Low-temperature baking smoking set and split type push pipe structure thereof

A low-temperature baking, tube structure technology, applied in tobacco, smoker's products, applications, etc., can solve the problems of small operating space and inconvenient cleaning, and achieve the effect of complete cleaning, convenient subsequent use, and increased operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

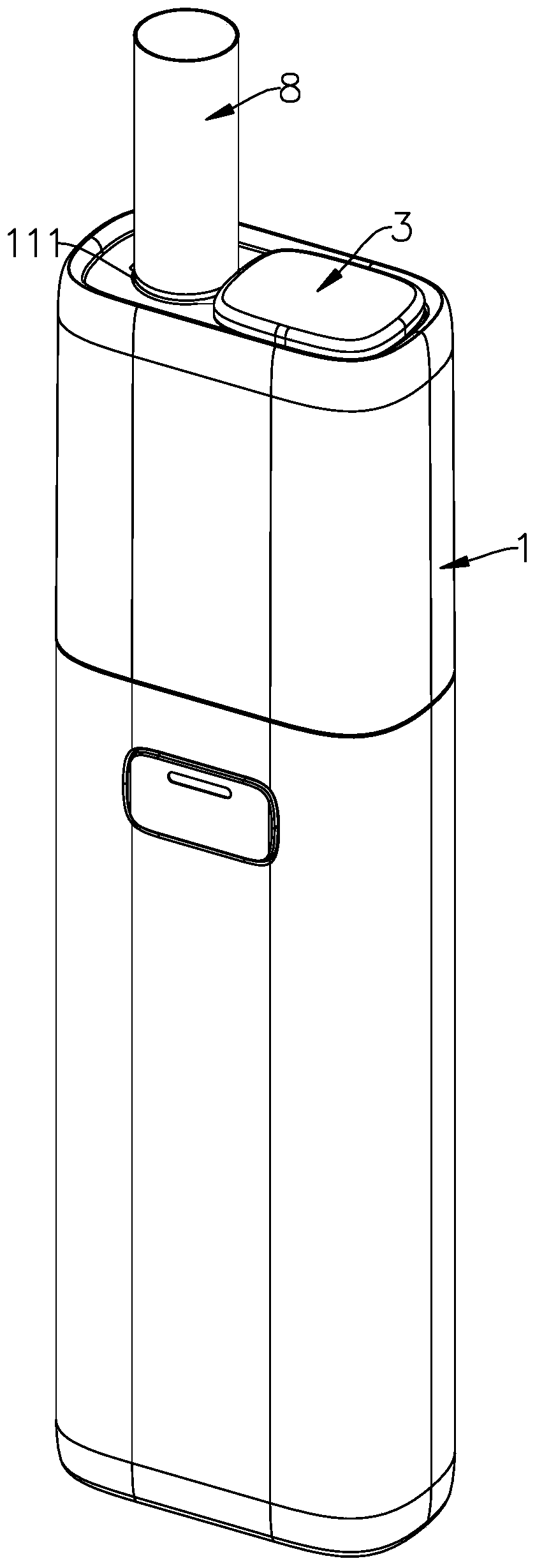

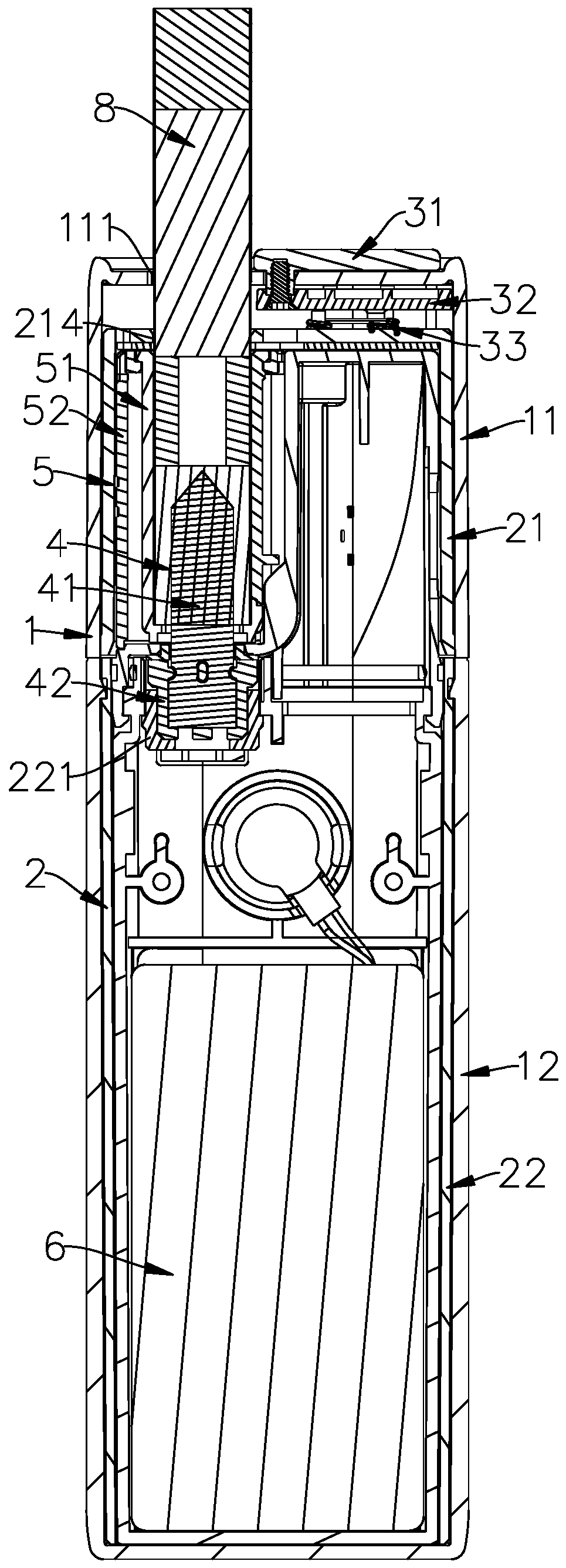

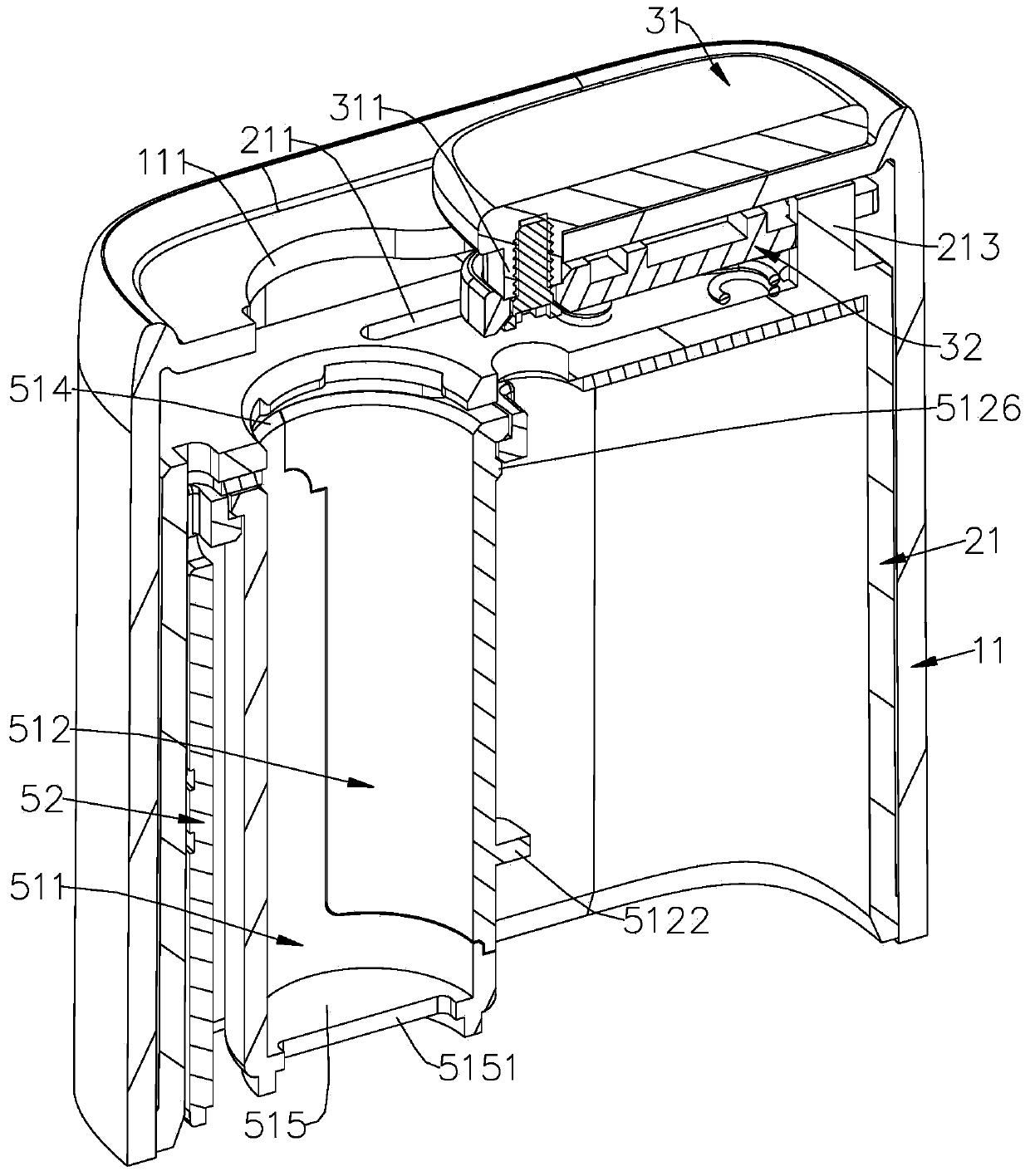

[0040] Figure 1-4 Shown are the low-temperature baking smoking articles in some embodiments of the present invention. The low-temperature baking smoking article may include a housing, a heating assembly 4, and a battery 6, and the heating assembly 4 and the battery 6 are both installed in the housing. A housing cavity 513 for accommodating the smoke body 8 is formed in the housing, and one end of the heating assembly 4 can be extended into the housing cavity 513 and inserted into the smoke body 8 to heat the smoke body 8.

[0041] In some embodiments, the low-temperature baking smoking set may further include a sliding cover assembly 3 connected to the shell. In some embodiments, the shell may include an inner shell 2 and an outer sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com