Vertical axis wind turbine with blade angle varying along with wind direction and wind velocity

A technology of blade installation and vertical shaft, which is applied to wind power generators at right angles to the wind direction, wind power motors, control of wind power motors, etc., and can solve problems such as low reliability, heat burnout, and large bending stress on the shaft body of the vertical shaft, etc. problem, to achieve the effect of expanding the working wind speed range, adjusting the rotation speed of the wind wheel, and reducing the starting wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

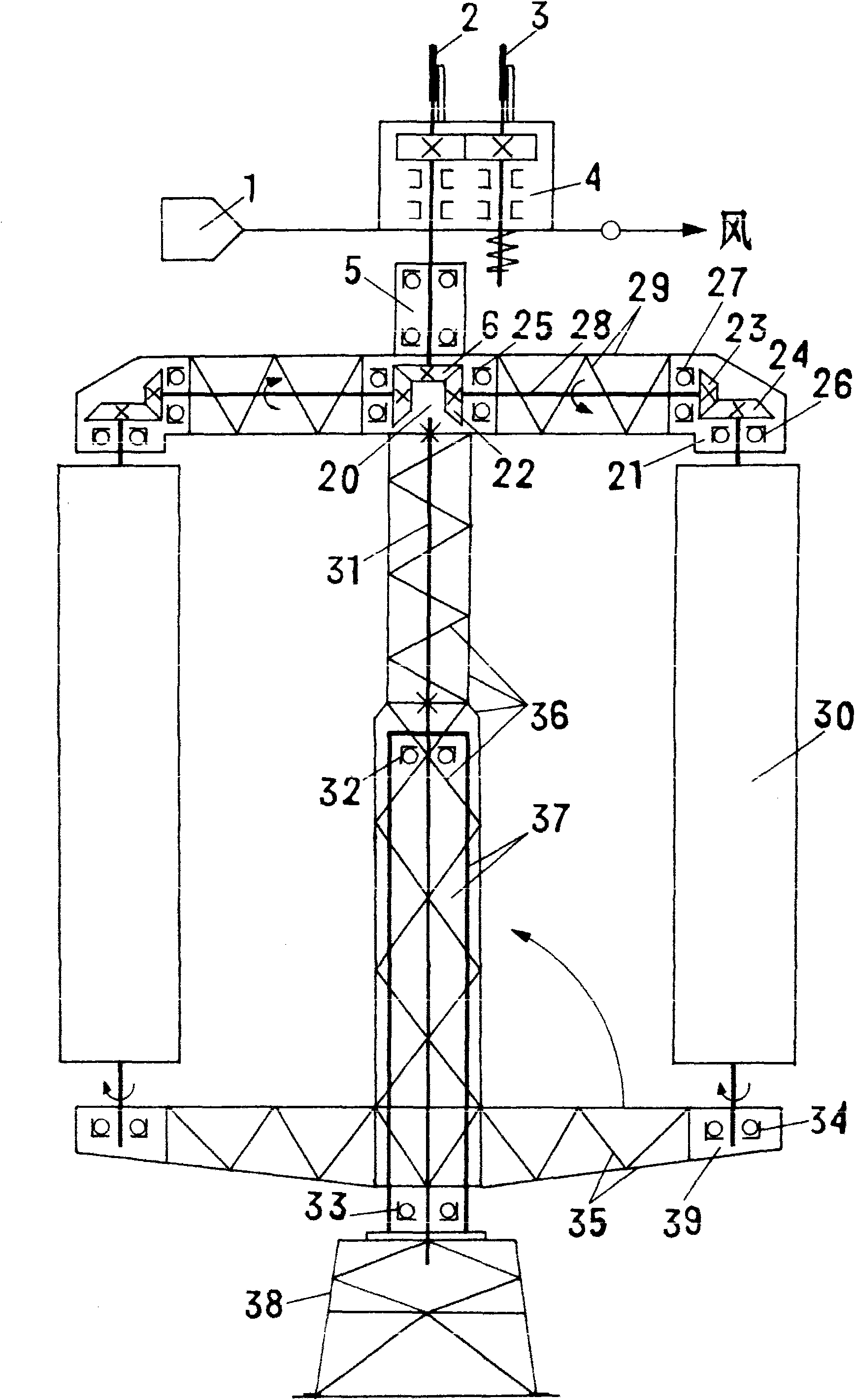

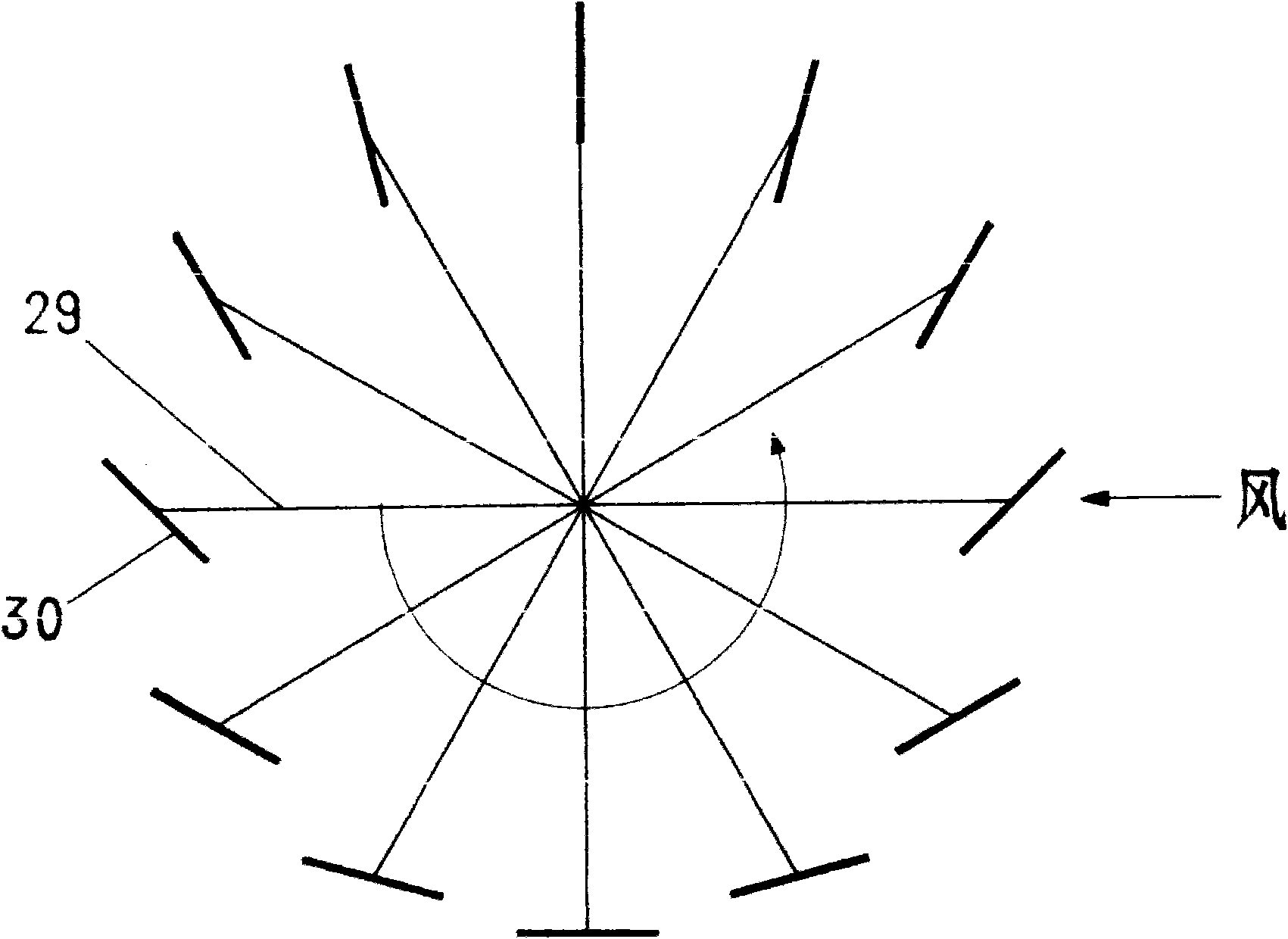

[0047] The relationship between each component and the overall mechanism of the wind turbine is described in detail below with reference to the accompanying drawings:

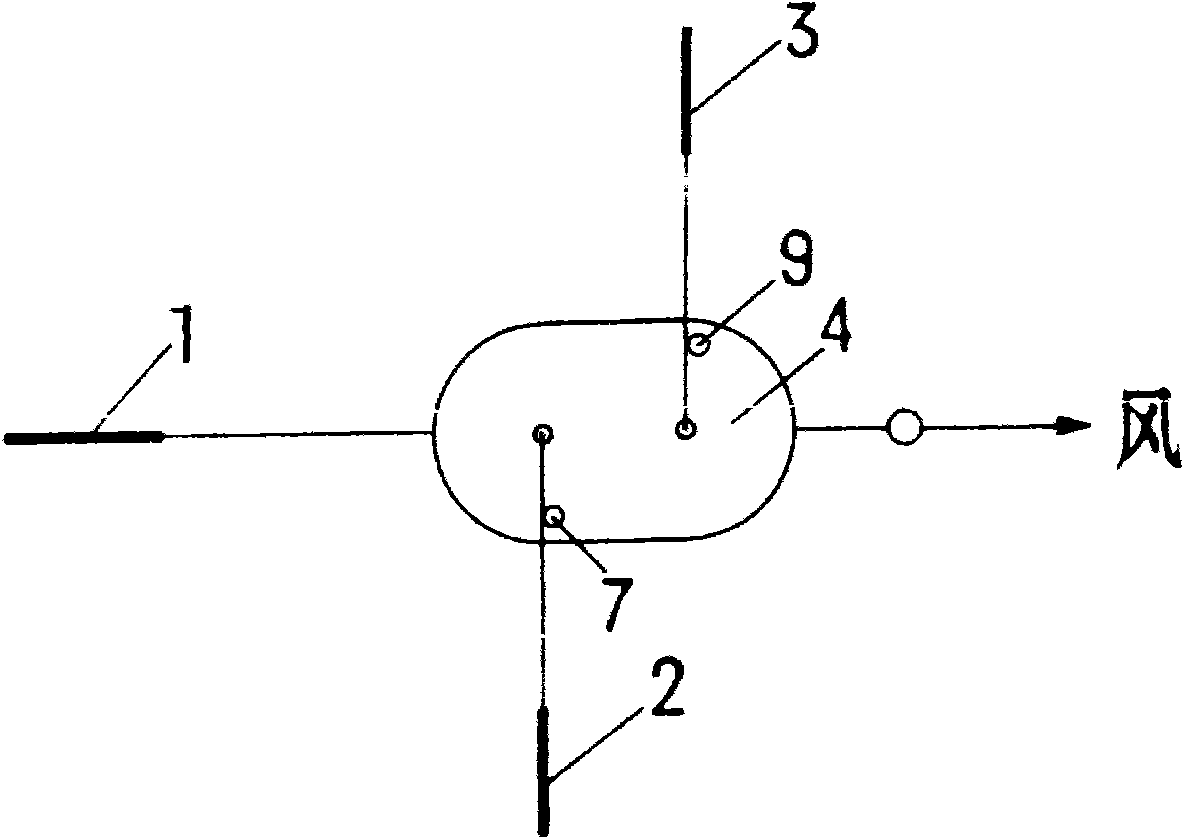

[0048] control figure 1 , Image 6 The middle part of the wind vane 1 pointing rod is connected to the bottom of the control box 4, and the axis of the wind vane 1 pointing rod should be parallel to and coincident with the geometric centerline along the length direction of the control box 4.

[0049] The two journals on the middle and upper part of the control vertical shaft 10 and the two journals on the middle and upper part of the speed regulating vertical shaft 8 are respectively connected with the front and rear bearing seats along the length direction of the bottom of the box through bearings 13, 14, 15, 16 and the control box 4. , the upper shaft heads of these two vertical shafts 10, 8 are respectively connected with a pair of spur gears 12, 11, and the pair of gears 12, 11 are meshed in the box 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com