Automatic glue-spraying mechanism of vehicle noise insulation pad

A technology for automobile sound insulation pads and glue spraying, which is applied to spray devices, devices that apply liquid to surfaces, coatings, etc., can solve problems such as low work efficiency, waste of glue, and large site area, so as to reduce the labor intensity of workers. , The effect of improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

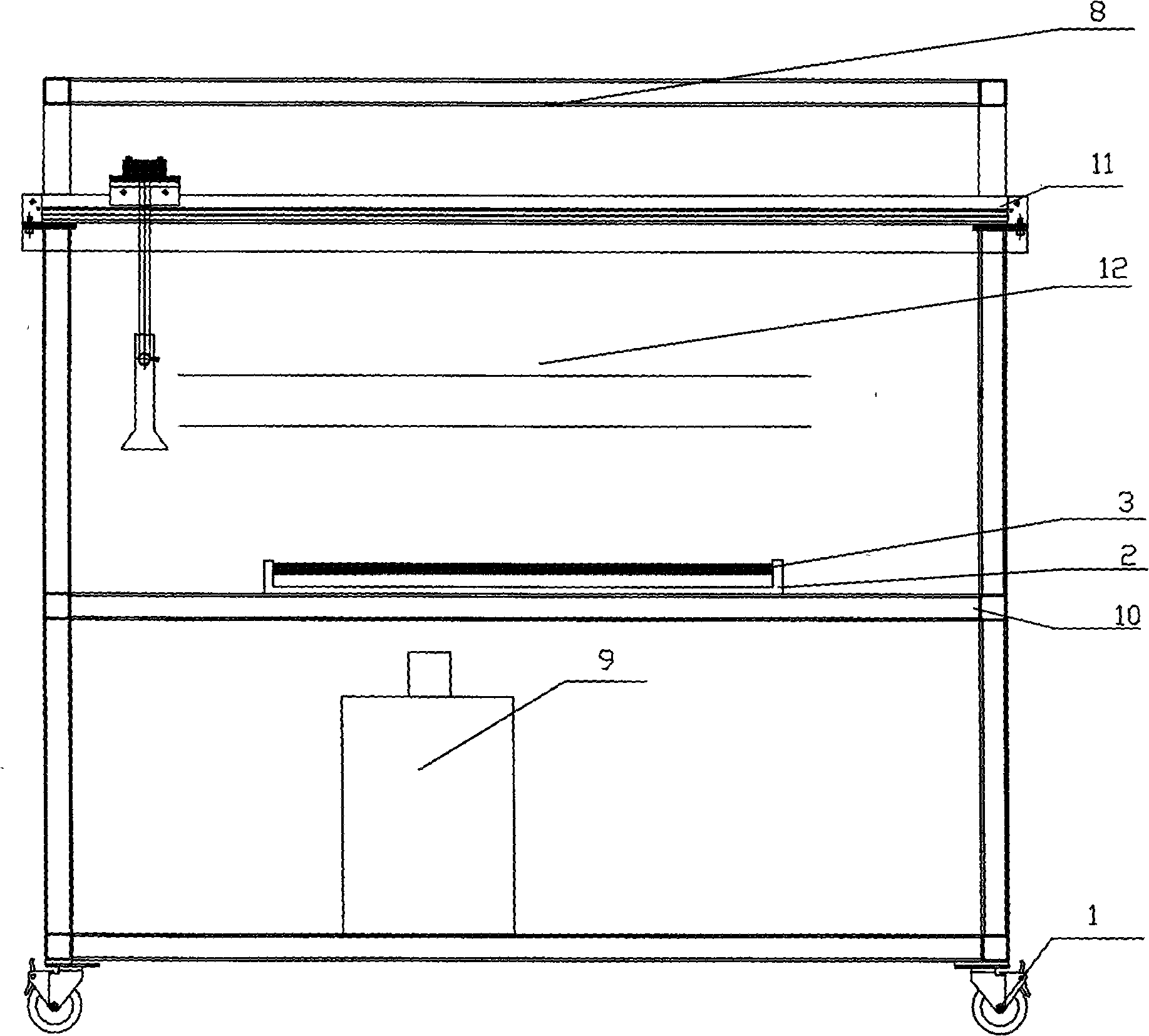

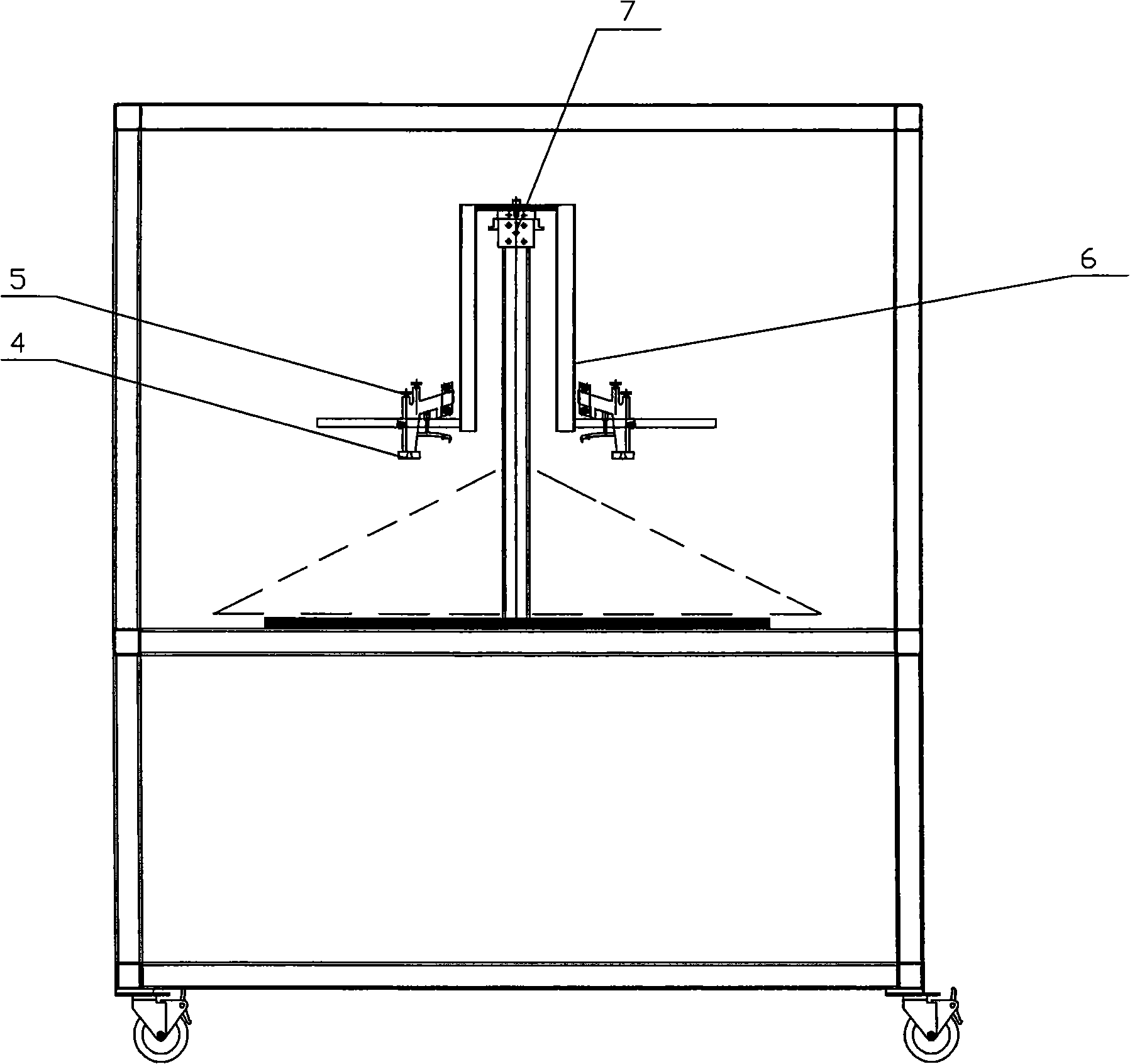

[0011] Such as Figure 1 ~ Figure 2 As shown, it includes universal wheel with brake 1, product positioning block 2, product 3, nozzle 4, pneumatic glue gun 5, glue gun connecting rod support 6, rodless cylinder 7, glue spray booth 8, glue bucket 9, etc.

[0012] The glue bucket 9 is placed on the base of the glue spray room 8, the fixed plate 10 and the glue spray rod 11 are installed in the glue spray room 8, the positioning block 2 is set on the fixed plate 10, and the glue spray device is installed on the glue spray rod 11. The glue device is made up of nozzle 4, pneumatic glue gun 5, glue gun connecting rod support 6 and rodless cylinder 7. The nozzle 4 is installed on the pneumatic glue gun 5. The nozzle 4 is provided with a taper, and the taper is 60 degrees. The pneumatic glue spray gun 5 is installed on the glue gun connecting rod support 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com