Catalyst for denitrating smoke at low temperature and production method and application thereof

A low-temperature flue gas and production method technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as low-temperature activity, high space velocity reaction activity improvement, and unknown operating space velocity, and achieve Efficient nitrogen oxide conversion rate, saving investment and maintenance costs, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

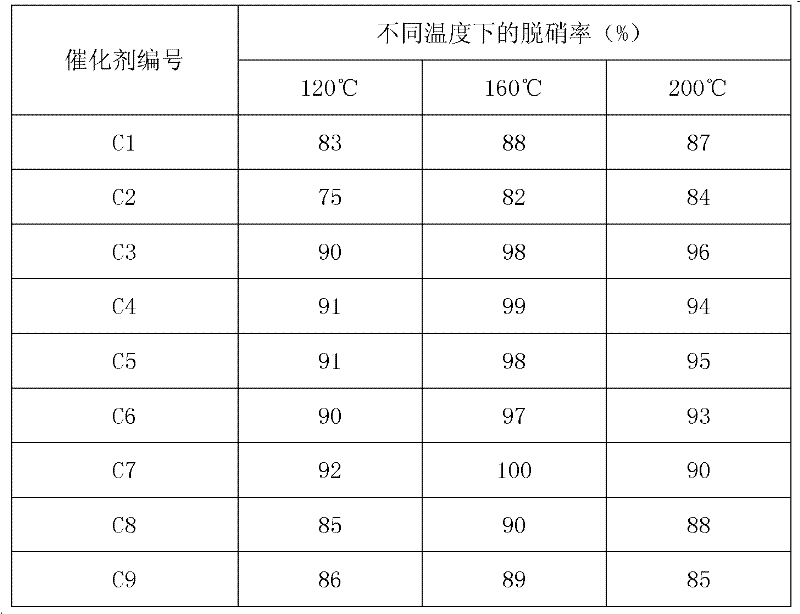

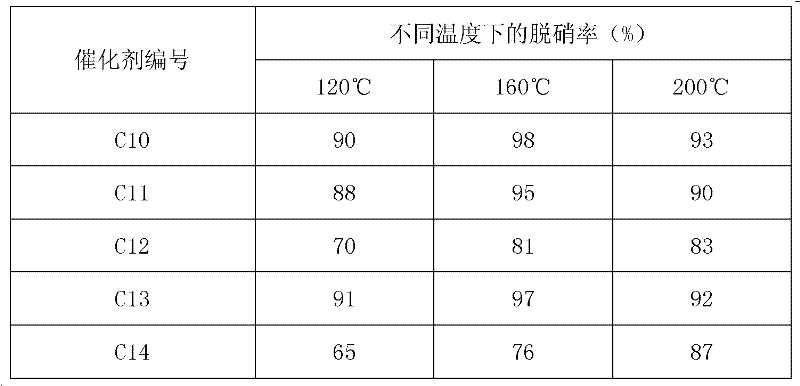

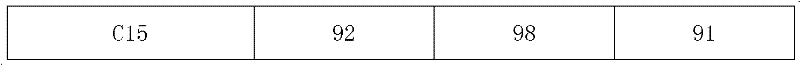

Examples

Embodiment 1

[0024] Take by weighing 108.0 grams of 50% Mn(NO 3 ) 2 The solution was mixed with an appropriate amount of deionized water to prepare 300ml of Mn(NO 3 ) 2 The aqueous solution is denoted as S1 solution. Weigh 29.5 grams of ammonium carbonate (purity 98%) and mix with deionized water to prepare 300 ml of ammonium carbonate aqueous solution with a molar concentration of about 1 mol / L, which is designated as A1 solution. Place the A1 solution in a 1.5L beaker at 25°C and keep stirring at a constant speed of 600rpm. At the same time, add the S1 solution to the A1 solution at a constant speed to start the precipitation reaction. Stop adding the A1 solution until the pH value reaches 8.5 to end the reaction. At this time, the reaction time for 10 minutes. Keep stirring at a constant speed at 25°C, and age the suspension in the beaker for 2 hours. The precipitate was filtered, and the filter cake was washed several times with deionized water until the pH value of the filtrate w...

Embodiment 2

[0026] Weigh 62.0 grams of manganese acetate Mn(Ac) 2 4H 2 O (purity 99%), 3.7 grams of Co (NO 3 ) 2 ·6H 2 O (purity 99%), 2.6 grams of cerium acetate Ce(Ac) 3 ·xH 2 O (purity 99%) and 1.5 grams of Zn (NO 3 ) 2 ·6H 2 O (purity 99%) is placed in the same beaker, add some deionized water and fully stir and dissolve until the solution is clear. After the solution is cooled to 25°C, use a graduated cylinder to prepare a 250ml salt solution and record it as S2 solution. The molar ratio of metal elements in the solution is Mn:Co:Ce:Zn=10:0.5:0.3:0.2. Weigh 32.0 grams of ammonium carbonate (purity 98%) and deionized water to fully mix and dissolve to prepare 300 ml of ammonium carbonate aqueous solution with a molar concentration of about 1 mol / L, which is designated as A2 solution. Put the S2 and A2 solutions into two 500ml separating funnels at 25°C, control the flow rate and add the S2 and A2 solutions into a 1.5L beaker at the same time at a constant speed (the bottom li...

Embodiment 3

[0028]Prepare S2 and A2 solutions according to the method in Example 2. Place the S2 solution in a 1.5L beaker at 20°C and keep stirring at a constant speed of 600rpm. Add the A2 solution into the S2 solution at a constant speed for a precipitation reaction until the pH value reaches 8.5, stop adding the A2 solution to end the reaction, and control the reaction time for 15 minutes. Continue to keep stirring at a constant speed, and age the suspension in the beaker for 2 hours. The suspension was filtered, and the obtained filter cake was washed several times with deionized water until the pH value of the filtrate was close to 7. The filter cake was baked at 120°C for 12 hours, crushed and ground to a particle size above 100 mesh, placed in a crucible and sent to a roasting furnace, and roasted at 300°C for 6 hours in an air atmosphere to obtain catalyst C4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com