Gluing equipment

An equipment and gluing technology, applied in the direction of coating, device for coating liquid on the surface, spray device, etc., can solve the problems of low work efficiency, misalignment, uneven distribution of glue dispensing amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

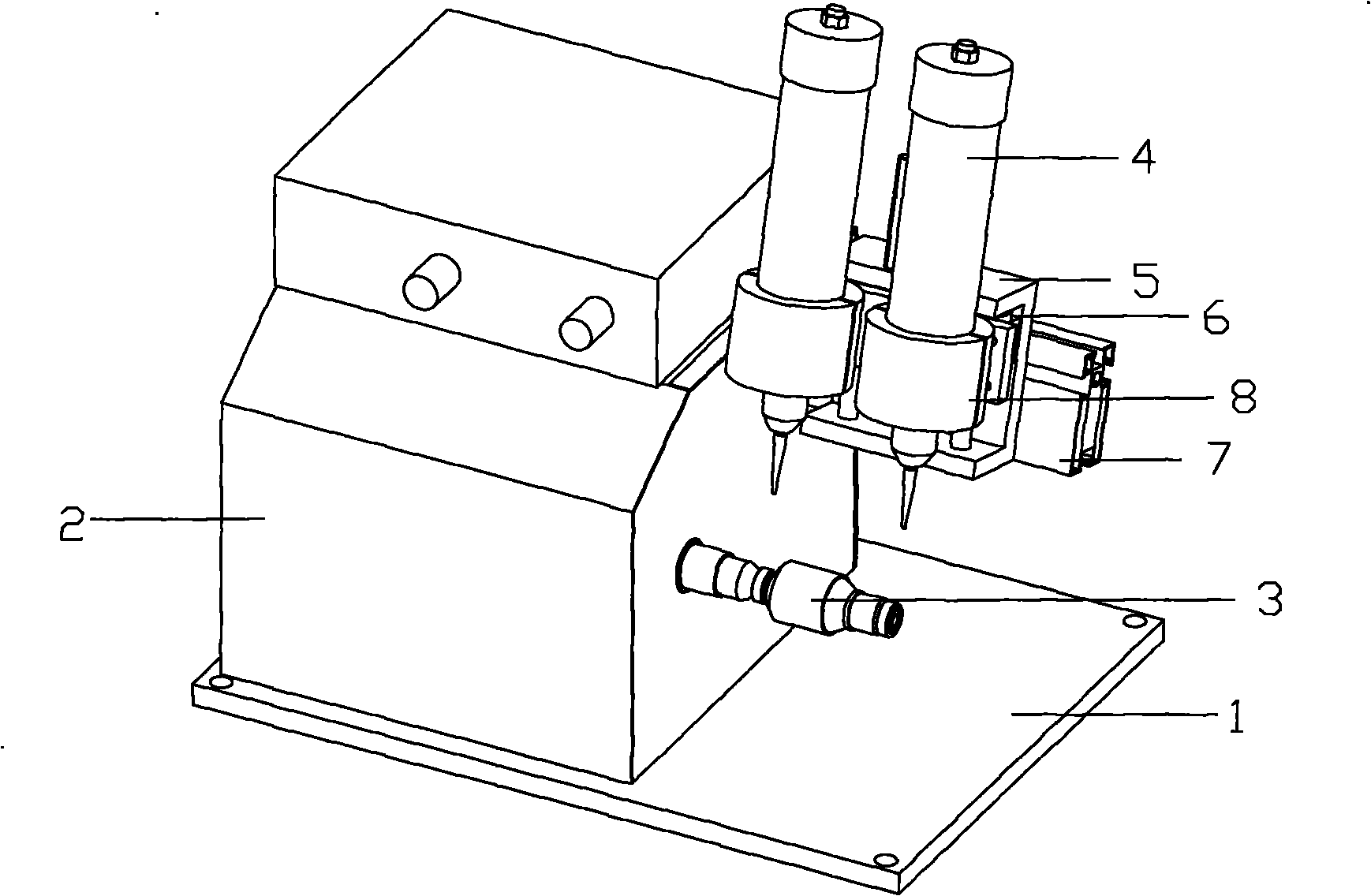

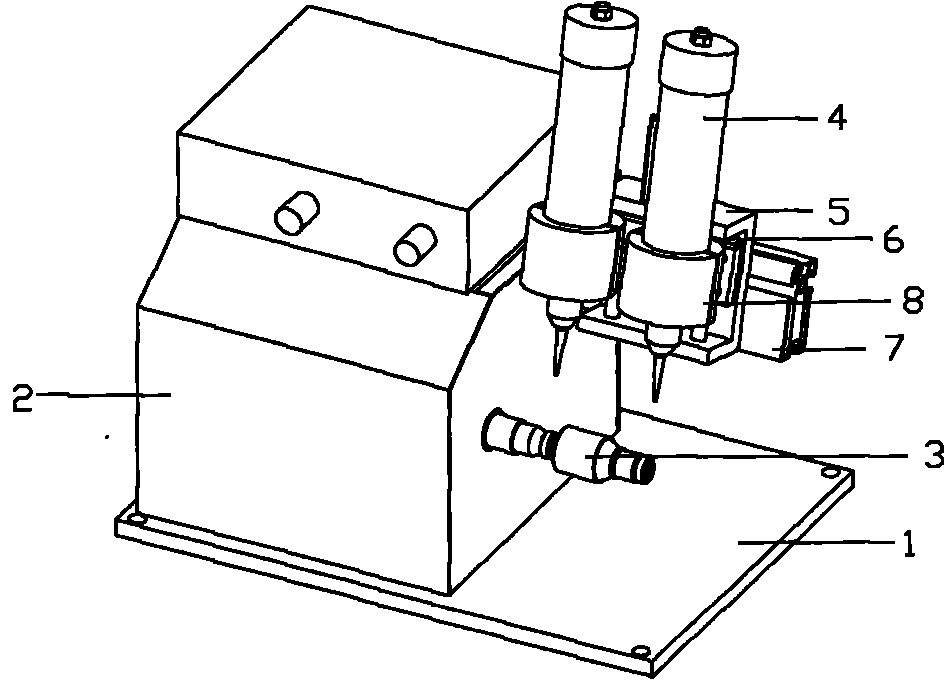

[0011] figure 1 The shown gluing equipment includes a fixed frame 3, an automatic glue gun 4, a base 1, a driving device 2 and a controller (not shown), and the driving device 2 is installed on one side of the base 1; on the other side of the base 1 At the space, a fixed frame 3 protrudes from the lower part of the driving device 2, and the fixed frame 3 can place two workpieces to be measured. A track 7 is fixed on the upper part of the driving device 2, and a slide is movably connected to the track 7. block 5, the slide block 5 can slide freely on the track; a chute 6 is arranged on the slide block 5, and two automatic glue guns 4 are movably installed on the slide block through respective sliding elements 8 matching with the chute Above, the fixed position of the track corresponds to the position of the lower fixed frame, so that the automatic glue gun can be aligned with the workpiece to be measured after adjustment. The controller can make the automatic glue spraying gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com