Novel piston used in plunger type water pump

A plunger-type, water-pump technology, applied in the components of the pumping device for elastic fluid, variable-capacity pump components, pump components, etc., can solve the problems of great influence and high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

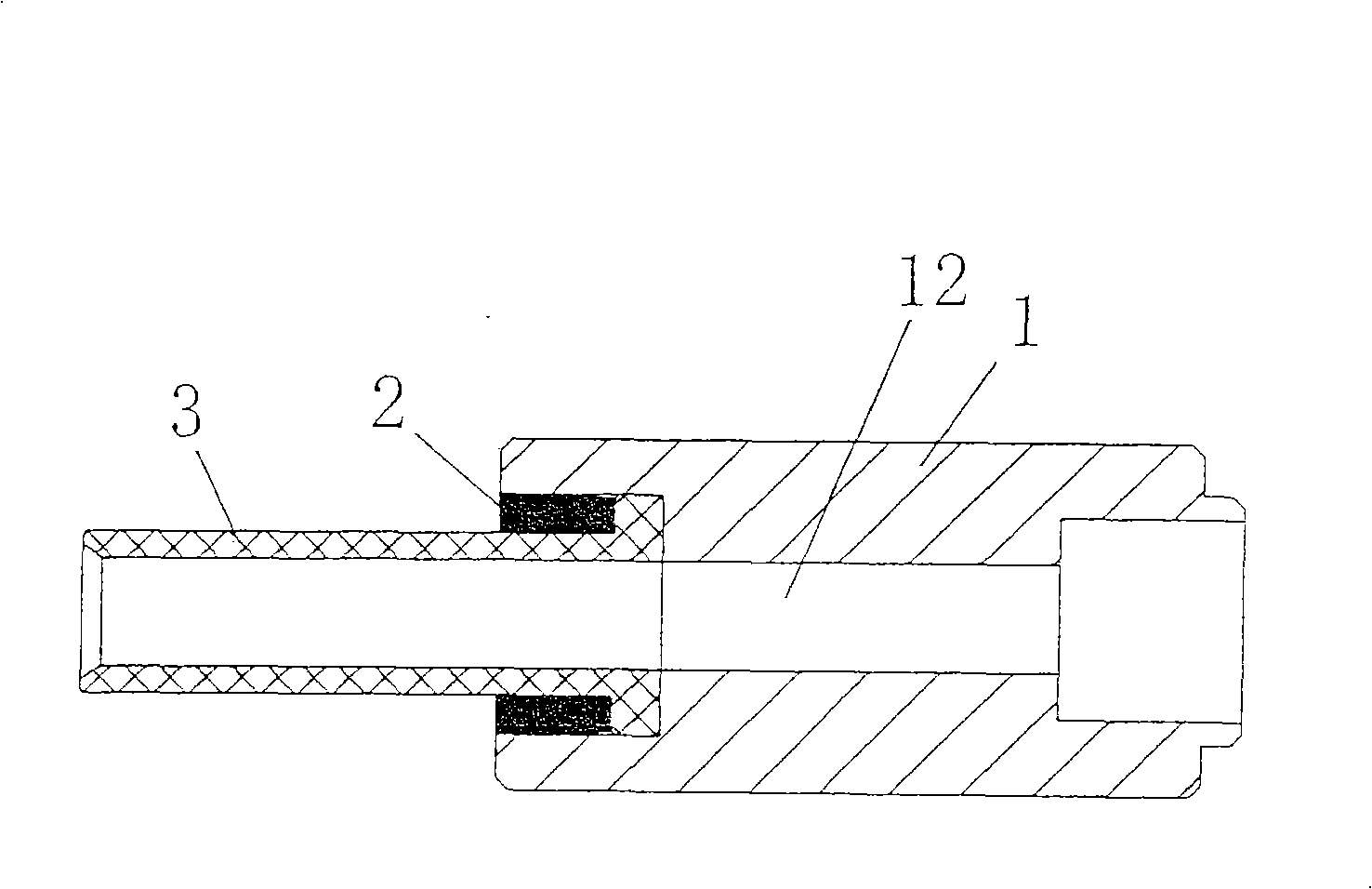

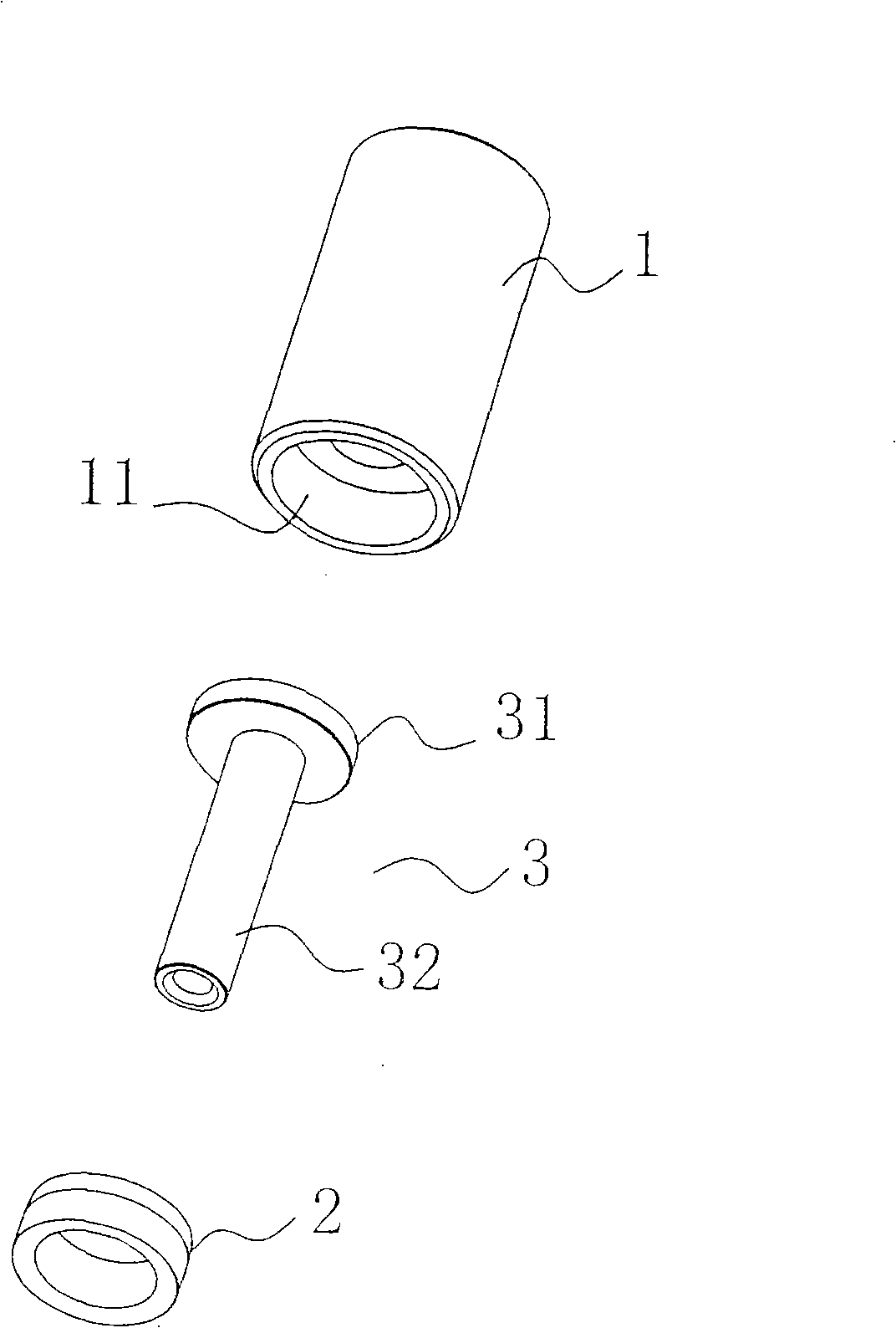

[0016] Such as Figure 1-6 As shown, the reciprocating piston in the plunger type water pump is composed of a metal core 1, a fixed ring 2, and a piston head 3; the metal core 1 made of magnetically conductive metal material is a hollow column structure, and its connection end is provided with a concave Groove 11, the groove 11 communicates with the hollow through hole 12 of the metal core 1, and the axes of the two coincide;

[0017] The piston head 3 has a "T"-shaped hollow structure, and the cross section of the connecting end 31 of the piston head 3 is slightly larger than the cross section of the piston head shaft 32;

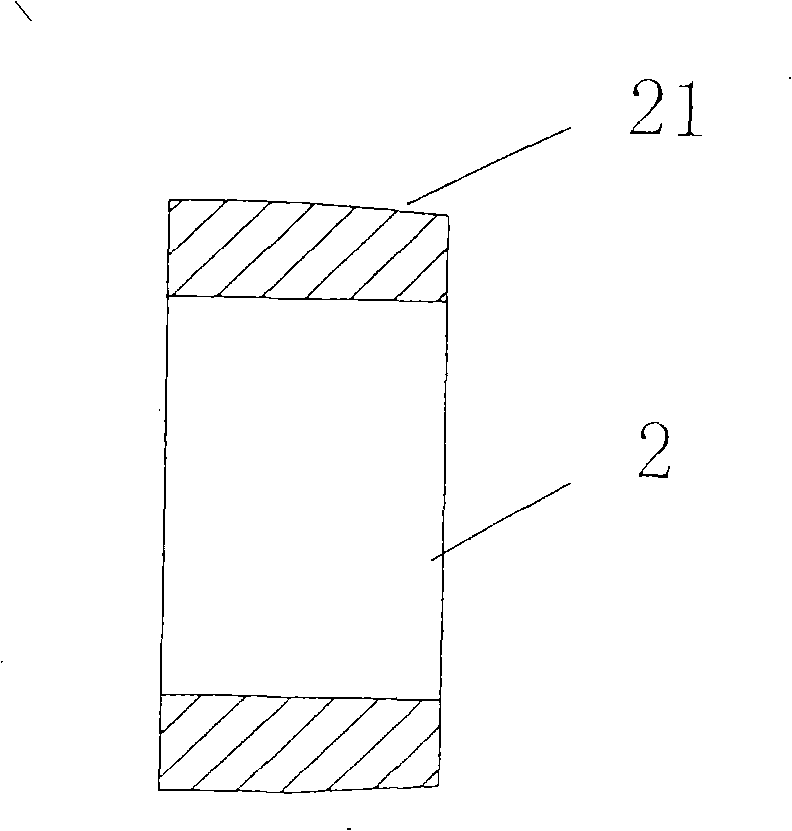

[0018] The inner hole of the fixing ring 2 is just enough to be sleeved on the shaft 32 of the piston head 3, and the shape and size of the outer cross-section of the fixing ring 2 and the shape and size of the cross-section of the groove 11 of the metal core 1 are interference fit;

[0019] The depth of the groove 11 of the metal core 1 is greater than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com