Cutting mechanism for slender inner circular round pipe

A technology of cutting mechanism and inner ring, which is applied in the direction of thread cutting machine, turning equipment, thread cutting device, etc., can solve the problems of limited angular velocity, slow feed speed, short processing distance, etc., and achieves improved orientation and penetration, higher than The effect of high bore speed and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

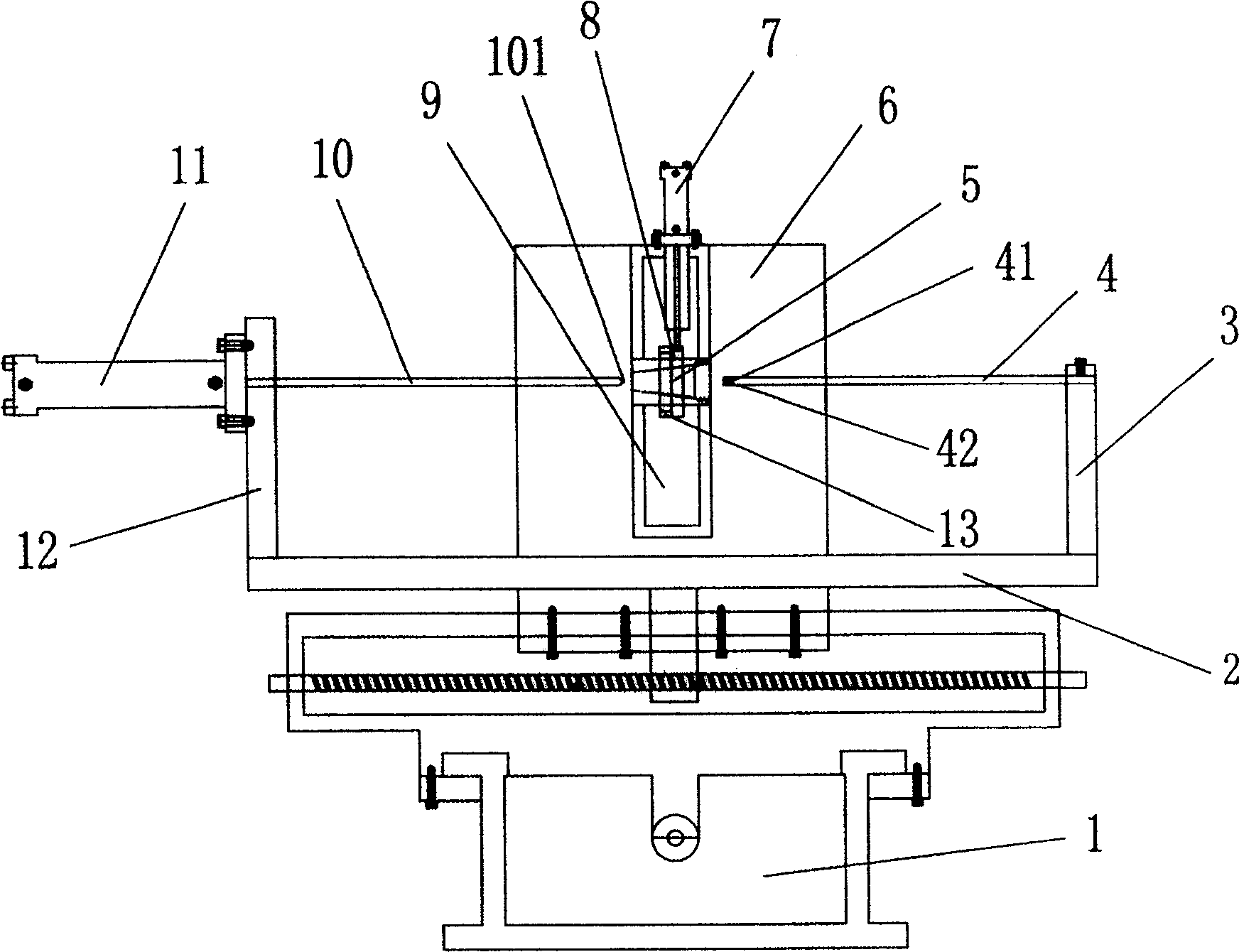

[0011] Attached below figure 1 Embodiments of the invention are illustrated:

[0012] A cutting mechanism for a slender inner annular tube is set on the adjustable workbench 1 of the two-dimensional work coordinates (position on the horizontal plane), and the cutting mechanism for the slender inner annular tube is set on its workbench 1. There is a base plate 2, a wall board 12 is arranged on one side of the base board 2, and a first hydraulic cylinder 11 is fixed on the wall board 12, and the first hydraulic cylinder 11 is connected with a push rod 10; 3 is provided with a cutter bar 4, and the front end of the cutter bar 4 is provided with a cutting edge 41, and the ejector rod 10 and the cutter bar 4 are opposite or reversely centered; The rod 10 is oppositely aligned with the cutter rod 4; generally, the ejector rod 10 and the cutter rod 4 are oppositely aligned, such as figure 1 As shown, the notch 42 of the cutter bar 4 cooperates with the tip 101 of the ejector rod. H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com