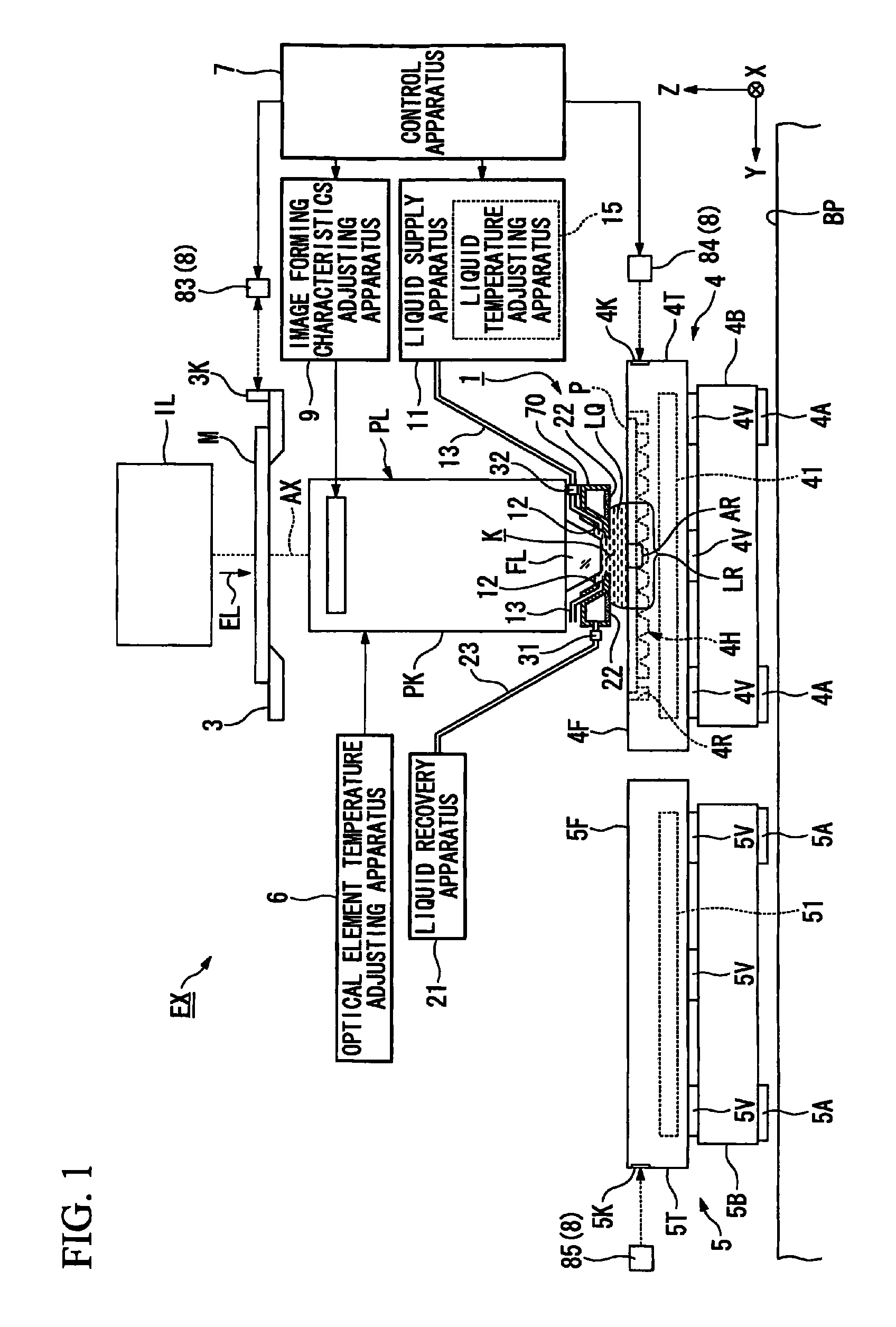

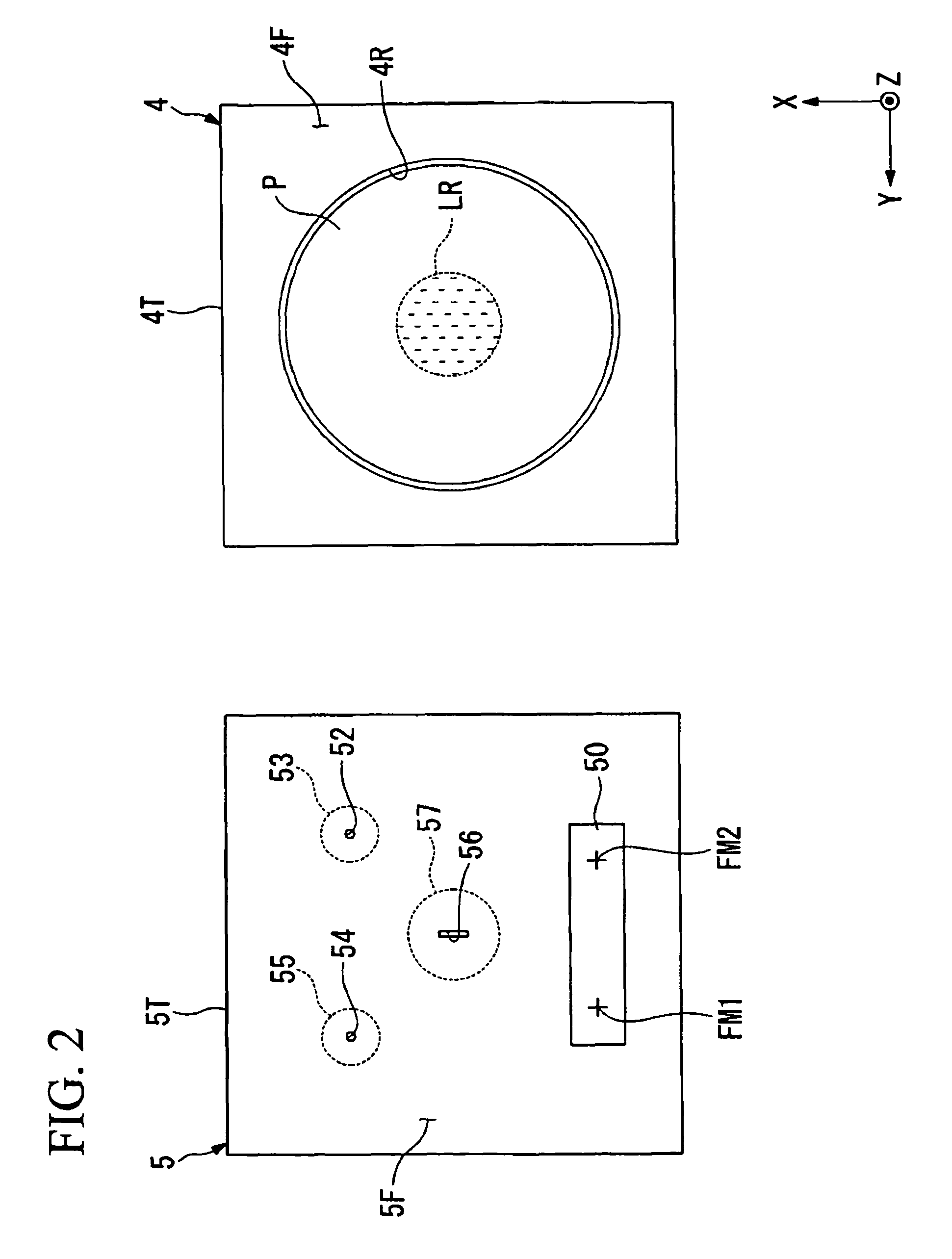

Exposing method, exposure apparatus, and device fabricating method

InactiveUS20080278695A1Specific performancePhotomechanical apparatusPhotographic printingObject basedComputer science

An exposure apparatus comprises: a first detection apparatus, which detects the temperature of a liquid after the liquid contacts a prescribed object; and a processing apparatus that detects the relationship between the temperature of the liquid and the temperature of the object based on the detection result of the first detection apparatus.

Owner:NIKON CORP

Low-hardness and high-strength thermoplastic polyurethane elastomer and preparation method thereof

The invention relates to the technical field of preparation of a polyurethane elastomer, specifically to a low-hardness and high-strength thermoplastic polyurethane elastomer and its preparation method. The low-hardness and high-strength thermoplastic polyurethane elastomer is prepared from a component A and a component B according to the mass ratio of 70-80:30-20, wherein the component A contains polyester of aliphatic dicarboxylic acids, 1,4-butylene glycol and diphenyl-methane-diisocyanate; and the component B is low density polyethylene. The component A and the component B are mixed, and then synthesis of an elastomer is carried out. Hardness of the elastomer is 60 A, tensile strength is greater than 40 KN / m, tensile strength is greater than 38 MPa, and elongation at break is greater than 700%. The elastomer has prominent comprehensive properties and can be widely applied in special fields of escalator rails, driving belts, synchronous belts, sealing strips and the like.

Owner:DONGGUAN JINGLUN IND

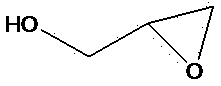

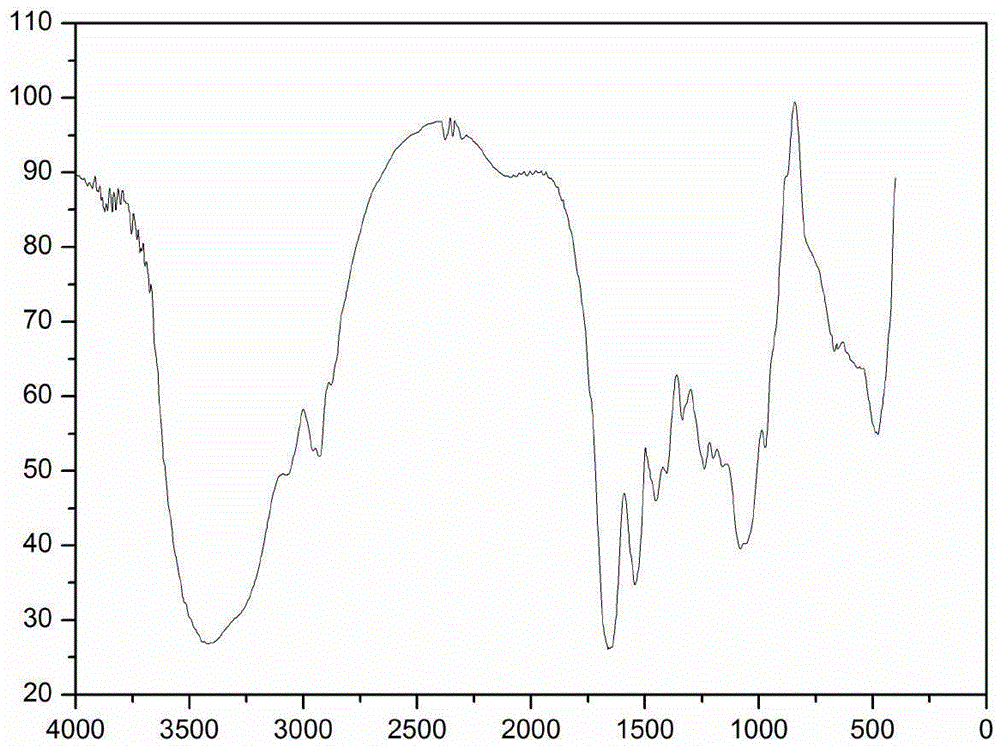

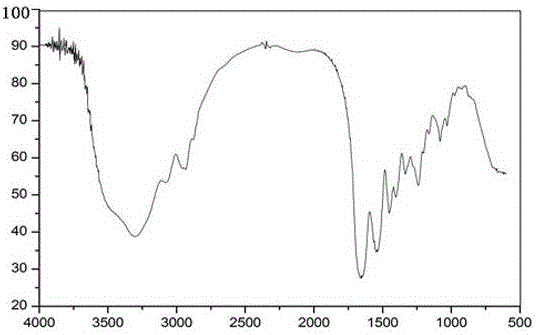

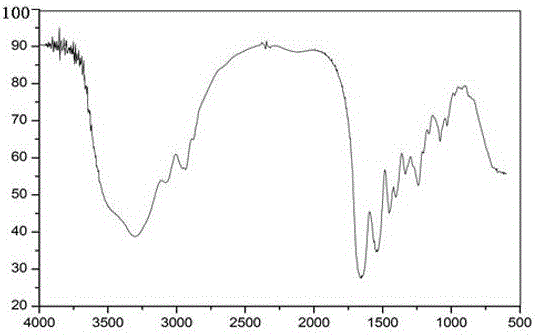

Preparation of mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane by freeze-drying method

The present invention relates to preparation of a mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane by a freeze-drying method. Surfactant sodium alkyl sulfate is dissolved in water and formulated into an aqueous solution, the aqueous solution is stirred for 1-2h at 40-60 DEG C under the condition of pH of 8 to 11, gelatin is added, stirring is performed for 4-8h, and mono-epoxy-terminated polysiloxane with the molecular weight of 500 is added to obtain a mono-epoxy-terminated polysiloxane-modified gelatin solution. The mono-epoxy-terminated polysiloxane-modified gelatin solution is centrifuged at a low temperature, after layering, water is added into an intermediate layer for even mixing, ethanol is added, after even mixing, 0.5-0.8ml of the mixture is measured and dropwise added into a gelatin substrate, standing is performed for 12-18h, liquid nitrogen is used for freezing, and the freeze-drying method is used for drying to obtain the mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane. The mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane has the characteristics that component concentration change is gradient in longitudinal section, and the mono-epoxy-terminated polysiloxane-modified gelatin gradient membrane is high in tensile strength, good in hydrophobicity and soft, and so on.

Owner:山东山科美谷科技发展有限公司

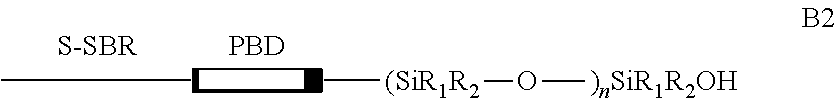

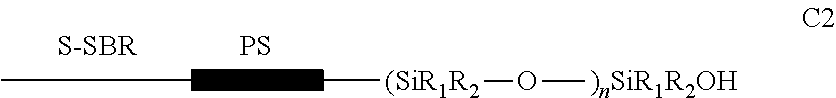

Process for the Preparation of a 1,3-Butadiene and Styrene Copolymer Containing a Random Section in its Main Chain Followed by a Block with a Structure Differentiated from the Main Chain, Homopolymeric or Copolymeric, Functionalized and the Product Obtained From This

Owner:LANXESS ELASTOMEROS DO BRASIL

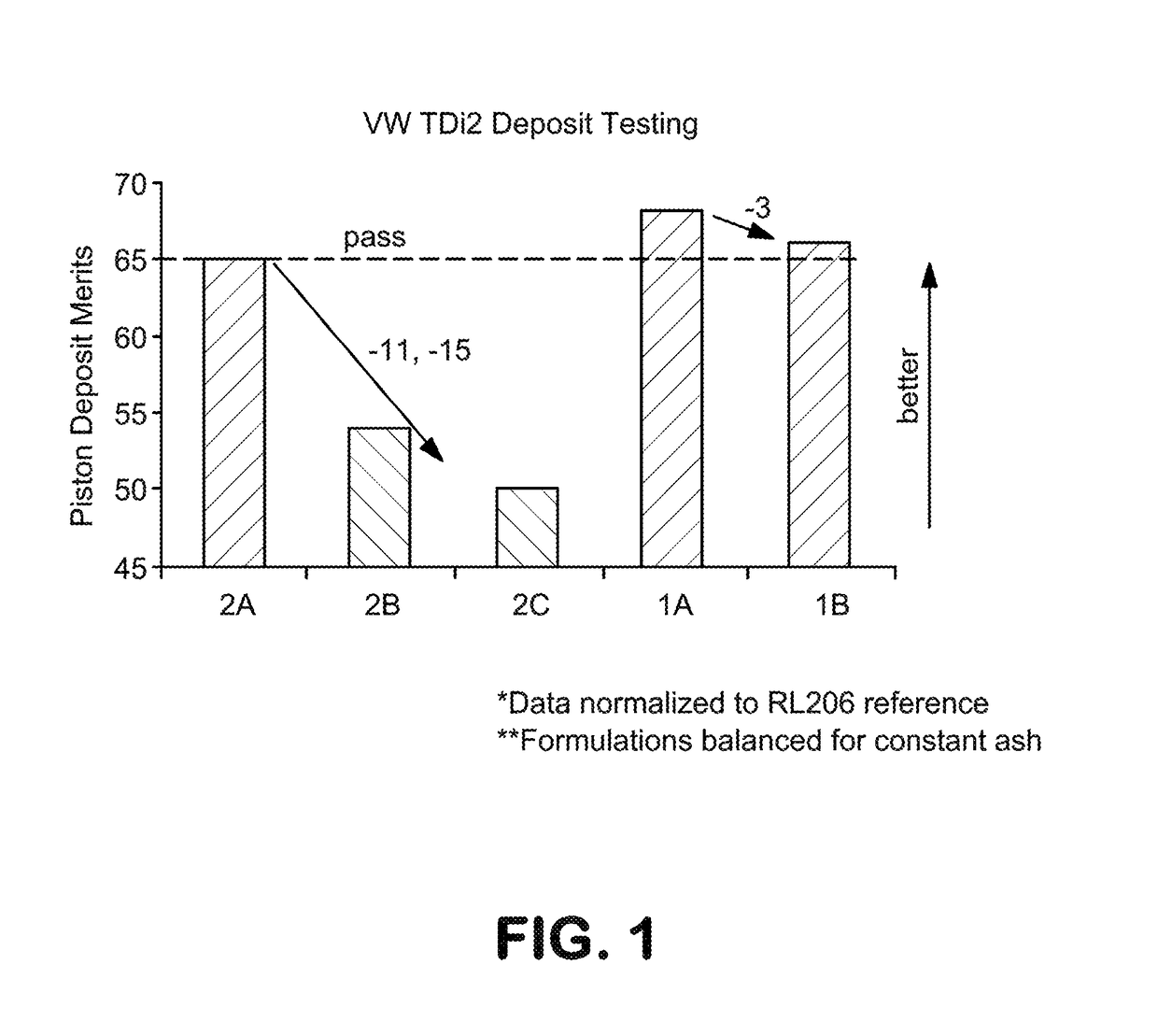

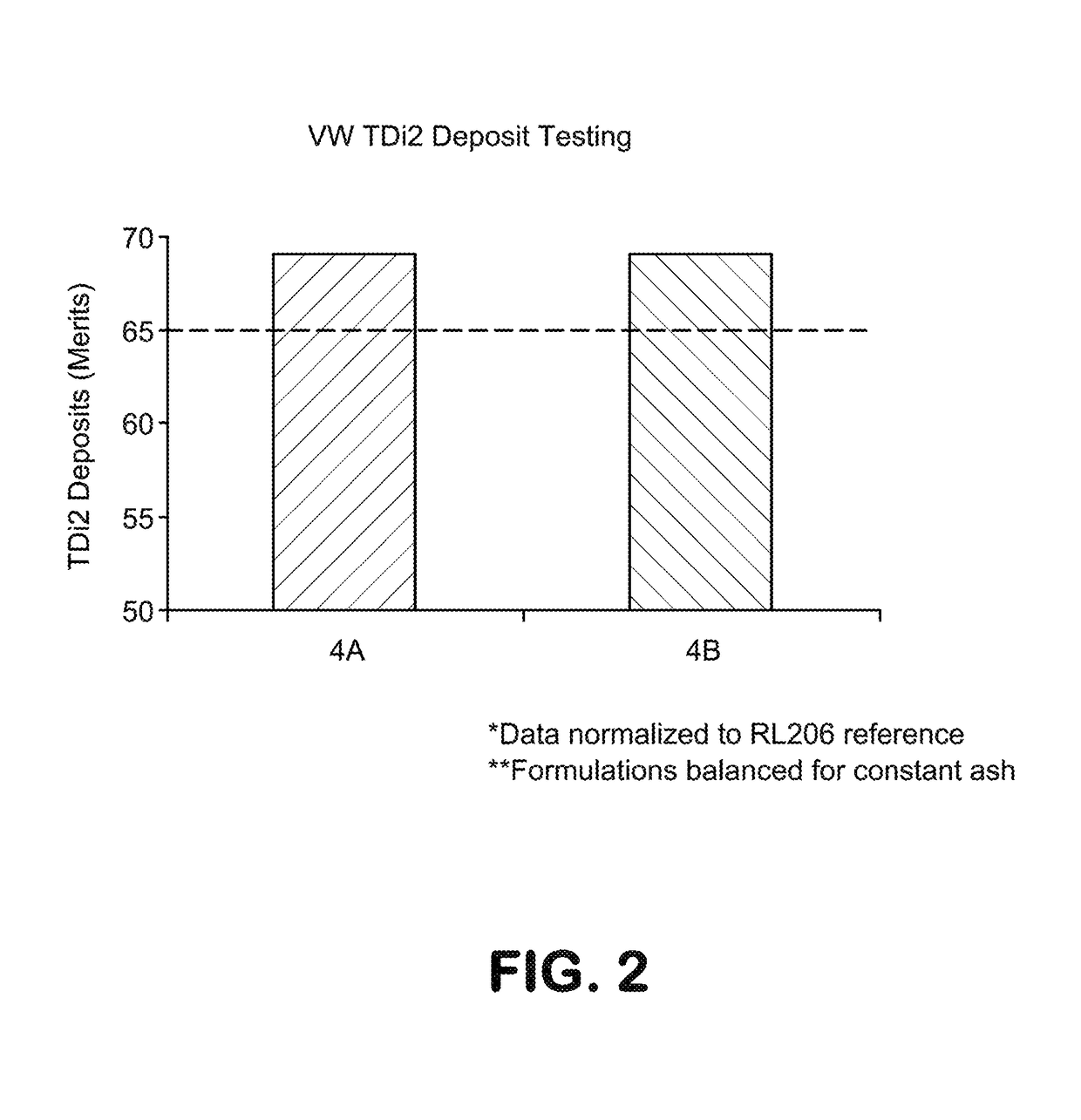

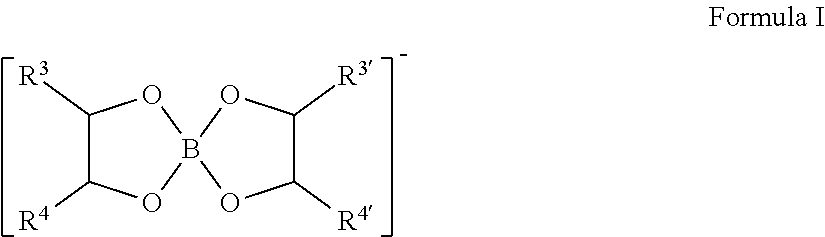

Lubricating compositions with enhanced deposit performance

InactiveUS20190024010A1Improve fuel economyPotential damageAdditivesBase-materialsControlled releaseBase oil

A lubricant composition includes a lubricating base oil, a controlled release friction modifier, a dispersant, a viscosity modifier and a cleanliness booster. The controlled release friction modifier is an ashless, dispersant-stabilized, borated controlled release friction modifier including an ionic tetrahedral borate compound including a cation and a tetrahedral borate anion, wherein the tetrahedral borate anion includes a boron atom having two bidentate di-oxo ligands of C18 tartrimide.

Owner:EXXON RES & ENG CO

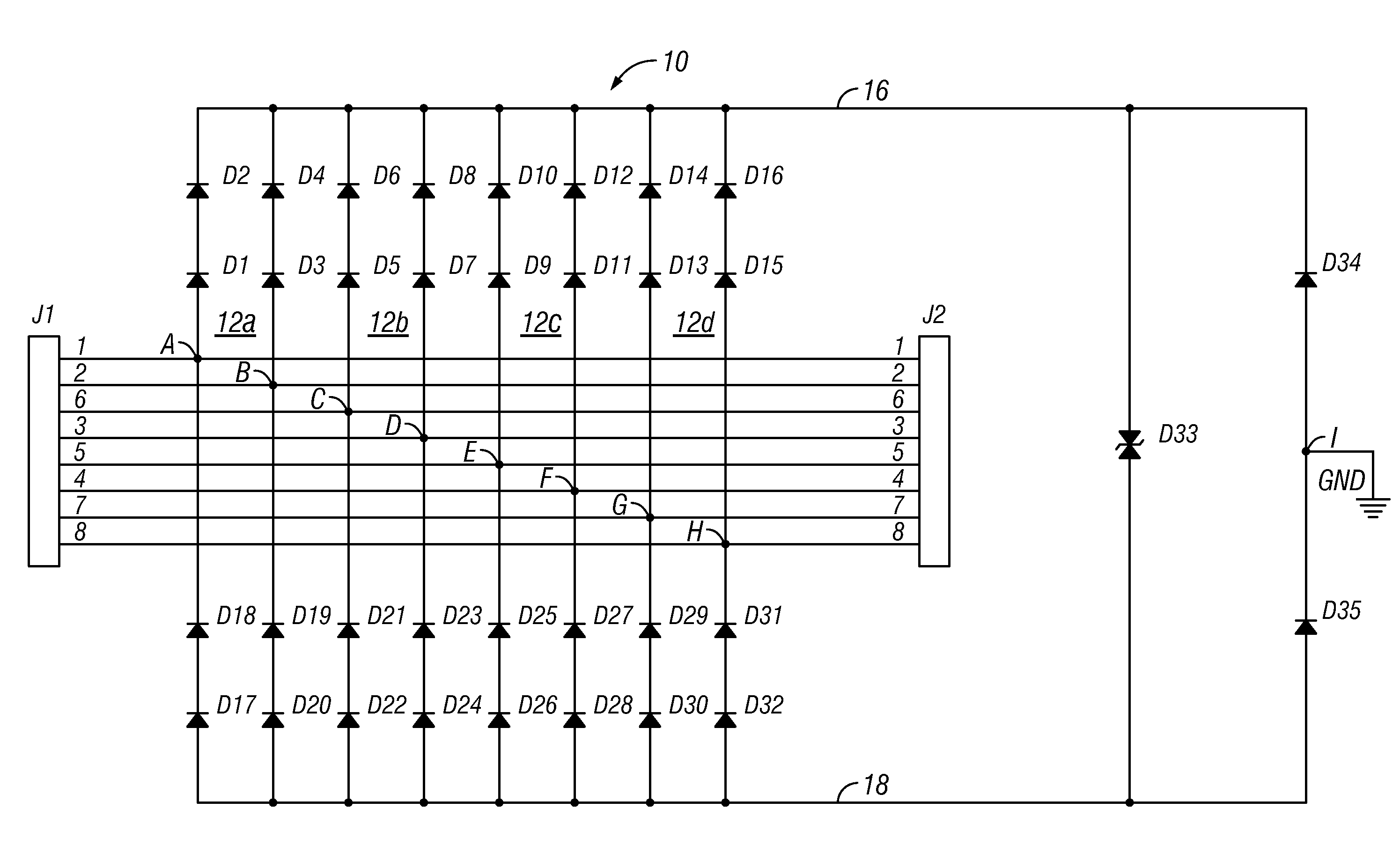

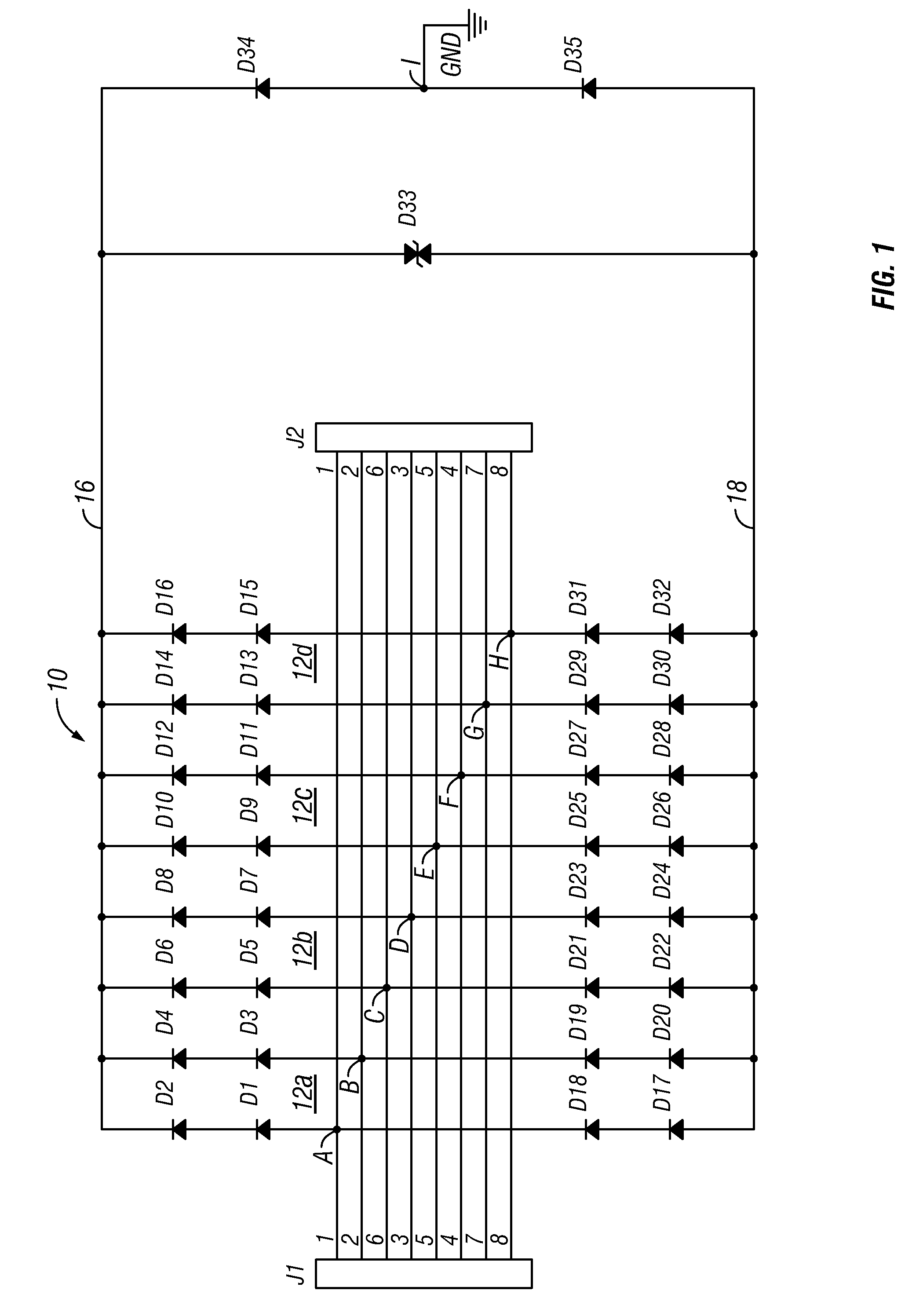

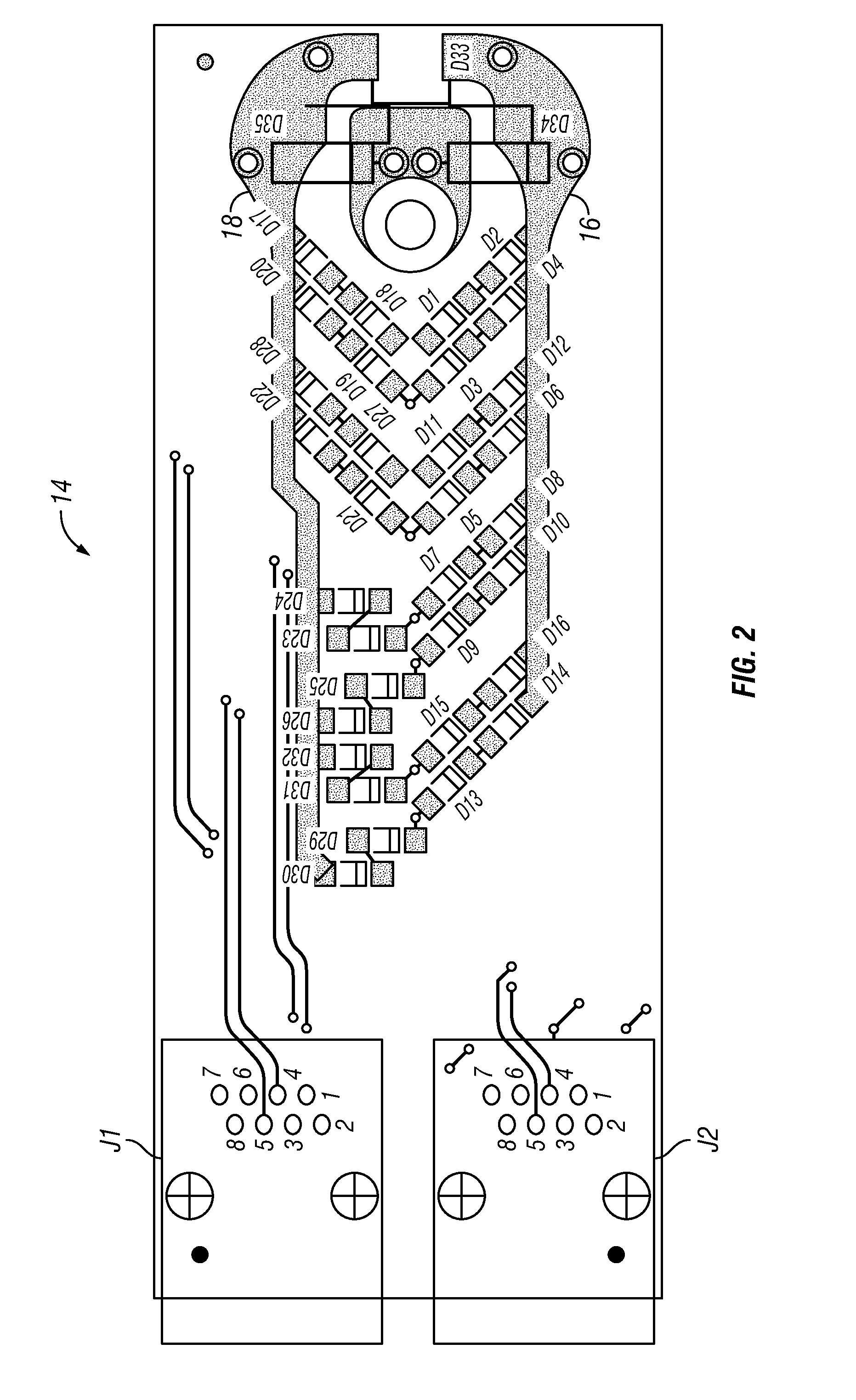

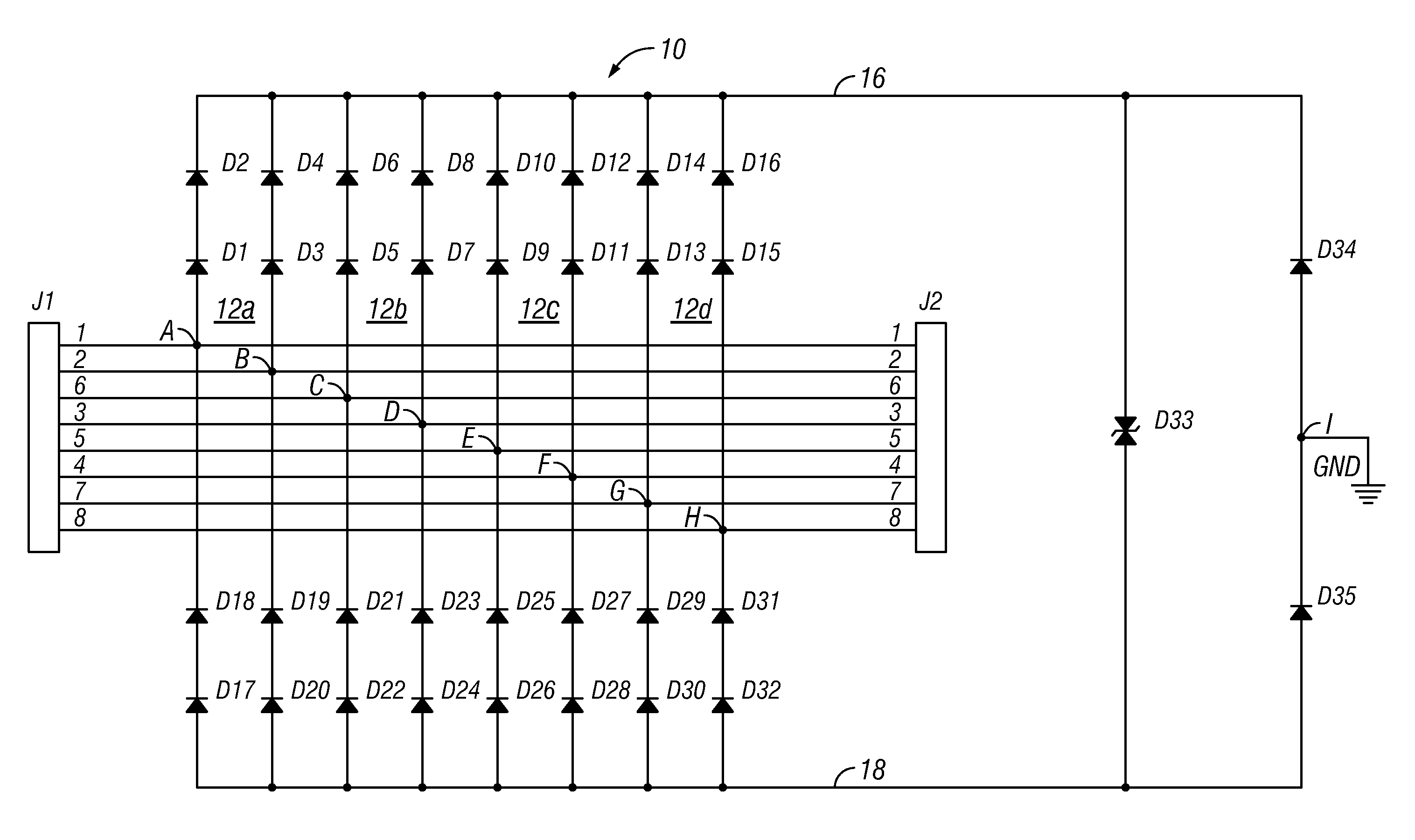

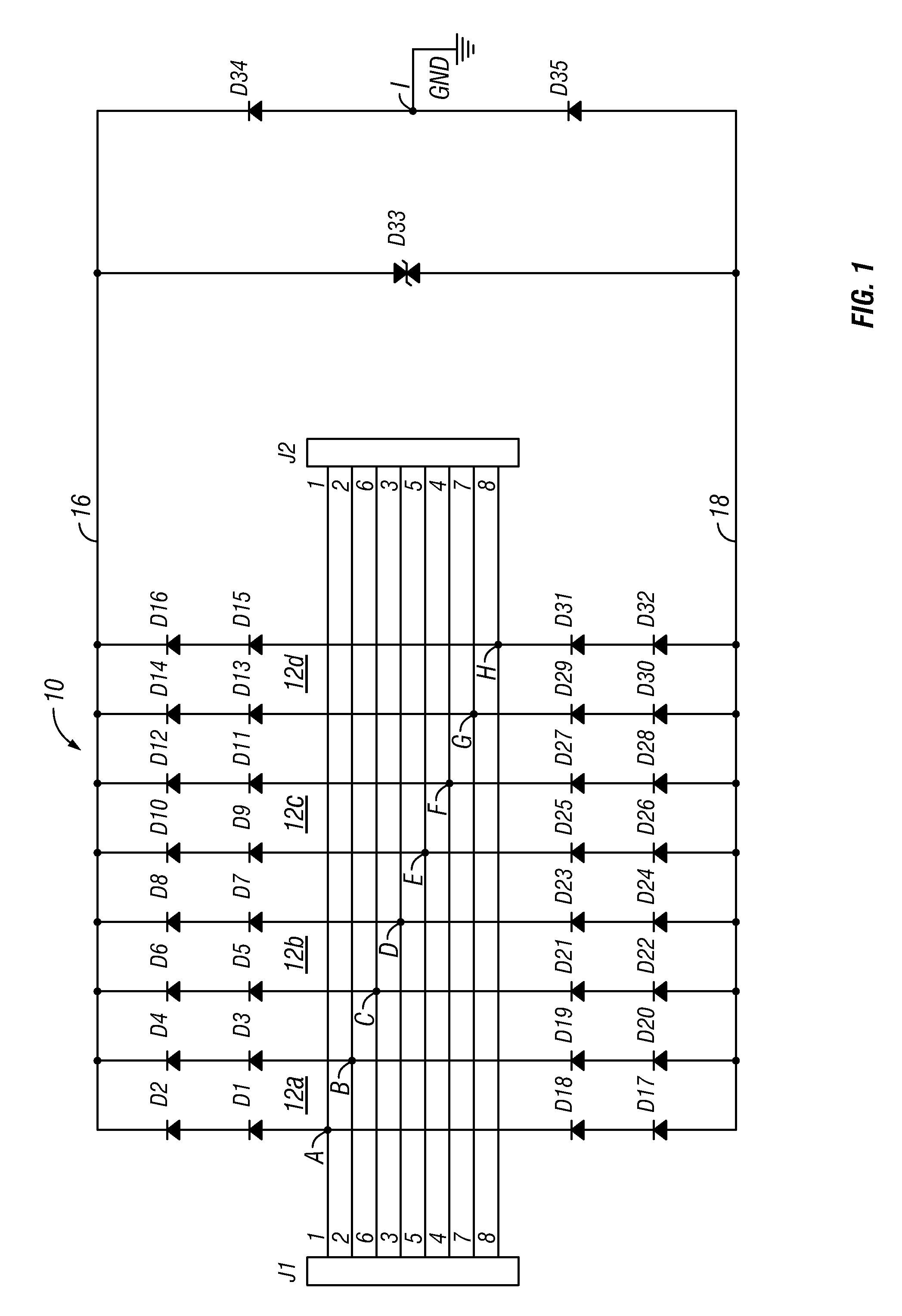

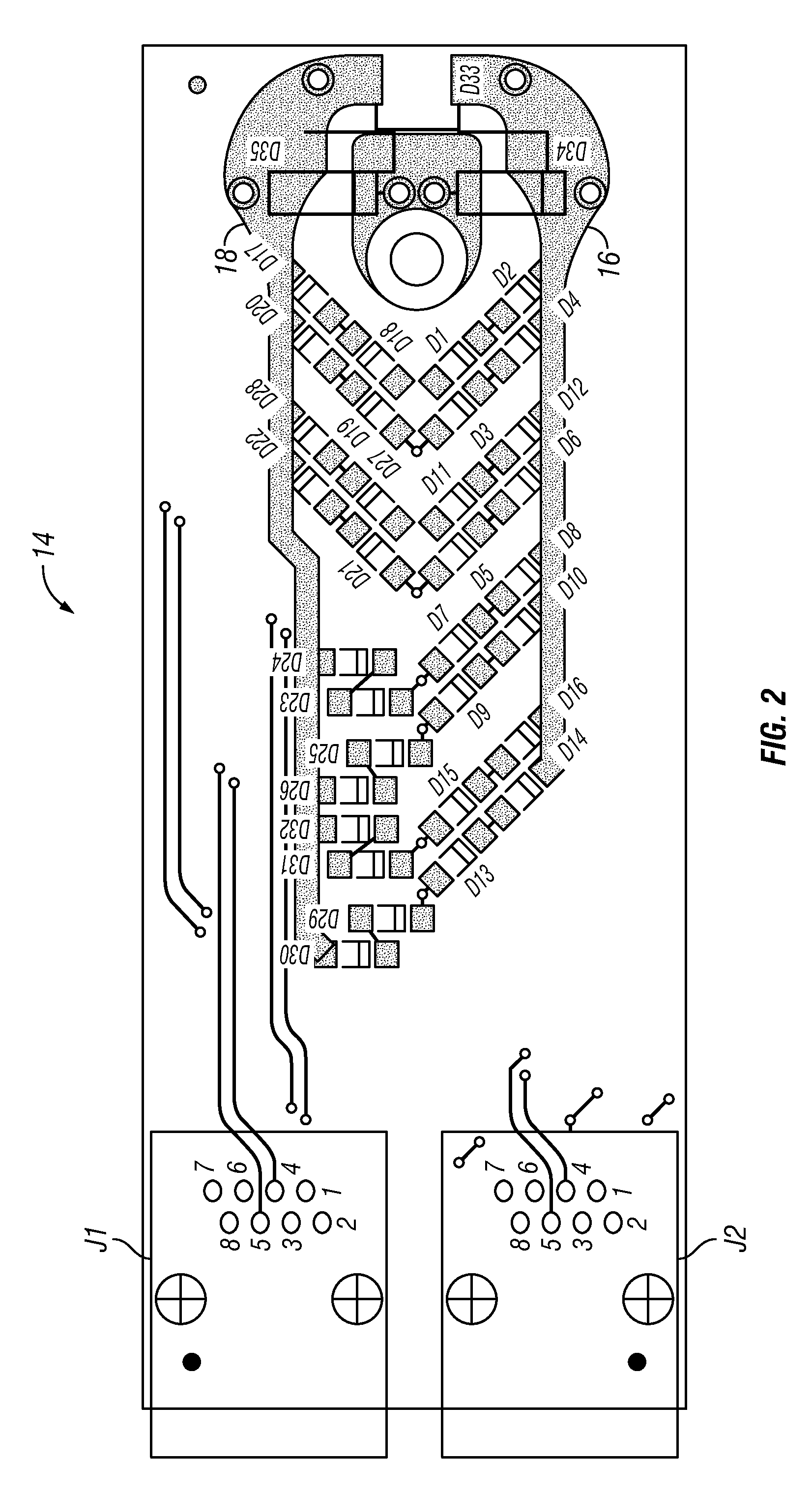

Transmission bandwidth extender/category 6 surge protector

ActiveUS20150171619A1Easy constructionCheap manufacturingEmergency protective arrangement detailsSubstation equipmentElectrical conductorRectifier diodes

A surge protector for protecting telecommunications related equipment and other associated sensitive electrical components from over-voltage transient occurring on tip / ring conductors of telecommunication lines coupled thereto includes a printed circuit board and a plurality of surge protection circuits being mounted on the printed circuit board. Each of the plurality of surge protection circuits includes a first set of steering diodes and a second set of steering diodes. A common transient voltage clamping device has a first end connected to a first conductor lead and a second end connected to a second conductor lead so as to be shared by the plurality of surge protection circuits. A common pair of series-connected rectifier diodes has a first end also connected to the first conductor lead and a second end also connected to the second conductor lead so as to be shared by the plurality of surge protection circuits.

Owner:ILLINOIS TOOL WORKS INC

Modified gelatin gradient film prepared from mixed glycidol and single-epoxy-terminated polysiloxane

The invention relates to a modified gelatin gradient film prepared from mixed glycidol and single-epoxy-terminated polysiloxane. A method for preparing the modified gelatin gradient film includes dissolving surfactants in water to prepare aqueous solution; adding gelatin into the aqueous solution under the conditions of the temperatures of 40-60 DEG C and the pH (potential of hydrogen) of 8-11; stirring the gelatin and the aqueous solution for 4-8 h and then adding the single-epoxy-terminated polysiloxane into the gelatin and the aqueous solution continuously or in batches to obtain mixtures; carrying out reaction for 12-30 h and then adding glycidol into the mixtures; continuing to carry out reaction at the temperatures of 40-60 DEG C for 6-12 h to obtain milk white turbid liquid; adding ethyl alcohol into the milk white turbid liquid and uniformly mixing the ethyl alcohol with the milk white turbid liquid to obtain mixed liquid; dripping 0.5-0.8 ml of the measured mixed liquid on gelatin substrates; allowing the gelatin substrates to stand still for 12-18 h and then freezing the gelatin substrates by the aid of liquid nitrogen; drying the gelatin substrates by the aid of a freeze dryer to obtain the gradient film. The dosage of the gelatin is 1-10% of the mass of the aqueous solution. The dosage of the single-epoxy-terminated polysiloxane is 0.2-1.0 times the molar weight of the gelatin. The dosage of the glycidol is 0-1 times the mass of the single-epoxy-terminated polysiloxane. A volume ratio of the ethyl alcohol to reaction liquid is (3-5):1. The modified gelatin gradient film has the advantages that the concentration of components of the modified gelatin gradient film changes in longitudinal sections in a gradient manner, the modified gelatin gradient film is high in tensile strength and good in hydrophobic property and is soft, and the like.

Owner:山东山科美谷科技发展有限公司

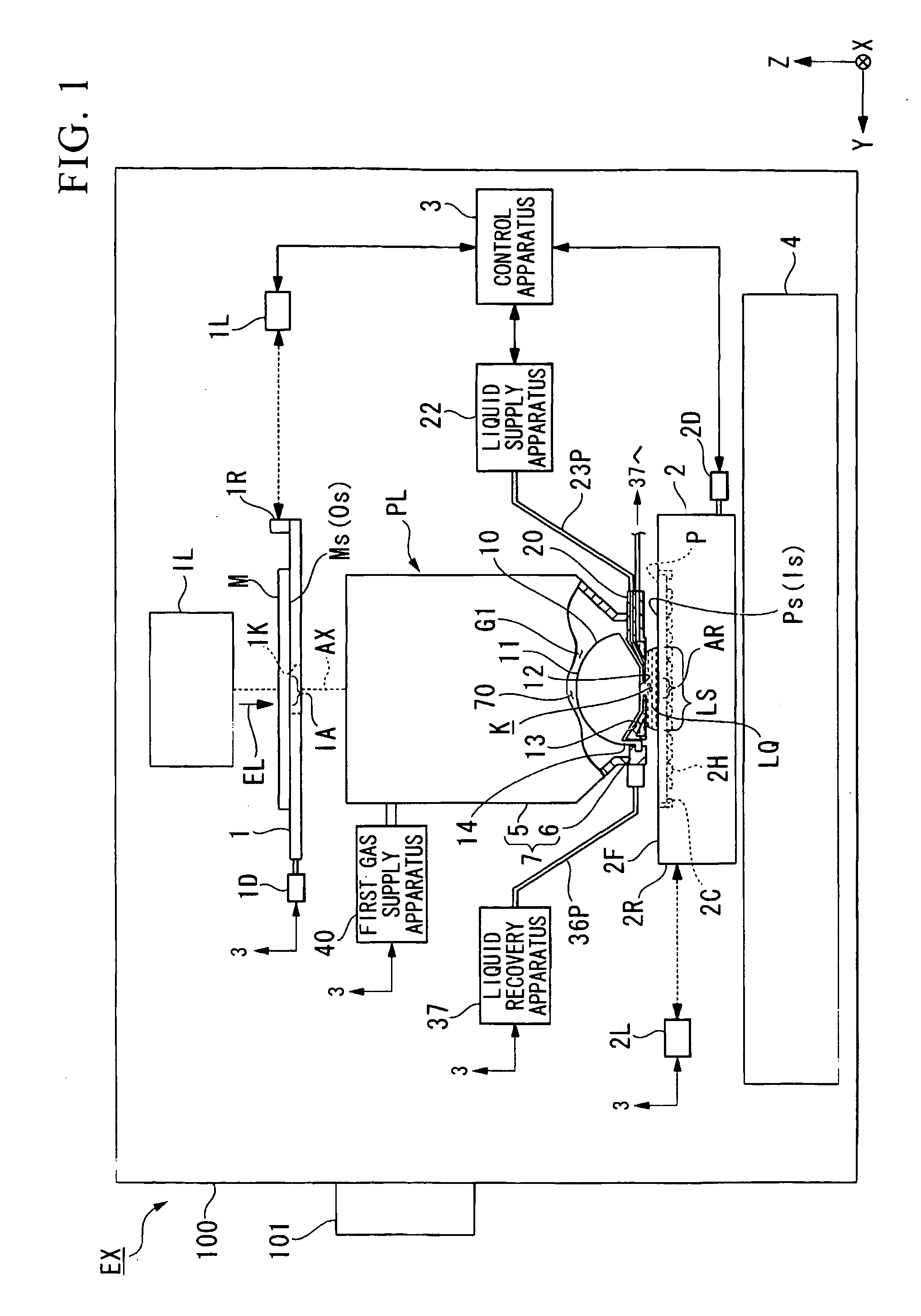

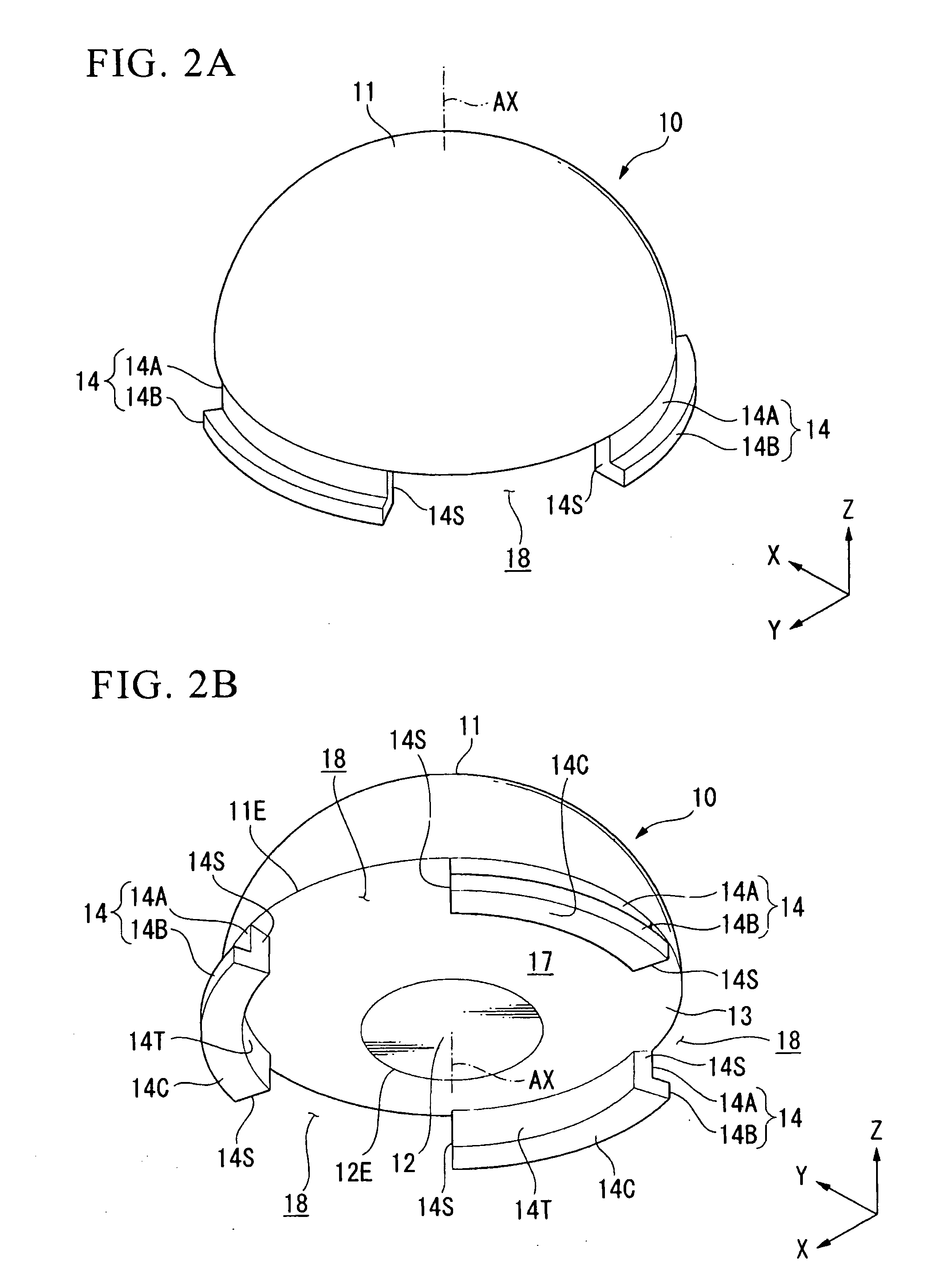

Projection optical system, exposing method, exposure apparatus, and device fabricating method

InactiveUS20080291408A1Overall small sizeSpecific performancePhotomechanical apparatusPhotographic printingOptics

A projection optical system projects an image of a first surface to a second surface through a liquid. The projection optical system comprises an optical element, wherein the first surface side contacts a gas and the second surface side contacts the liquid. The optical element has an incident surface, which is convex toward the first surface, an emergent surface, an outer circumferential surface between an outer circumference of the incident surface and an outer circumference of the emergent surface, and holding parts, which are formed at a circumferential edge part of the outer circumferential surface so that they project toward the second surface.

Owner:NIKON CORP

Synthesis of olefins from oxygen-free direct conversion of methane and catalysts thereof

ActiveUS9932280B2Specific performanceGood dispersionCatalystsHydrocarbon preparation catalystsMolten stateReaction temperature

Provided is a method for the preparation of a metal lattice-doping catalyst in an amorphous molten state, and the process of catalyzing methane to make olefins, aromatics, and hydrogen using the catalyst under oxygen-free, continuous flowing conditions. Such a process has little coke deposition and realizes atom-economic conversion. Under the conditions encountered in a fixed bed reactor (i.e. reaction temperature: 750˜1200° C.; reaction pressure: atmospheric pressure; the weight hourly space velocity of feed gas: 1000˜30000 ml / g / h; and fixed bed), conversion of methane is 8-50%. The selectivity of olefins is 30˜90%. And selectivity of aromatics is 10˜70%. There is no coking. The reaction process has many advantages, including a long catalyst life (>100 hrs), high stability of redox and hydrothermal properties under high temperature, high selectivity towards target products, zero coke deposition, easy separation of products, good reproducibility, safe and reliable operation, etc., all of which are very desirable for industrial application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Exposing method, exposure apparatus, and device fabricating method

InactiveUS8243254B2Specific performancePhotomechanical apparatusPhotographic printingObject basedComputer science

An exposure apparatus comprises: a first detection apparatus, which detects the temperature of a liquid after the liquid contacts a prescribed object; and a processing apparatus that detects the relationship between the temperature of the liquid and the temperature of the object based on the detection result of the first detection apparatus.

Owner:NIKON CORP

Novel calcium-wood composite material and composite board prepared from same

InactiveCN102250431ARealize the polycondensation reactionSpecific performancePolyvinyl chlorideComposite plate

The invention discloses a novel calcium-wood composite material, and relates to a composite board prepared from the material. The material is characterized by comprising the following components in percentage by weight: 35-40 percent of fly ash, 35-40 percent of wollastonite, 15-30 percent of polyvinyl chloride resin, 0.2-2.5 percent of carbon black, 1-3 percent of zinc borate and 3-6 percent of composite calcium-zinc modifier. Through high-temperature coupling and crosslinking, polymerization condensation reaction of an inorganic matter and an organic matter is realized; the material is granulated to form particles after a high molecular structural function is changed; a special equipment mould is applied to perform extrusion molding; and then a novel calcium-wood composite board with superior performance is formed after a three-dimensional pattern is embossed on the surface.

Owner:石维春 +1

Method using centrifugal extraction to prepare gradient film modified by single epoxy terminated polysiloxane

The invention relates to a method using centrifugal extraction to prepare a gradient film modified by single epoxy terminated polysiloxane. The method includes: dissolving surfactant sodium alkyl sulfate into water to prepare an aqueous solution, stirring for 1-2 hours under the condition that the temperature is 40-60 DEG C and pH is 8-11, adding gelatin, stirring for 4-8 hours, and adding single epoxy terminated polydimethylsiloxane with the molecular weight being 500 to obtain a gelatin solution modified by the single epoxy terminated polydimethylsiloxane; centrifuging the gelatin solution at low temperature, adjusting centrifuging speed and time, adding ethanol, well mixing, dripping 0.5-0.8ml of the mixture on a gelatin substrate, standing for 12-18 hours, and drying in an oven of 40-50 DEG C to obtain the gradient film, wherein the volume ratio of the ethanol to reaction liquid is (3-5):1. The gradient film is high in hydrophobic performance, high in tensile strength, soft and the like.

Owner:QILU UNIV OF TECH

A kind of strongly hydrophobic gelatin leather finishing agent containing polysiloxane and glycidol and preparation method thereof

ActiveCN103436168BPlay a plasticizing roleImprove performanceFibre treatmentProtein coatingsEpoxyPolymer science

The invention relates to a strongly hydrophobic gelatin leather finishing agent containing polysiloxane and glycidol and a preparation method thereof. The gelatin is dissolved in water to prepare an aqueous solution with a concentration of 2-20%. Under the conditions of 40~70°C and pH 6~12, add glycidol to the first reaction bottle to obtain solution 1; add surfactant to the second reaction bottle, the amount of surfactant is gelatin mass 0.5~20%, continue to stir, and at the same time add epoxy polysiloxane containing Si-O-Si repeating units in batches or continuously to obtain solution 2. Mix solution 1 and solution 2 in different proportions, weigh 15-20g and place it in a polytetrafluoroethylene mold, add 5-10mL of ethanol, tetrahydrofuran, methanol or a mixture of two or three solvents, and store at 40-80°C Drying in an oven under normal pressure obtains a gelatin leather finishing agent with excellent functions. The finishing agent has the characteristics of strong hydrophobicity, super ductility, heat resistance, oxidation resistance, and wet rub resistance.

Owner:QILU UNIV OF TECH

A kind of antibacterial gelatin leather finishing agent containing polysiloxane and quaternary ammonium salt and preparation method thereof

InactiveCN103436169BAntibacterialImprove antibacterial propertiesAntifouling/underwater paintsFibre treatmentPolymer scienceActive agent

The invention relates to an antibacterial gelatin leather finishing agent containing polysiloxane and a quaternary ammonium salt and a preparation method thereof. The gelatin is dissolved in water to prepare an aqueous solution with a concentration of 2 to 20%, and the gelatin is prepared at 40 to 70°C and the pH is Under the condition of 6~12, add epoxy quaternary ammonium salt in the 1st reaction bottle, obtain solution 1; Add surfactant in the 2nd reaction bottle, the consumption of surfactant is 2~20% of gelatin quality, Continue stirring while adding the epoxypolysiloxane containing Si-O-Si repeating units batchwise or continuously to obtain solution 2. Mix solution 1 and solution 2 in different proportions, weigh 15-20g and place it in a polytetrafluoroethylene mold, add 5-10mL of ethanol, tetrahydrofuran, methanol or a mixture of two or three solvents, and store at 40-80°C Dry in an oven at normal pressure to obtain a multifunctional gelatin leather finishing agent. The coating agent has the characteristics of antibacterial, adjustable hydrophilicity and hydrophobicity, soft film formation, and strong oxidation resistance.

Owner:QILU UNIV OF TECH

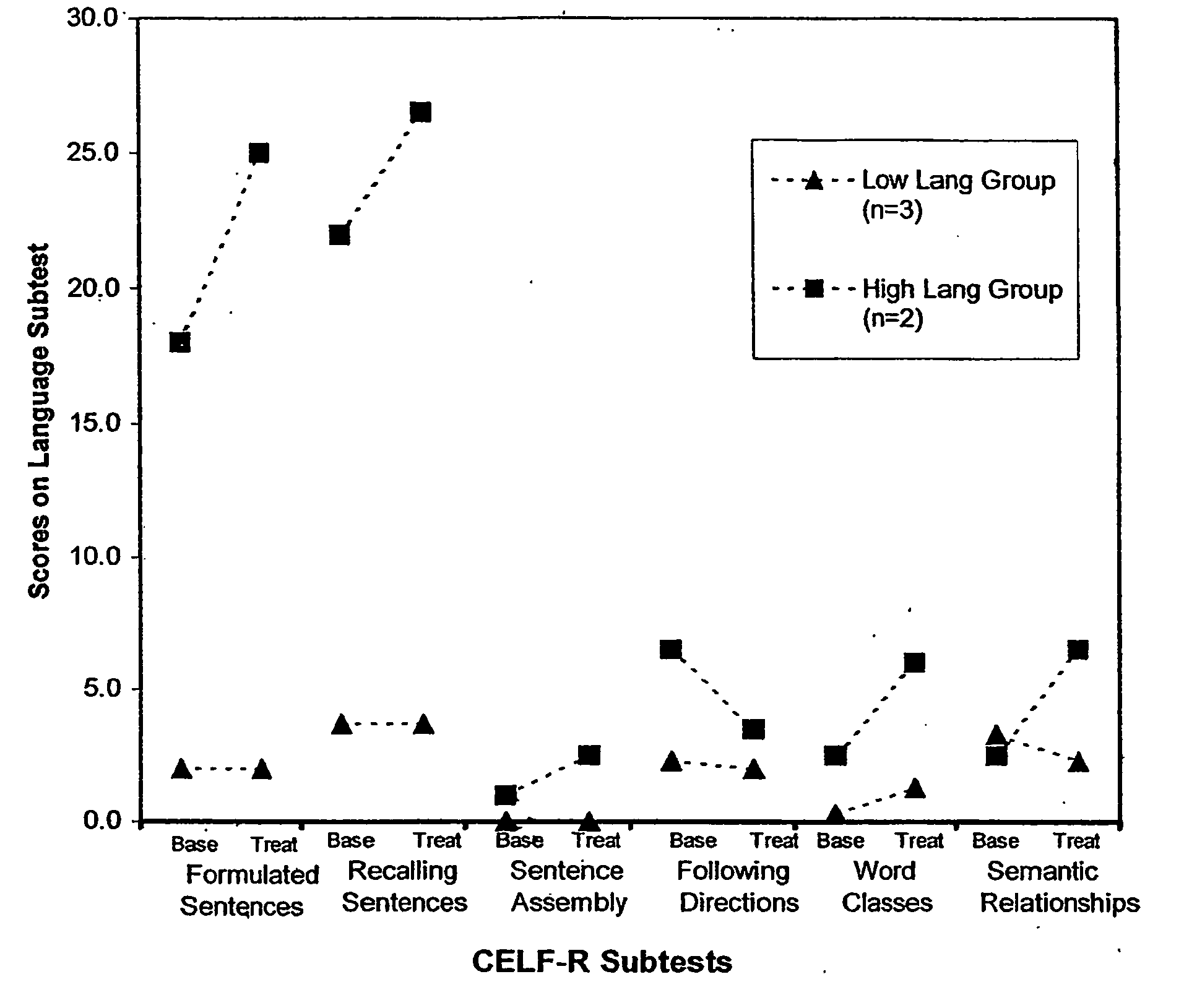

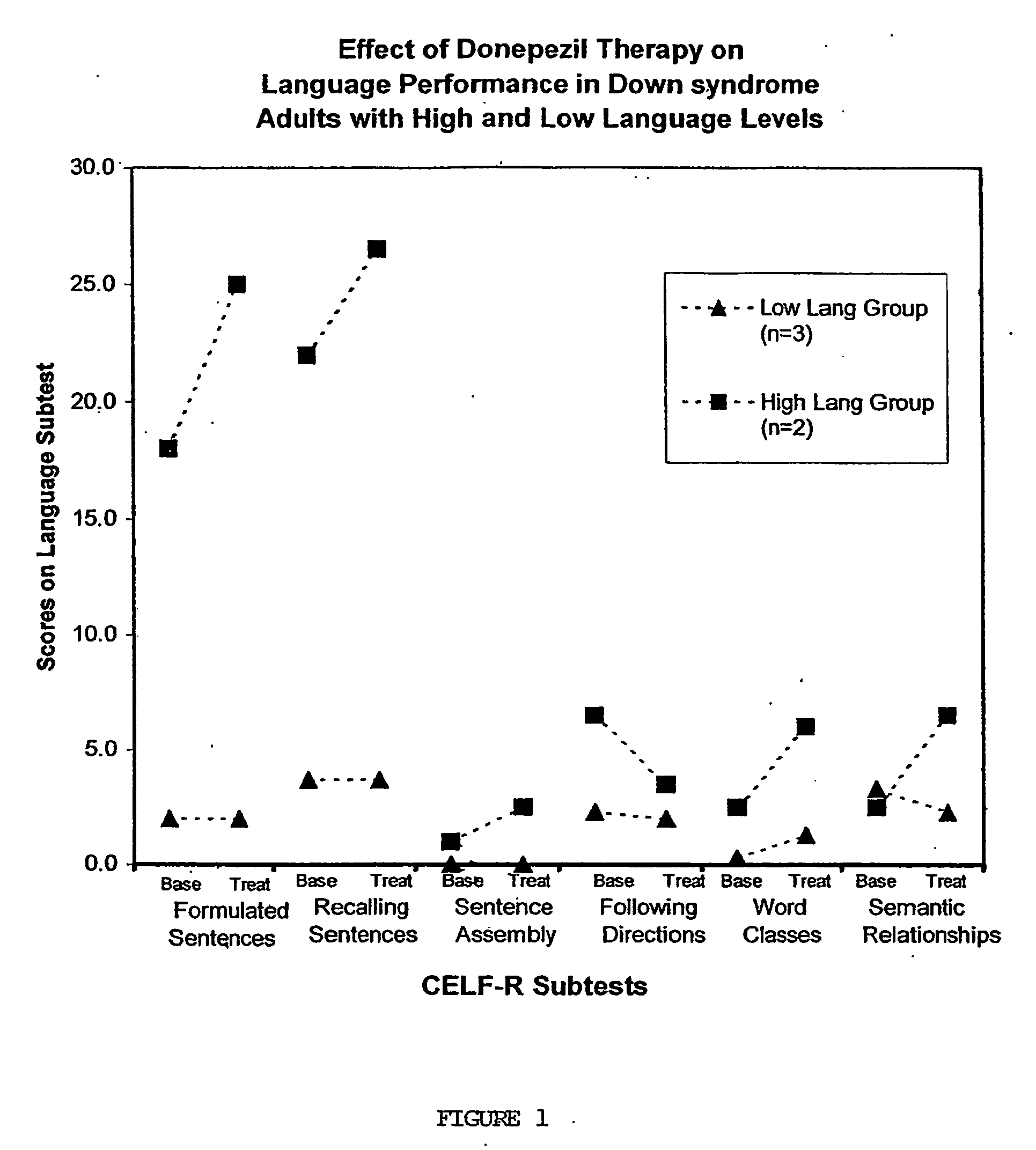

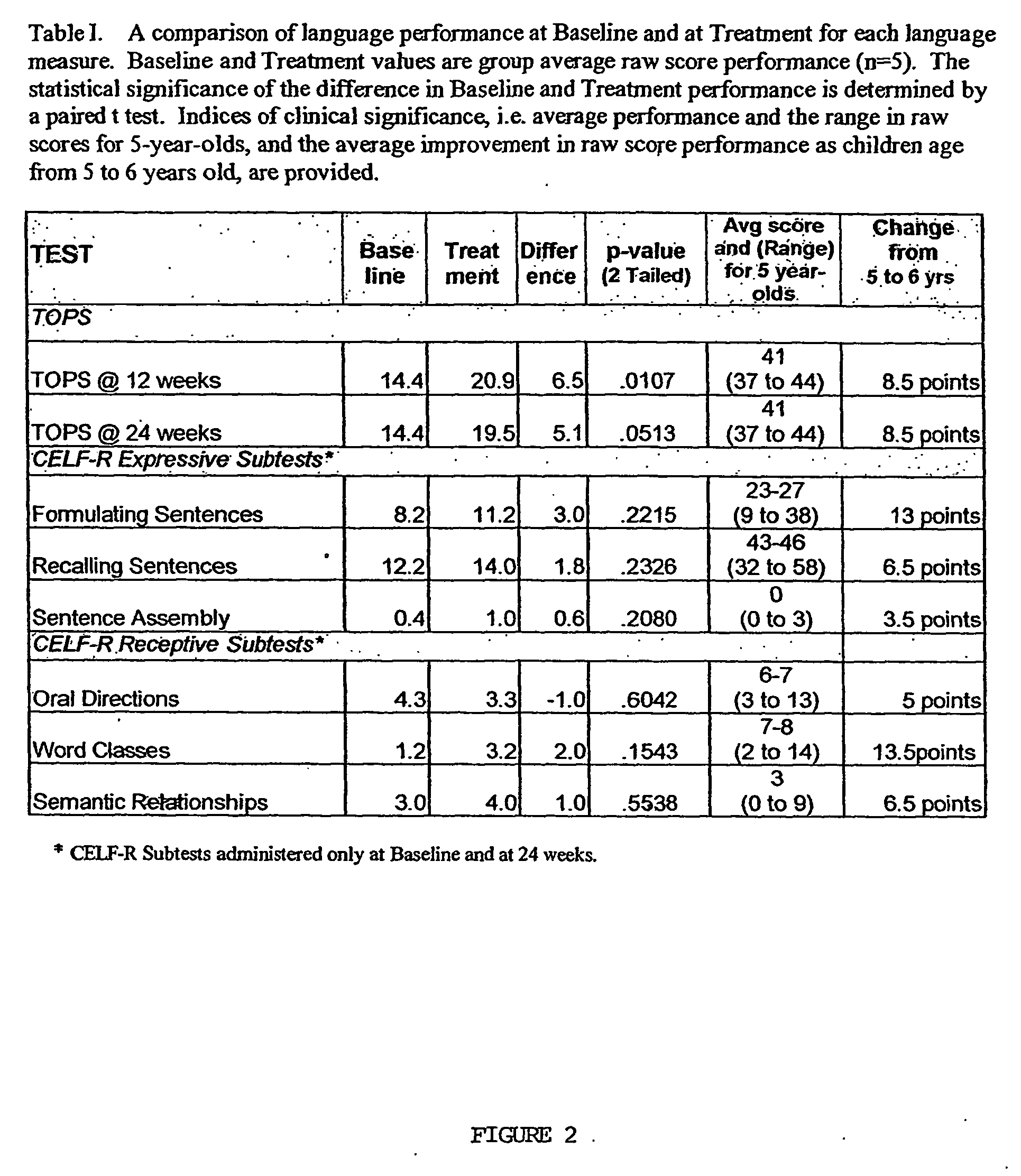

Cholinergic therapy for individuals with learning disabilities

InactiveUS20060129385A1Improve the level ofImprove performanceNervous disorderPeptide/protein ingredientsInformation processingTherapeutic effect

Cholinergic agents are used to improve specific learning deficits and language function in individuals of normal intelligence. Psychosocial deficits including a pragmatics impairment, reading deficits, a problem solving impairment, an information processing impairment, an adaptive function impairment, social skills impairment, attention impairment, a mood impairment and employment skills impairment, can also be treated in this manner. The cholinergic treatments can be combined with more traditional educational, psychological, and behavioral therapies for enhanced therapeutic benefit.

Owner:DUKE UNIV

Transmission bandwidth extender/category 6 surge protector

ActiveUS9570904B2Specific performanceEasy constructionSubstations coupling interface circuitsArrangements responsive to excess voltageElectrical conductorRectifier diodes

A surge protector for protecting telecommunications related equipment and other associated sensitive electrical components from over-voltage transient occurring on tip / ring conductors of telecommunication lines coupled thereto includes a printed circuit board and a plurality of surge protection circuits being mounted on the printed circuit board. Each of the plurality of surge protection circuits includes a first set of steering diodes and a second set of steering diodes. A common transient voltage clamping device has a first end connected to a first conductor lead and a second end connected to a second conductor lead so as to be shared by the plurality of surge protection circuits. A common pair of series-connected rectifier diodes has a first end also connected to the first conductor lead and a second end also connected to the second conductor lead so as to be shared by the plurality of surge protection circuits.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com