Wood preservative preparing method

A wood preservative and nanoparticle technology, used in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of weakening antiseptic and bactericidal performance, reducing reactivity, and increasing particle size, achieving long storage period and improving reactivity. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of wood preservative of the present invention, comprises the following steps:

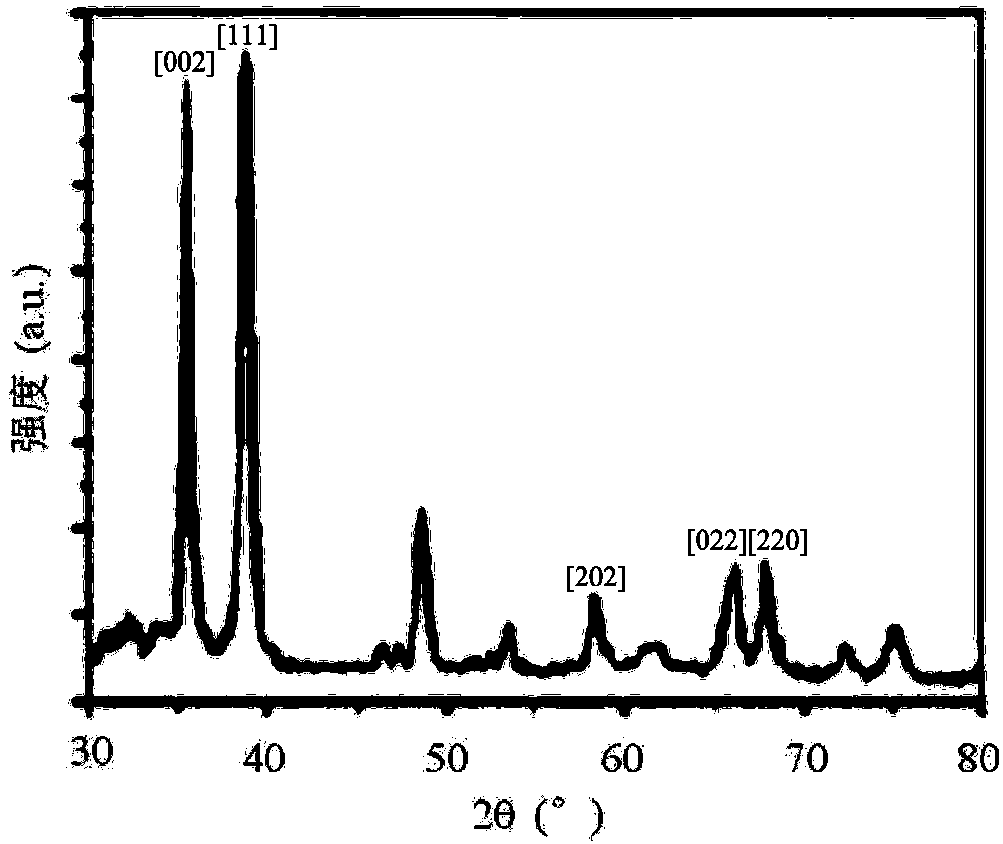

[0035] (1) Using n-propyl titanate as precursor, TiO was prepared by sol-gel method 2 sol suspension, while adding an appropriate amount of dilute oxalic acid solution (commercially available) drop by drop, and controlling the pH of the reaction process to be 4 to 5, to obtain TiO-containing 2 The precipitated suspension was then processed in an autoclave with a heating rate of 2.5 °C / min, a temperature of 115 °C, and a time of 60 min to obtain TiO with photocatalytic activity 2 ;

[0036] (2) With propylene glycol as a solvent, the TiO obtained in step (1) 2 Formulated with 1% TiO by mass 2 dispersion suspension;

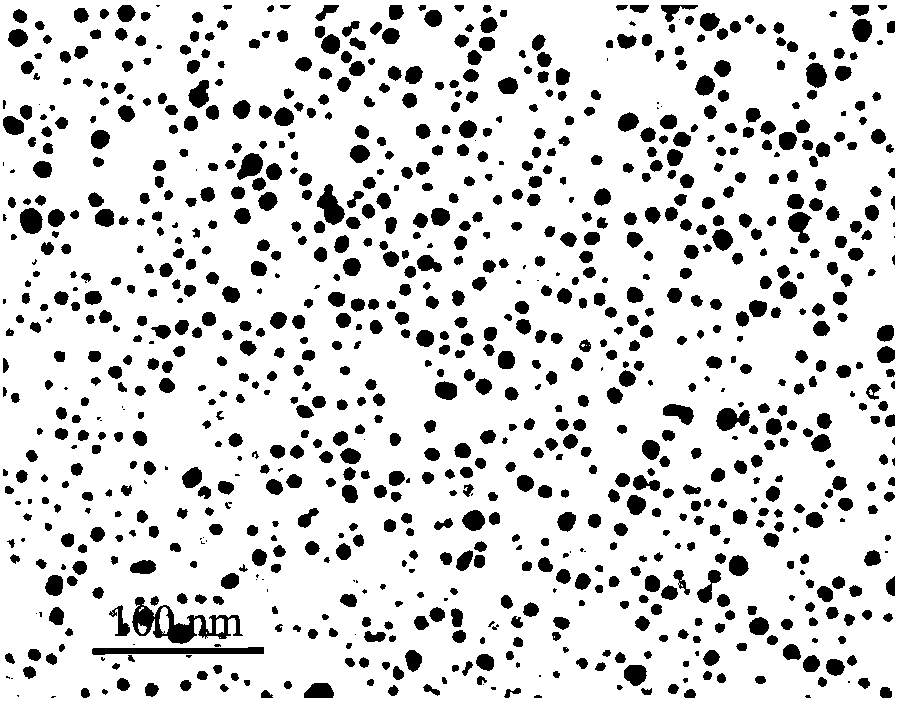

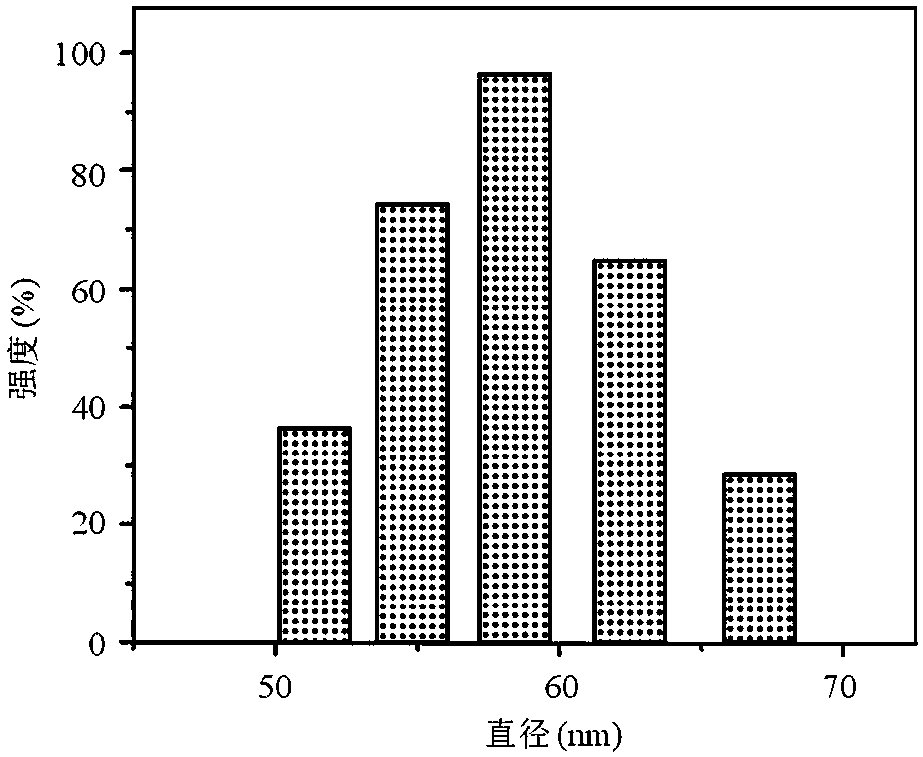

[0037] (3) Add a certain amount of nano-silver oxide with a size less than 40nm to TiO 2 Disperse the suspension to obtain nano-silver oxide / TiO with a mass percentage of nano-silver oxide of 1%. 2 / propylene glycol mixture;

[0038] (4) Nano s...

Embodiment 2

[0044] A kind of preparation method of wood preservative of the present invention, comprises the following steps:

[0045] (1) Using n-propyl titanate as precursor, TiO was prepared by sol-gel method 2 sol suspension, while adding an appropriate amount of dilute oxalic acid solution (commercially available) drop by drop, and controlling the pH of the reaction process to be 4 to 5, to obtain TiO-containing 2 The precipitated suspension was then processed in an autoclave with a heating rate of 2.5 °C / min, a temperature of 125 °C, and a time of 90 min to obtain TiO with photocatalytic activity 2 ;

[0046] (2) With propylene glycol as a solvent, the TiO obtained in step (1) 2 Formulated with 1% TiO by mass 2 dispersion suspension;

[0047] (3) Add a certain amount of nano zinc oxide with a size less than 50nm to TiO 2 Disperse the suspension to obtain nano-zinc oxide / TiO with a mass percentage of nano-zinc oxide of 3%. 2 / propylene glycol mixture;

[0048] (4) Nano zinc ox...

Embodiment 3

[0053] A kind of preparation method of wood preservative of the present invention, comprises the following steps:

[0054] (1) Using n-propyl titanate as precursor, TiO was prepared by sol-gel method 2 sol suspension, while adding an appropriate amount of dilute oxalic acid solution (commercially available) drop by drop, and controlling the pH of the reaction process to be 4 to 5, to obtain TiO-containing 2 The precipitated suspension was then processed in an autoclave with a heating rate of 2.5 °C / min, a temperature of 135 °C, and a time of 120 min to obtain TiO with photocatalytic activity 2 ;

[0055] (2) With propylene glycol as a solvent, the TiO obtained in step (1) 2 Formulated with 1% TiO by mass 2 dispersion suspension;

[0056] (3) Add a certain amount of nano-copper oxide with a size less than 50nm to TiO 2 Disperse the suspension to obtain nano-copper oxide / TiO with a mass percentage of nano-copper oxide of 5%. 2 / propylene glycol mixture;

[0057] (4) Nano-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com