Glue spraying device for packing box glue spreader

A box gluing and gluing technology, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as uneven gluing, improvement, and unfavorable quality of packaging boxes, achieve uniform gluing, reduce costs, and reduce costs. Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

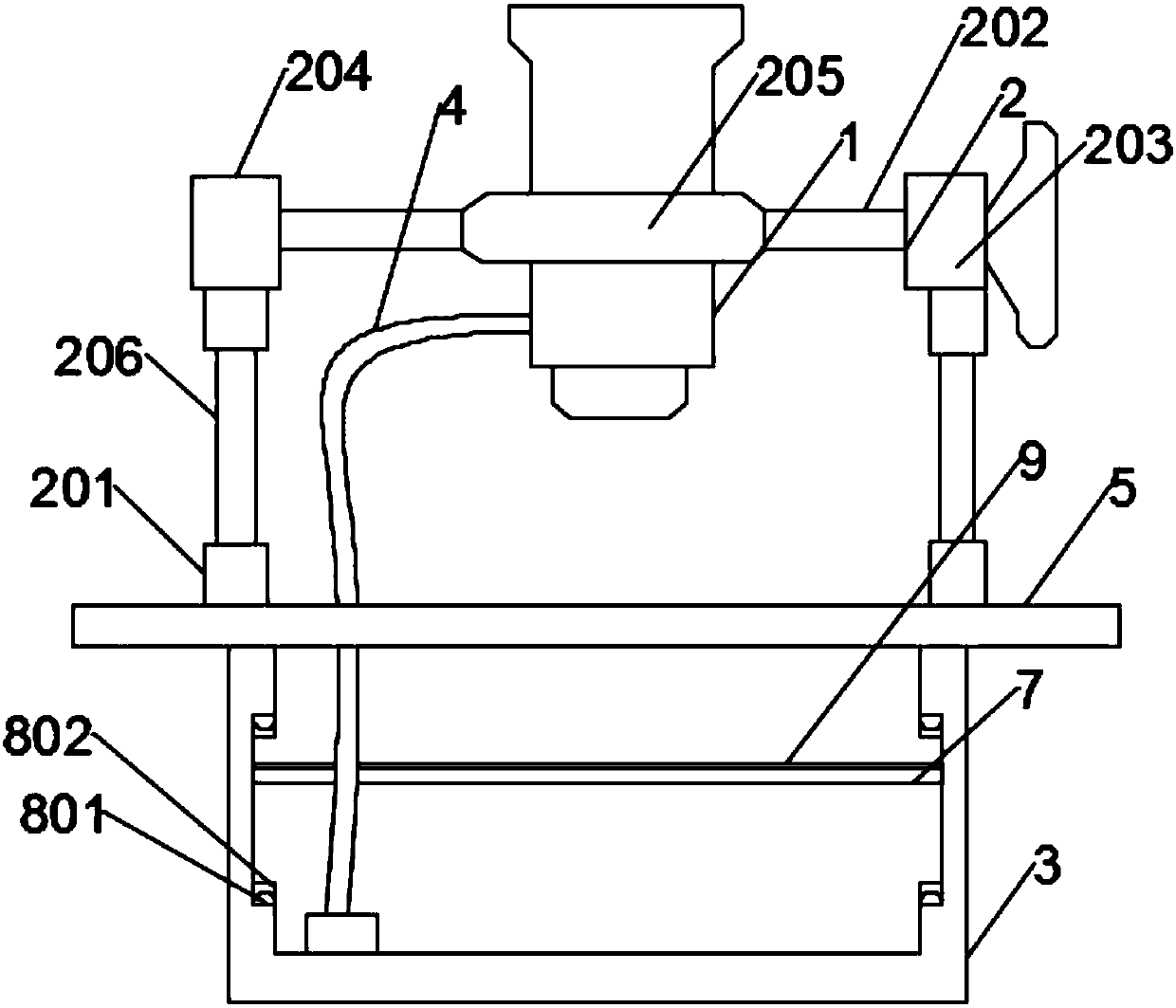

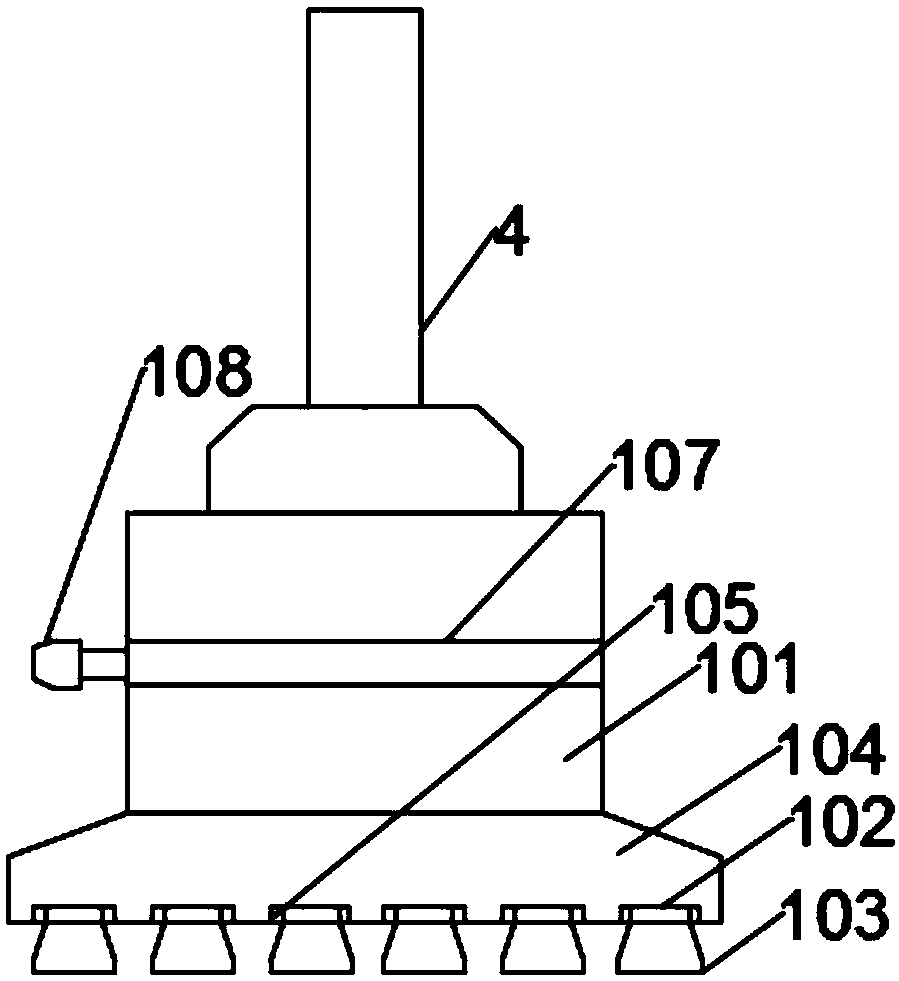

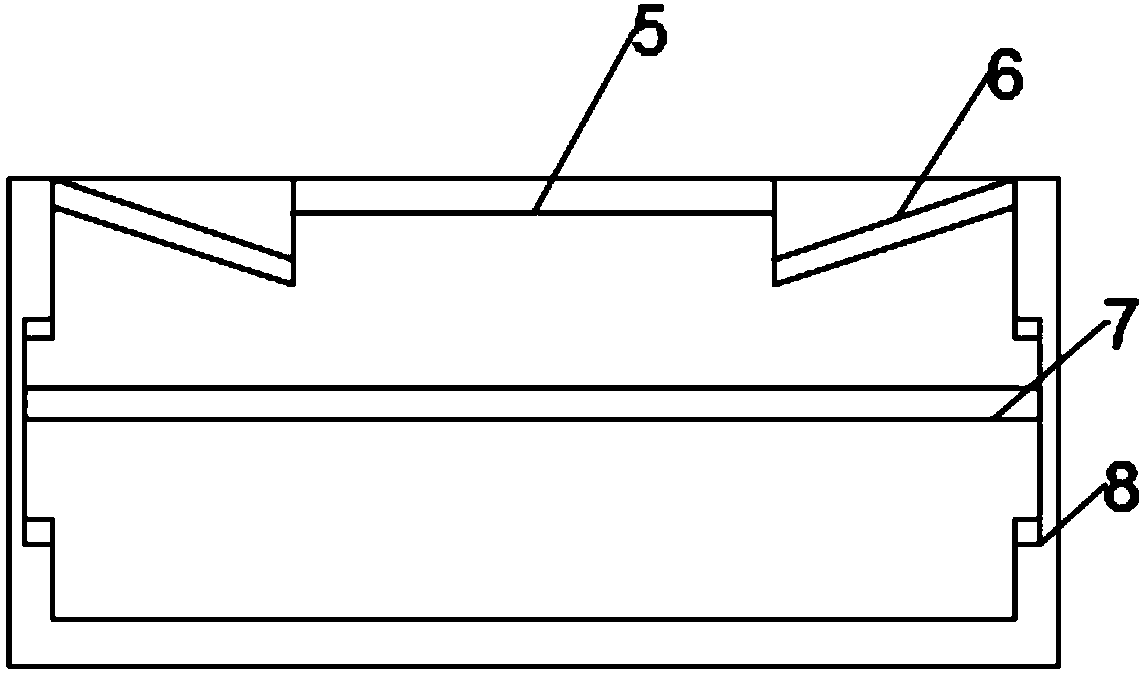

[0024] Such as Figure 1 to Figure 4 As shown, the present invention provides a glue spraying device of a packaging box glue applicator, comprising a glue spray head 1, an adjustment frame 2 and a glue supply cylinder 3, and the glue spray head 1 is connected to the glue supply cylinder 3 through the adjustment frame 2 Together, the glue spray head 1 is connected to the glue supply cylinder 3 through the glue spray hose 4 to spray glue, the top of the glue supply cylinder 3 is provided with a placement plate 5, and the adjustment frame 2 and the placement plate 5 are fixed Installed together, the adjustment frame 2 includes an adjustment rod 202 and two fixed rods 201, the top end of the fixed rod 201 at one end is provided with a connecting seat 203, and the top end of the fixed rod 201 at the other end is provided with a blocking seat 204, The adjustment rod 202 runs through the connecting seat 203, the surface of the adjustment rod 202 is provided with a mounting seat 205, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com