Use method of adhesive spraying device for wood plate frame

A frame and glue spraying technology, which is applied in the directions of spraying device, liquid spraying device, and device that coats liquid on the surface, etc., can solve the problems of high labor intensity of staff, difficult to guarantee product quality, and large influence of human factors, and achieves a high level of improvement. Glue spray efficiency, ensure service life, and improve the effect of glue coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

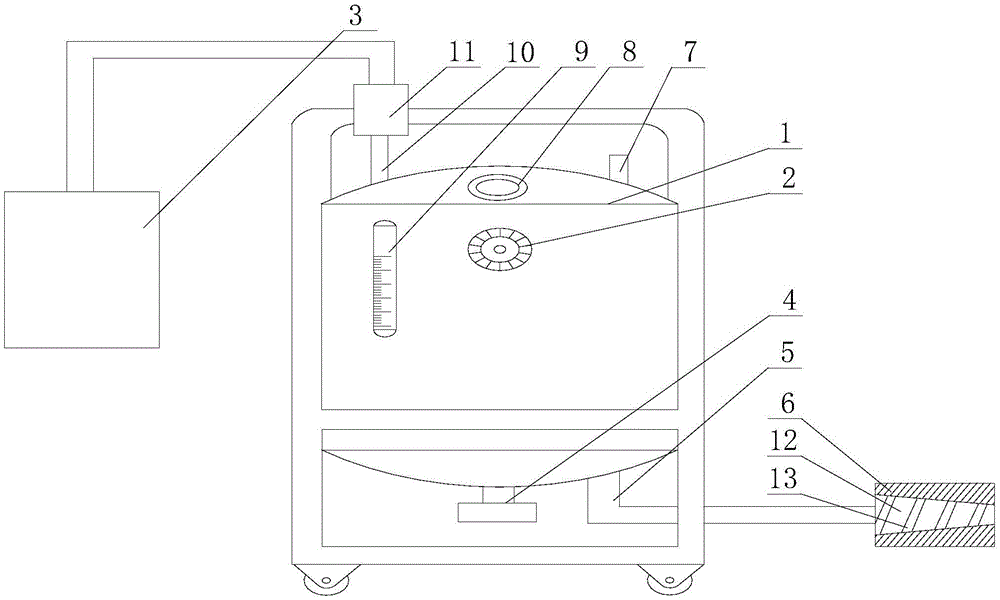

[0025] Such as figure 1 As shown, this embodiment includes the following steps:

[0026] A Fill a certain amount of glue into the tank through the glue inlet, and read the initial amount of glue inside the tank in real time through the liquid level gauge;

[0027] B Start the air pump, and the air flow starts to inject into the tank through the intake pipe. As the pressure in the tank increases, the glue is directly sprayed on the working surface of the wooden board through the rubber outlet pipe and the nozzle under the action of air pressure;

[0028] C When the glue passes through the nozzle, the inner diameter of the nozzle decreases along the direction of the glue exit, so that the glue passes through a flow channel between the glue outlet pipe and the nozzle that suddenly becomes smaller, and the glue exit speed of the unit flow rate suddenly accelerates ;The spiral protrusion can make the glue rotate at a high speed before spraying, and the glue can form a cone-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com