Rapid packaging method of aerosol packaging system

A packaging method and packaging system technology, applied in packaging, packaging objects under special gas conditions, transportation and packaging, etc., can solve the problems of waste of drug resources, difficulty in debugging, chronic drug leakage, etc., and reduce the contact area and time , Improving the efficiency of finished drug products and avoiding the waste of drug resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. In the following description, the method of the present invention is applied to a preferred embodiment, which is only used as an example, and those skilled in the art can think of other obvious variants.

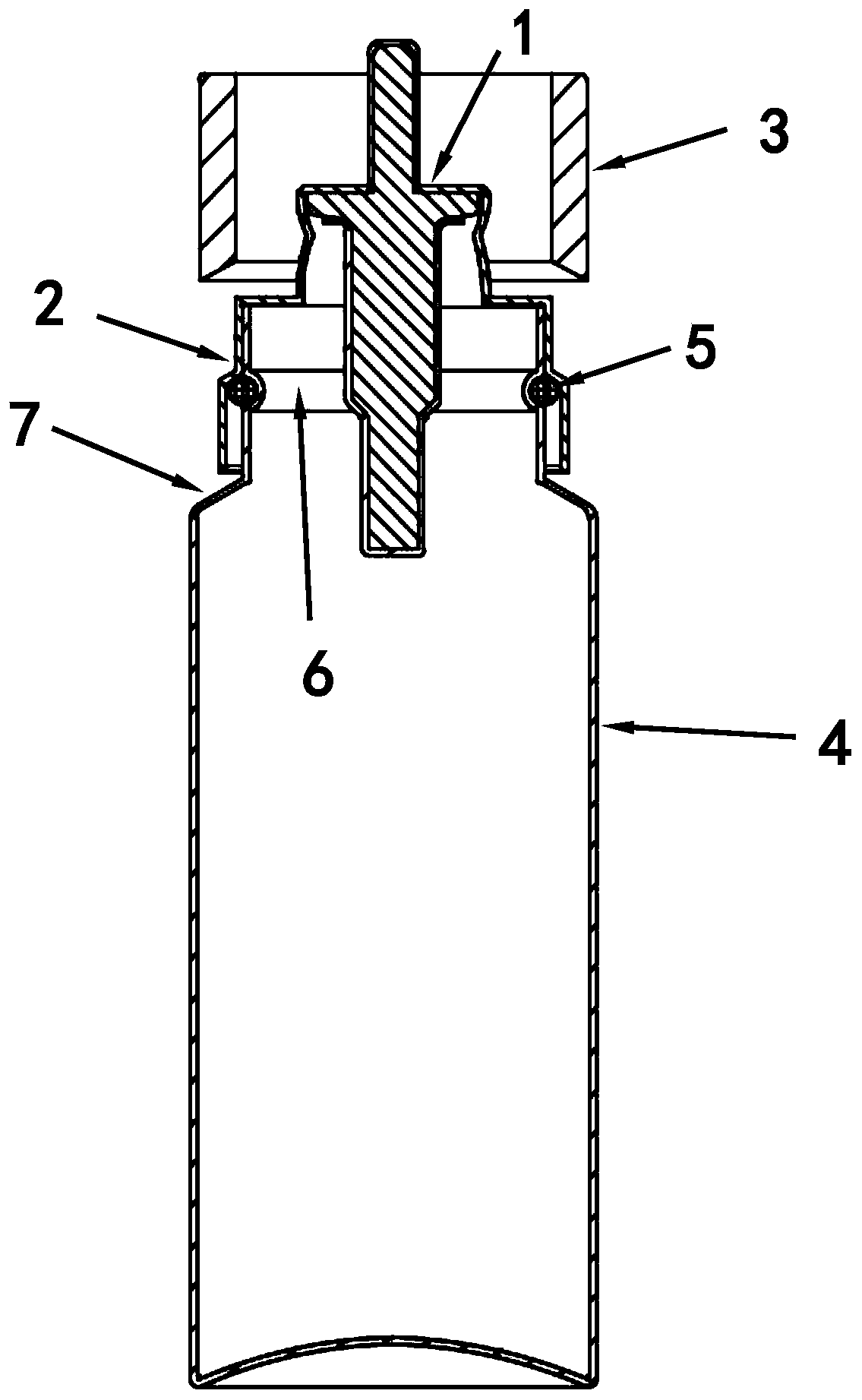

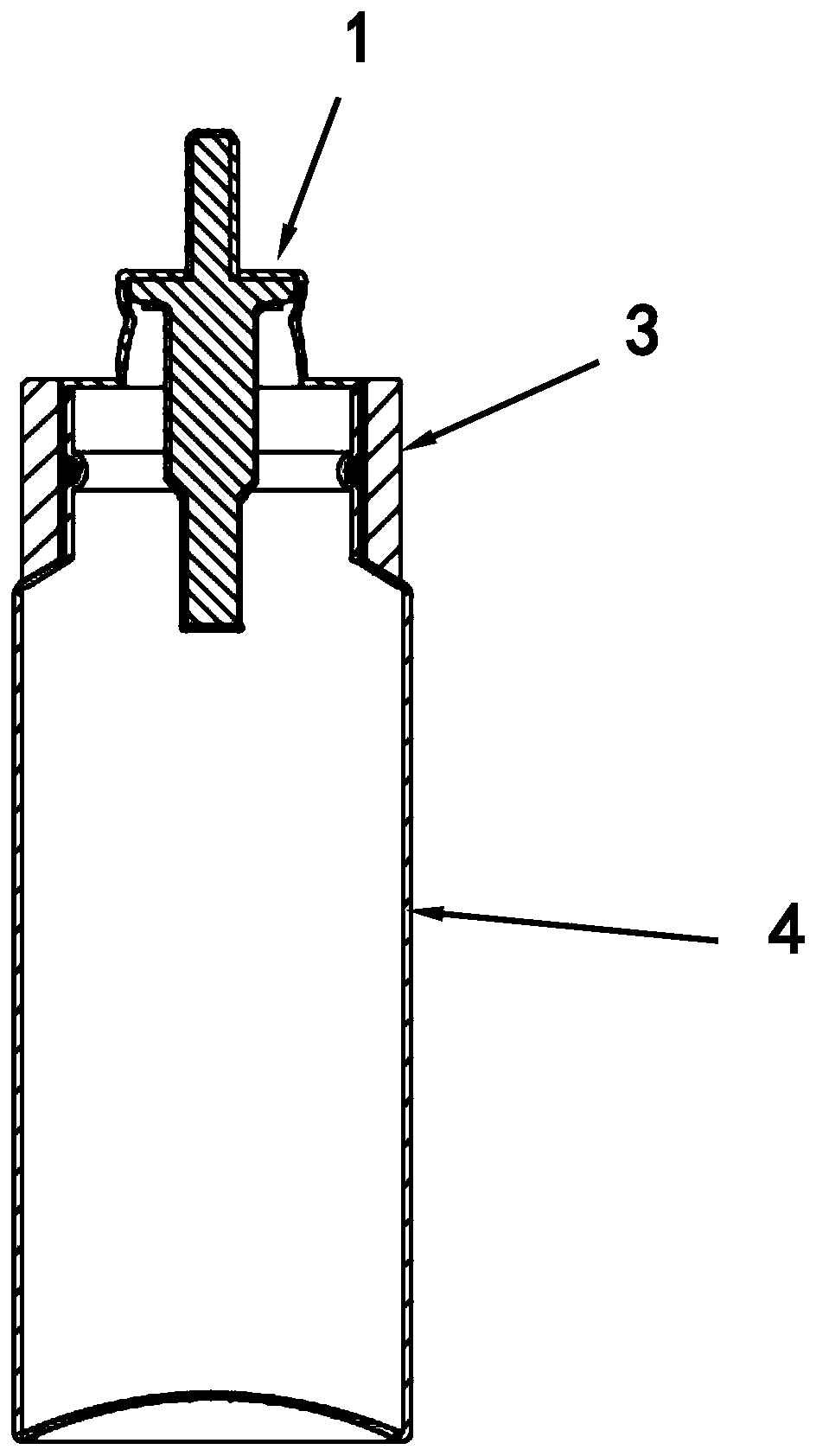

[0014] Such as Figure 1-2 As shown, a quick packaging method of the aerosol packaging system based on the sealing ring 3, the sealing sealing ring 5 and the assembly position of the sealing sealing ring 5 is characterized in that the quick packaging method is specifically carried out according to the following steps:

[0015] 1. Install the sealing ring 5: Assemble the sealing ring 5 into the sealing groove 6 below the mouth of the air inlet aerosol bottle 4, half of the sealing ring 5 is embedded in the sealing groove 6, and half is exposed outside the sealing groove 6.

[0016] 2. Install the aerosol quantitative valve 1: the ae...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com