Automatic grinding and scraping machine for yellow skin of poultry gizzard

A scraper, automatic technology, applied in poultry processing, slaughtering, food science, etc., can solve the problems of many operators, time-consuming and laborious processing, etc., and achieve high equipment integration, reduced labor costs, and good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

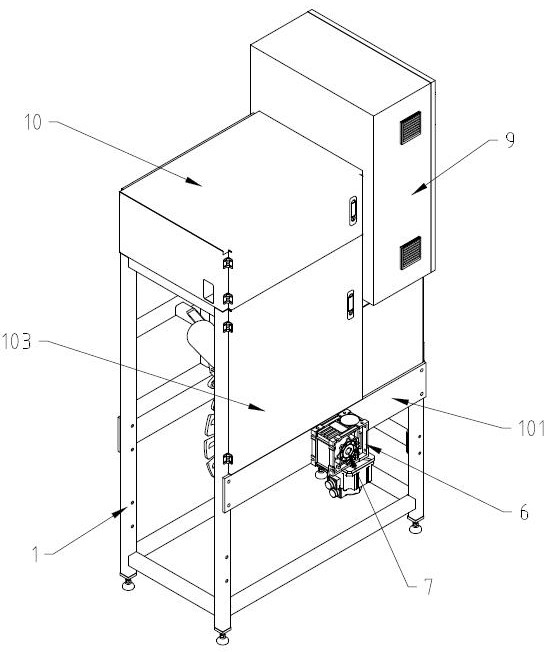

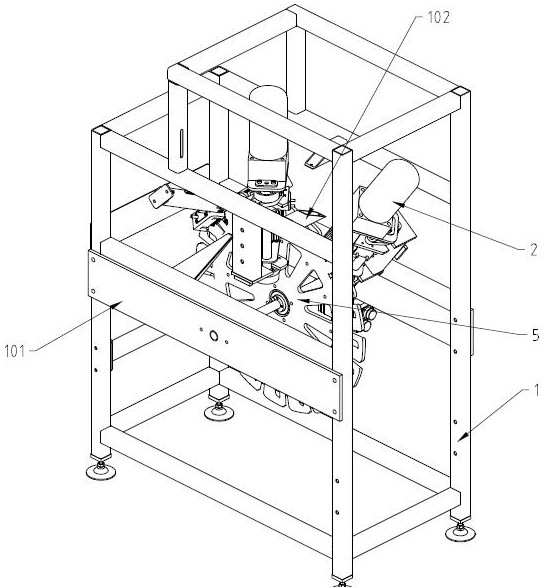

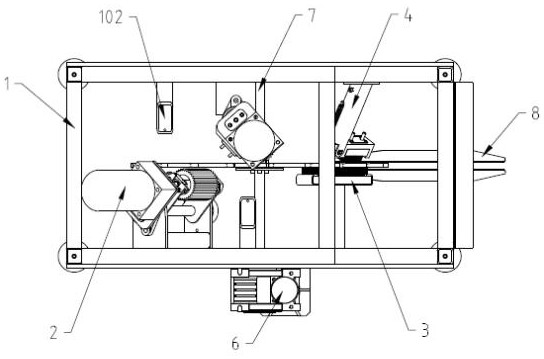

[0038] see Figure 1-Figure 4 , Figure 1-Figure 4It is a structural schematic diagram of a poultry gizzard yellow skin automatic grinding and scraping machine of this embodiment, including a frame 1, a gizzard grinding assembly 2, a scrub brush assembly and a friction roller 5, and the friction roller 5 is placed vertically at the center of the frame 1, Its outer edge is provided with several poultry gizzard inlets and outlets 501, which can be connected with the assembly line, so that the poultry gizzards are like duck gizzards. After coming from the assembly line, they automatically enter the poultry gizzards inlet and outlet 501, and then rotate upwards with the friction roller 5 to pass through the gizzard grinding assembly in turn. 2 and scrape the yellow skin with the scrub brush assembly.

[0039] Further, the middle of the friction roller 5 is pierced with a first rotating shaft 7, both ends of the first rotating shaft 7 are assembled on the frame 1, and one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com