Lateral pushing buckling groove device of automobile glass gluing equipment

A technology of automotive glass and buckle grooves, which is applied to the surface coating device, coating, etc., can solve problems such as unstable gluing, loose installation, and poor shock absorption at the corners of the front windshield of the car, achieving The effect of spraying glue evenly and applying glue tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

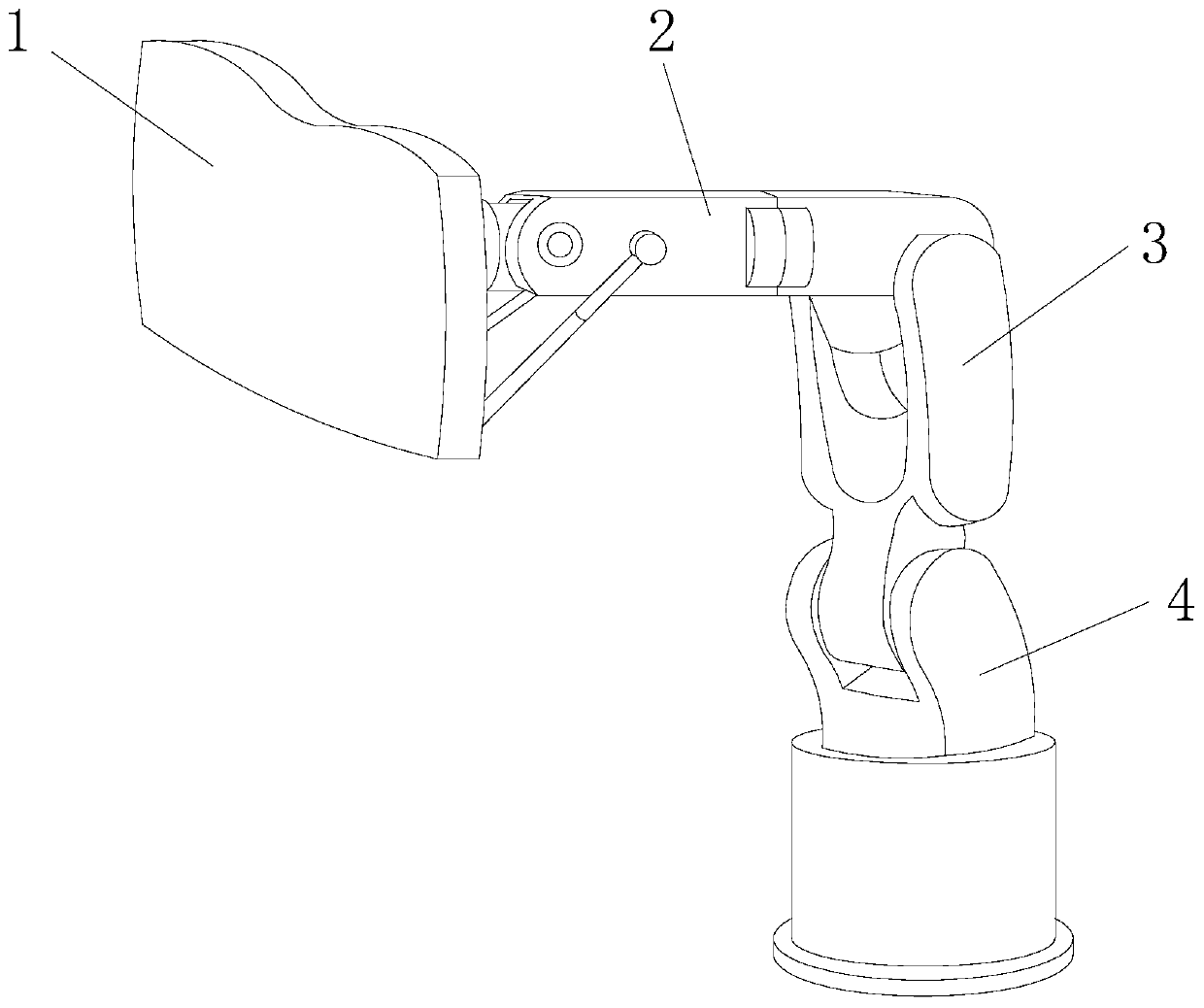

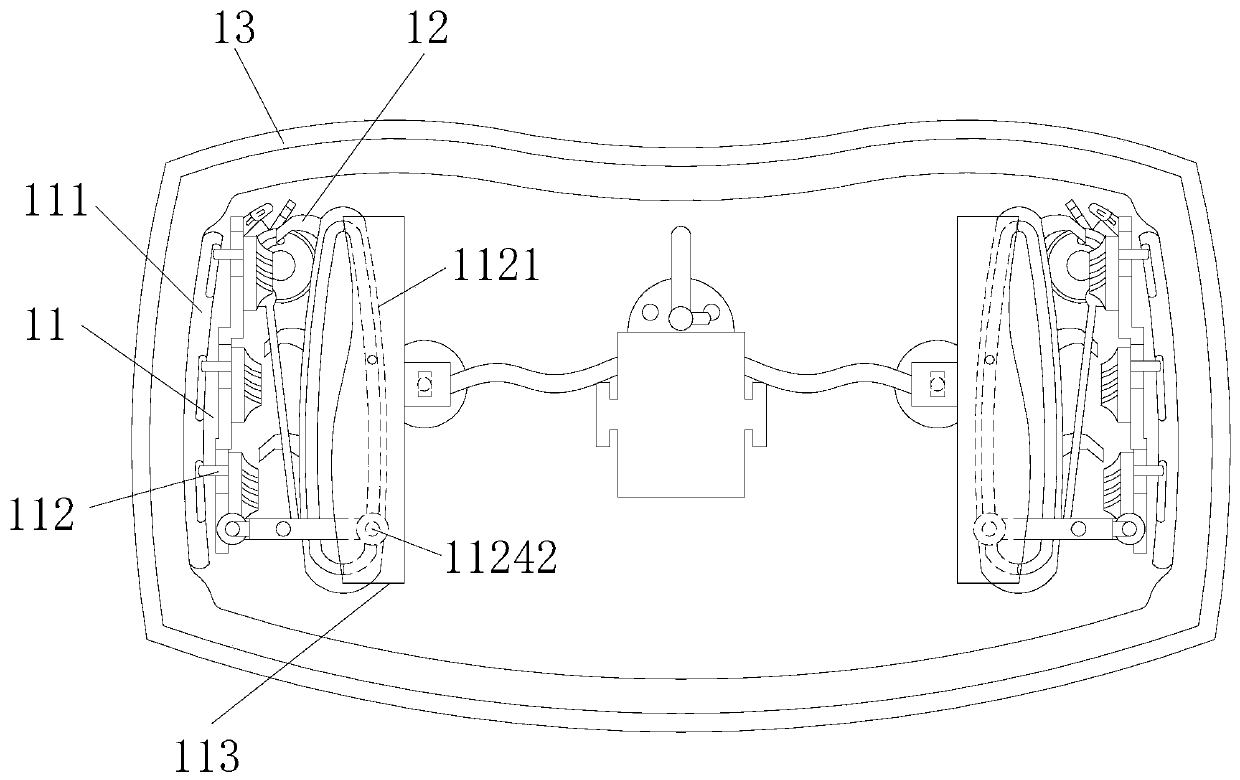

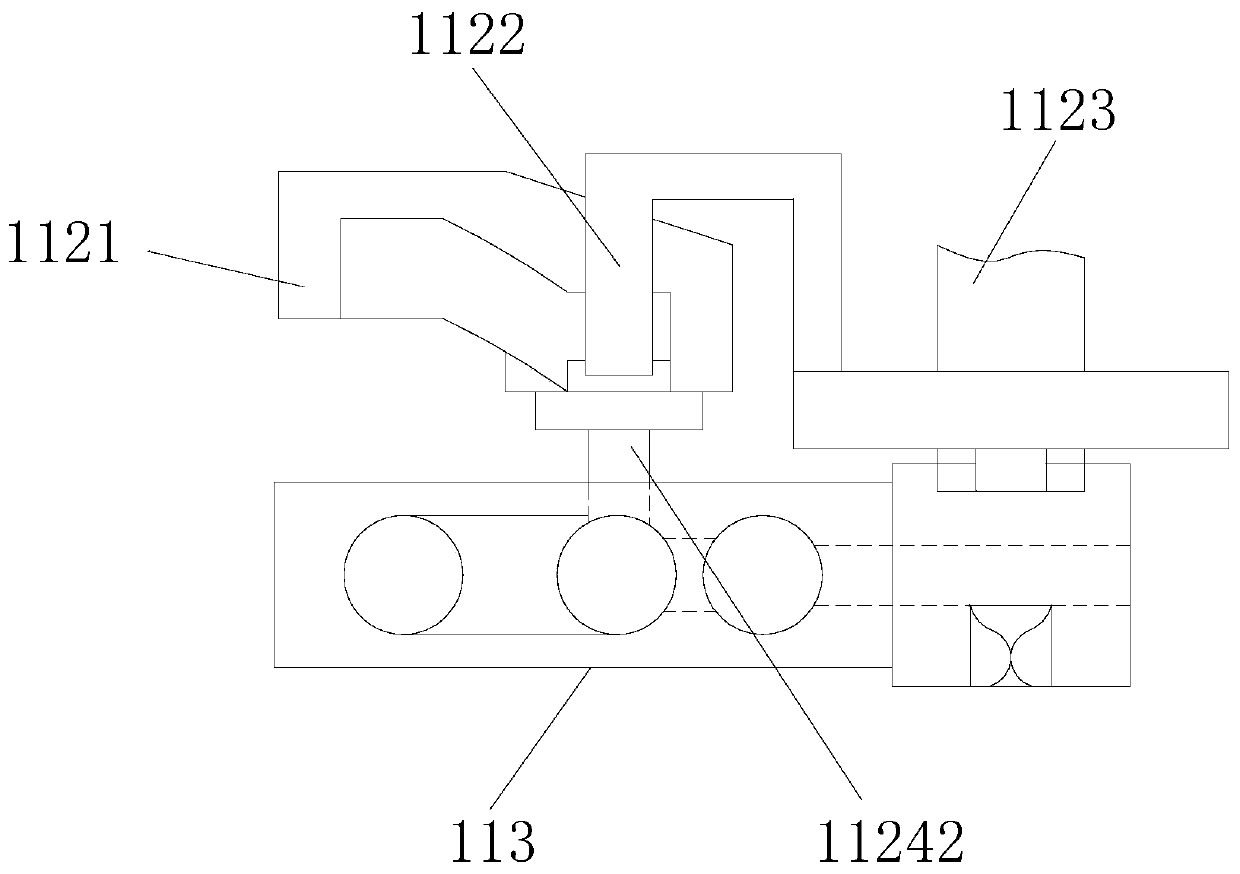

[0027] Such as Figure 1-Figure 8 As shown, the present invention provides a side push button groove device for automotive glass gluing equipment, and its structure includes a side push button groove device 1, a spraying machine arm 2, a rocker arm 3, and a base 4. The side push button groove device 1 is mechanically cooperated with the spraying machine arm 2 through the sliding hinge rod, the rocker arm 3 is connected with the spraying machine arm 2 through a shaft, the base 4 is mechanically cooperated with the spraying machine arm 2 through the rocker arm 3, and the side push buckle groove The device 1 includes a leveling mechanism 11, a lock groove mechanism 12, and an arc cover 13. The leveling mechanism 11 is vertically installed inside the arc cover 13, and the lock groove mechanism 12 is mechanically matched with the leveling mechanism 11 through an arc tube.

[0028] The leveling mechanism 11 includes a uniform arc disc 111, a pendulum accumulator mechanism 112, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com