A glass substrate oca glue cleaning device

A technology for cleaning devices and glass substrates, applied in the direction of cleaning flexible objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as poor working environment, low production efficiency, and high labor intensity, and achieve improved cleaning efficiency and cleaning Cleanliness, avoidance of detachment, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

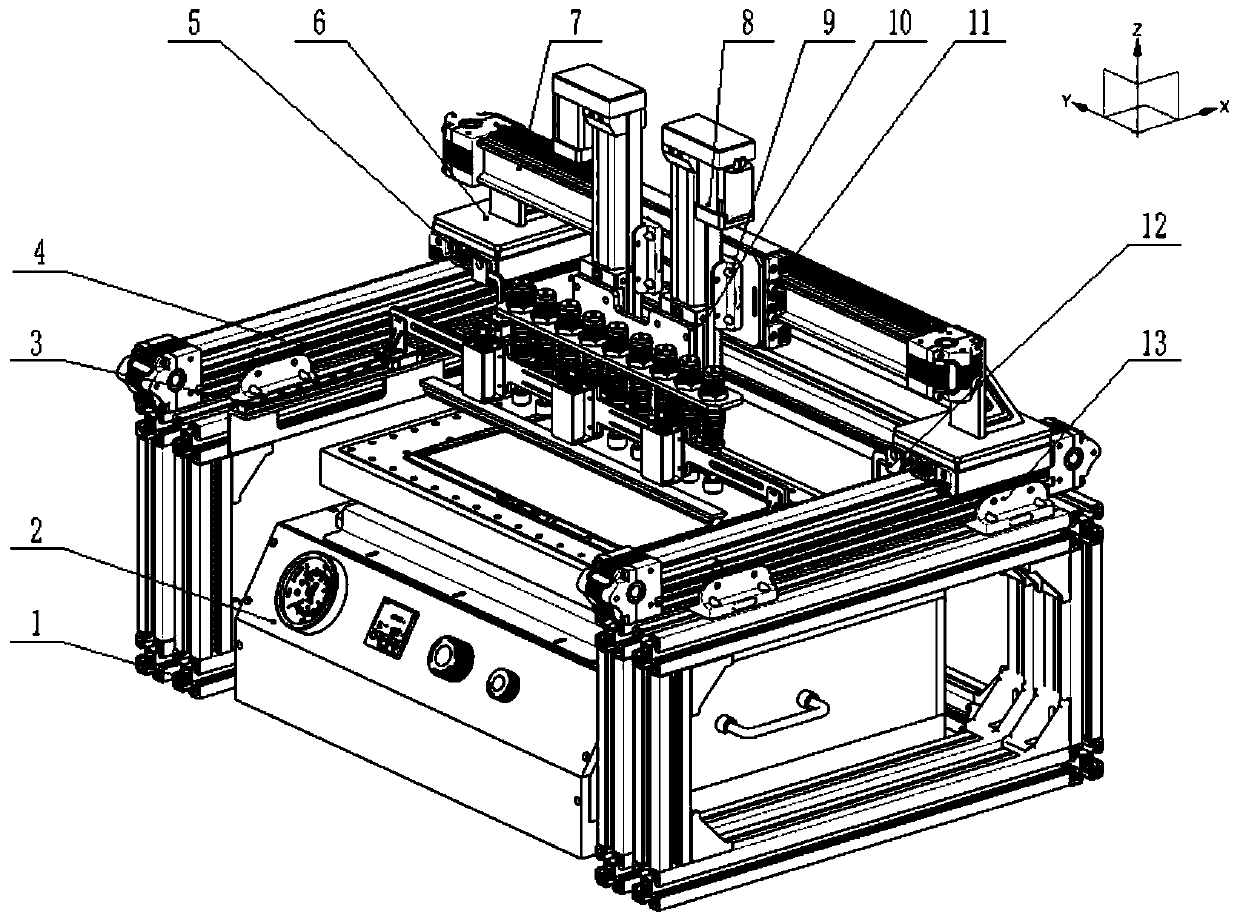

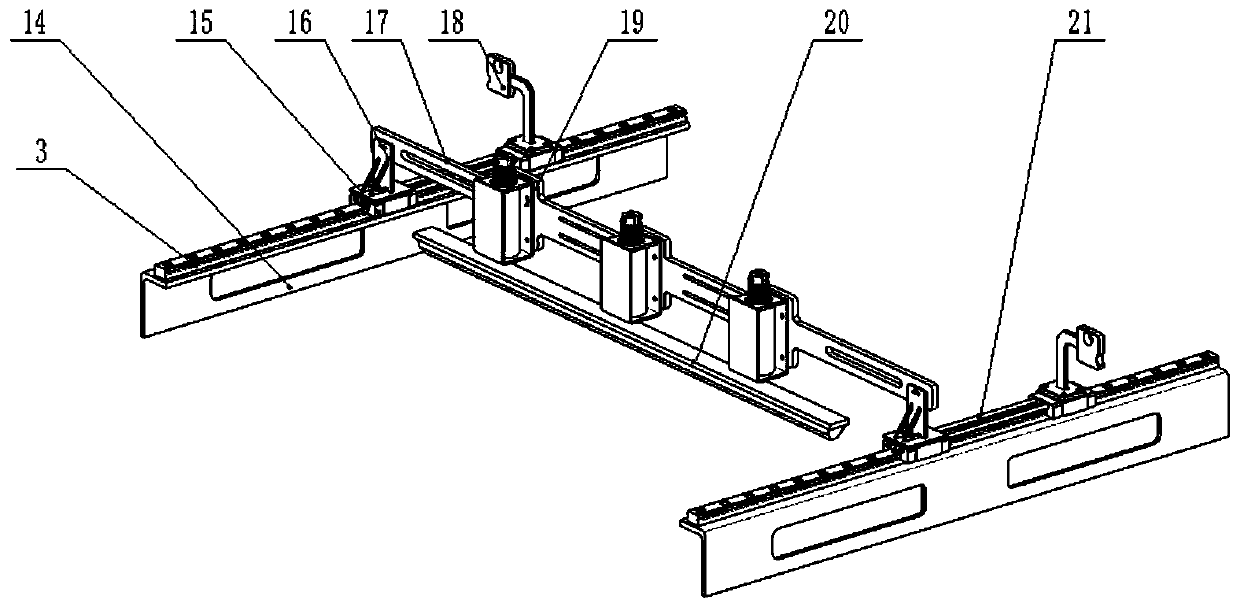

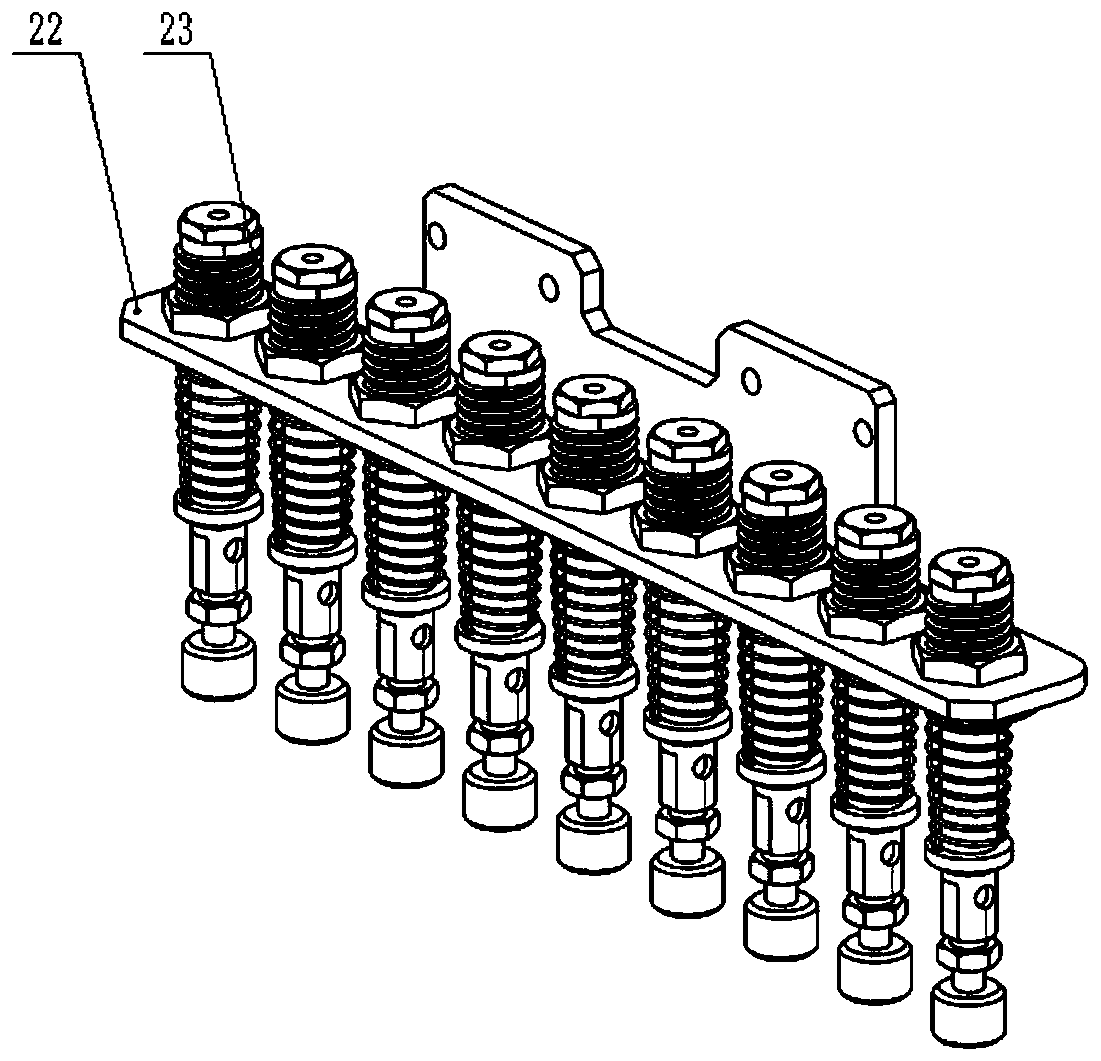

[0027] see Figure 1~6 , the embodiment of the present invention is provided with a bottom frame 1, a pressing mechanism, a movement mechanism and a glue cleaning mechanism;

[0028] The bottom frame 1 is a square aluminum alloy frame that is not closed on one side, and is used to fix the pressing mechanism, the movement mechanism and the glue cleaning mechanism; a vacuum heating and adsorption table 2 is placed in the middle of the bottom frame 1, and the vacuum heating and adsorption There are suction holes on the surface of table 2. The vacuum heating and adsorption table 2 is connected with the suction pump and can generate a certain amount of adsorption force. The vacuum heating and adsorption table 2 and the bottom frame 1 need to be placed on a horizontal table to ensure that the bottom surface is flush During actual work, workers need to heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com