Municipal road guardrail cleaning equipment

A technology for cleaning equipment and roads, applied in road cleaning, cleaning methods, construction, etc., can solve the problems of manual steering and high noise, and achieve the effect of improving the efficiency of use, reducing the consumption of manpower, and improving the speed of cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

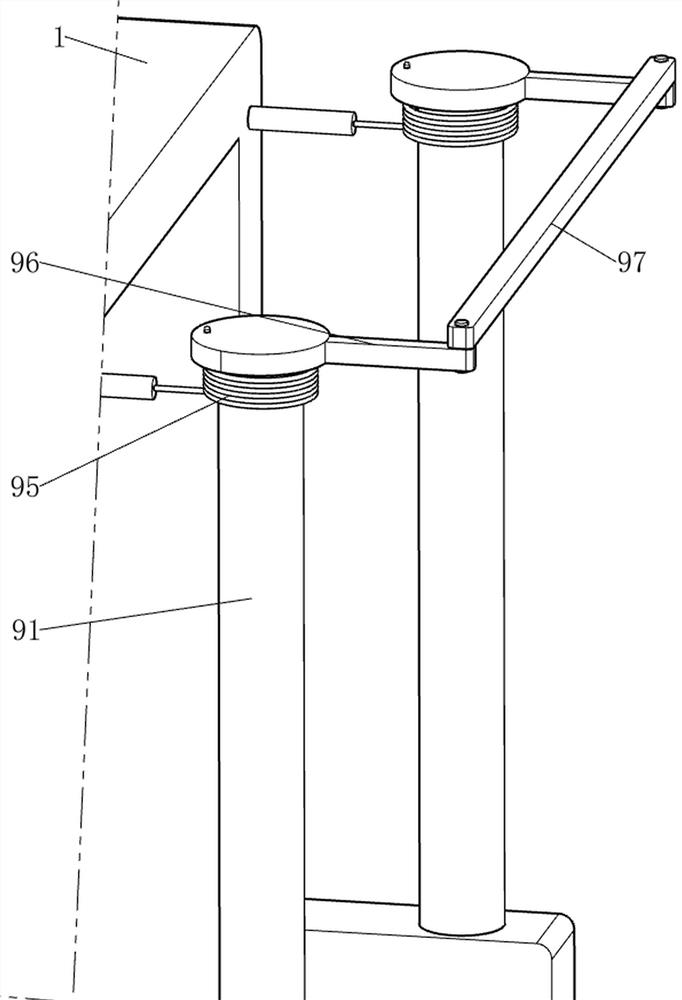

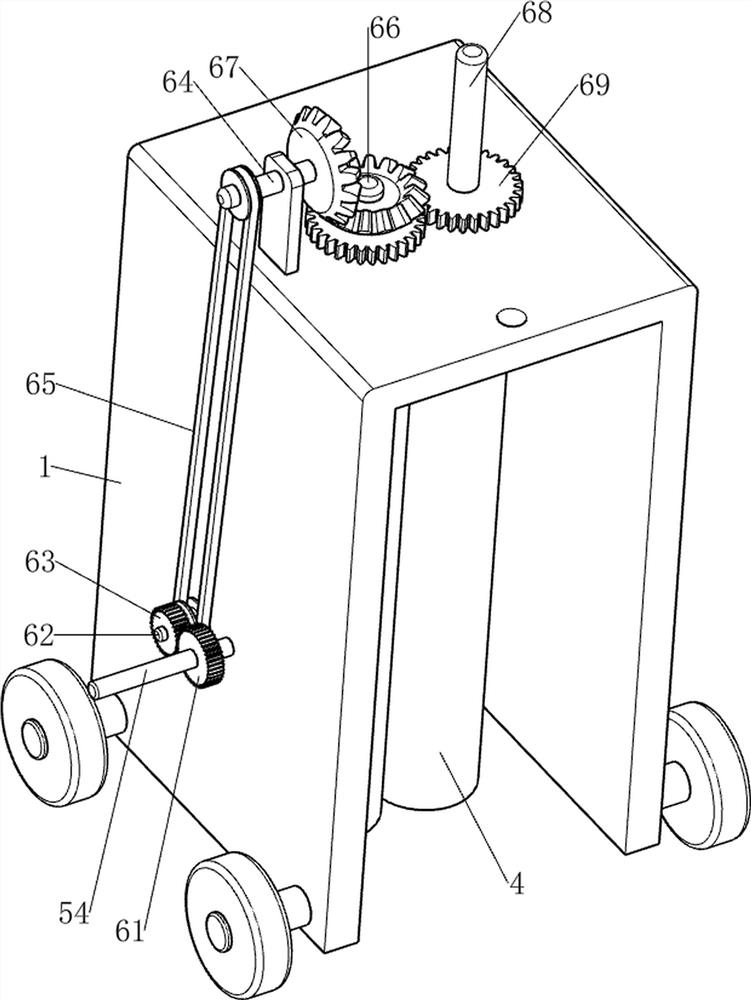

[0030] A municipal road guardrail cleaning equipment, such as Figure 1-Figure 3 As shown, it includes a casing 1, a first rotating shaft 2, a roller 3, a rolling brush 4, a moving assembly 5 and a cleaning assembly 6. The left and right sides of the lower part of the casing 1 are rotatably provided with a first rotating shaft 2. The number of the first rotating shaft 2 There are four, the outer sides of the four first rotating shafts 2 are connected with rollers 3, the upper part of the inner wall of the casing 1 is rotatably provided with two rolling brushes 4, the left and right sides of the casing 1 are provided with moving assemblies 5, and the moving assemblies 5 and the first rotating shaft 2, the upper part of the housing 1 is provided with a cleaning component 6, and the cleaning component 6 cooperates with the roller brush 4.

[0031] When the worker needs to clean the guardrail, the worker can first move the device to a designated position, and then the worker can s...

Embodiment 2

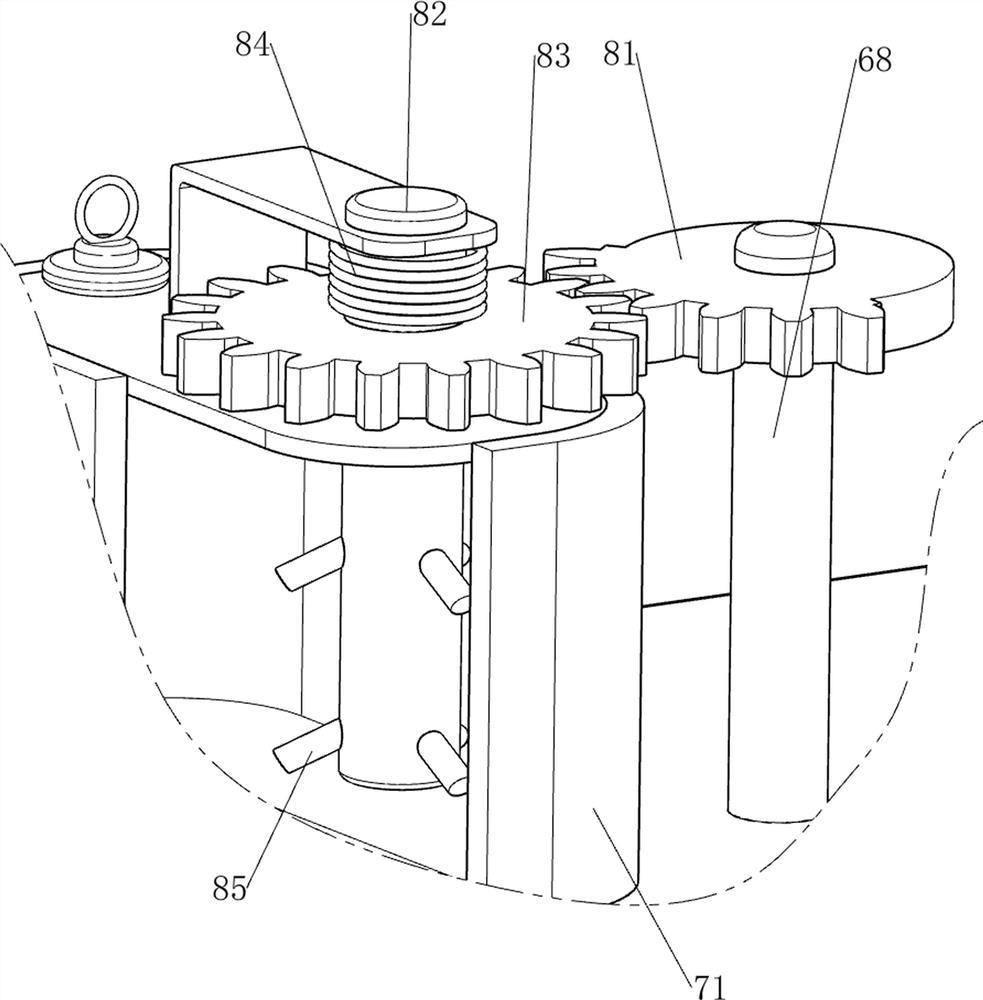

[0037] In a preferred embodiment of the present invention, as Figure 4-Figure 8 As shown, it also includes a water spray assembly 7. The water spray assembly 7 includes a water tank 71, a water outlet pipe 72, a compression spring 73, a first limit block 74, a sliding rod 75, a rubber plug 76 and a plug 77. A water tank 71 is arranged on the side, a water outlet pipe 72 is arranged at the bottom of the water tank 71, and a sliding rod 75 is slidably arranged in the water outlet pipe 72. A compression spring 73 is sleeved on the lower part of the sliding rod 75 , and the two ends of the compression spring 73 are respectively connected to the water outlet pipe 72 and the first limiting block 74 . A plug 77 is provided on the left side of the top of the water tank 71 .

[0038] When the worker needs to further clean the guardrail, the worker can first open the stopper 77, and then add a sufficient amount of cleaning agent into the water tank 71. When the first limit block 74 mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com