Performance Testing System of Wheel Speed Sensor Based on Simulated Code Wheel

A wheel speed sensor, analog coding technology, applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, instruments, etc. High energy consumption, poor reliability of test results, etc., to eliminate the stability of motor speed, realize online automated testing, and high temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

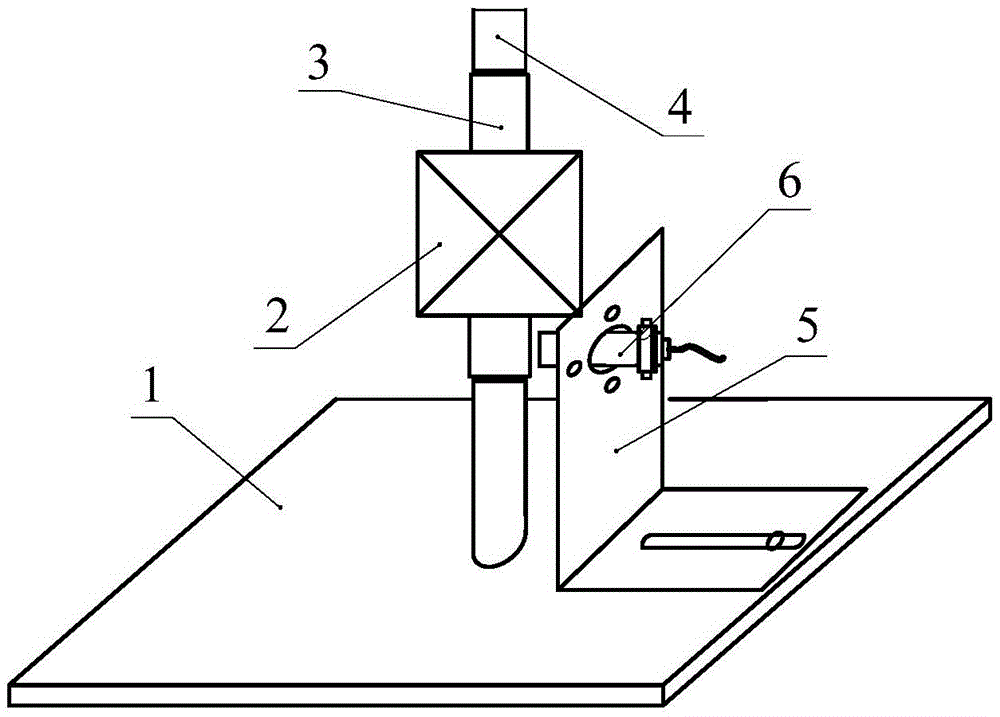

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings of the specification.

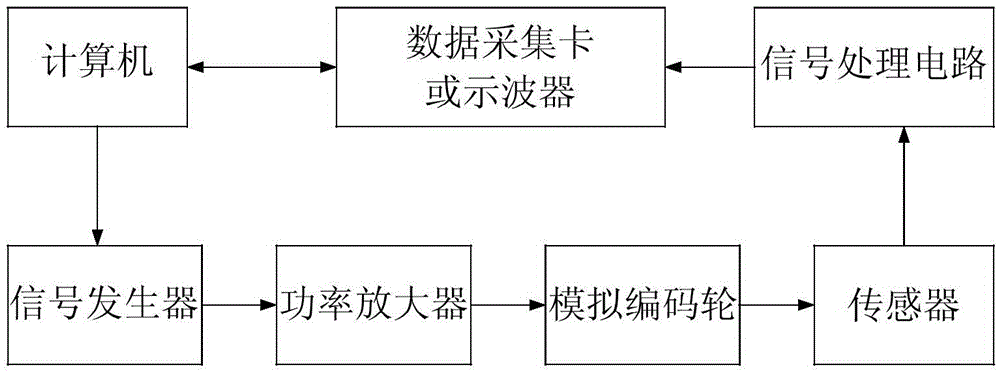

[0021] The invention discloses a wheel speed sensor performance test system based on an analog code wheel, such as figure 1 As shown, it is mainly composed of 7 parts: computer, analog code wheel, power amplifier, signal generator, data acquisition card or oscilloscope, wheel speed sensor and signal processing circuit.

[0022] The computer is the core of the entire testing system, with a friendly human-computer interaction interface, and it is the carrier of the wheel speed sensor testing software. The computer test software includes a test item parameter setting module, a signal generator control module, and a test result processing module (including a test result display module and a test result storage module). Realize the computerized all-digital acquisition, test analysis and test process automation. The computer is connected to the sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com