Lubricating compositions with enhanced deposit performance

a technology of lubricating compositions and deposits, applied in the field of lubricating compositions, can solve the problems of complex chemistry used in the formulation of engine oils, limited solubility of polar additives, and high non-polarity, and achieve the effects of reducing the potential damage of ash, improving overall fuel economy, and reducing the formation of deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0101]As noted above, creating engine oil compositions including a CRFM presented certain challenges to the present inventors. Particularly, the addition of a CRFM to the lubricating oil composition can result in unmanageable deposit formation from the CRFM.

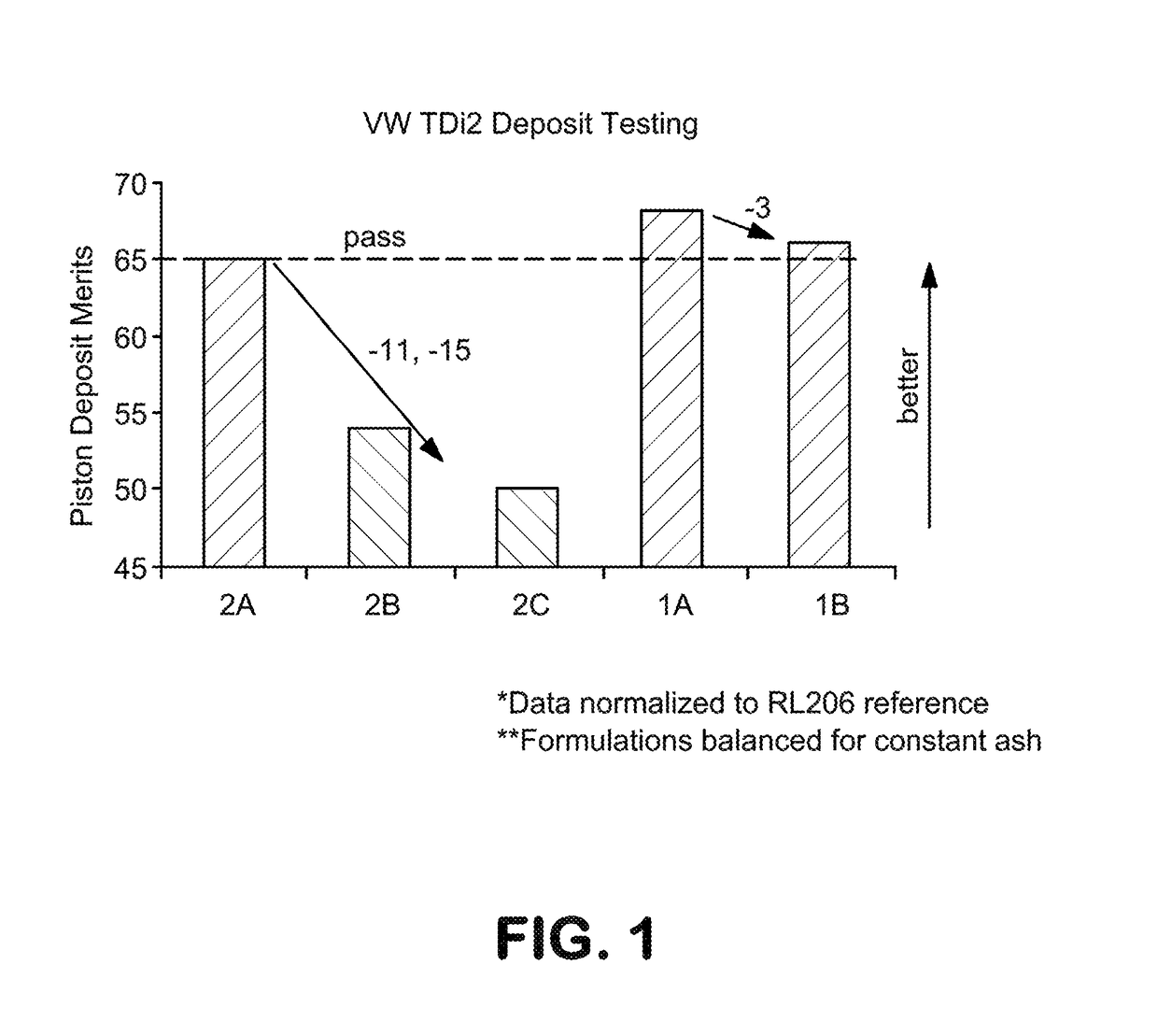

[0102]FIG. 1 illustrates a graph of TDi2 piston deposit merits for initial CRFM formulations. The piston deposit merit is a cleanliness grade for an engine oil. A merit score of 65 indicates a passing grade with 70 indicating an exceptionally clean formulation. As is illustrated in FIG. 1, an initial lubricating oil (comparative example 2A), which did not include any CRFM, had a deposit merit score of 65. When CRFM was added to this initial oil, the deposit merit score drop significantly to 54 (comparative example 2B) and 50 (comparative example 2C), respectively. Thus, with merely adding CRFM to an existing engine oil, the deposit merit score dropped to well below passing. Similarly, another initial lubricating oil (comparative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity indices | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com