Crossed roller bearing with roller path with convexity and manufacturing method thereof

A technology of a crossed roller bearing and a manufacturing method, which is applied to a crossed roller bearing with a convex raceway and its manufacturing field, can solve the problems of insufficient running accuracy and service life, reduced bearing capacity, poor machining accuracy, etc. The effect of improving operation accuracy and reliability, reducing friction torque and operating temperature rise, and improving anti-skew ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

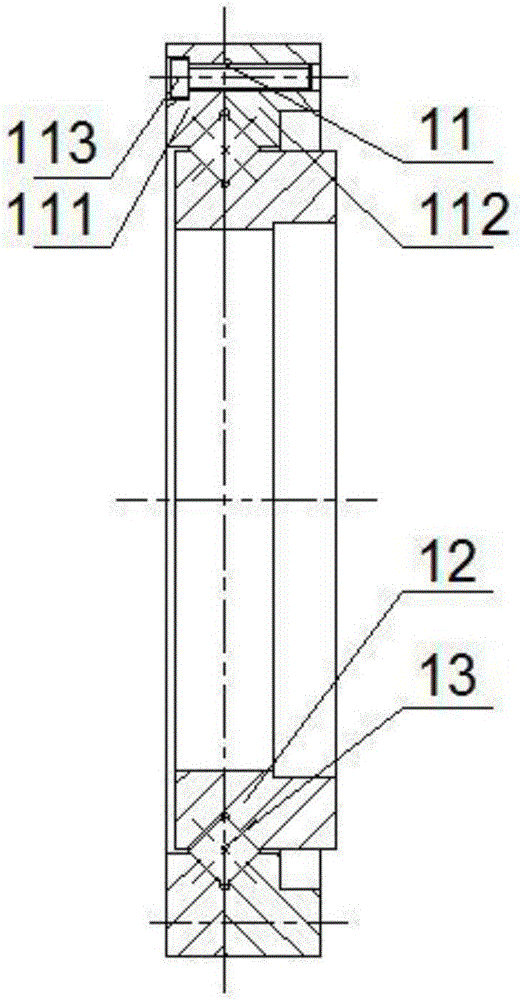

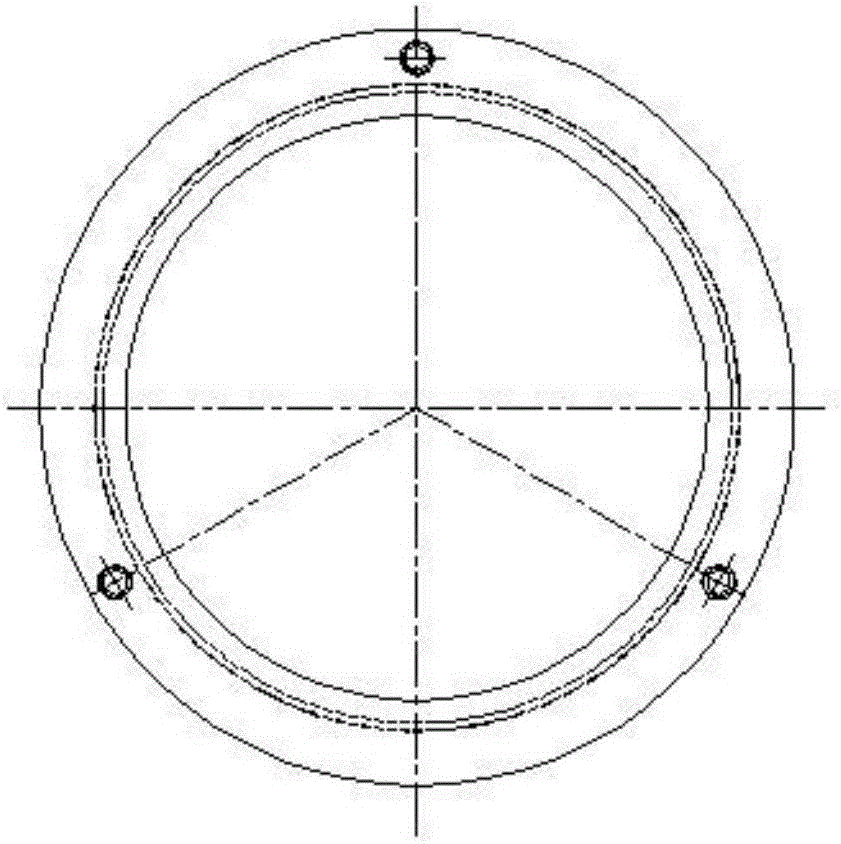

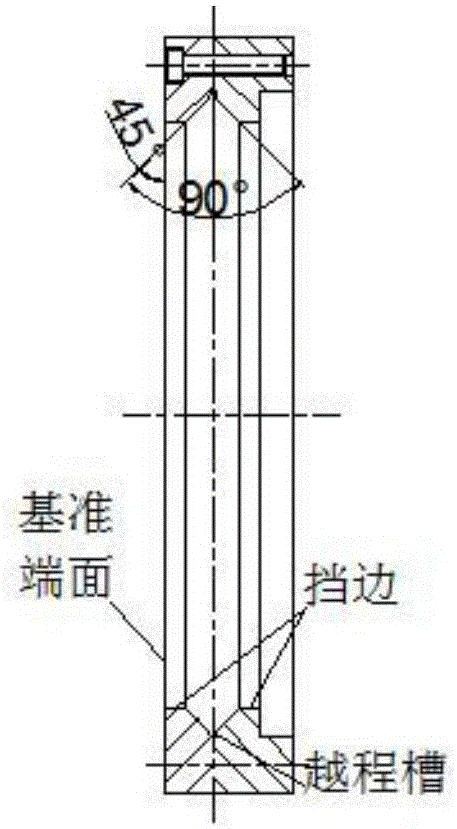

[0094] Embodiment 1, as figure 1 Shown is a schematic diagram of a crossed roller bearing, which is a crossed cylindrical roller bearing with a convex outer ring, including an outer ring 11 with a ring-shaped inner V-shaped raceway, an inner ring 12 with a ring-shaped outer V-shaped raceway, embedded Cylindrical rollers 13 arranged crosswise between the V-shaped raceway of the outer ring and the V-shaped raceway of the inner ring. The outer ring 11 is designed as a two-half structure, including two halves of rings 111 and 112. The two halves of the rings are connected by several connecting screws. 113 connections are fastened to an integral outer ring. From Figure 2B and image 3 It can be seen that the angle between the V-shaped raceways of the inner ring and the outer ring near the respective reference end faces and the respective reference end faces is 45 degrees, and the angle between the raceways on both sides is 90 degrees. The raceway is sandwiched between the ring...

Embodiment 2

[0098] Example 2. Partially split inner ring with convex cross tapered roller bearing - logarithmic curve convex

[0099] Partially split inner ring with convex crossed tapered roller bearings such as Figure 4 As shown, it includes the outer ring 21, the inner ring 22, the tapered rollers 23 embedded between the V-shaped raceway of the outer ring and the V-shaped raceway of the inner ring and arranged crosswise, the cone top of one row of tapered rollers and the other row of cones The cone tops of the rollers fall on two points on both sides of the bearing on the center line of rotation of the bearing respectively. Outer ring 21 such as Figure 5 As shown, it is an overall structure, and the inner ring 22 is as Figure 4 , Figure 6A , 6B As shown in and 6C, in order to fill a sufficient number of tapered rollers 23 into the bearing, the inner ring 22 is designed as a partially split structure with a raceway block, and the inner ring 22 is composed of a notched inner ring...

Embodiment 3

[0101] Embodiment 3. Structure, processing and assembly of partially split inner ring with convex cross tapered roller bearing

[0102] For partially split crossed roller bearings, only one of the rings, the inner ring or the outer ring, needs to be partially split, Figure 4 The assembly drawing of the cross-tapered roller bearing with convex inner ring is given, Figure 5 is a cross-sectional view of the outer ring 21, it can be seen that the outer ring 21 is an integral structure, Figure 6A is a sectional view of the inner ring 22, Figure 6B is the left side view of the inner circle 22, Figure 6C yes Figure 6B In the A-direction view, it can be seen that the inner ring 22 is a partially dissected structure, which is composed of a notched inner ring 221, a raceway block 222 and a connecting screw 223, wherein the connecting screw 223 fixes the block 222 on the notched On the inner ring 221, the blockage matches the gap. The manufacturing method of the partially spli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com