Horizontal hand feeling wood grain metal heat transfer printing process

A technology of metal thermal transfer printing and hand feeling, applied in printing, copying/marking methods, special surfaces, etc., can solve the problems of wood grain printing and background color easy to fall off, high cost, uneven spraying, etc., and achieve high product efficiency, Improved binding force and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

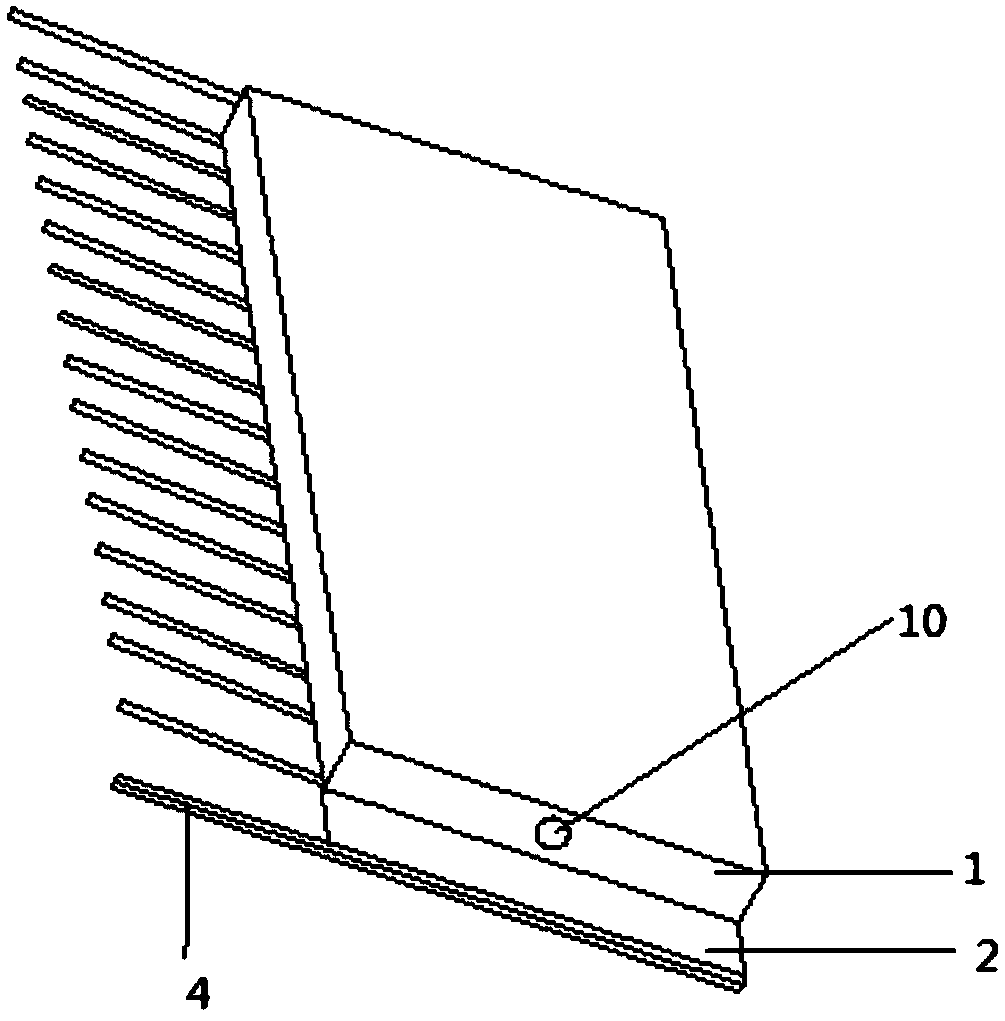

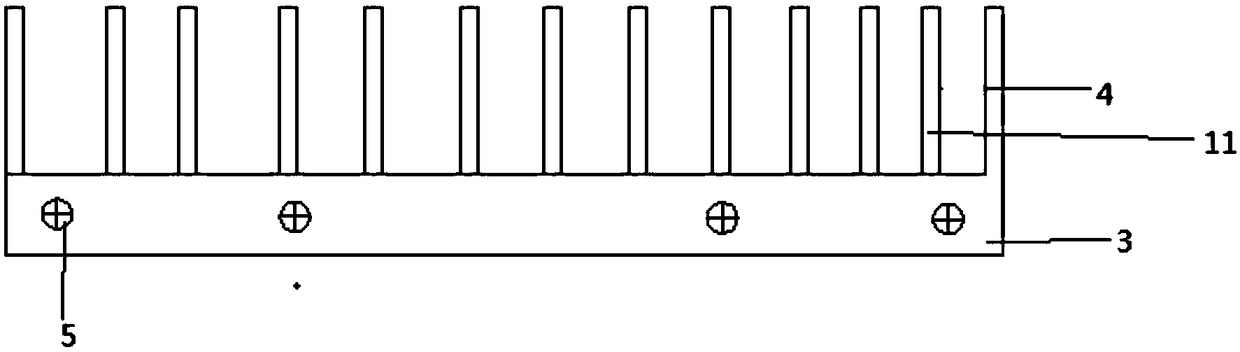

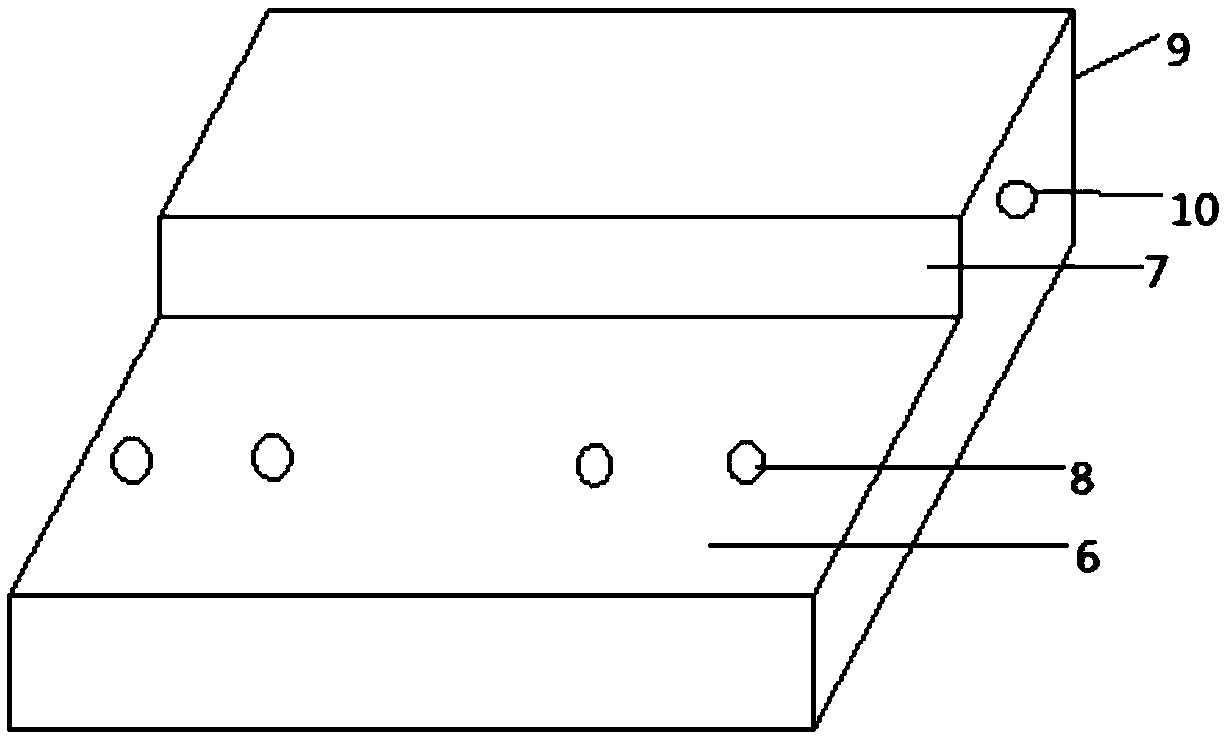

[0034] A horizontal hand feeling wood grain metal thermal transfer printing process is characterized in that its production process includes the following steps:

[0035] S1 metal prototype pretreatment: use pure water to dedust the metal prototype, then carry out degreasing and chemical removal treatment in turn, and then still wash with pure water, go through chromium-free passivation treatment, and finally wash with pure water to complete the pretreatment ;

[0036] S2 baking: Put the pretreated metal prototype into the baking room for drying to remove the residual moisture on the surface and increase the surface adhesion;

[0037] S3 spraying: After the metal prototype material obtained in step S2 is blown and dust-removed with a blower, the material is hung, and the powder electrostatic spraying primer is carried out in the spray booth;

[0038] S4 curing: Send the metal prototype material sprayed with the primer in step S3 into the baking room, after curing at high temp...

Embodiment 2

[0052]A horizontal hand feeling wood grain metal thermal transfer printing process is characterized in that its production process includes the following steps:

[0053] S1 metal prototype pretreatment: use pure water to dedust the metal prototype, then carry out degreasing and chemical removal treatment in turn, and then still wash with pure water, go through chromium-free passivation treatment, and finally wash with pure water to complete the pretreatment ;

[0054] S2 baking: Put the pretreated metal prototype into the baking room for drying to remove the residual moisture on the surface and increase the surface adhesion;

[0055] S3 spraying: After the metal prototype material obtained in step S2 is blown and dust-removed with a blower, the material is hung, and the powder electrostatic spraying primer is carried out in the spray booth;

[0056] S4 curing: Send the metal prototype material sprayed with the primer in step S3 into the baking room, after curing at high tempe...

Embodiment 3

[0070] A horizontal hand feeling wood grain metal thermal transfer printing process is characterized in that its production process includes the following steps:

[0071] S1 metal prototype pretreatment: use pure water to dedust the metal prototype, then carry out degreasing and chemical removal treatment in turn, and then still wash with pure water, go through chromium-free passivation treatment, and finally wash with pure water to complete the pretreatment ;

[0072] 0S2 Baking: Put the pretreated metal prototype into the baking room for drying to remove the residual moisture on the surface and increase the surface adhesion;

[0073] S3 spraying: After the metal prototype material obtained in step S2 is blown and dust-removed with a blower, the material is hung, and the powder electrostatic spraying primer is carried out in the spray booth;

[0074] S4 curing: Send the metal prototype material sprayed with the primer in step S3 into the baking room, after curing at high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com