Method for operating a fuel pump

A technology of fuel pump and fuel oil, which is applied in the direction of fuel injection control, electrical control, machine/engine, etc. It can solve the problems of excessive switching loss, temperature rise of switching electronic equipment, and decrease of service life of switching electronic equipment, so as to save integral adjustment device effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

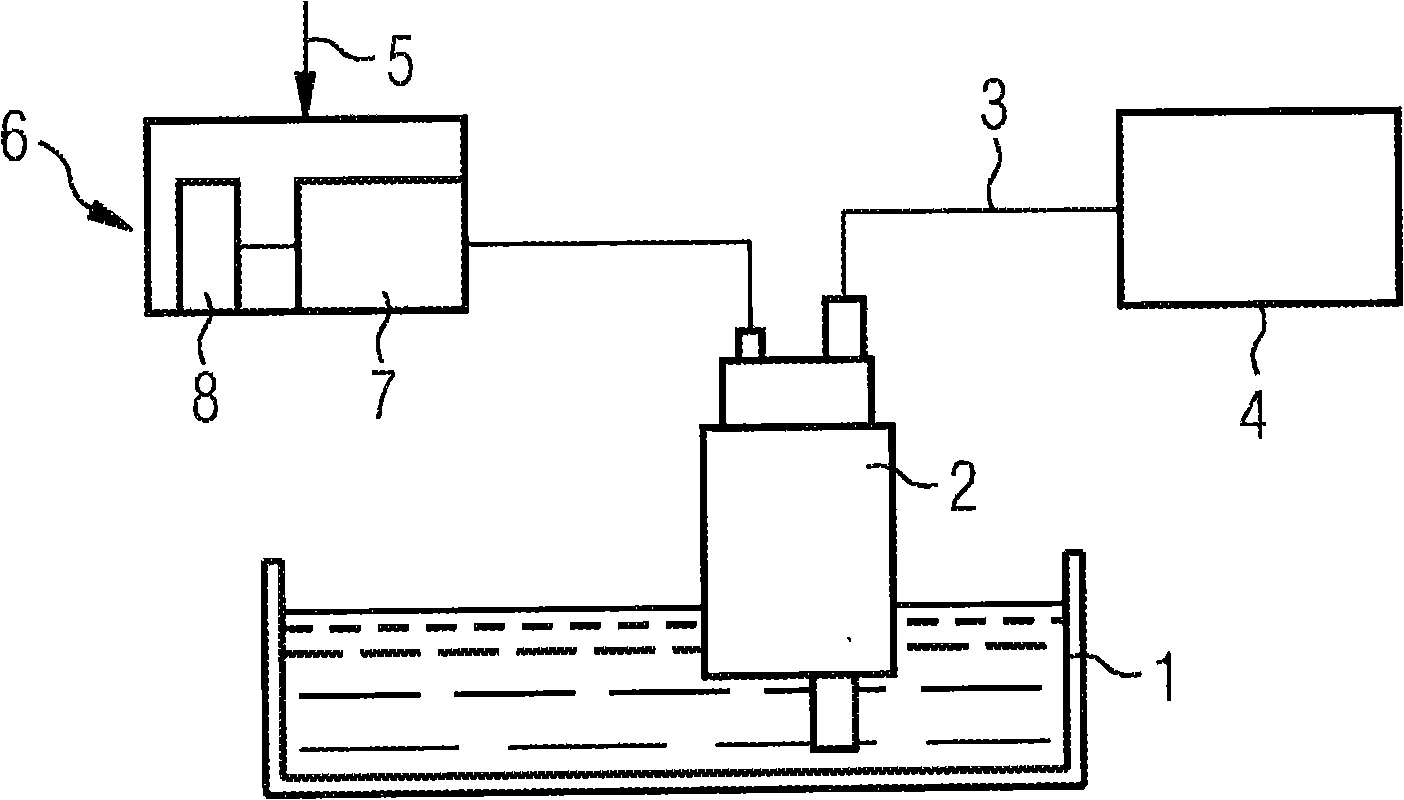

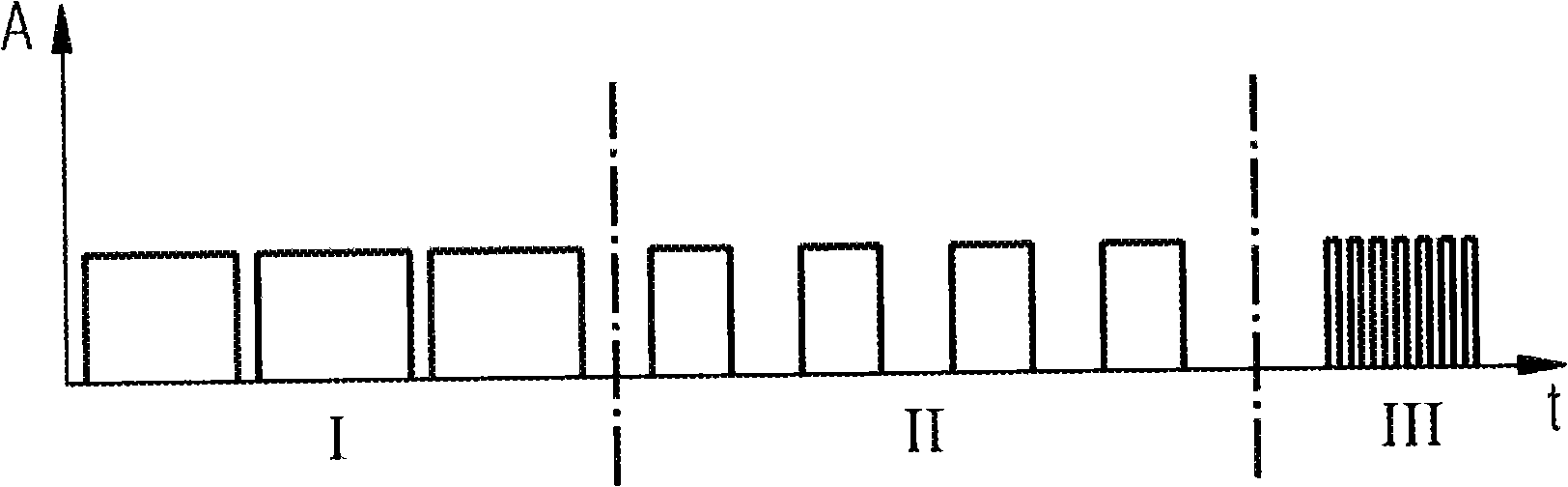

[0020] figure 1 A fuel tank 1 of a motor vehicle, not further shown, is shown schematically. A fuel pump 2 is arranged in the fuel tank 1 and delivers fuel from the fuel tank 1 to an internal combustion engine 4 of the motor vehicle via a feed line 3 . An electronic signal 5 obtained in a known manner is transmitted to the control electronics 6 for the fuel pump 2 , which is a criterion for the momentary fuel demand on the internal combustion engine 4 . Control electronics 6 includes a pulse generator 7 , which supplies the current for fuel pump 2 to fuel pump 2 in the form of pulses. The pulses are delivered with a constant amplitude, the pulse width being the criterion for the electrical energy delivered. The electronic control signal 6 is arranged in the shown figure outside the fuel tank 1 , for example as a component of the engine control system. However, it is also conceivable to arrange the control electronics 6 on or in the fuel tank 1 , for example on a flange or i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com