Internet vacuum drum shaping apparatus used for high speed thin sheet toilet paper machine

A technology of vacuum forming and toilet paper, which is applied in the direction of paper machine, paper machine wet end, paper making, etc. It can solve the problems of uneven paper sheet forming, low dehydration efficiency, large pulp disturbance, etc., and achieve low manufacturing cost, low transmission power, The effect of long life of the net

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

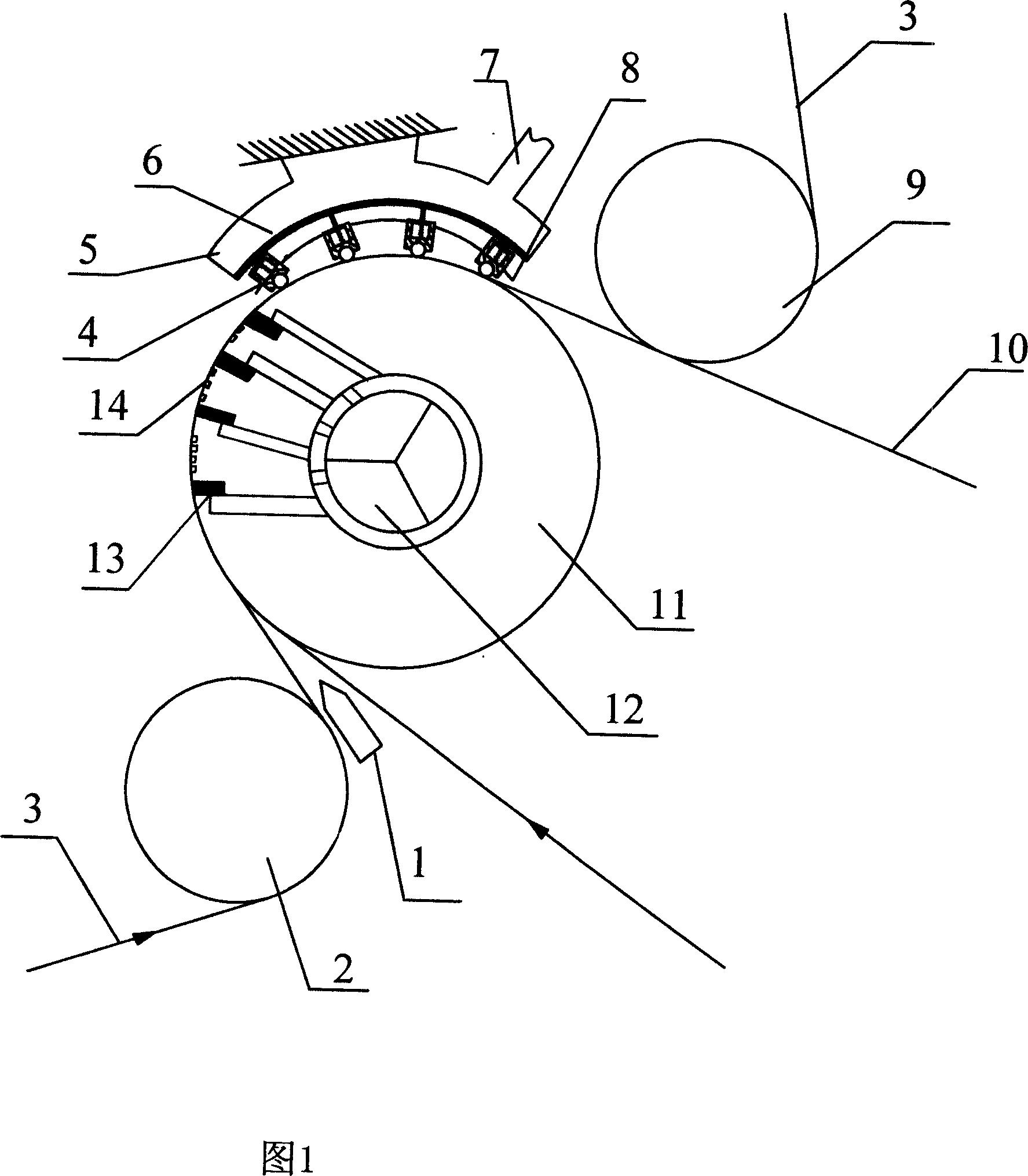

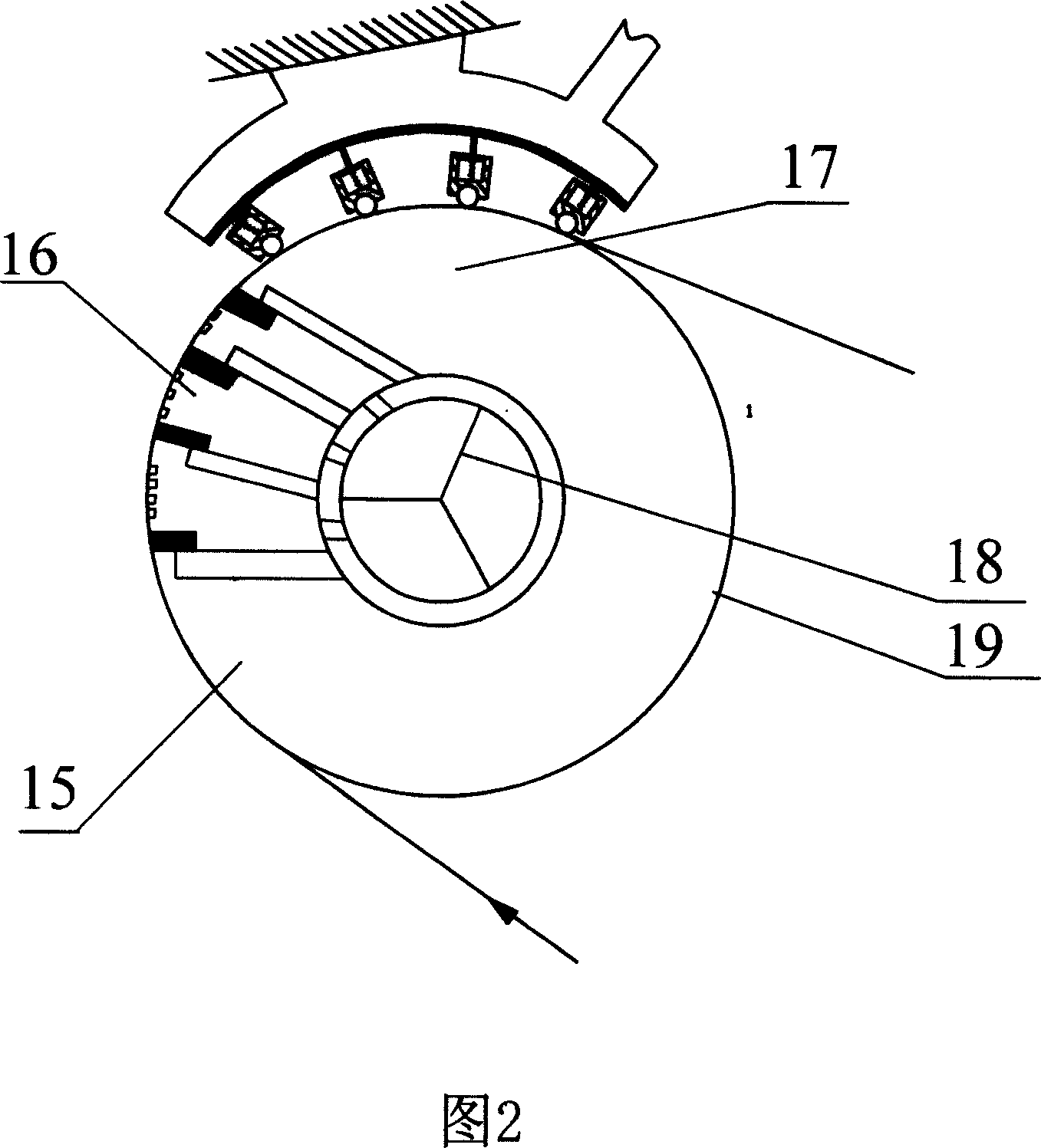

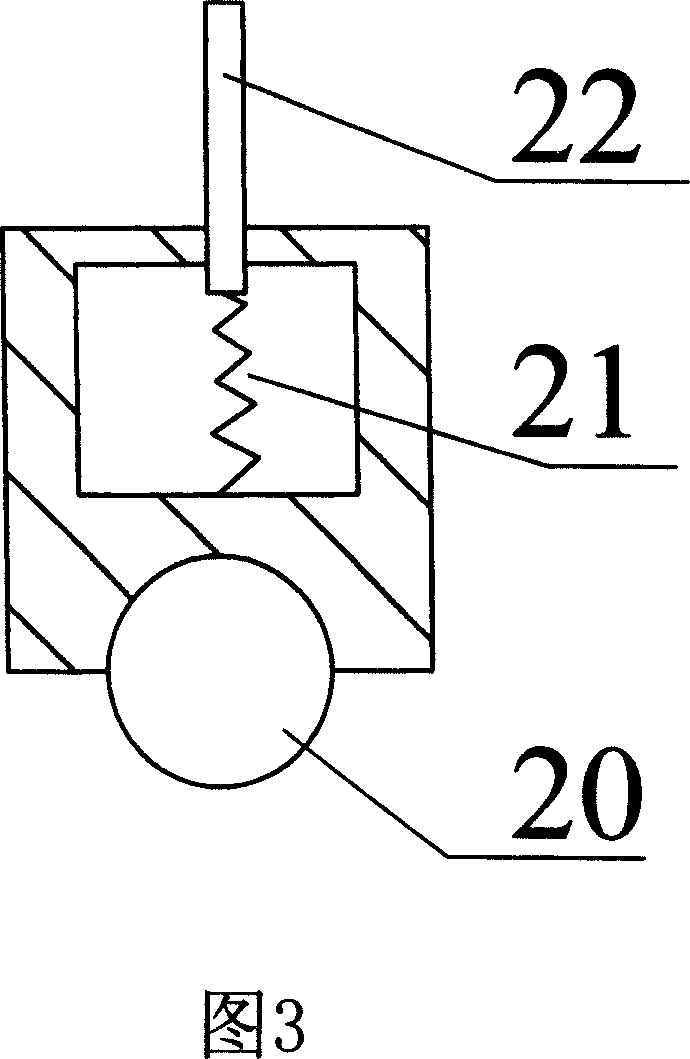

[0020] As shown in Figures 1 and 2, a gap vacuum roller former for a high-speed tissue machine includes an outer wire 3 supported by a breast roll 2, a guide roll 9, and a vacuum forming roll 11, which cooperates with the outer wire The inner wire 10, the headbox 1 located at the wedge-shaped opening formed by the outer wire 3 and the inner wire 10, the vacuum forming roll 11 is composed of a roll core provided with a vacuum chamber 12 and a roll shell 19, and the roll shell 19 is connected to the transmission mechanism The vacuum chamber 12 and the roll shell 19 are sealed with a sealing element 13, the surface of the roll shell 19 is provided with a water storage groove 14, and the shaper also includes a pressure pulse extruder located on the outside of the outer wire 3 and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com