Quartz tube cleaning process for growth of cadmium zinc telluride

A quartz tube and cadmium zinc telluride technology, which is applied in the field of quartz tube cleaning, can solve the problems of affecting cleaning quality, damage to operating personnel, and incomplete cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

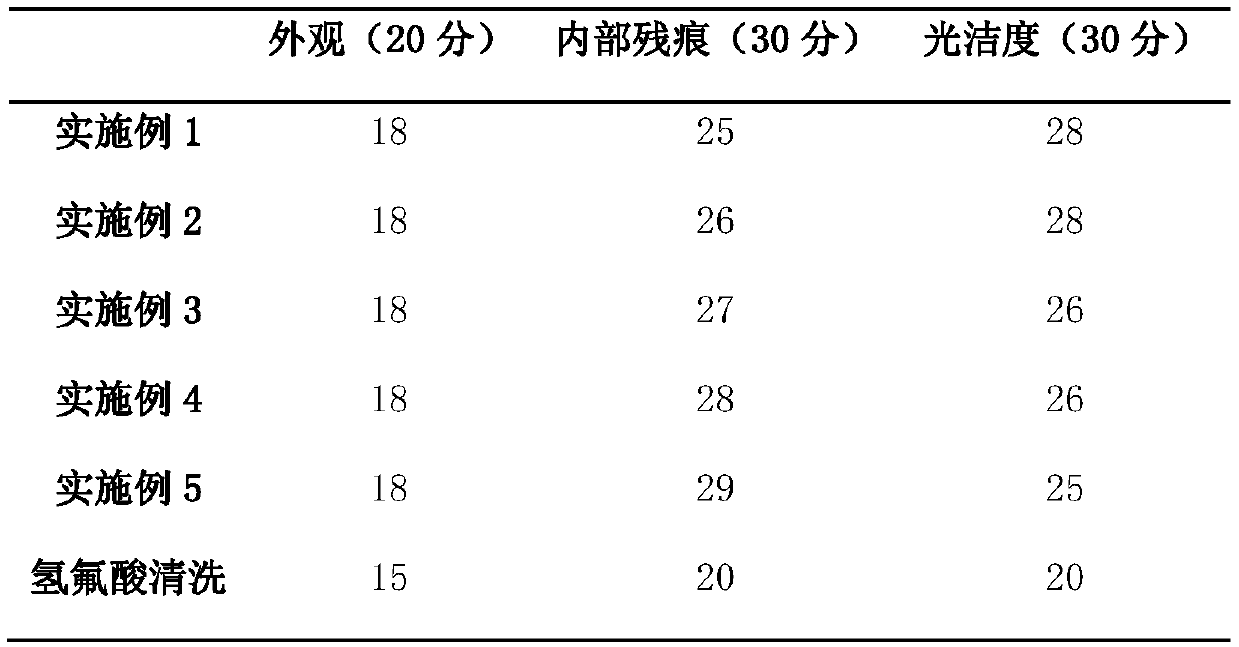

Examples

Embodiment Construction

[0014] For the following, through the description of the examples, the specific implementation of the present invention, such as the manufacturing process involved, the operation and use method, etc., will be described in further detail, so as to help those skilled in the art to have a more complete concept of the invention and the technical solution of the present invention. , accurate and in-depth understanding.

[0015] In order to solve the deficiency of cleaning the quartz tube for growing CdZnTe in the prior art, the present invention provides a cleaning process for growing CdZnTe with a quartz tube, in which the growing CdZnTe quartz tube is scrubbed with abrasive paper while it is hot, and then Place the quartz tube in the bromomethanol solution, sonicate for 3-8 hours under the action of ultrasound, take it out, place it in sodium hydroxide solution, soak it in ultrasonic for 40-70 minutes, take it out, wash it with water, and dry it.

[0016] In order to increase the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com