Elevator for existing building and parking garage

A technology for parking garages and buildings, which is applied to elevators, buildings, building types, etc. in buildings, and can solve the problems of insufficient space utilization efficiency, large man-hour consumption, and prolonged residence time, so as to save installation and adjustment steps , The hoistway space is minimized, and the structure is compact and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

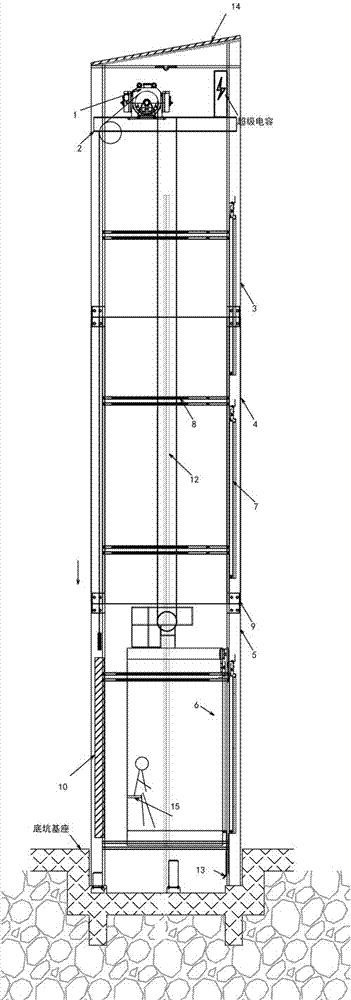

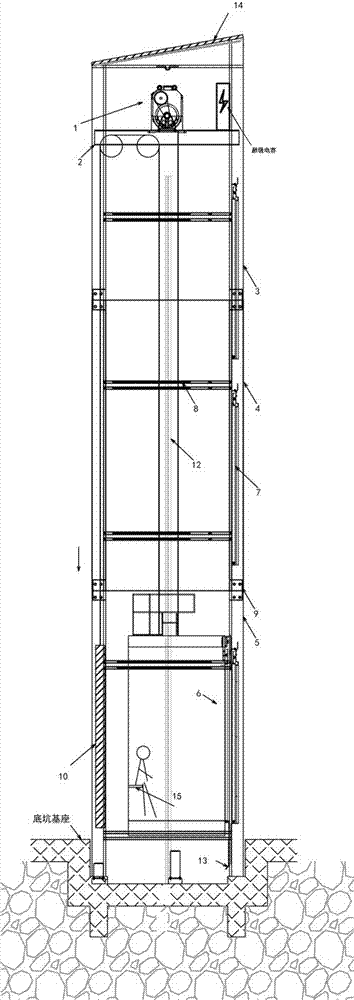

[0032] In order to deepen the understanding of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

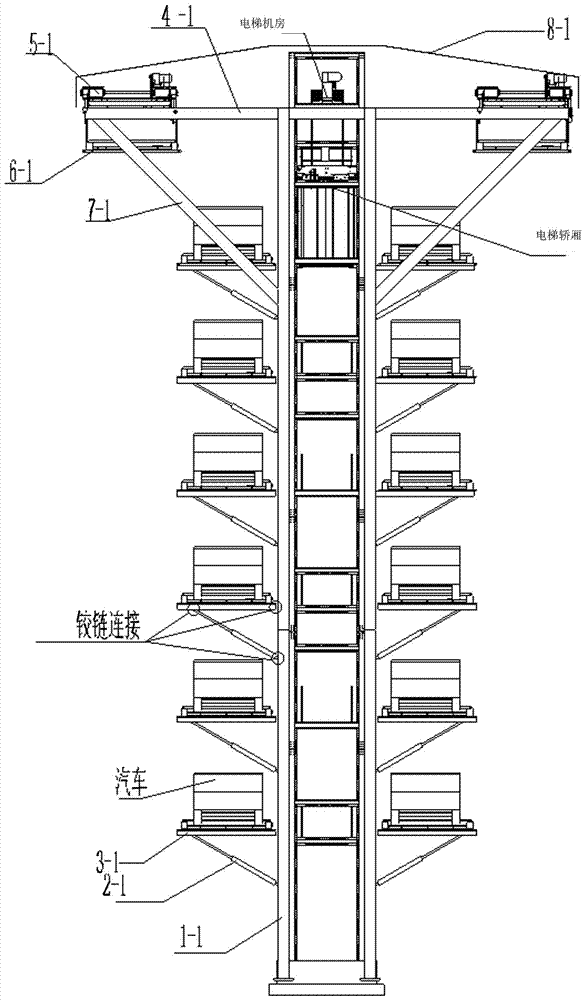

[0033] like Figure 1-14As shown, the present invention is an existing building installation ladder and a parking garage. A parking garage is provided on one or both sides or three sides of the installation ladder, and the installation ladder includes a The bottom section steel structure 5, the bottom pit is 600mm, at least one section of middle section steel structure 4 is arranged above the bottom section steel structure 5, preferably, the said middle section steel structure 4 is one section or two sections, additionally The ladder is composed of three to four sections as a whole. During assembly and transportation, the steel structure of the bottom section is assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com