Assembling structure of fingerprint module and mobile terminal

A fingerprint module and assembly structure technology, which is applied in the field of communication, can solve problems such as glass cover breakage, achieve the effect of improving glass breakage, solving poor appearance, and improving solid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

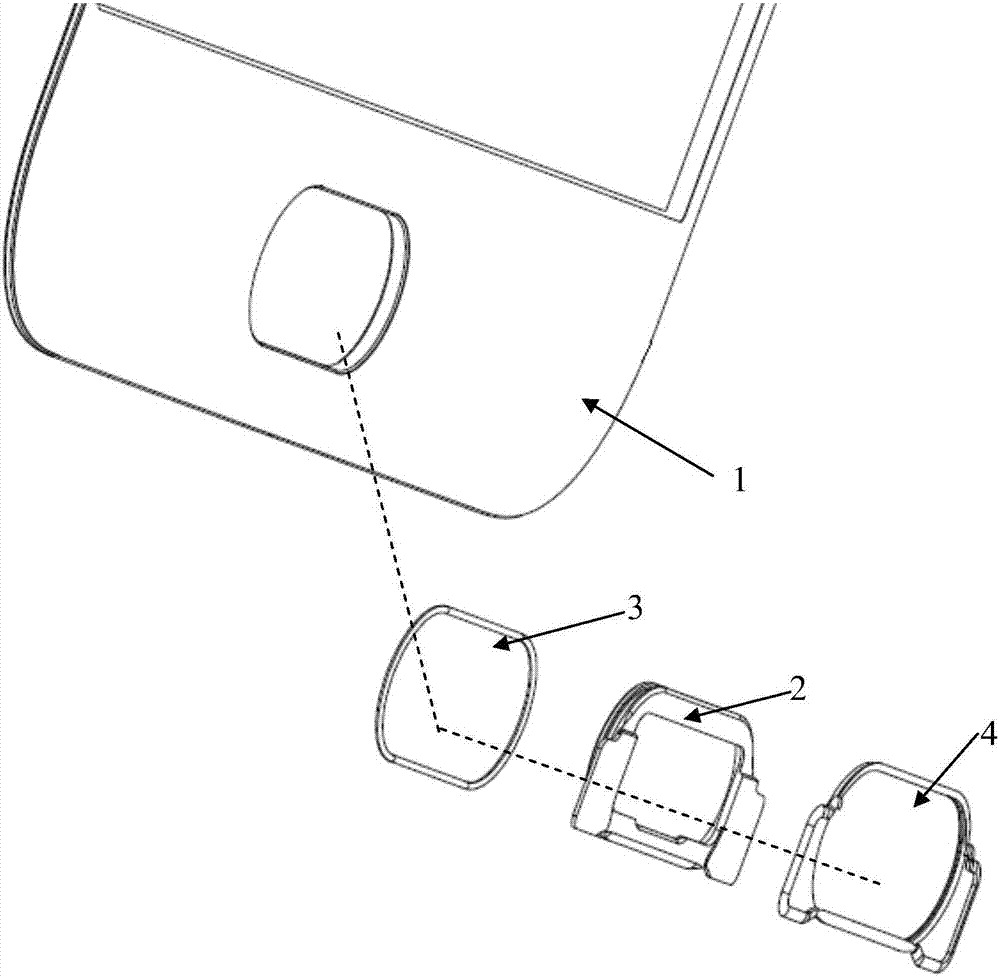

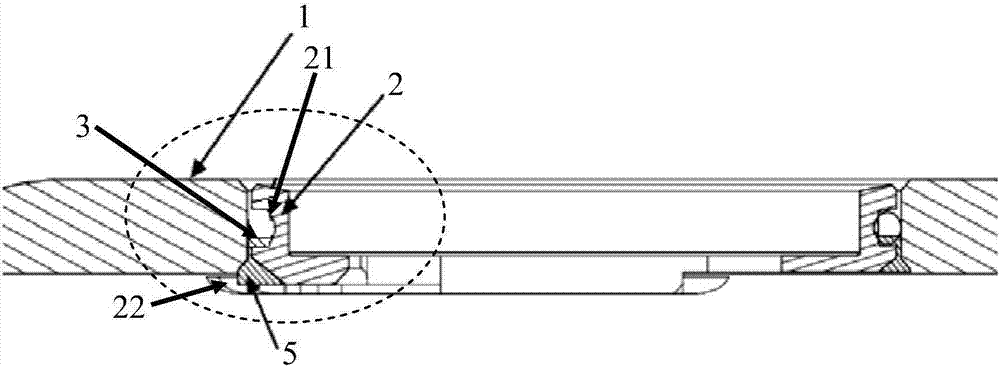

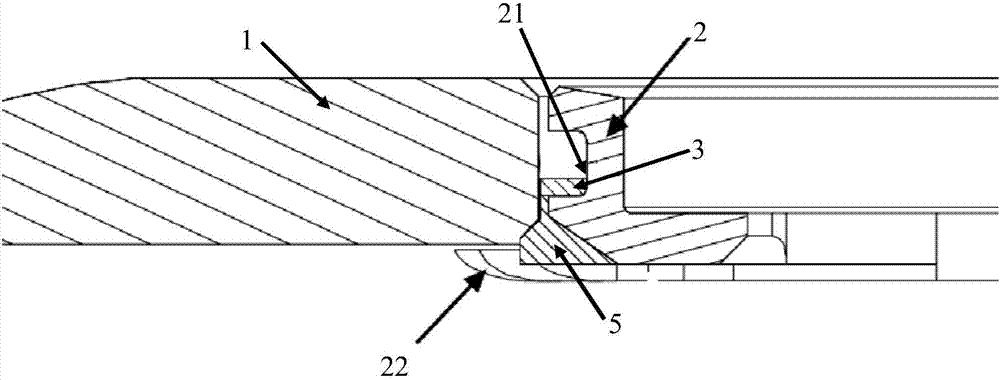

[0019] like figure 1 , figure 2 and image 3 As shown, the first embodiment of the present invention provides an assembly structure of a fingerprint module, including:

[0020] glass cover 1;

[0021] A fingerprint module, the fingerprint module includes a fingerprint identification component 4, a decorative part 2 and a flexible part 3; wherein, the decorative part 2 is sleeved on the fingerprint identification component 4, and the outer wall of the decorative part 2 A glue overflow groove 21 and a raised structure 22 are provided; the flexible member 3 is embedded in the glue overflow groove 21;

[0022] The fingerprint module is fixed on the glass cover 1 by adhesive bonding, and the adhesive 5 is located on the raised structure 22, the glass cover 1 and the flexible member 3 within the enclosed space. The adhesive 5 is generally glue, which is not specifically limited here.

[0023] In the first embodiment of the present invention, the fingerprint identification ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com