Micro-flow injection pump system for electrostatic spinning

A technology of electrospinning and injection pump, which is applied in the components, pump, and pump control of the pumping device for elastic fluid, which can solve the problem of inability to automatically feed accurately at low speed, and achieve a wide range of injection speed and convenient operation. , Controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

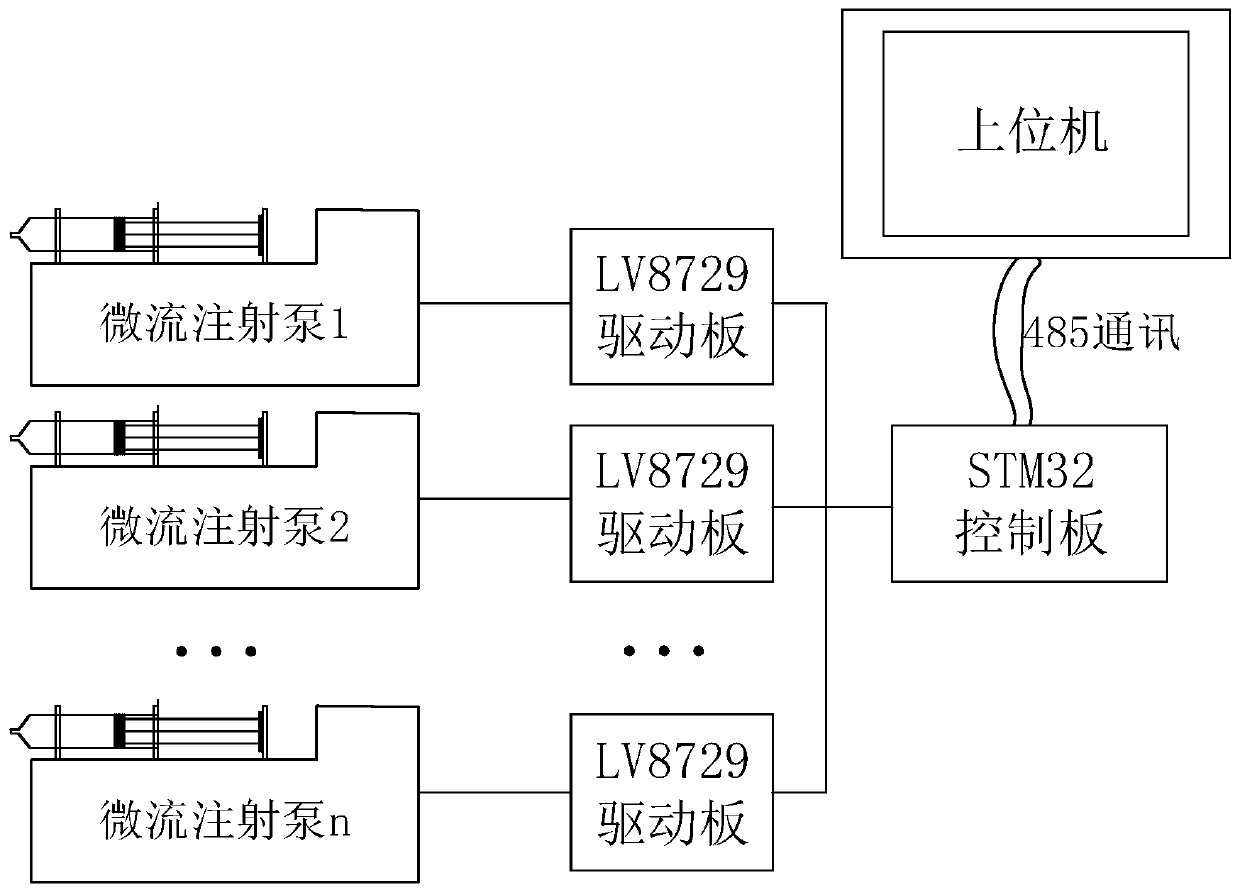

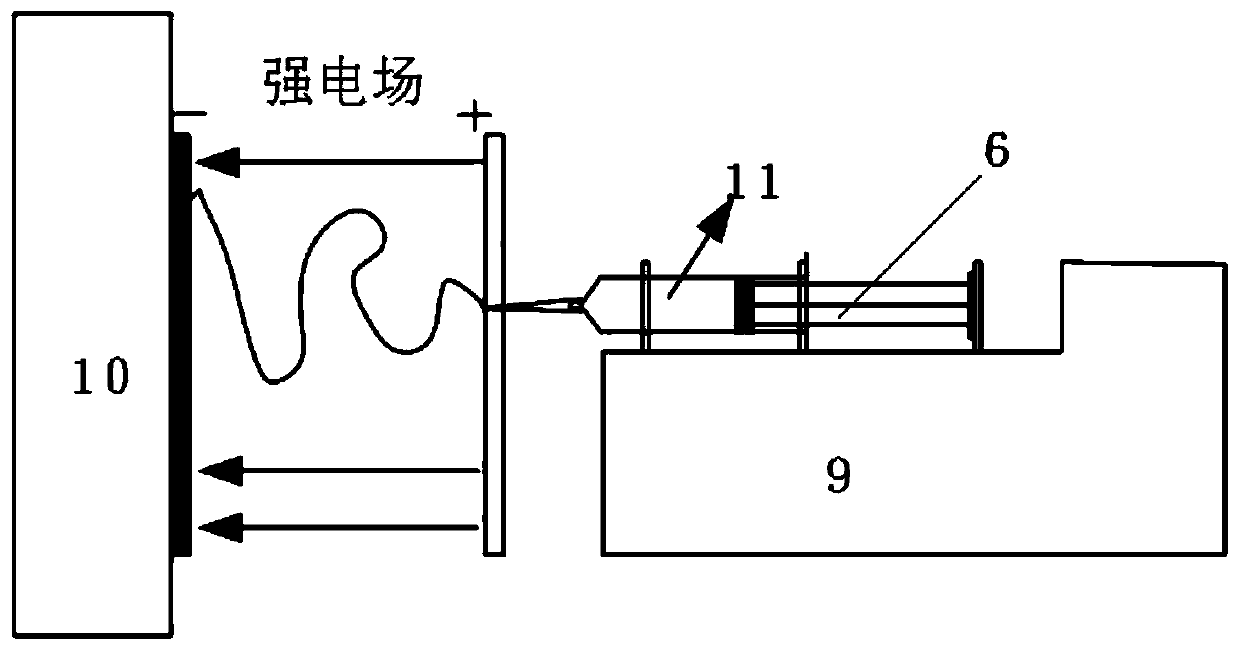

[0032] Such as figure 1 Shown: the main structure of the microfluidic injection pump system design includes a microfluidic syringe pump, a stepper motor driver (LV8729 driver board, LV8729 motor driver chip of Sanyo Semiconductor Corporation), a lower computer main control module (STM32 control board, Italian stm32f407 of French semiconductor company) and host computer (MCGS touch screen). The main body of the microfluidic syringe pump is designed as follows:

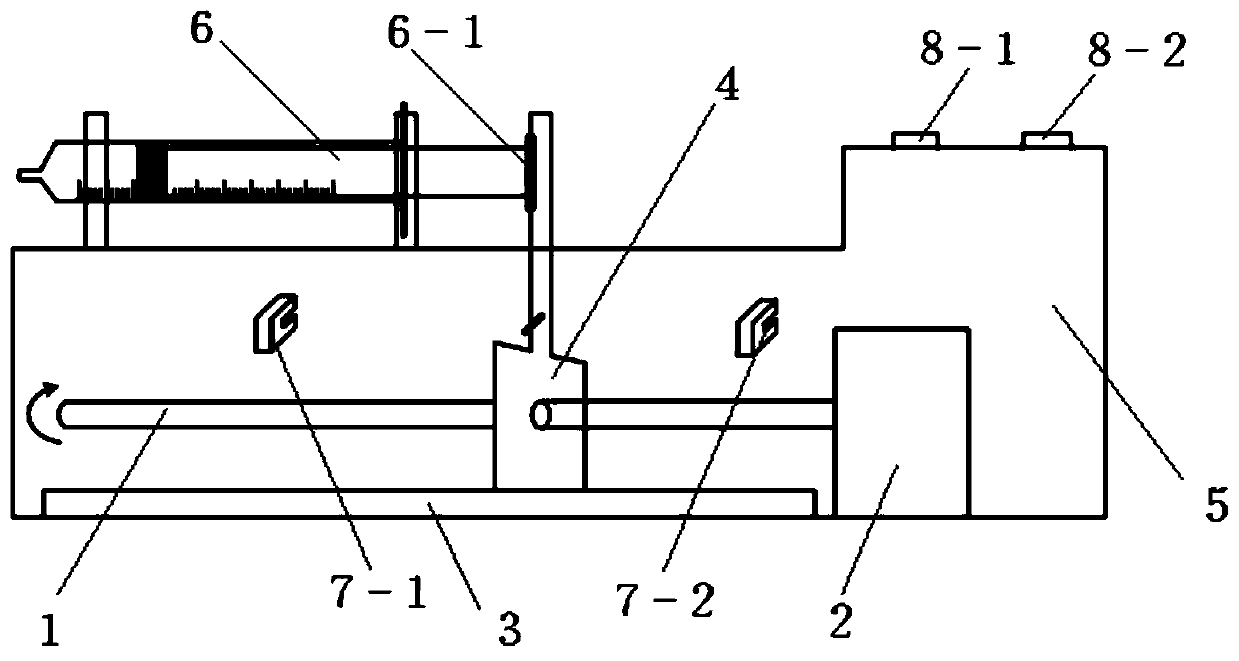

[0033] Such as figure 2 As shown: the micro-flow pump system uses a two-phase hybrid screw stepper motor 2 as the main core of the system, and the motor 2 must meet the requirements of low step angle, large torque and high precision; as a better embodiment , choose a Wheatstone 42 stepper motor as the motor 2 of the syringe pump system, the fixed step an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com