Production equipment for sticking non-woven fabric to aluminous gusset plate

A technology of production equipment and aluminum gussets, which is applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of large amount of glue, poor production efficiency, glue outflow, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

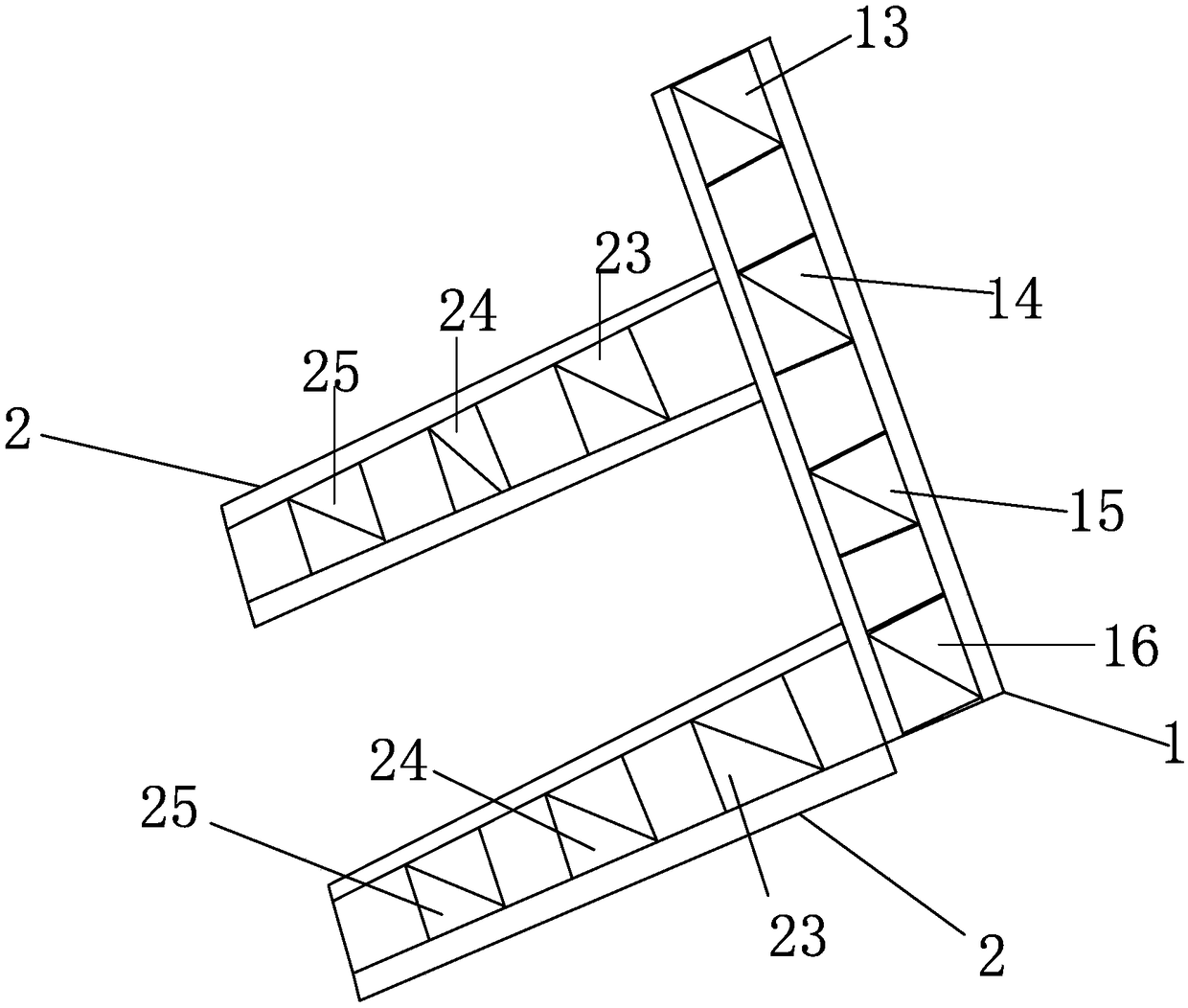

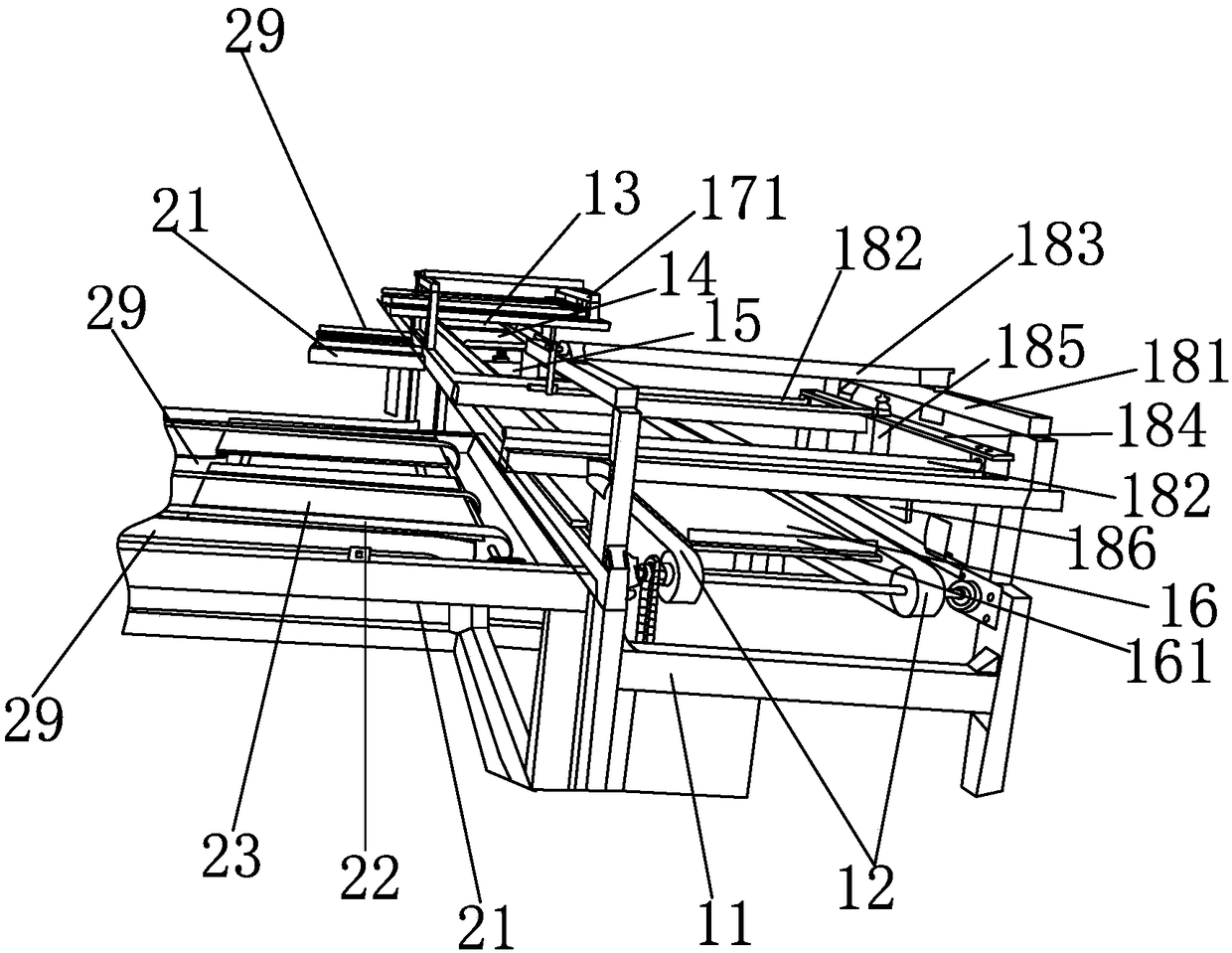

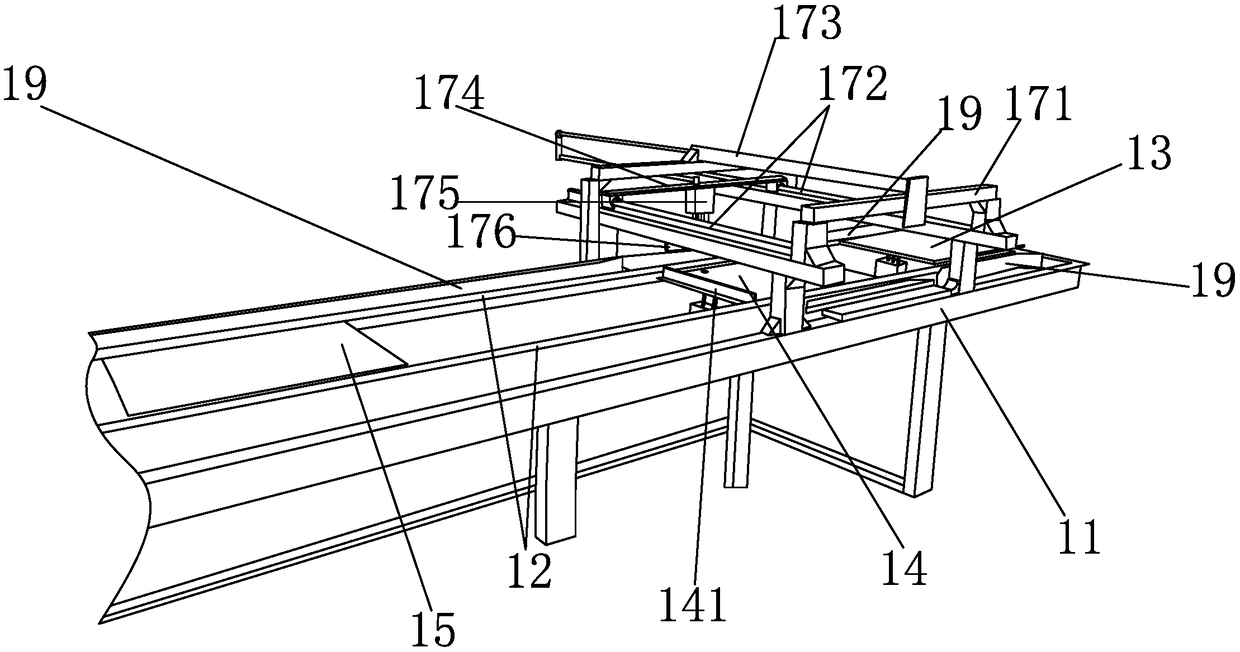

[0029] refer to Figure 1 to Figure 11 , a kind of production equipment for laminating aluminum gussets to non-woven fabrics, comprising a main transmission line 1 for transmitting aluminum gussets, two or more sub-transmission lines 2 arranged on the side of the main transmission line 1, the main transmission line 1 includes the first frame 11, the first conveyor belt group 12 that is movably arranged on the first frame 11, the starting end plate placing platform 13, the first pushing plate platform 14, the first intermediate transition platform 15, and the second pushing plate platform 16 , the starting end plate-putting platform 13, the first pushing plate platform 14, the first intermediate transition platform 15, and the second pushing plate platform 16 can all move up and down and are arranged in sequence along the first conveyor belt group 12 transmission directions, and the sub-transmission line 2 includes the second frame 21, the second conveyor belt group 22 receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com