A kind of preparation method of horizontal self-sealing micro-propeller

A self-sealing, thruster technology, applied in the field of micro-propulsion technology and micro-electromechanical systems, can solve the problems of difficult to achieve propulsion direction control, low energy density, etc., to improve the ignition success rate and efficiency, improve energy density, and improve ignition efficiency. success rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

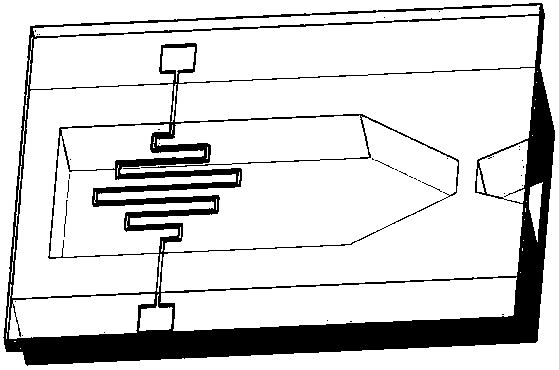

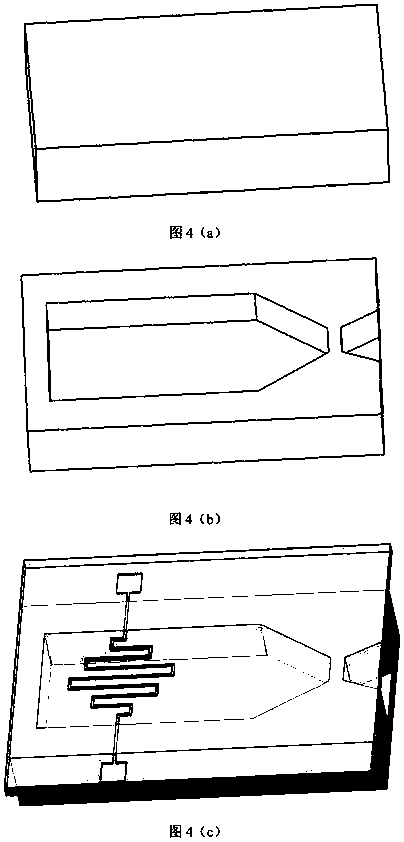

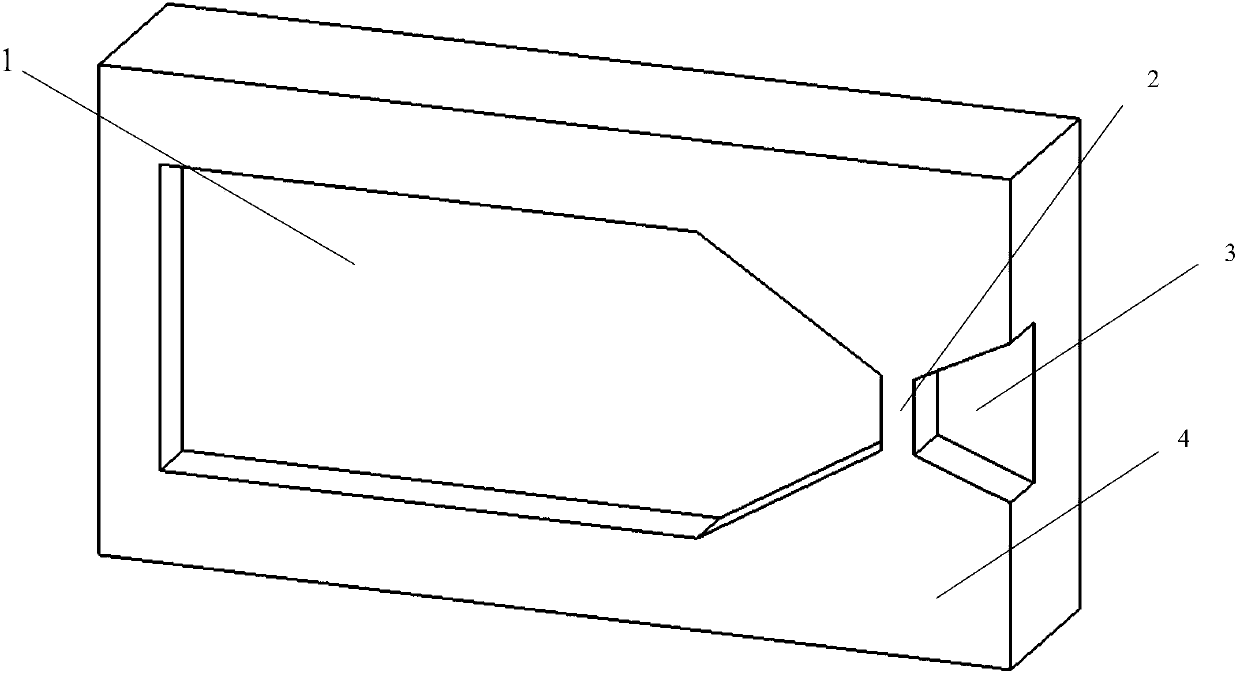

[0023] refer to figure 1 , figure 2 , the horizontal self-sealing micro-propeller in this embodiment includes a combustion chamber 1, an isolation layer 2, a nozzle 3, a silicon substrate 4, a glass sheet 5, an igniter 6, an ignition resistor 7, and a welding pad 8; The combustion chamber 1, the isolation layer 2 and the nozzle 3 are formed by dry etching on the silicon wafer. The shape and size of the combustion chamber 1 and the nozzle 3 can be changed according to the required amount of solid propellant and other It is required to design the shape and size, and the thickness of the isolation layer can also be calculated according to the thrust requirement and injection velocity, generally about 5-10 microns; the combustion chamber 1 is filled with solid propellant; The surface is sputtered with an ignition resistor 7 and a pad 8 to form an igniter 6; the ignition resistor 7 is composed of a snake-shaped folded gold film resistor, and the ignition resistor 7 can also be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com