Polysiloxane, glycidol and quaternary ammonium salt-containing multifunctional gelatin leather finishing agent and preparation method

A leather finishing agent, glycidol technology, applied in leather surface treatment, biocide-containing paint, antifouling/underwater coatings, etc., can solve the problems of poor water resistance and corrosion resistance, strong plastic feeling, etc., and achieve flexibility The effect of improving, increasing elastic modulus, improving anti-corrosion and antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

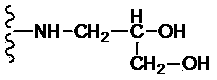

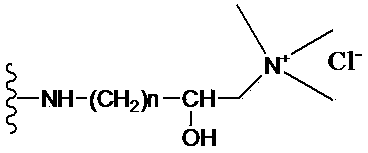

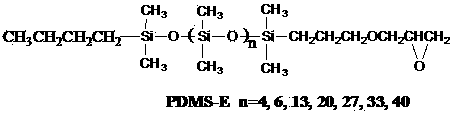

[0068] Add 12 grams of gelatin (accounting for 11.76% of the total mass) in the 250ml three-necked reaction flask equipped with a thermometer socket, a sampling port and a condenser socket, and its molecular structure is verified by infrared spectroscopy, see figure 1 ), 85 grams of deionized water, stirring and heating to 50°C, after the gelatin is completely dissolved, add 0.25mL of 3 mol / liter sodium hydroxide, adjust the reaction pH to 10.0, add 13g of epoxy quaternary ammonium salt, and the reaction product is safe After dissolving, the stirring was continued for 8 hours to prepare a gelatin polymer solution (solution 1) grafted with epoxy quaternary ammonium salt.

[0069] The infrared spectrogram of epoxy quaternary ammonium salt modified gelatin ( image 3 ), the original 1643cm -1 The N~H absorption peak of the primary amino group disappears, and at the same time at 1475cm -1 -N(CH 3 ) 3 C-H new absorption peaks. One N-H absorption peak that appeared in the spec...

Embodiment 2

[0077] The described method is consistent with Example 1, the only difference is that the ratio of solutions 1, 2, and 3 is replaced by a mass ratio of 2:1:1, wherein the mass of solution 1 is 9g, solution 2 is 4.5g, and solution 3 is 4.5g .

[0078] The viscosity of the obtained liquid is ~620 centipoise (50°C), and it is placed in a normal-pressure oven at 45°C and dried for 6 hours to form a film with strong flexibility. The glass transition temperature (T g ) is 224℃, the T of gelatin film after modification g Decrease to 142 ℃ and 185 ℃, there is obvious microphase separation; the elongation at break of the raw gelatin film is 0, and the tensile strength is 1.3MPa, and the elongation at break of the modified gelatin film increases to 320%, and the tensile strength increases to 13.4 MPa, indicating that the flexibility of the modified gelatin is significantly enhanced; the antibacterial rate of the raw gelatin film against Escherichia coli is 18.3%, and that of the modi...

Embodiment 3

[0081] The described method is the same as that in Example 1, except that the mass of gelatin is changed to 3 grams (accounting for 2.83% of the total mass), the pH is changed to 6.0, and the mixture is heated and stirred to 40°C.

[0082] The viscosity of the obtained liquid is ~480 centipoise (50°C), and it is placed in a normal pressure oven at 45°C and dried for 6 hours to form a film with strong flexibility. The glass transition temperature (T g ) is 224℃, the T of gelatin film after modification g Decrease to 126 ℃ and 175 ℃, there is obvious microphase separation; the elongation at break of the raw gelatin film is 0, and the tensile strength is 1.3 MPa, and the elongation at break of the modified gelatin film increases to 375%, and the tensile strength increases to 3.4 MPa, indicating that the flexibility of the modified gelatin is significantly enhanced; the antibacterial rate of the raw gelatin film against Escherichia coli is 18.3%, and that of the modified gelatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com