A kind of antibacterial gelatin leather finishing agent containing polysiloxane and quaternary ammonium salt and preparation method thereof

A technology of leather finishing agent and polysiloxane, applied in leather surface treatment, biocide-containing paint, small leather/big leather/leather/fur treatment, etc., can solve the problems of gelatin film antibacterial property, etc., and achieve High-efficiency sterilization and algae killing ability, good water resistance, and the effect of improving anti-corrosion and anti-bacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Add 12 grams of gelatin (accounting for 11.76% of the total mass) and 85 grams of deionized water into a 250ml three-neck reaction bottle equipped with a thermometer socket, a sampling port, and a condenser socket, stir and heat to 50°C. After the gelatin is completely dissolved, add 0.25mL of 3 mol / L sodium hydroxide, adjust the reaction pH to 10.0, add 8g of epoxy quaternary ammonium salt, after the reactants are not safely dissolved, continue to stir for 8 hours to prepare epoxy quaternary ammonium salt graft modified gelatin polymerization solution (Solution 1).

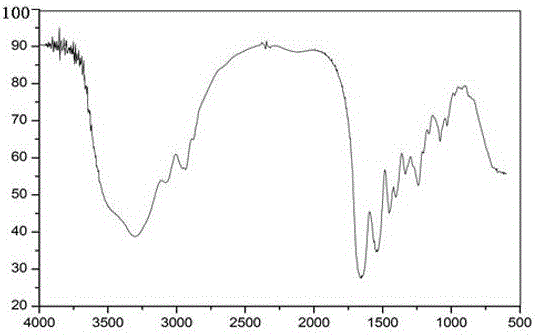

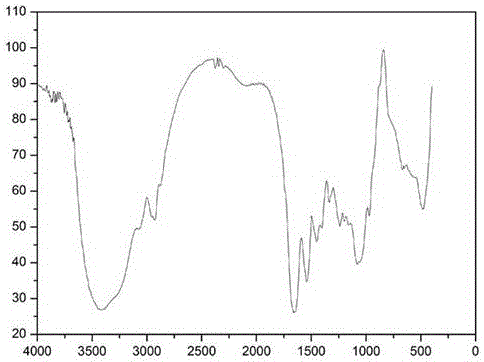

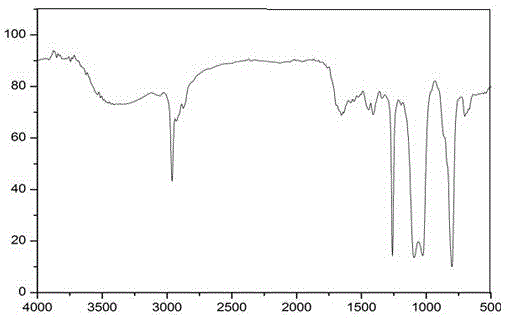

[0059] The infrared spectrogram of epoxy quaternary ammonium salt modified gelatin ( figure 2 ), the original 1643cm -1 The N~H absorption peak of the primary amino group disappears, and at the same time at 1475cm -1 -N(CH 3 ) 3 C-H new absorption peaks. One N-H absorption peak that appeared in the spectrum disappeared, and one ~N(CH 3 ) 3 The characteristic absorption peak of C-H on the top indica...

Embodiment 2

[0065] The described method is the same as that in Example 1, except that the mass of gelatin is changed to 3 grams (accounting for 2.83% of the total mass), the pH is changed to 6.0, and the mixture is heated and stirred to 40°C.

[0066] The viscosity of the obtained liquid is ~360 centipoise (50°C), and it is placed in a normal-pressure oven at 50°C for 6 hours to form a film with strong flexibility. The glass transition temperature (T g ) is 224℃, the T of gelatin film after modification g The temperature dropped to 196°C; the antibacterial rate of raw gelatin film against Escherichia coli was 18.3%, and that of the modified gelatin film increased to 86.2%, and the antibacterial rate increased significantly. 13 C NMR showed that the γ-C signal on the lysine and arginine molecules on the gelatin molecule in the glycidol-modified gelatin product disappeared, and new peaks appeared at 61 and 63ppm, which were - C Peaks of HOH- groups; new peaks appeared at 69 and 72ppm a...

Embodiment 3

[0070] The described method is consistent with that of Example 1, except that the mass of gelatin is changed to 16 grams (accounting for 15.09% of the total mass), the pH is changed to 12.0, and the mixture is heated and stirred to 40°C.

[0071] The viscosity of the obtained liquid is ~460 centipoise (50°C), and it is placed in a normal-pressure oven at 50°C for 6 hours to form a film with strong flexibility. The glass transition temperature (T g ) is 224℃, the T of gelatin film after modification g The antibacterial rate of raw gelatin film against Escherichia coli was 18.3%, and that of the modified gelatin film increased to 68.4%, and the antibacterial rate increased significantly. 13 C NMR showed that the γ-C signal on the lysine and arginine molecules on the gelatin molecule in the glycidol-modified gelatin product disappeared, and new peaks appeared at 61 and 63ppm, which were - C Peaks of HOH- groups; new peaks appeared at 69 and 72ppm as- C h 2 OH group peak;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com