Cutting die with automatic waste clearing function

An automatic cleaning and functional technology, which is applied in metal processing and other fields, can solve the problems of negative impact of waste process, inability to clean dust and waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

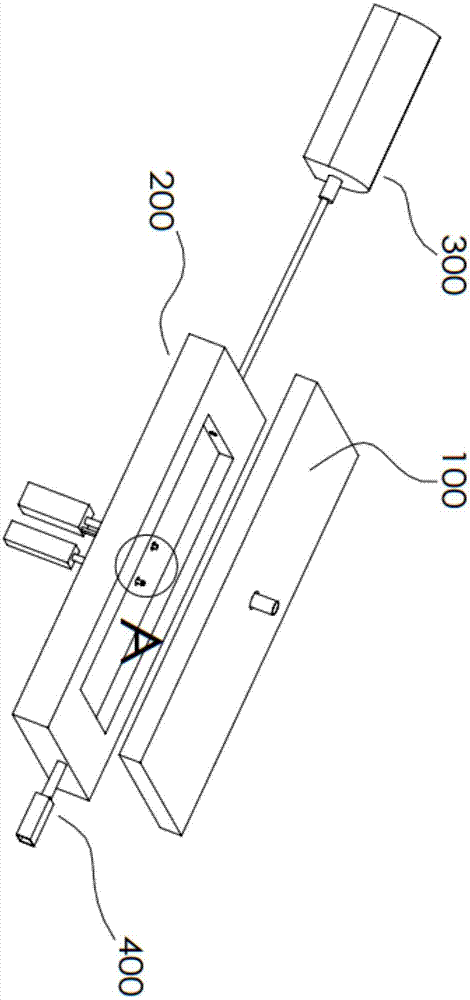

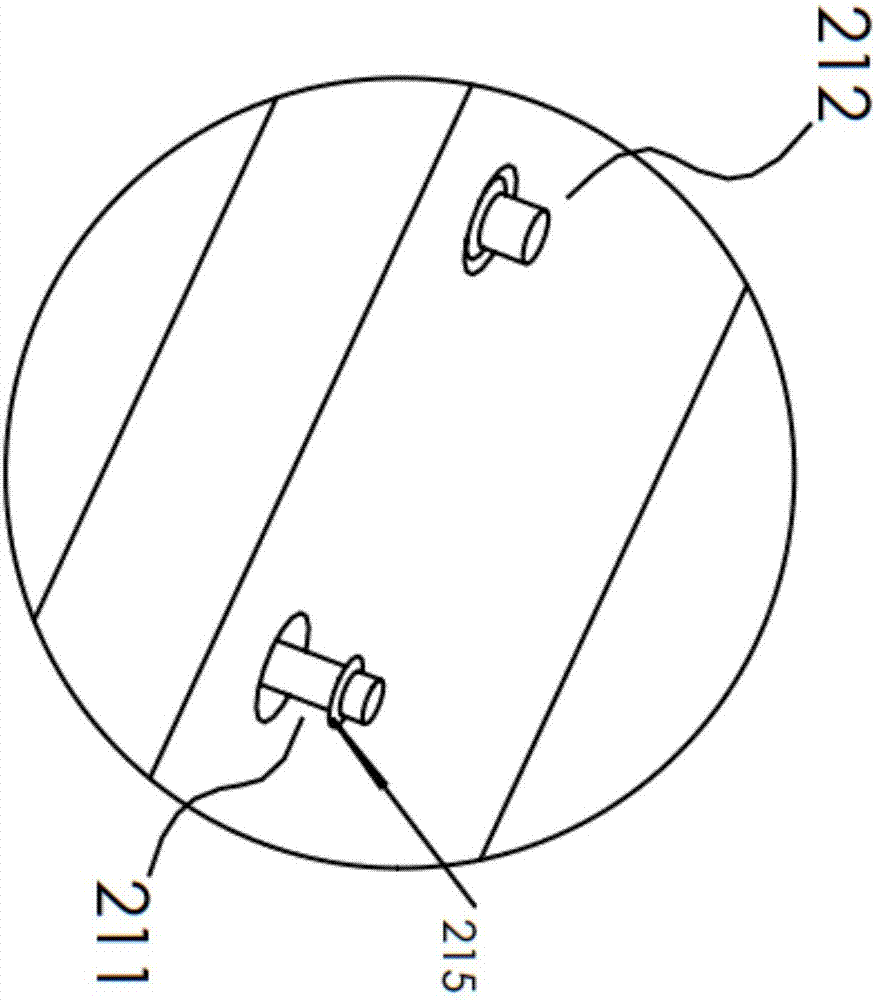

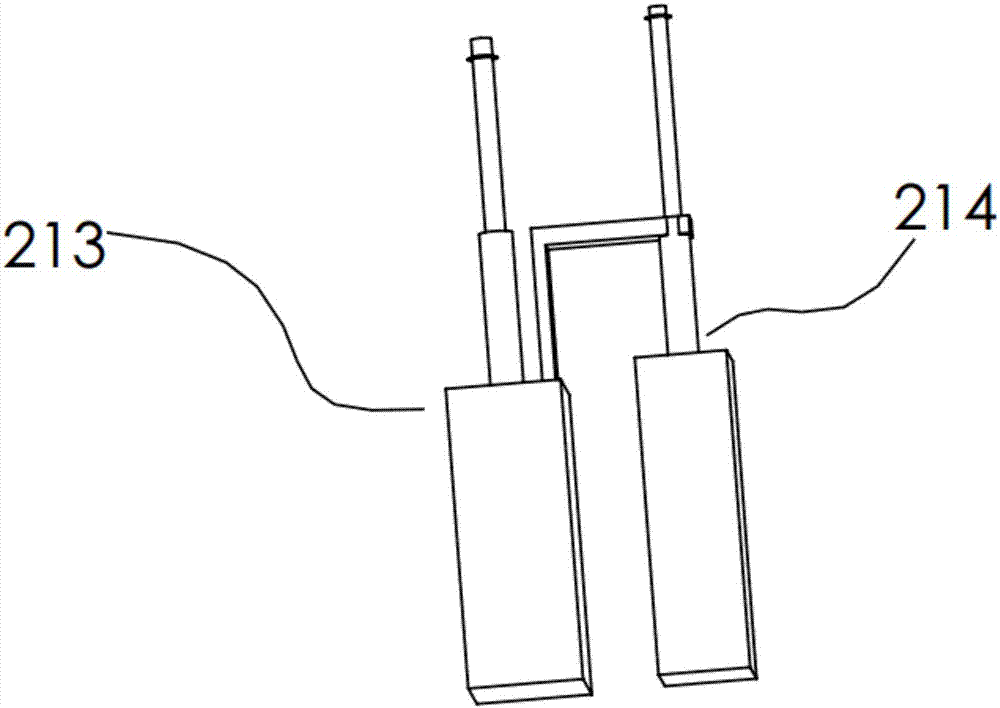

[0033] A cutting die with automatic waste removal function, comprising: a male template 100, whose main body is a flat cuboid structure; a female template 200, whose main body is a flat cuboid structure, and the female template 200 is located below the male template 100, and The upper surface of the 200 is provided with a recessed cavity 210 for placing the workpiece to be processed. The recessed cavity 210 is provided with a first through hole and at least a second through hole, and a first through hole is provided in the first through hole. Locating pin 211, second locating pin 212 is arranged in the second through hole, the lower side of the first locating pin 211 is connected with the telescopic rod of the first cylinder 213, the lower side of the second locating pin 212 is connected with the second The telescopic rod connection of the cylinder 214; the gas device 300, which includes a horizontally arranged first air valve 310 and at least one vertically arranged second air...

Embodiment 2

[0038] The suction cavity 410 is disposed on a second side of the master template 200 , and the second side is opposite to the first side. The suction cavity 410 is provided with a trumpet-shaped suction port, and the suction port faces the concave cavity 210 . The first end of the waste storage box 420 communicates with the suction cavity 410 , and the second end of the waste storage box 420 is open. Preferably, the waste material storage box 420 is provided with a filter structure, and the diameter of the holes on the filter structure is less than 0.1 mm.

[0039] By arranging the suction chamber 410 opposite to the first air valve 310 , an air fluid channel is formed, so that all waste materials can be collected into the waste material storage box 420 .

[0040] As mentioned above, the workpiece to be processed is lifted through the edge structure to provide a stable support, and at the same time the edge structure is bent downward so that waste materials will not accumula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com