Vertical cotton glue sprayer

A technology of glue spraying machine and vertical cotton, which is applied in the direction of painting room, spraying device, liquid spraying device, etc., can solve the problems of product quality decline, low production efficiency, uneven glue spraying, etc., so as to reduce the impact of the environment and improve the Product quality and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

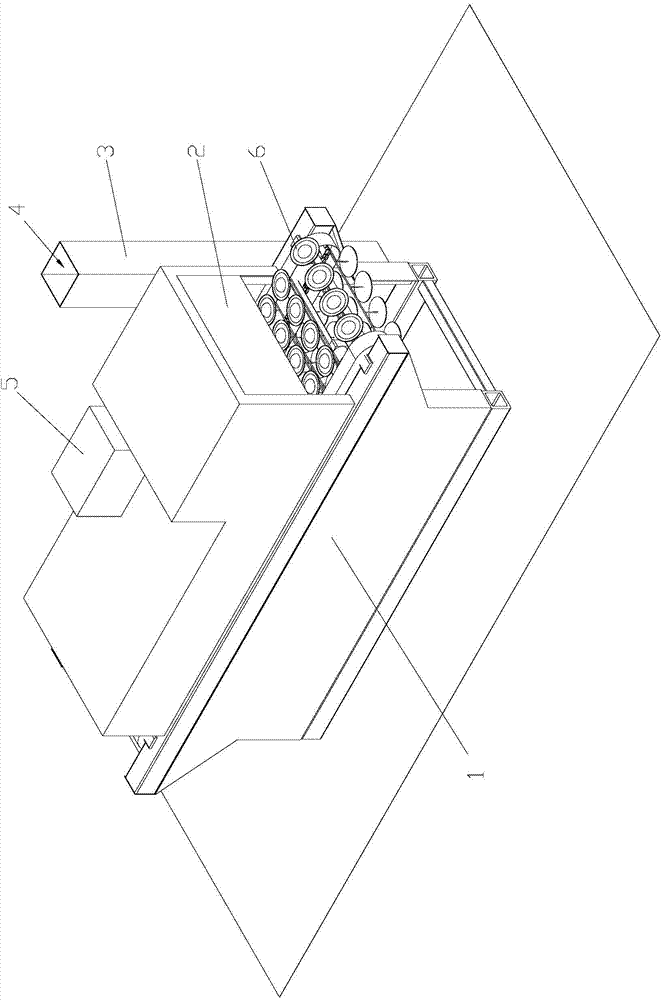

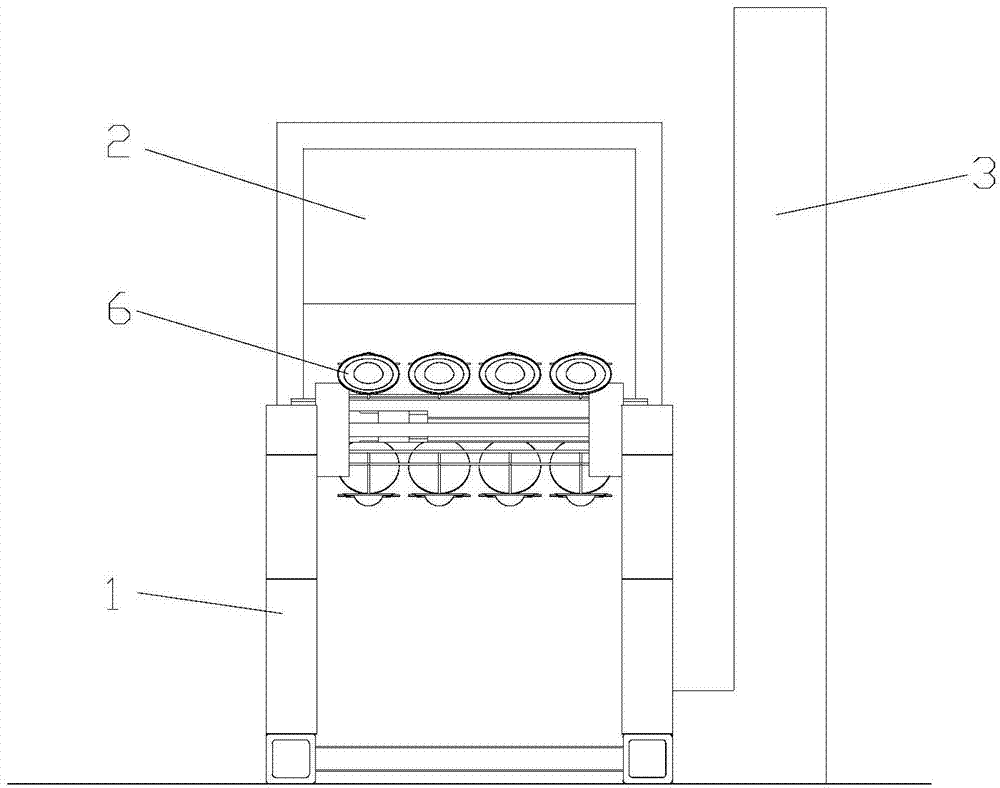

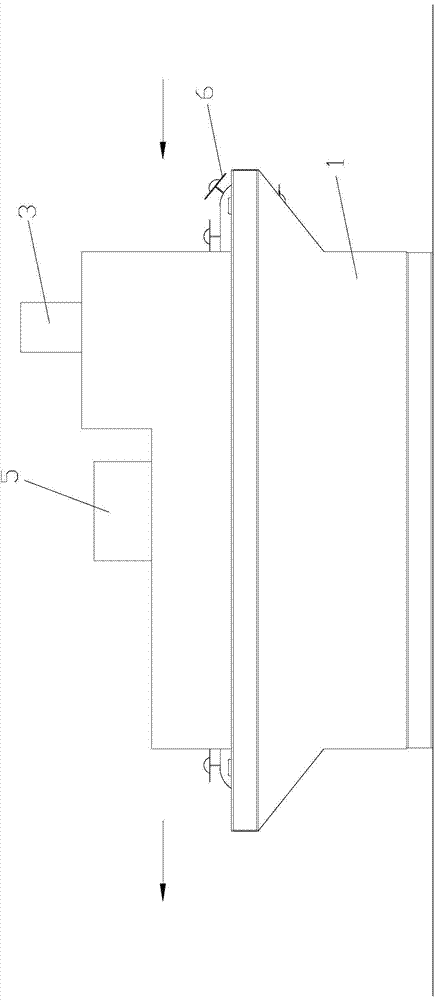

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] see Figure 1 to Figure 7 , a vertical cotton glue spraying machine, including a box body 1 with an inlet and an outlet at the front and rear ends respectively, an automatic glue spraying device is provided above the front part of the inner cavity, and the entrance of the box body 1 penetrates into the The inner cavity of the box body 1 and the chain conveyor passing through the outlet of the box body 1 . The height of the front part of the box body 1 is higher than the height of the rear part, so that the front part of the inner cavity of the box body 1 is higher and the rear part is lower, so as to prevent the glue spray from spreading to the inner cavity rear part. An electrical cabinet 5 is also provided above the rear of the casing.

[0027] The chain transmission device includes a chain 7 , a driven gear 8 , a driving gear 9 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com