Revolving drum type tube bundle drying machine

A tube bundle drying and rotary drum technology, applied in non-progressive dryers, dryers, drying of solid materials, etc., can solve problems such as large transmission power, and achieve the effect of reducing transmission power, reducing manufacturing costs, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

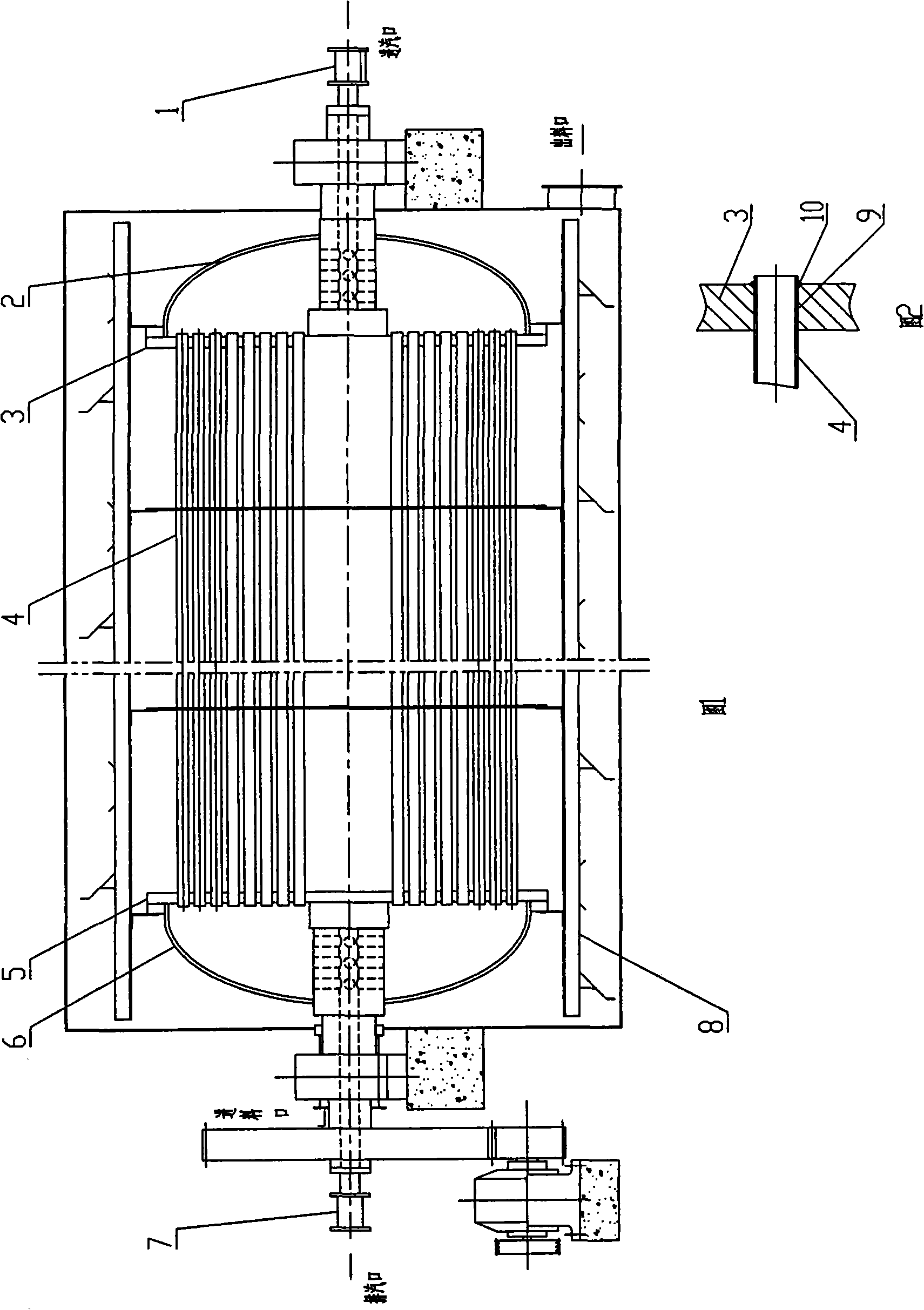

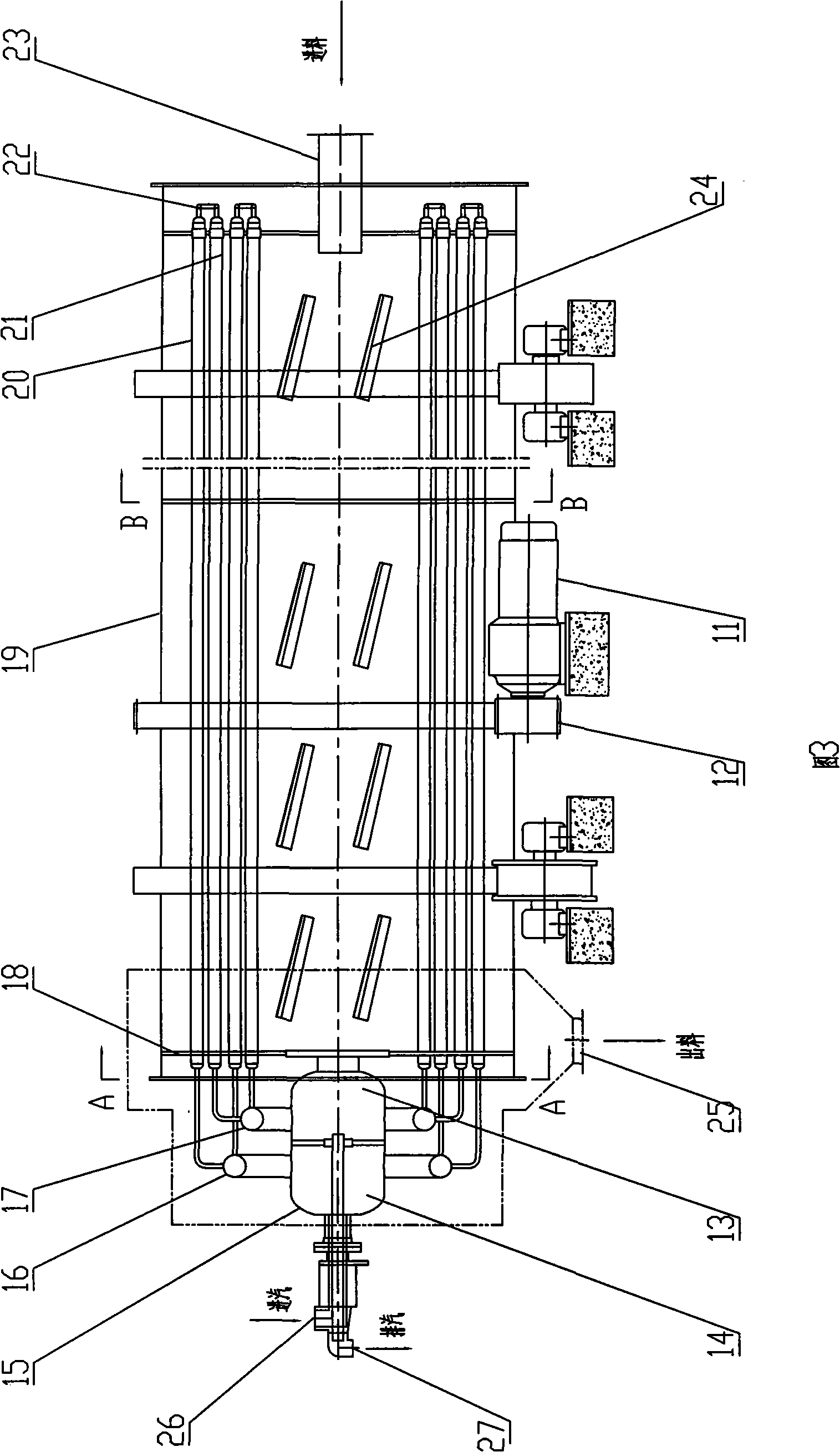

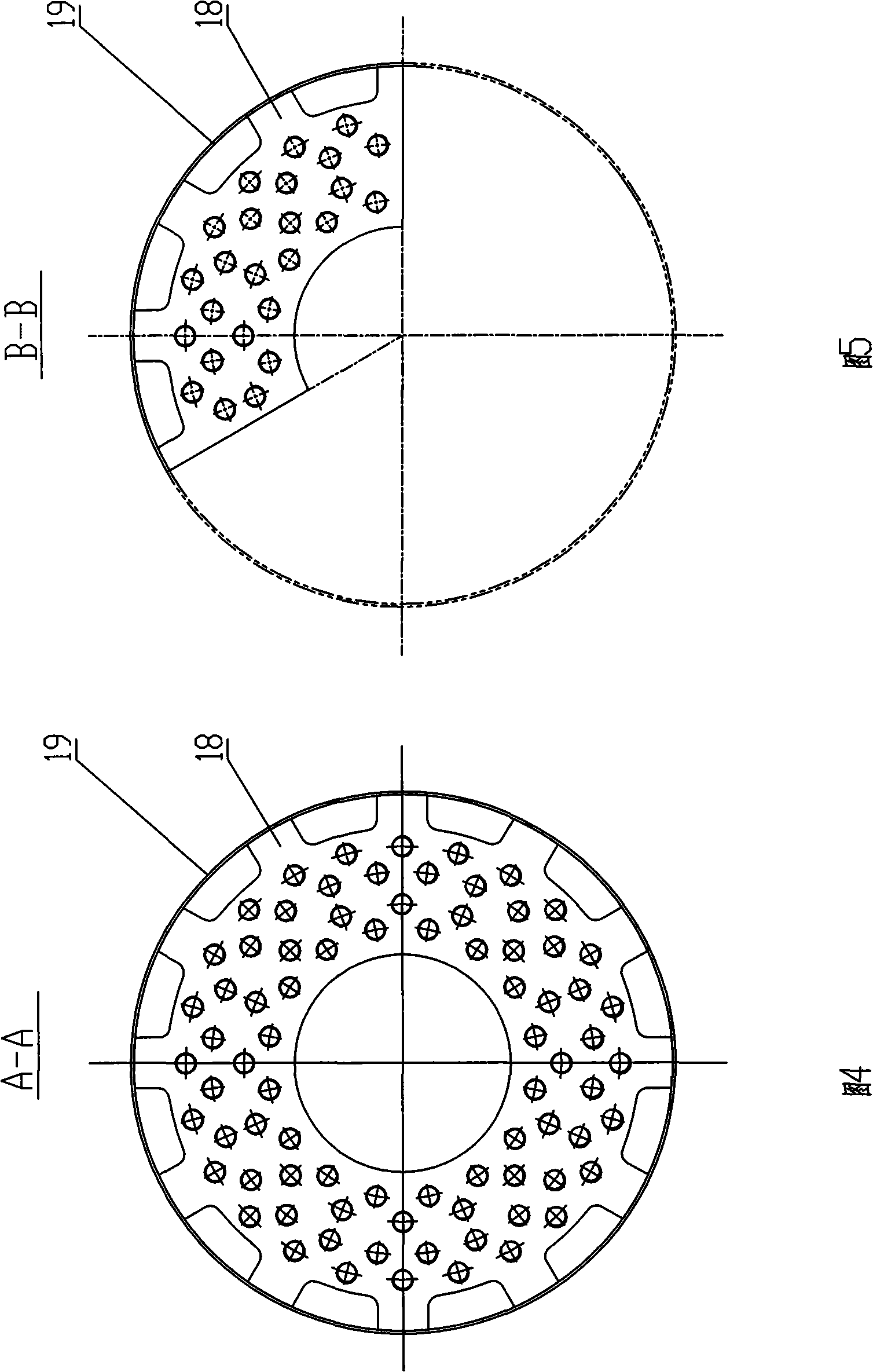

[0024] As shown in Fig. 3, Fig. 4 and Fig. 5, the drum type tube bundle dryer of the present invention includes a drum 19 with a feed inlet at one end and a discharge outlet at the other end, and a drum 19 arranged axially on the drum. Several heat exchange tubes in the cavity of the drum 19, characterized in that the heat exchange tubes are installed in the inner cavity of the drum 19 through at least two horizontal support tube plates 18 fixedly connected to the inner wall of the drum 19; The heat exchange tubes are composed of steam inlet heat exchange tubes 20 and exhaust steam heat exchange tubes 21 arranged at intervals, and one end of every two adjacent steam inlet heat exchange tubes 20 and exhaust steam heat exchange tubes 21 passes through a rotary elbow 22 communicated to form a circuit, and the other end is respectively connected with the inlet steam collecting ring 16 and the exhaust steam collecting ring 17; the inlet steam collecting ring 16 and the exhaust steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com