Self-cleaning glue spraying machine

A glue spraying machine and self-cleaning technology, which is applied in the field of glue spraying machines, can solve the problems of low cleaning efficiency, increase labor intensity of workers, and affect the working efficiency of glue spraying machines, so as to improve glue spraying efficiency, clean up conveniently and quickly, and lower The effect of cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

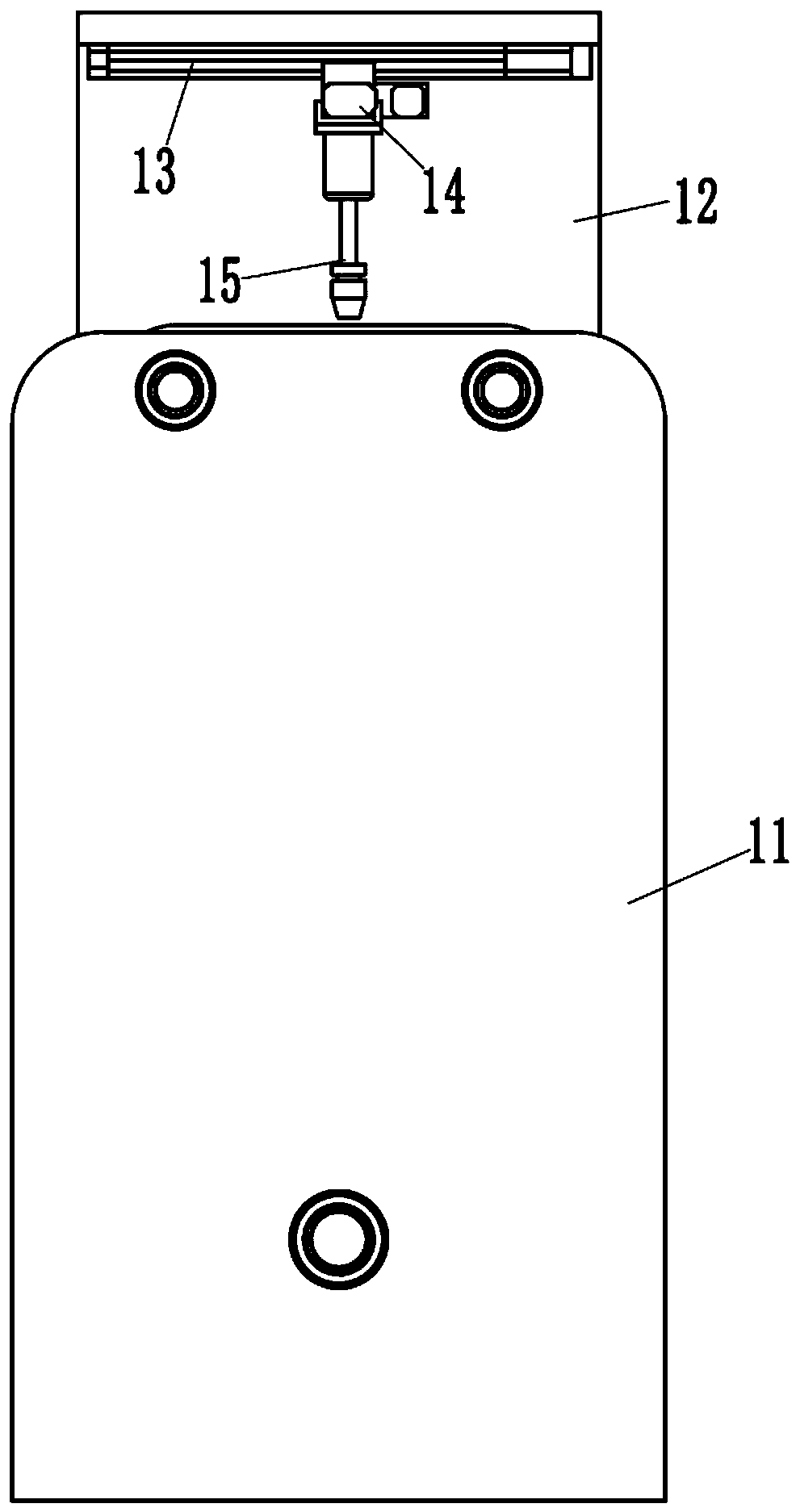

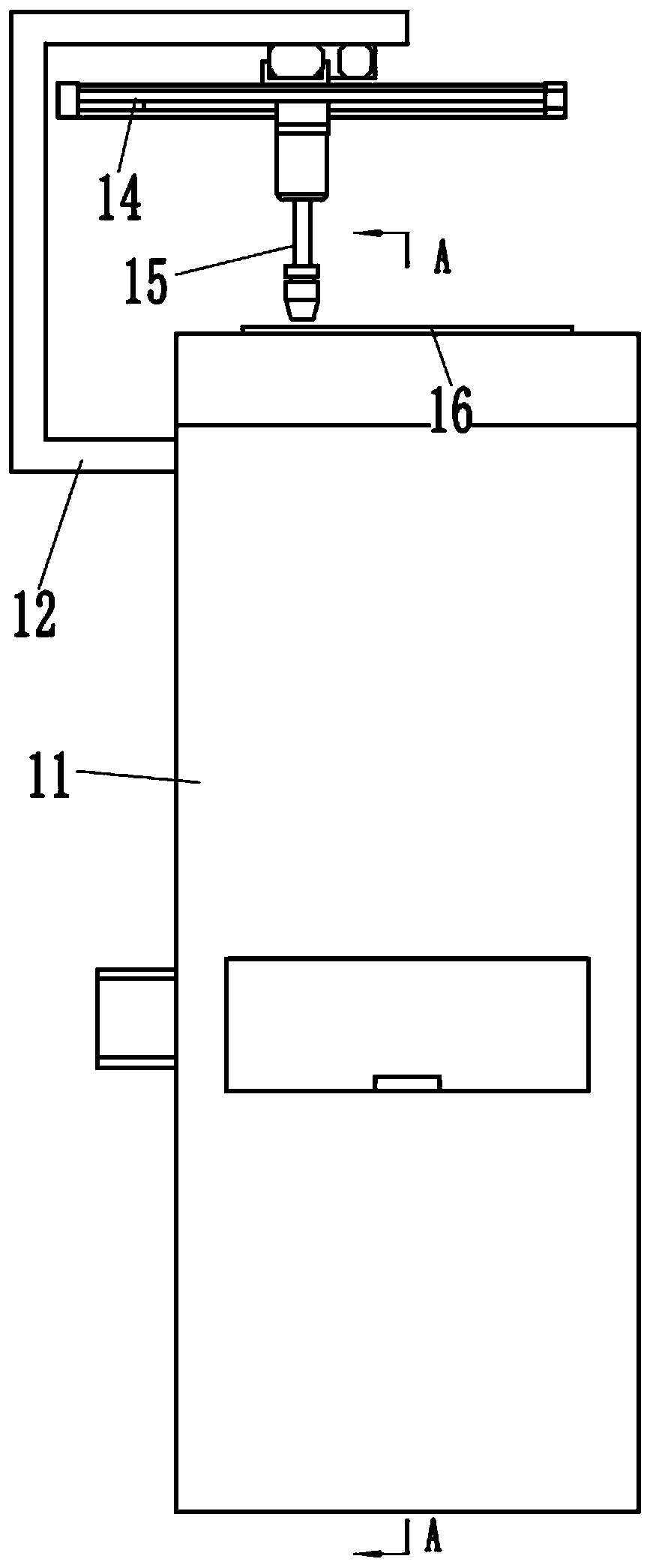

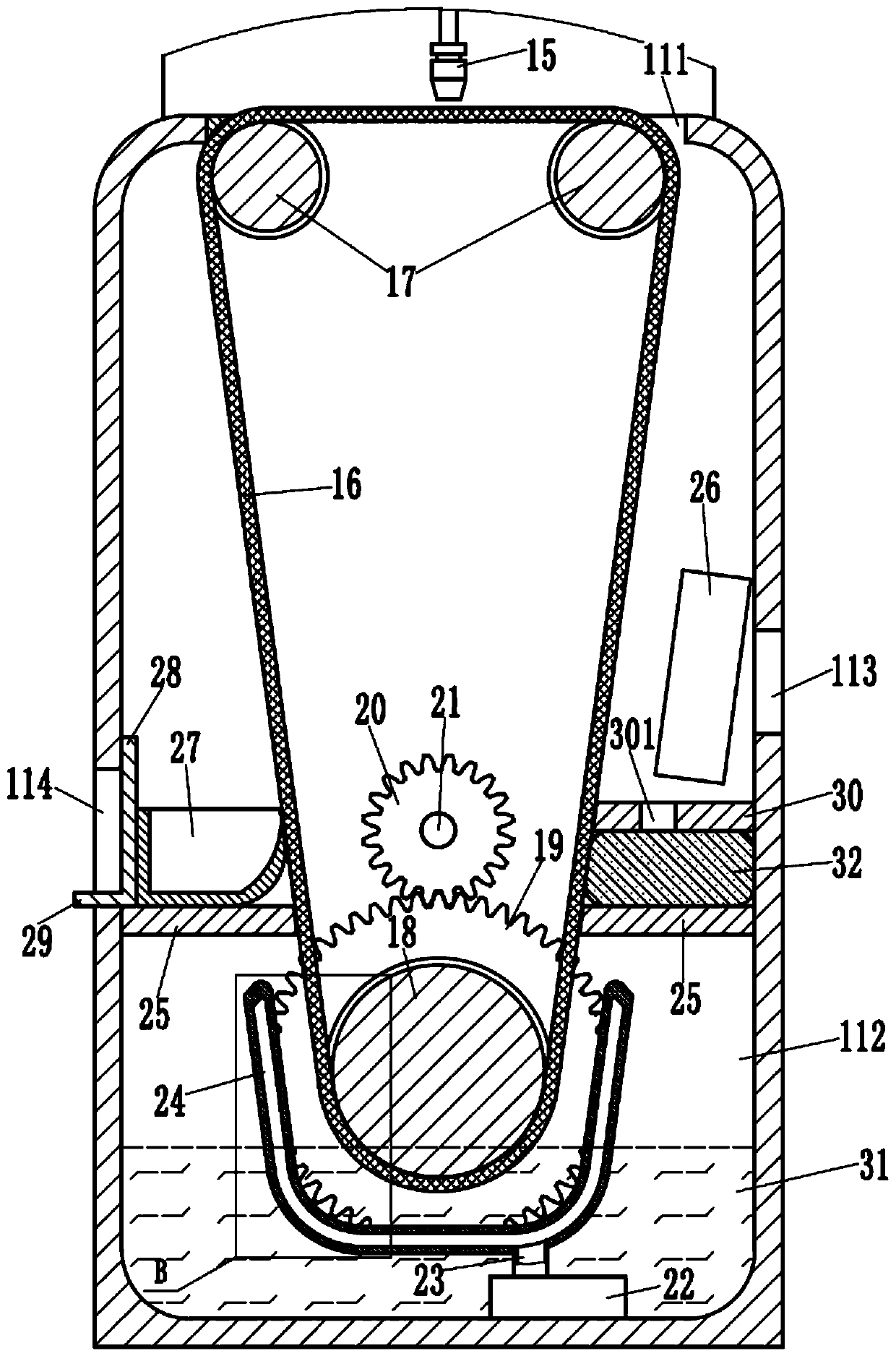

[0015] Examples, see e.g. Figure 1 to Figure 4 As shown, a self-cleaning glue spraying machine includes a chassis 11, a frame 12 is fixed on the rear side wall of the chassis 11, an X-axis linear module 13 is fixed on the frame 12, and the first X-axis linear module 13 A Y-axis linear module 14 is fixed on the slider, and a glue spray head 15 is fixed on the second slider of the Y-axis linear module 14. A gap 111 is formed on the upper side wall of the chassis 11. The glue spray head 15 The bottom of the belt is provided with a support belt 16, and the support belt 16 is tensioned on two driven pulleys 17 and a driving pulley 18 arranged at the same height, and the driving pulley 18 is located below the middle of the two driven pulleys 17, The two ends of driving pulley 18 and two driven pulleys 17 are respectively hinged on the front side wall and the rear side wall of cabinet 11; On the upper end surface of the gap 111, the rear end of the driving pulley 18 is fixed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com