Straw powder glue mixing and paving system

A technology of straw powder and paving machine, which is applied in the pretreatment of molding materials, flat products, household components, etc. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

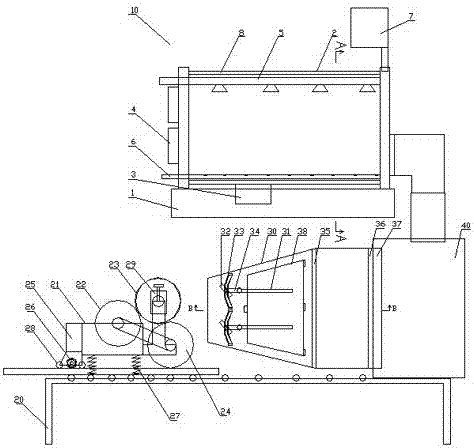

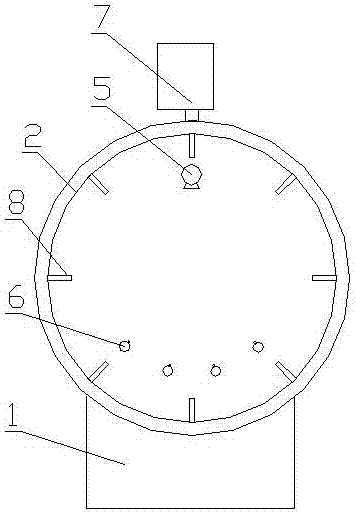

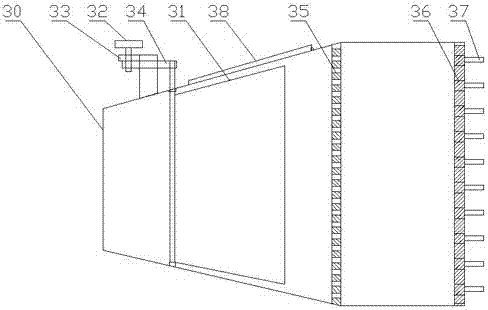

[0015] As shown in the accompanying drawings, the present invention includes an atomized rubber mixer and a paving machine. The bottom of the paving machine is provided with a pallet conveying roller table, and the outlet of the atomized rubber mixer communicates with the feed port of the paving machine. The atomizing glue mixing machine includes a frame, a cylinder body, a cylinder body drive motor, a fan, a glue spray pipe, a set of air ducts and a cyclone separator, and a set of lifting plates are arranged in the cylinder ring, and the two ends of the cylinder body are respectively movable. There are feed head and discharge head, feed port and air inlet are opened on the feed head, discharge port and air outlet are opened on the discharge head, the cylinder body passes through the feed head and discharge seal The head is installed on the frame, and the cylinder driving motor is installed on the frame to drive the cylinder to rotate. The air outlet of the fan is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com