Detector array target calibration system and method

A detector array and calibration system technology, applied in the field of detector array target calibration, can solve the problems of high cost, high difficulty and low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

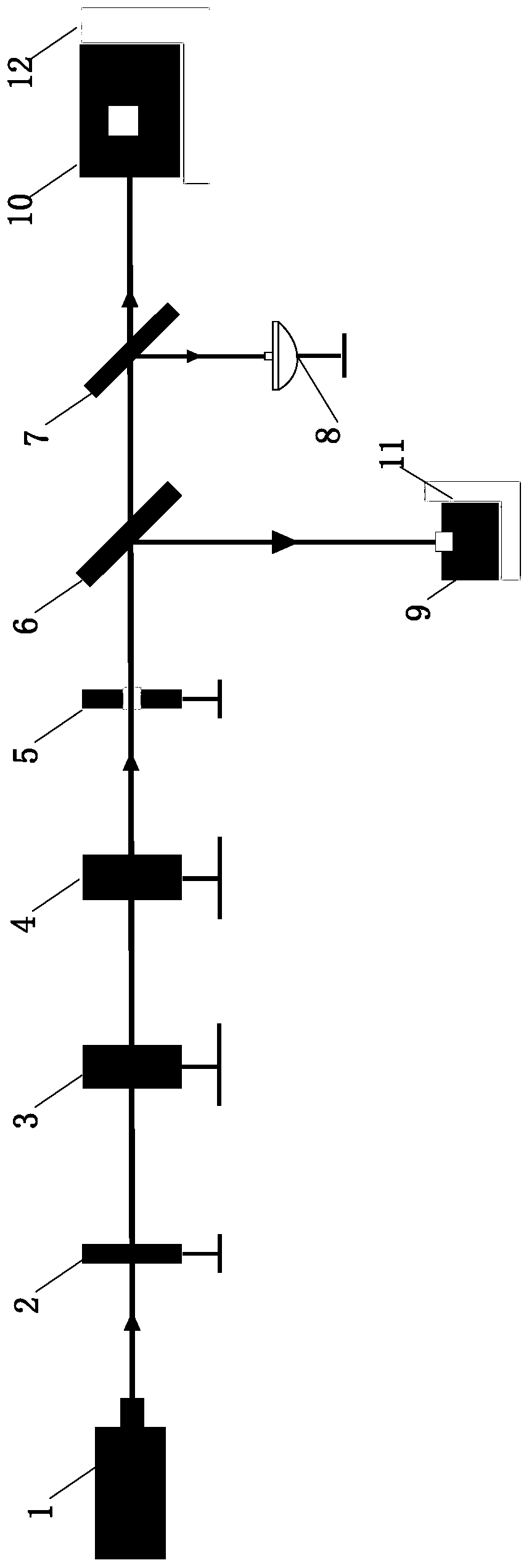

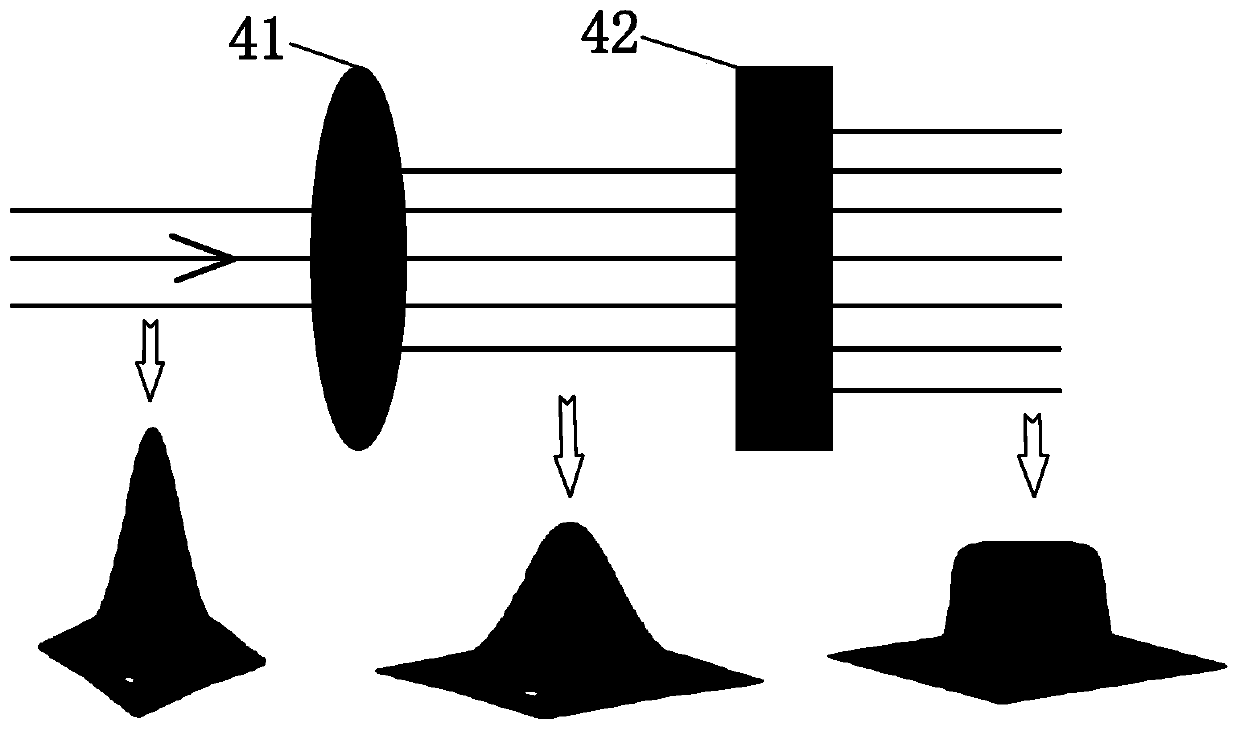

[0033] Such as figure 1 and Figure 7 As shown, a detector array target calibration system includes a spot acquisition device, a first beamsplitter 6, a second beamsplitter 7, a power meter 8, a signal conditioning sampling unit, a data processing control unit, and a distance to the first beamsplitter 6. The same calibration detector module 9 and detector array target 10 to be calibrated. In this embodiment, the calibration detector module 9 has only one detector unit 101 , and the detector array target 10 includes a plurality of detector units 101 arranged in an array. The light spot 13 output by the described light spot acquisition device is respectively emitted to the calibration detector module 9 and the detector array target 10 to be calibrated after passing through the first beam splitter 6, and the second beam splitter 7 arranged on the optical path splits a beam The light is emitted onto the power meter 8; in this embodiment, the second beam splitter 9 is arranged on...

Embodiment 2

[0050] A method for using a detector array target calibration system described in Embodiment 1, comprising the following steps:

[0051] S1. Build a system, match a suitable spot acquisition device according to the measurement wavelength and power density range of the detector array target 10 to be calibrated, and then build the system;

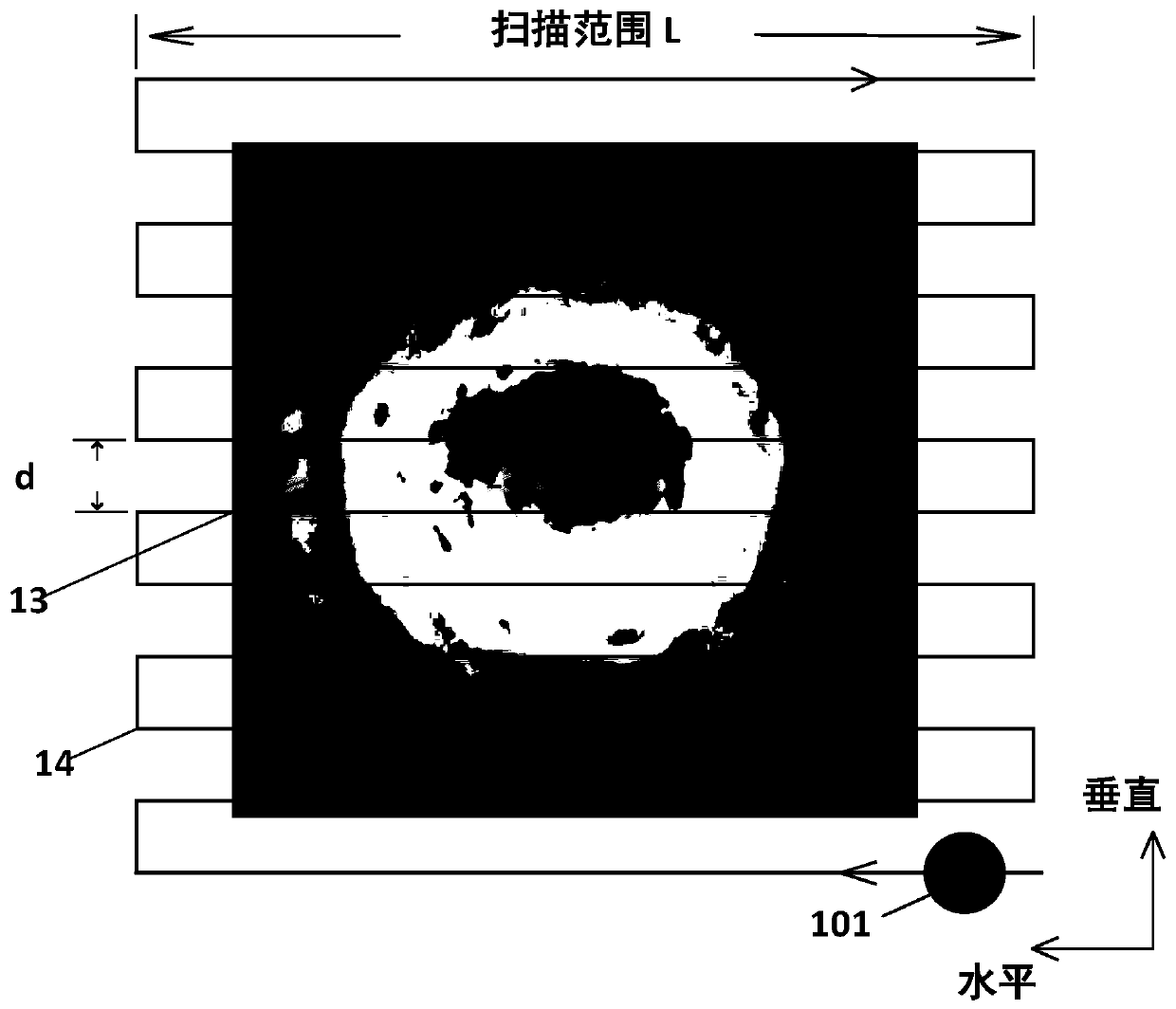

[0052] S2. The data processing control unit controls the first two-dimensional scanning platform 11 to drive the standard calibration detector module 9 to perform single-point scanning according to the set path 14 . After the scan is completed, the signal conditioning sampling unit collects the AD response value of the detector unit 101 in the standard calibration detector module 9, and then transmits it to the data processing control unit, and the data processing control unit obtains the light spot 13 counted by the power meter 8 Total power P sum , to calculate the true power density ρ;

[0053] The specific steps are as follows:

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com