Patents

Literature

120 results about "Goose feathers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing graphene powder

InactiveCN101966988AGood dispersionIncrease the amount of dissolutionBulk chemical productionCentrifugationReaction temperature

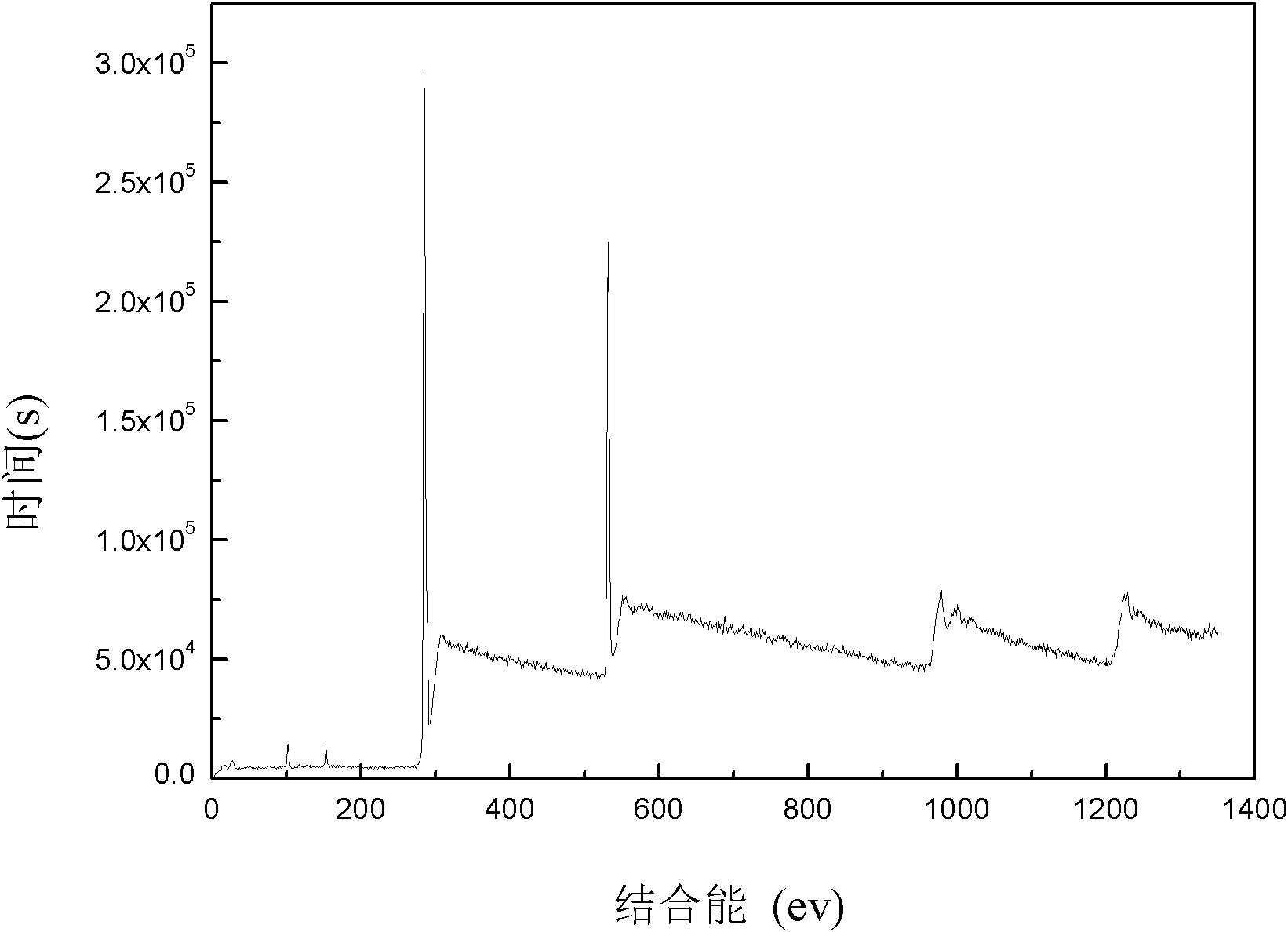

The invention discloses a method for preparing graphene powder, which belongs to the field of graphene preparation and aims to solve the technical problems of low efficiency, low yield and environmental protection in the conventional graphene preparation methods. The method of the invention comprises the following steps of: 1, preparing graphite oxide; 2, stripping the graphite oxide; 3, performing purification, namely, performing centrifugation treatment and collecting upper-layer solution; and 4, controlling the reaction temperature to be above the supercritical temperature of a solvent in the step 2 to perform reaction for 1 to 24 hours under the conditions of the protection of an inert gas and the pressure of 20 to 100 MPa, naturally cooling or quenching with water a reaction kettle, and slowly exhausting the gas from the kettle to obtain the graphene powder. The graphene powder prepared by the method is goose feather-like black fluffy powder. The method of the invention has the advantages of the high efficiency of 100 percent, high yield and less environmental pollution.

Owner:HARBIN INST OF TECH

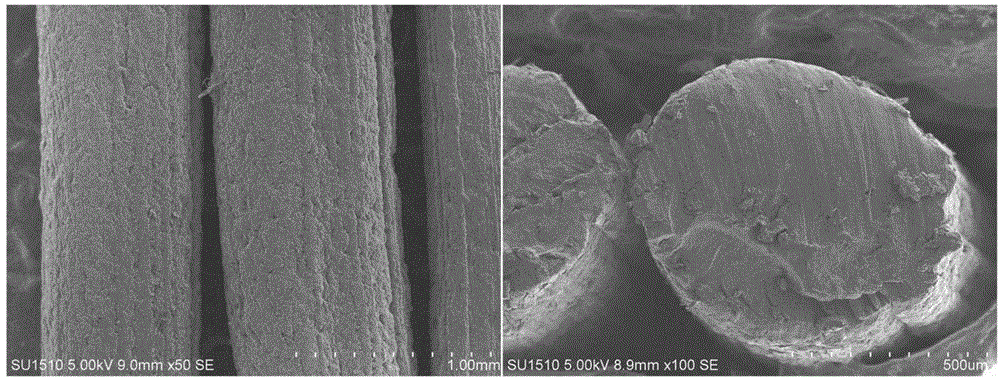

Preparation method of keratin complex fiber

InactiveCN104862818AReduce pollutionTime-consuming and laborious to solveConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberSolvent

The invention relates to a preparation method of keratin complex fiber, which comprises the following steps: 1, mixing the dried keratin powder, high polymer for fiber forming, ionic liquid and the like, and mechanically stirring and dissolving to obtain a keratin complex solution at certain temperature; (2) preparing a keratin complex fiber by using a dry jet wet spinning process. According to the invention, the keratin used according to the invention comes from leftovers of processing industry such as chicken feather, drake feather, goose feather and wool, and as for the recycle of the waste, on one hand, the economic benefit is increased, on the other hand, the environment pollution can be reduced. The selected high polymer for fiber forming and keratin can dissolve together in the same ionic liquid, so that the characteristics of high efficiency, simpleness and convenience can be achieved. Compared with the pure keratin fiber, the strength and elongation at break of the spun regenerated keratin can be improved greatly, the practical use value can be increased; the keratin complex fiber has wide potential application in the fields of clothing, wig, tissue engineering and the like. In addition, the solvent ionic liquid can be completely recycled, can not pollute the environment and has the meaning of sustainable development.

Owner:JIANGNAN UNIV

Special fertilizer for cotton base fertilizer

InactiveCN102816023AReduce invalid releaseIncrease the chelating structureFertilizer mixturesDisease damageManganese

The invention discloses a special fertilizer for a cotton base fertilizer. The special fertilizer is prepared by silkworm excrement, wintergreen oil residue, decomposed coal, diatomite, biological bacteria, urea, diammonium hydrogen phosphate, potassium sulfate, goose feather bar, carboxymethylcellulose, 35% of sulfuric acid, lime, zinc sulfate, magnesium sulfate, manganese sulfate, nanometer iron-ore tailing powder, sweet wormwood extract, azadirachtin and wintergreen oil according to a certain weight ratio. According to the special fertilizer, amino acid is generated by feathers after acid hydrolysis, trace elements or secondary elements are cheated, and a chelate structure of the trace elements or the secondary elements is reinforced by the carboxymethylcellulose, so that the trace elements or the secondary elements can be effectively utilized and ineffective releases of the trace elements or the secondary elements can be reduced; an inorganic slow release component and a soil improvement component, namely the diatomite and the decomposed coal, are added in a formula of the special fertilizer to improve the soil and to be beneficial to the effective release of fertilizer efficiency and full absorption of the fertilizer by the crops; biological insecticide components, namely the nanometer iron-ore tailing powder, the sweet wormwood extract and the azadirachtin can effectively reduce pest and disease damage of soil, are safe and pollution-free, and do not pollute an environment or the crops; and the special fertilizer has the advantages that the formula is reasonable, the nutrition is more comprehensive and balanced, the use effect is good, the utilization rate of fertilizer efficiency can be remarkably increased, the yield and the quality of cotton are greatly improved, and the economic benefit of the cotton is increased.

Owner:MAANSHAN KEBANG ECO FERTILIZER

Special fertilizer for single cropping rice

InactiveCN102815998AReduce invalid releaseIncrease the chelating structureClimate change adaptationAgriculture gas emission reductionSodium BentonitePaulownia

The invention discloses a special fertilizer for single cropping rice. The special fertilizer is prepared by traditional Chinese medicine residue, nanometer iron-ore slag powder, wood charcoal, sepiolite, bacterial bacteria, urea, calcium superphosphate, potassium chloride, goose feather, carboxymethylcellulose, 30% of sulfuric acid, lime, zinc sulfate, ferrous sulfate, sodium molybdate, paulownia saw powder, rhizoma nardostachyos extract, willow branch powder and wintergreen oil according to a certain weight ratio. According to the special fertilizer, amino acid is generated by feathers after acid hydrolysis, trace elements or secondary elements are cheated, and a chelate structure of the trace elements or the secondary elements is reinforced by the carboxymethylcellulose, so that the trace elements or the secondary elements can be effectively utilized and ineffective releases of the trace elements or the secondary elements can be reduced; an inorganic slow release component and a soil improvement component, namely the bentonite and the wood charcoal, are added in a formula of the special fertilizer to improve the soil and to be beneficial to the effective release of fertilizer efficiency and full absorption of the fertilizer by the crops; biological insecticide components, namely the paulownia saw powder, the rhizoma nardostachyos extract and the willow branch powder, can effectively reduce pest and disease damage on the soil, are safe and pollution-free, and do not pollute an environment or the crops; and the special fertilizer has the advantages that the formula is reasonable, the nutrition is more comprehensive and balanced, the use effect is good, the utilization rate of fertilizer efficiency can be remarkably increased, the yield of the single cropping rice is greatly increased, the quality of the single cropping rice is greatly improved, and the economic benefit of the single cropping rice is increased.

Owner:如皋市玺运生态农业科技有限公司

Down feather composite fiber modified by polypropylene fiber and preparation method of down feather composite fiber

InactiveCN104195664AThe ratio is scientific and reasonableDelicate feelMonocomponent protein artificial filamentArtifical filament manufactureSucrosePhosphoric acid

The invention discloses a down feather composite fiber modified by polypropylene fiber. The down feather composite fiber modified by polypropylene fiber is prepared from the following raw materials in parts by weight: 18-20 parts of superfine duck down powder, 25-30 parts of puffed goose feather powder, 12-15 parts of polypropylene fiber, 3-5 parts of kaolin, 0.3-0.6 part of calcium saccharate, 1-2 parts of wolfberry fruit, 2-4 parts of fruit of Chinese magnoliavine, 1-3 parts of radix rehmanniae, 3-5 parts of cucumber juice, 0.1-0.3 part of ammonium dihydrogen phosphate, 120-130 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 110-140 parts of 1-ethyl-3-diethyl methyl imidazole phosphoric acid, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber modified by polypropylene fiber, the components such as the polypropylene fiber, the wolfberry fruit, the fruit of Chinese magnoliavine and the radix rehmanniae are added; the prepared product is soft and smooth in hand feeling, has the characteristics of the down feather, also has the characteristics of being light, soft, warm, breathable, moisture permeable, mildew-proof, mothproof and washable, and is wide in application prospect and further and more competitive in the market.

Owner:ANHUI LION GOOSE PROD

Fertilizer specially used for winter wheat base fertilizer

InactiveCN102816026AReduce invalid releaseIncrease the chelating structureFertilizer mixturesAdditive ingredientInsect pest

The invention discloses a fertilizer specially used for a winter wheat base fertilizer. The fertilizer is prepared from silkworm bombycis, peanut bran, fulvic acid, diatomite, biological bacteria, urea, diammonium phosphate, potassium sulfate, goose feathers, carboxymethylcellulose, sulfuric acid having a concentration of 30%, lime, ferrous sulfate, zinc sulfate, borax, garlic powder, nanoscale iron ore tailing powder, radix euphorbiae lantu powder and wintergreen oil according to a certain weight ratio. In the invention, the goose feathers are hydrolyzed by acids and medium and trace elements are chelated and carboxymethylcellulose improves a chelate structure, is conducive to effective utilization of the medium and trace elements, and reduces invalid release of the medium and trace elements. A formula of the fertilizer provided by the invention utilizes an inorganic slowly-released component of diatomite and a soil improvement component of fulvic acid so that soil is improved and effective release of active fertilizer ingredients and full crop uptake are promoted, and utilizes garlic powder, nanoscale iron ore tailing powder and radix euphorbiae lantu powder as biological insecticidal components so that plant insect pests in soil are effectively reduced and safety and no pollution on the environment and crops are realized. The fertilizer provided by the invention has the reasonable formula, contains comprehensive and uniform nutrients, has good use effects, obviously improves fertilizer efficiency, greatly improves a yield and quality of winter wheat, and improves economic benefits of winter wheat.

Owner:如皋市玺运生态农业科技有限公司

Compound feed for improving feather quality of medium and big meat gooses and preparation method thereof

The invention discloses a perfect compound feed which comprises corn, soybean meal, cottonseed meal, whole-milk rice bran, rice bran meal, wheat, wheat bran, brewer's grain, alfalfa meal, soybean oil, baking soda, table salt, calcium hydrophosphate, calcium powder, lysine hydrochloride, methionine, choline chloride, mould inhibitor, antioxidant, microelement additive and vitamin complex. The feed disclosed by the invention conforms to various nutritive indexes necessary to the medium and big gooses in the growth process, can prevent the wing curling of the medium and big gooses, and obviously improves the feather quality of the medium and big gooses.

Owner:铁骑力士食品有限责任公司

Special organic/inorganic composite biological pesticide fertilizer for mulberry and preparation method thereof

The invention discloses special organic / inorganic composite biological pesticide fertilizer for mulberry. The fertilizer consists of the following raw materials in percentage by weight: 18-23 parts of fowl manure, 12-16 parts of cow dung, 12-26 parts of sheep manure, 10-15 parts of straw, 5-10 parts of peat soil, 6-12 parts of animal bone meal, 6-9 parts of tree leaves, 5-8 parts of mushroom slag, 14-16 parts of urine, 11-13 parts of calcium superphosphate, 13-15 parts of calcium nitrate, 9-12 parts of potassium sulfate, 0.07-0.11 part of ammonium molybdate, 1.8-2.2 parts of copper sulfate, 0.9-1.3 parts of manganese sulfate, 4-6 parts of ferrous sulfate, 11-14 parts of potassium humate, 5-7 parts of egg shell powder, 0.05-0.1 part of borax, 13-15 parts of goose feather, 5-6 parts of microorganism yeast, 9-12 parts of celastrus orbiculatus, 5-6 parts of azadirachtin and 5-7 parts of monkshood. The composite biological pesticide fertilizer has the advantages of being remarkable in yield increase benefit, integrated in fertilization and sterilization, environment-friendly and free from pollution.

Owner:合肥科友生物科技有限公司

Down feather composite fiber compounded by waste down feather fiber and acrylic staple fiber and preparation method of down feather composite fiber

ActiveCN104195665AEfficient use ofPrevent mildew and insectsMonocomponent protein artificial filamentSpinning solutions preparationPerilla frutescensMaterials science

The invention discloses a down feather composite fiber compounded by waste down feather fiber and acrylic staple fiber. The down feather composite fiber compounded by the waste down feather fiber and the acrylic staple fiber is prepared from the following raw materials in parts by weight: 10-15 parts of superfine goose down powder, 20-25 parts of waste down feather fiber, 25-30 parts of nano goose feather powder, 18-20 parts of acrylic staple fiber, 14-17 parts of collagen fiber, 7-9 parts of nano bamboo charcoal powder, 17-21 parts of coconut shell, 0.3-0.6 part of magnesium oxide, 1-3 parts of perilla frutescens bark, 2-4 parts of rhizoma smilacis glabrae, 13-15 parts of rice straw pulp fiber, 100-120 parts of 1-butyl-3-methyl imidazole dibutyl phosphate, 120-140 parts of 1,3-dimethyl imidazole dimethyl phosphate, 2-4 parts of additives and a proper amount of water. According to the down feather composite fiber compounded by the waste down feather fiber and the acrylic staple fiber, the waste down feather fiber is effectively used; the cost is reduced; meanwhile, perilla frutescens bark and rhizoma smilacis glabrae are added in the down feather composite fiber, so that the mildew and moth of the down feather composite fiber during the storage, transportation and utilization of the down feather composite fiber can be effectively avoided; especially, after the down feather composite fiber is used as a filler and made into articles of daily use, due to the bacteria resistance and bacteriostasis of the down feather composite fiber, the corresponding products have the obvious antibacterial, anti-inflammatory, deodorant, mildew-proof, anit-pruritic and astringent functions, have no stimulation to the skin and are well received by consumers.

Owner:ANHUI LION GOOSE PROD

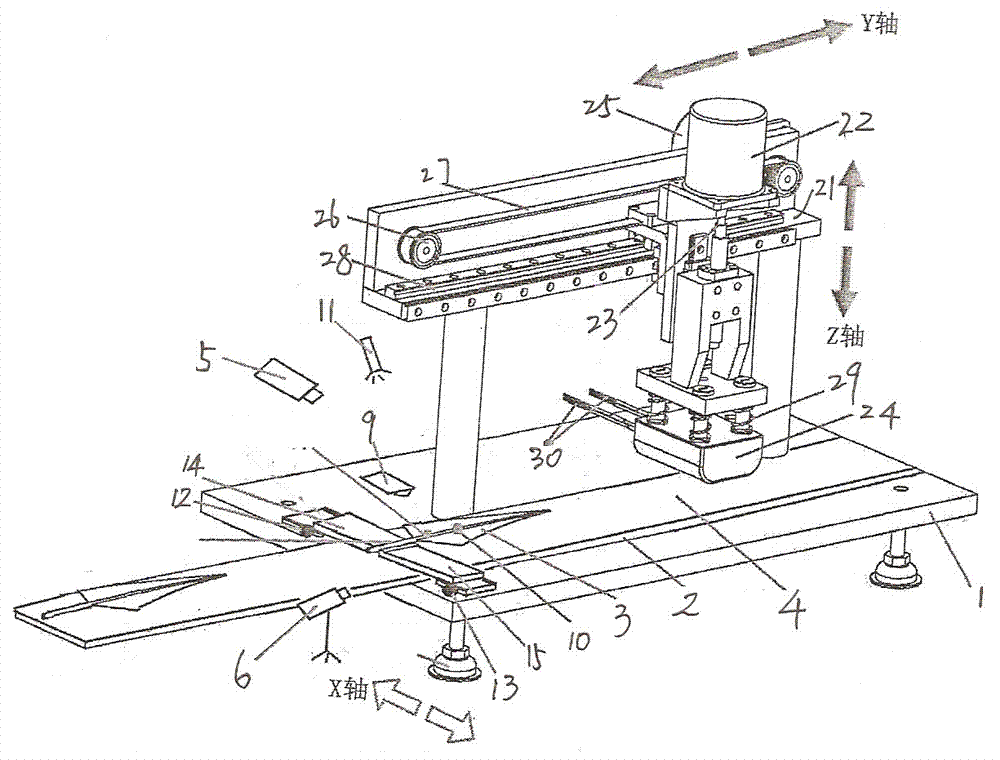

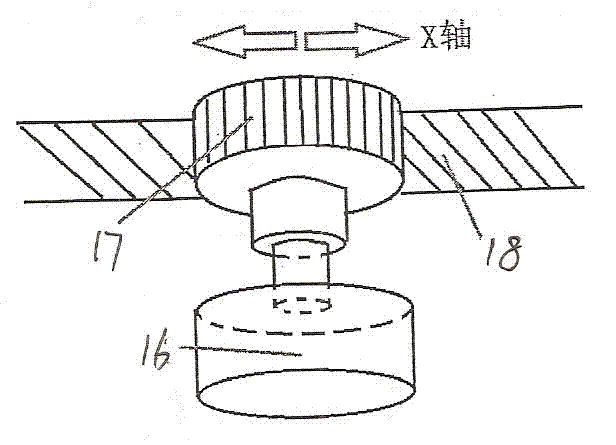

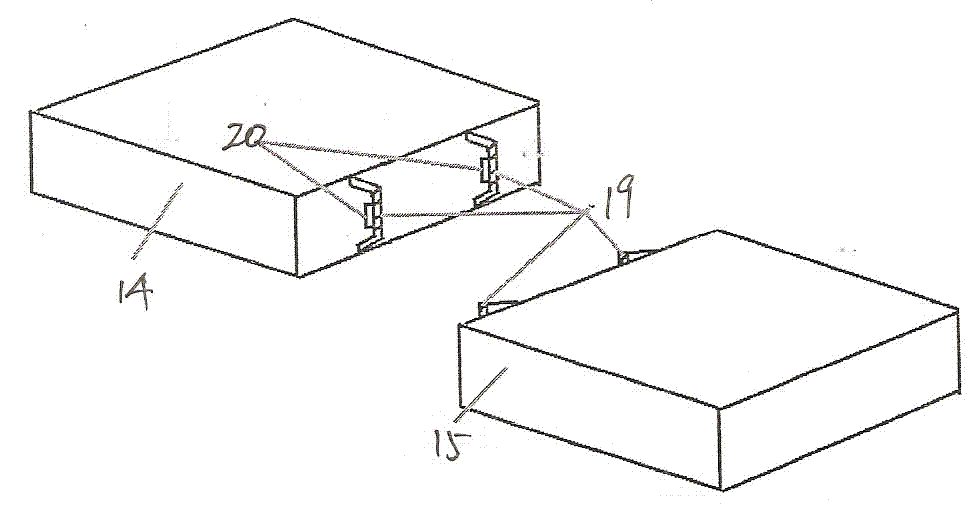

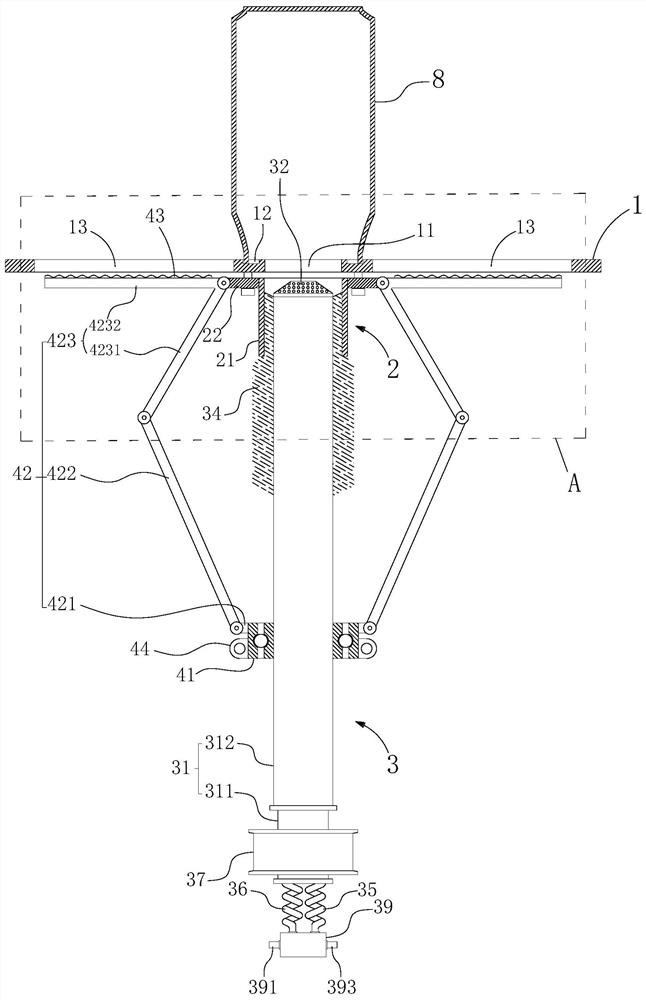

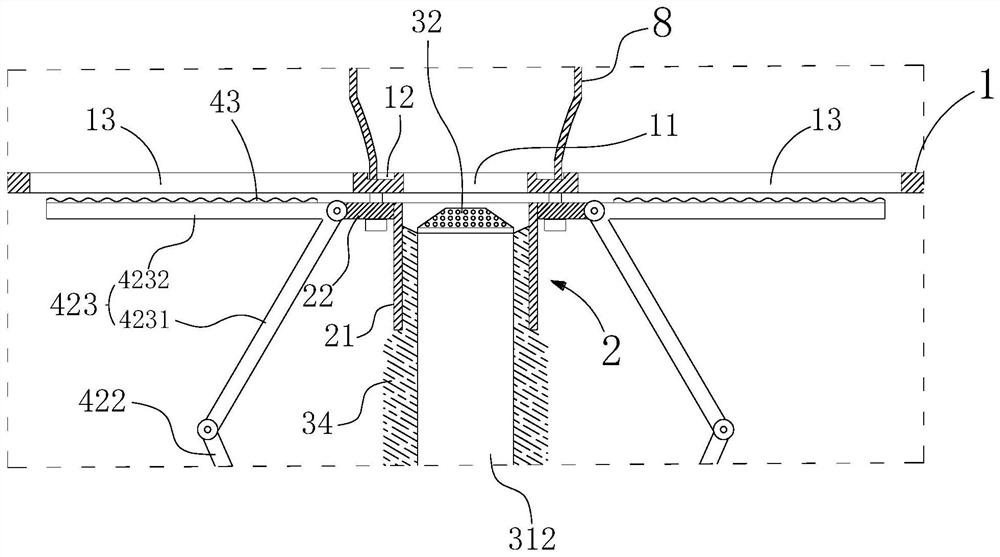

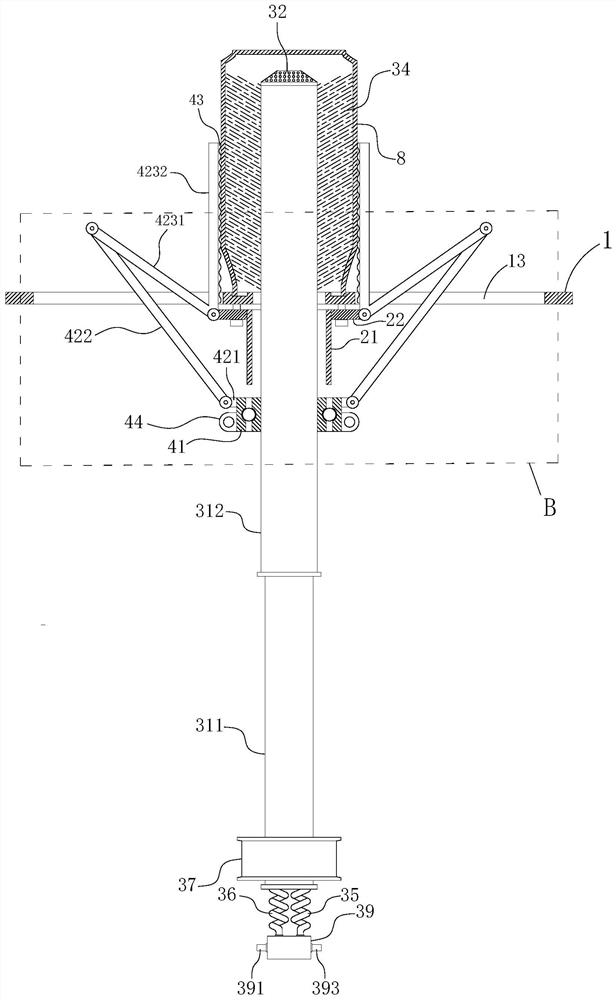

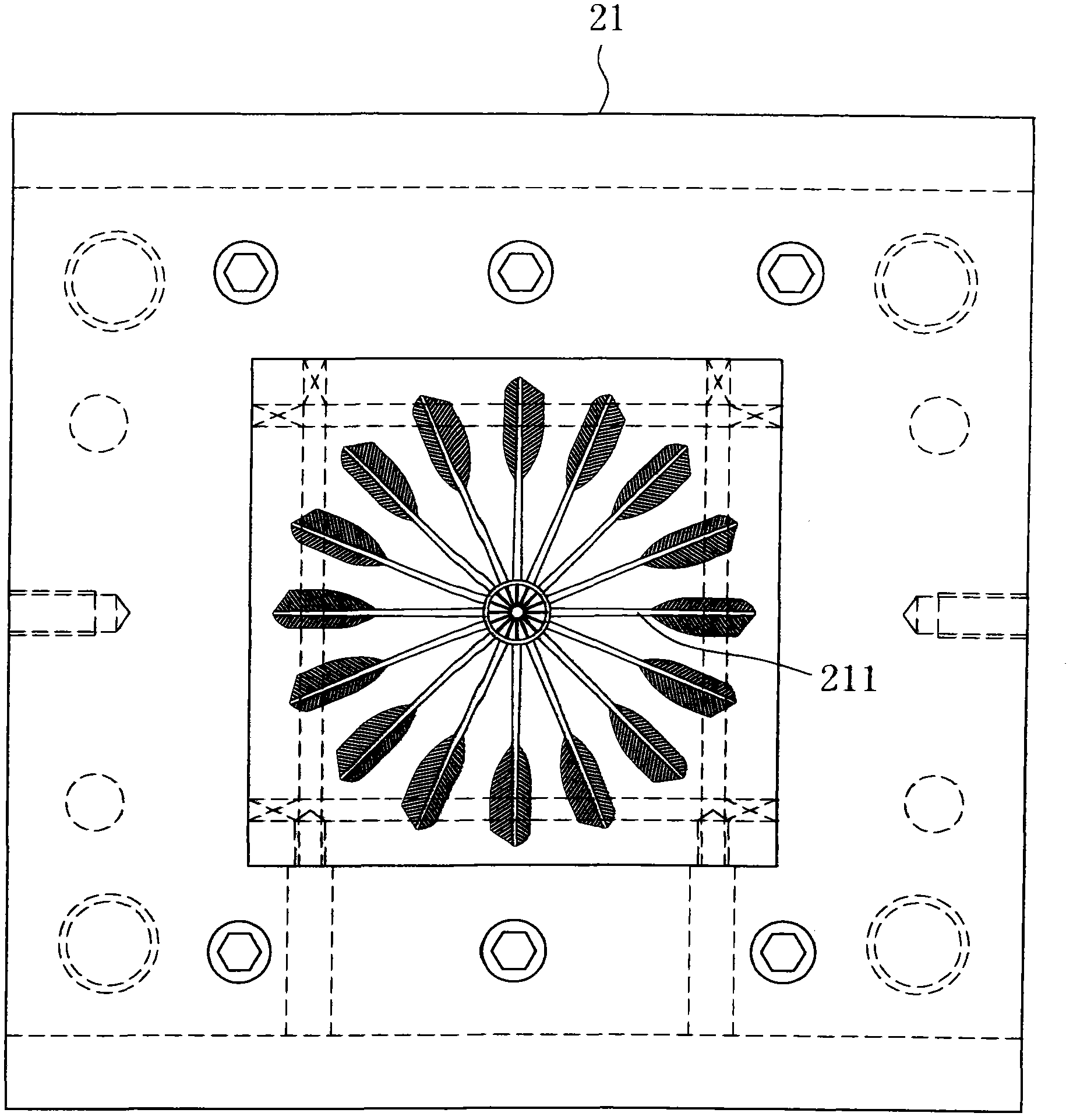

Full-automatic goose feather sorting and ironing integrated system

ActiveCN103111062ACompact structureReasonable structureOptically investigating flaws/contaminationSport apparatusMicrocomputerControl system

The invention discloses a full-automatic goose feather sorting and ironing integrated system. An ironing plate is arranged on a base, a conveying belt for conveying goose feathers is arranged above the ironing plate, a goose feather rod clamping device is arranged above the conveying belt, an ironing evening device for ironing the goose feathers is arranged behind the goose feather rod clamping device, a camera A used for sorting goose feathers is arranged above the front of the goose feather rod clamping device, a camera B used for detecting quality of ironed goose feathers is arranged on one side of the conveying belt, the camera A and the camera B are connected with an FPGA which is connected with a single chip microcomputer, and a blowing system for blowing unqualified goose feathers is arranged at the back of the goose feather rod clamping device. The full-automatic goose feather sorting and ironing integrated system fills the gap of absence of the full-automatic goose feather sorting and ironing integrated system at present and is compact and simple in structure and high in automation degree, and a measuring and controlling system is reasonable in structure and high in intelligent degree.

Owner:义乌市鼎莎针织有限公司

Protein film and its preparation method

Disclosed are a protein membrance for fur of animals such as chicken, duck, goose and pig, ox and sheep, and hard protein of horn of ox, goat, of hoof shell of pig, ox and sheep, made by softening, crushing down and hydrolysis, and its preparing method. The protein membrance can be made into that has resistance to water or not, replacing for plastic mulching film, plastic film or packaging material of whole degradation without pollution. The intermediate-albumin gluegenerated in the preparing course can be used as stickerwithout pollution for chemical and dye printing industries. The invention has abundant raw material, simple technique, low cost, comprehensive usage, no pollution to the environment and no need for special equipment, with wide application range and value; it will bring about remarkable social and economic benefits.

Owner:王乙桐

Badminton manufacturing technique

The invention discloses a badminton manufacturing technique which comprises the following steps: selecting qualified goose feather as a badminton skirt; inserting the selected feather into a base, keeping the feather at equal interval and consistent distances from the top ends of the feather to the top end of the base, and encircling into a circle by the top ends of the feather; putting the assembled semi-finished product of badminton into a drying machine, injecting bottom water into inner and outer rings of the badminton, placing for 7 days and waiting for the drying of the glue; binding double-layer lines on the feather part of the semi-finished product of badminton, coating the glue onto the lines after binding the lines and fixing the line positions; uniformly coating a layer of fluorescent materials on the inner and outer sides of the feather of the semi-finished product of badminton and the outer surface of a cork base; detecting the rotation and mass of each semi-finished product of badminton, testing stability and trying to play, and then distinguishing the stabilizing level A, B, C and D. The badminton manufacturing technique has the advantages that high-quality goose feather and cork base are adopted according to the technique, each material of the badminton meets the strict requirement, the finished product is strictly tested and high quality of each delivered product is guaranteed.

Owner:JIANGSU YAOZHANG SPORTING GOODS

Method for preparing feather protein by alkali hydrolysis of animal hairs

InactiveCN103145823AProduction specializationIndustrialization of productionDepsipeptidesPeptide preparation methodsZinc hydroxideFiltration

The invention belongs to the chemical field, and relates to a novel method for preparing feather protein by alkali hydrolysis of animal hairs. A strong alkali substance is used to decompose keratin which can be hydrolyzed into various free amino acids. Waste feathers, alkali and water are used for reaction according to a mass ratio of 100 : 10-300 : 100-500, wherein the waste feathers refer to waste chicken feathers, drake feathers, goose feathers and hairs of various birds and animals; the alkali refers to the barium hydroxide, calcium hydroxide, zinc hydroxide and the like. The hydrolysis is carried out for 0.5-5 hours at a temperature of 80-180 DEG C; then the temperature is reduced to below 500 DEG C; ammonium arbonate, ammonium bicarbonate and the like are added; precipitate is removed by filtration; and a mother solution is concentrated to obtain the feather protein with high purity.

Owner:NANJING INST OF TECH

Intelligentized goose feather ironing device

ActiveCN104174148ACompact structureReasonable structureOptically investigating flaws/contaminationSport apparatusEngineeringSingle chip

The invention discloses an intelligentized goose feather ironing device. According to the goose feather ironing device, an ironing plate is arranged on a base; a conveyor belt used for conveying goose feather is arranged at the upper part of the ironing plate; a goose feather rod clamping device is arranged at the upper part of the conveyor belt; an ironing and flatting device used for ironing and processing goose feather is arranged behind the goose feather rod clamping device; a camera A used for carrying out sorting operation on goose feather is arranged at the front upper part the goose feather rod clamping device; a camera B used for carrying out quality detection on the ironed and processed goose feather is arranged on the side surface of the conveyor belt; the camera A and the camera B are connected with an FPGA (Field Programmable Gate Array); the FPGA is connected with a single-chip microcomputer; a blowing system used for blowing away disqualified goose feather is arranged behind the goose feather rod clamping device; an initiative light source for guaranteeing stable lighting intensity is mounted on the near side of the camera A. The goose feather ironing device is compact and simple in structure, high in automatized degree, reasonable in structure of a measuring and controlling system and high in intelligentized degree.

Owner:义乌市鼎莎针织有限公司

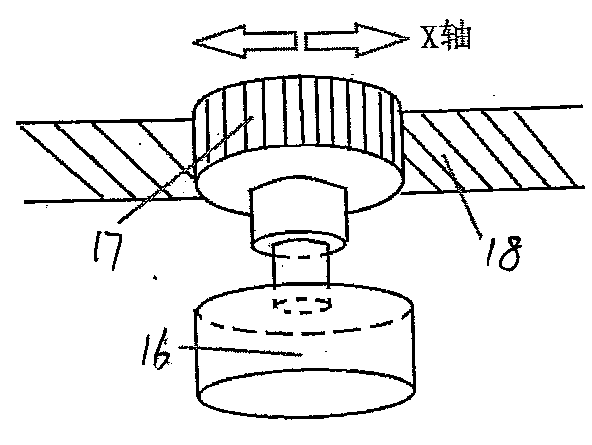

Improved cleaning device for inner cavity of glass bottle

The invention discloses an improved cleaning device for an inner cavity of a glass bottle. The improved cleaning device for the inner cavity of the glass bottle comprises a working table, a fixing sleeve, an inner cavity cleaning mechanism and a clamping mechanism; the fixing sleeve is fixed below the working table; the inner cavity cleaning mechanism comprises a telescopic pipe, an umbrella-shaped nozzle, an inner sleeve, a water conveying hose, a gas conveying hose and a belt pulley, the telescopic pipe can extend into the glass bottle, goose feathers are arranged on the outer wall of an outer tube, the umbrella-shaped nozzle is installed at the top of the telescopic pipe, the inner sleeve is installed in the interior of the telescopic pipe, the water conveying hose and the gas conveyinghose are installed below the inner sleeve, the belt pulley is connected to the lower side of the telescopic pipe in a sleeving mode; and the clamping mechanism comprises a bearing C, two sets of connecting rod mechanisms and two clamping plates, the bearing C can drive the telescopic pipe to move up and down, the two sets of connecting rod mechanisms are located on the two sides of the bearing Crespectively and can be driven by the bearing C to carry out corresponding actions, and the two clamping plates are respectively arranged on the two sets of connecting rod mechanisms and can clamp theglass bottle on the working table along with the actions of the connecting rod mechanisms. The improved cleaning device for the inner cavity of the glass bottle can replace a mode that the inner cavity of the glass bottle is manually cleaned, can help enterprises to improve the cleaning efficiency and save the cost.

Owner:金合民

Sambucus chinensis culture soil and preparation method thereof

InactiveCN105175121ALow costImprove survival rateBio-organic fraction processingOrganic fertiliser preparationPhylum CyanobacteriaBiotechnology

The invention relates to sambucus chinensis culture soil. The culture soil is prepared from the following components in parts by weight: 100-250 parts of sludge, 50-70 parts of coal residues, 30-35 parts of plant ash, 20-28 parts of cyanobacteria, 12-24 parts of orange peels, 20-30 parts of watermelon peels, 25-35 parts of mushroom dregs, 15-30 parts of goose manure, 12-22 parts of pig manure, 8-13 parts of goose feather, 20-22 parts of bacterial powder, 15-18 parts of animal urine, 9-12 parts of calcium dihydrogen phosphate, 6-12 parts of ammonium hydrogen carbonate, 12-14 parts of rape seed cake powder, 5-8 parts of sodium potassium tartrate, 2-4 parts of zinc sulfate, 1-5 parts of calcium carbonate, 18-22 parts of bacillus subtilis and 13-26 parts of a trichoderma viride strain agent.

Owner:合肥科友生物科技有限公司

Active soil technology of CNT natural natural farming

InactiveCN108633371AReduce interventionQuickly restore the micro-ecologyClimate change adaptationPisciculture and aquariaNatural mineralBiology

The invention relates to the technical field of soil remediation, in particular to an active soil technology of CNT natural natural farming. The method comprises the following steps of: dividing the land in a sudoku arrangement; building ridges; excavating a fish pond, and setting up a duck shed and a goose shed; planting ryegrass, zea mexicana, and Chinese pennisetum; extracting water in the fishpond regularly to irrigate the land, mixing duck hair and goose feather with bacillus megatherium and putting the mixture uniformly into the land; and putting in crushed limestone and basalt; utilizing natural circulation to enable the energy and mineral substances to flow on the hardened soil, and reducing the intervention of the chemical fertilizer pesticide. The soil micro-ecology of the hardened soil is quickly recovered by taking root of the herbaceous plant, supplemented with the natural mineral rock powder, the decomposed protein and the like, so as to have the capability of decomposing, flowing and transforming minerals, and the soil activity is greatly improved. And certain duck, goose, fish, and field snail and other agricultural and sideline products can also be obtained whilethe soil is repaired.

Owner:广州品客科技有限公司

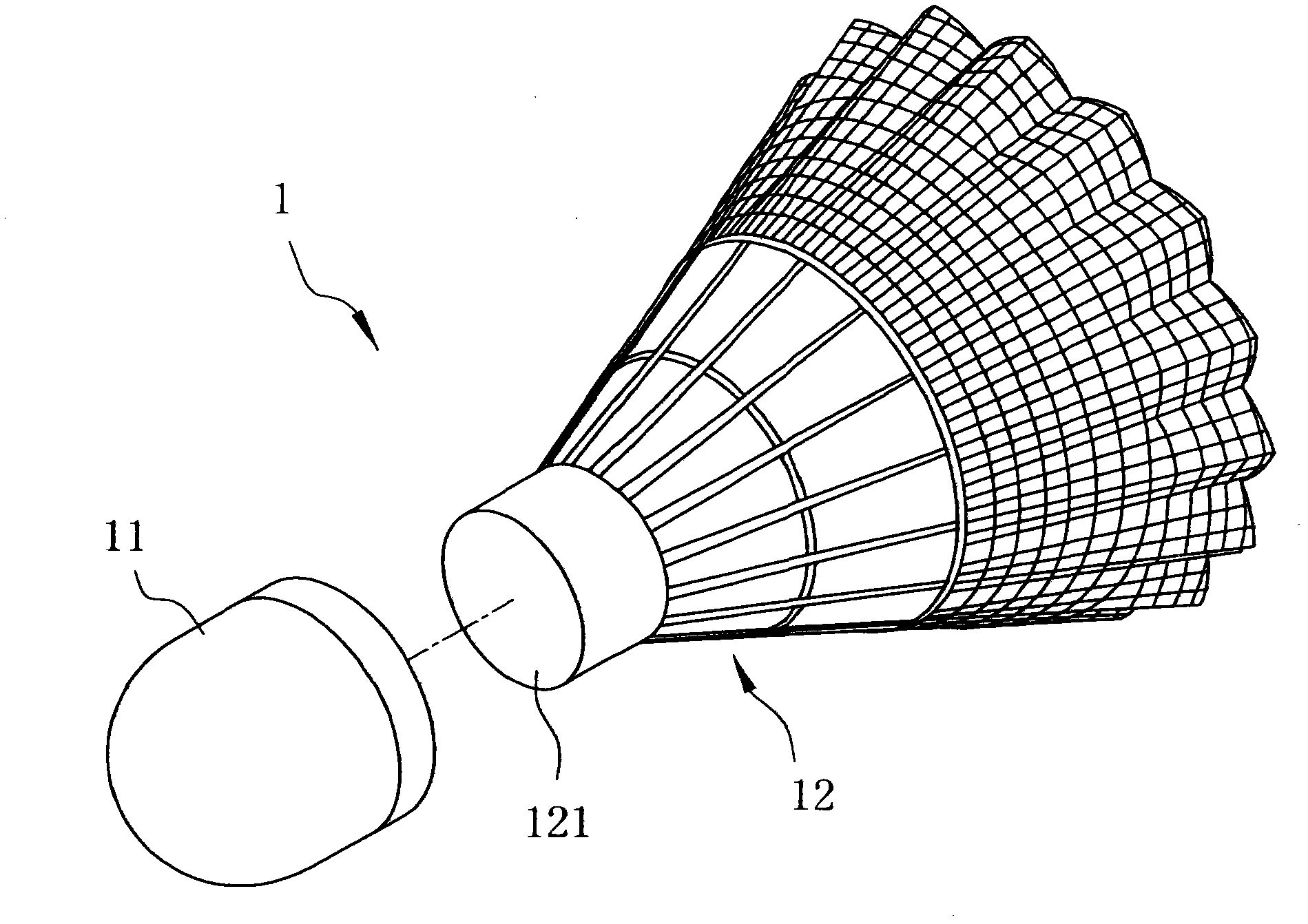

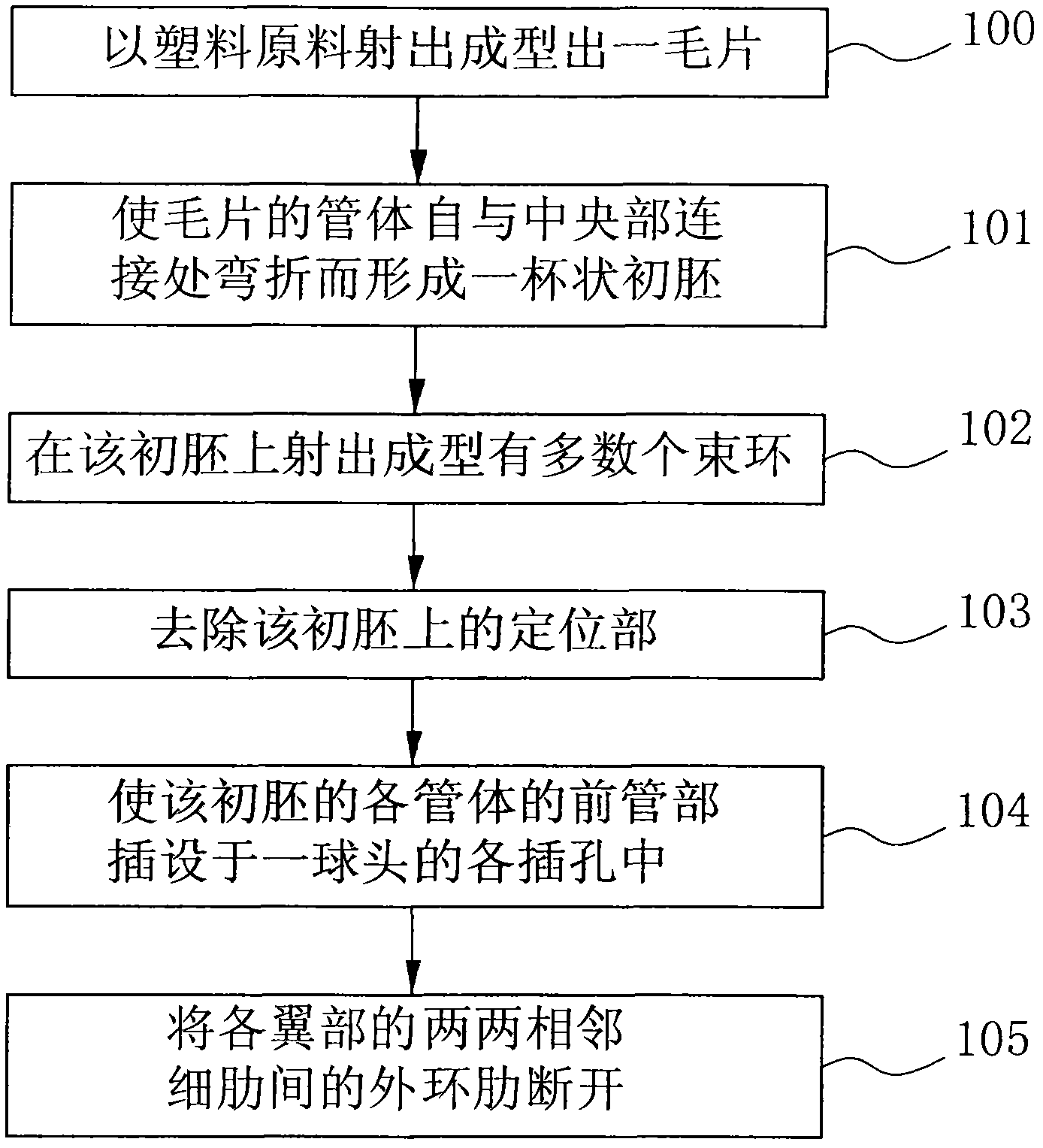

Elaborate goose feather shuttlecock and production method thereof

The invention discloses an elaborate goose feather shuttlecock and a production method thereof. The method comprises the following steps: (a) carrying out ejection molding on a plastic material to obtain a feather sheet, wherein, the feather sheet comprises a central portion, a plurality of pipe bodies stretching to the central portion at regular intervals, and a plurality of wing portions respectively formed on the tail ends of the pipe bodies; (b) buckling the connecting portions between the pipe bodies and the central portions in a predetermined angle to form a cup-shaped initial blank; (c) carrying out injection molding to form an upper ring, a middle ring, and a lower ring at intervals on the pipe bodies; (d) removing the central portions; and (e) respectively inserting the pipe bodies in a jack on a ball head to obtain the elaborate goose feather shuttlecock. According to the invention, the large-scale automation production of the elaborate goose feather shuttlecock can be realized, the production cost and usage cost can be reduced; and the produced elaborate goose feather shuttlecock has better quality than traditional plastic shuttlecock, and can be recycled to meet the requirements of environmental protection.

Owner:王宏源 +1

Photoelectric detection type goose feather pressing and sorting device

ActiveCN104259111ACompact structureReasonable structureOptically investigating flaws/contaminationSport apparatusControl systemEngineering

The invention discloses a photoelectric detection type goose feather pressing and sorting device. A conveying belt for conveying goose feathers is arranged above a pressing plate; a goose feather rod clamping device is arranged above the conveying belt; a pressing device for pressing the goose feathers is arranged behind the goose feather rod clamping device; a camera A for the goose feather sorting operation is arranged at the front upper side of the goose feather rod clamping device; a camera B for detecting the quality of the pressed goose feathers is arranged on the side surface of the conveying belt; the camera A and the camera B are connected with a FPGA; the FPGA is connected with a single-chip microcomputer; an air blowing system for blowing away the unqualified goose feathers is arranged behind the goose feather rod clamping device; and the middle position of a pressing plate is opened for mounting a photoelectric detecting switch connected with the single-chip microcomputer. The device has the advantages of compact and simple structure, high automation degree, reasonable structure of a measurement and control system and high intelligent degree.

Owner:义乌市鼎莎针织有限公司

Production method of antibacterial down fibers

The invention discloses a preparation method of antibacterial down fiber, which belongs to the technical field of non-woven materials. The present invention adds hydrogen peroxide to sterilize and oxidize waste goose feathers after destemming, then filters and dries, and adds antibacterial traditional Chinese medicine to keep warm. Wrapping the cylinder filled with down, moving it into a steamer, removing the film after cooling, adding chitosan and standing overnight, filtering and air-drying, so as to obtain the preparation method of antibacterial down fiber. Examples prove that the present invention is easy to operate, uses waste goose feathers as raw materials, reduces costs, realizes waste utilization, and the made down fiber has strong antibacterial properties and high absorbency, and will not breed bacteria to produce peculiar smell during use, and is antibacterial The rate reaches more than 95%, the practicality is high, and it is worth popularizing.

Owner:吴迪

Bactericidal mildewproof down composite fibers and manufacturing method thereof

InactiveCN104762694AStrong antibacterial and bactericidalStrong anti-inflammatoryConjugated cellulose/protein artificial filamentsArtifical filament manufactureKapok fiberIrritation

The invention discloses bactericidal mildewproof down composite fibers prepared from the following raw materials in parts by weight: 11-14 parts of goose down superfine powder, 15-20 parts of puffed goose feather powder, 6-9 parts of kapok fibers, 8-12 parts of coconut palm fibers, 17-19 parts of sugarcane skins, 3-5 parts of bentonite, 5-8 parts of hollow vitrified micro bubbles, 1-3 parts of Chinese thorowax roots, 2-4 parts of white peony roots, 0.1-0.3 part of aluminum sulfate, 0.04-0.08 part of zinc oxide, 2.3-4.6 parts of polyacrylate, 0.05-0.08 part of sodium dodecylbenzene sulfonate, 1.2-3.5 parts of nano silicon dioxide, 100-120 parts of 1-butyl-3-methylimidazol acetate, 110-130 parts of 1-butyl-3-methylimidazol dibutylphosphoric acid ester, 1-3 parts of an auxiliary agent and an appropriate amount of water. The down composite fibers prepared by a method disclosed by the invention have relatively strong bacteriostatic, bactericidal, inflammation diminishing, deodorant and mildewproof effects, are irritation-free to skin, are lightweight and warm-keeping, and are deeply loved by consumers.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Inner filler for down quilt

The invention discloses inner filler for a down quilt. The inner filler comprises, by weight, 5-10 parts of goose feather, 5-10 parts of duck feather, 5-10 parts of chicken feather, 1-3 parts of wool, 1-3 parts of camel's hair, 40-60 parts of polyester fiber, 20-30 parts of cotton fiber, 1-3 parts of bamboo fiber, 1-3 parts of silk, 1-5 parts of antioxidant, 2-5 parts of drying agent and 3-6 parts of auxiliary material. The inner filler made of the various raw materials has the advantages that the breathability of down is achieved while the close-fitting comfortableness of quilts is achieved, investment is lowered, the weight of the quilt is increased, and effects of close fitting and warm keeping are achieved.

Owner:ANHUI XIAZHEN GRP

Method for producing L-cystine

InactiveCN102887844AConvenient sourceSimple processOrganic compound preparationHydropoly/poly sulfide preparationActivated carbonGoose feathers

The invention discloses a method for producing L-cystine. L-cystine belongs to the field of amino acids. The method comprises that poultry feathers (comprising drake feathers, goose feathers, pig hairs and human hair), hydrochloric acid, liquid alkali, pure water, activated carbon and liquid ammonia are used as raw materials; and L-cystine is prepared by acidolysis of poultry feathers and animal hairs. The method provided by the invention utilizes the raw materials having wide sources, has simple processes and a low production cost, does not discharge a waste liquid in production and is convenient for volume production. L-cystine produced by the method has wide purposes in medicines and is a nutritional supplement agent and a cosmetic additive.

Owner:XINYI HANLING BIO ENG

Processing method of leaf picture

InactiveCN101823397AMaintain soft propertiesEasy to collectDecorative surface effectsWood fibreToughness

A processing method of leaf picture relates to the technical field of the artwork processing with the raw material of leaf. The processing method of the invention comprises the following steps: removing the mesophyll from the leaf to obtain the vein, washing, drying, and then directly printing characters or patterns on the dried vein. The invention keeps the straight of the vein picture without the use of glue, as well as retains the intrinsic softness of the vein. The wood fibre of the leaf can be reserved permanently like paper, and the reservation period of the product of the invention can be prolonged greatly compared with traditional picture made by glue. The product of the invention has the thickness like that of the cicada wings and has the weight like that of the goose feather. The product has good softness and toughness and environmental protection, and is convenient for carrying. The method of the invention uses the printing to form characters and patterns, thereby having high processing efficiency, large output, and low production cost, which facilitates the underselling and the popular collection.

Owner:高在心

Growing and fattening pig feed additive

InactiveCN105941946AImprove immunityReduce the prevalenceFood processingAnimal feeding stuffLean meatImmunocompetence

The invention discloses a growing and fattening pig feed additive. The additive is prepared from the following materials: carrot, lettuce, tomato, wild roxburgh rose, dried tangerine or orange peel, hawthorn, rhubarb, algae, sweet potato, pumpkin, fish scale, fish skin, fish oil, hair, cornstalk, bagasse and yeast, wherein the hair is one or more types of chicken feather, drake feather and goose feather. The pig breeding and fattening feed additive provides enough nutritional energy for growing and fattening pigs, so as to balance nourishment, remarkably improve the body immunocompetence of the growing and fattening pigs, reduce the prevalence rate of the growing and fattening pigs, increase gastrointestinal beneficial bacteria, regulate gastrointestinal functions, improve gastrointestinal absorptivity, enhance appetites of the growing and fattening pigs, and promote healthy and rapid growth of the growing and fattening pigs. Therefore, the growing and fattening pigs with relatively high lean meat percentage can be obtained conveniently.

Owner:广西顺帆投资有限公司

Spinnable ecological bacteriostatic down fiber and making method thereof

InactiveCN104947221AImprove adsorption capacityPermanent bondMonocomponent protein artificial filamentArtifical filament manufacturePolyesterTextile fiber

The invention discloses a spinnable ecological bacteriostatic down fiber, which is characterized by being prepared from the following raw materials by weight part: 14-16 of goose down, 25-35 of goose feather, 3-5 of polyester fiber, 4-7 of modal fiber, 3.6-6.7 of chitin, 0.2-0.5 of zirconium sulfate, 1-3 of montmorillonite, 6-9 of amino silicone oil, 1.5-2.5 of nano-titanium dioxide, 150-180 of 1-butyl-3-methylimidazole chloride, and a proper amount of water. According to the invention, the synergistic effect of chitin and nano-titanium dioxide is adopted, the antibacterial properties of are thorough, and the prepared ecological bacteriostatic down fiber can be used individually or mixed with other textile fiber to produce non-woven products or textiles. The product has the characteristics of excellent spinnability, good heat retention, good light weight and elasticity, good moisture absorption performance, good appearance quality and the like, and can be popularized and applied in textile or nonwoven field.

Owner:ANHUI HANSHAN COUNTY FUQIANG DOWN PROD

Polyester-fiber dyeing auxiliary agent

A disclosed polyester-fiber dyeing auxiliary agent is composed of the following raw materials in parts by weight: 12-15 parts of guar gum, 7-10 parts of carboxymethylcellulose sodium, 1-3 parts of a surfactant, 1-3 parts of anhydrous sodium sulphate, 4-8 parts of a water softener, 0.5-1 part of branched isomerous alcohol ether, 2-4 parts of barium chloride, 3-5 parts of ammonium chloride, 0.1-0.5 part of goose feather protein, 0.1-0.3 parts of a cross-linking agent, 3-5 parts of a chelating agent, 5-10 parts of an emulsifier, 0.5-3 parts of a stabilizing agent, 8-10 parts of sodium silicate, 3-6 parts of magnesium sulfate, and 2-8 parts of fatty alcohol polyoxyethylene ether. The auxiliary agent helps to effectively improving the dyeing degree and the color fixing rate of polyester fiber, shorten dyeing time and improve the handfeel of polyester fiber textiles subjected to dyeing.

Owner:QINGDAO TOPLINK INFORMATION TECH

Feed additive capable of increasing yield of goose feathers

InactiveCN105942001ANo side effectsRaw materials are easy to getAnimal feeding stuffAccessory food factorsWeight gainingAnimal science

The invention relates to the technical field of feed, in particular to a feed additive capable of increasing the yield of goose feathers. The additive is prepared from 20-30 parts of lens culinaris, 5-7 parts of human hair, 1.2-1.6 parts of magnetite, 9-12 parts of Chinese honeylocust spine, 5-10 parts of oregano, 0.03-0.06 part of vitamin B6, 0.012-0.017 part of L-alanine, 0.1-0.15 part of calcium ascorbate and 0.2-0.4 part of microcrystalline cellulose, wherein the adding proportion of the additive in feed is 5-8% by weight. By adding the feed additive capable of increasing the yield of goose feathers into the daily ration of white geese, the feature picking yield of each time and the number of annual feather picking times can be remarkably increased, and normal growth and weight gaining of white geese are not influenced.

Owner:安徽省家牧动物营养科技有限公司

Reactive dyeing assistant for polyester fibers

The invention relates to the field of dyeing assistants, in particular to a reactive dyeing assistant for polyester fibers. The reactive dyeing assistant comprises a surfactant, sodium sulfate, a water softener, branched heterogeneous alcohol ether, rare earth chloride, 3-chloro-2-hydroxypropyltrimethyl ammonium chloride and goose feather protein extracted from goose feather. According to the reactive dyeing assistant for the polyester fibers, the degree of dyeing and the degree of fixation of the polyester fibers can be increased effectively by the aid of addition of a small amount of sodium sulfate and cooperation of the goose feather protein, only a small amount of sodium sulfate is added, so that scratching of polyester fiber textiles can be avoided, the quality of polyester fibers in a dyeing process is guaranteed, and the usability is improved; meanwhile, the utilization rate and the dyeing efficiency of a dye can be increased effectively by the aid of the assistant, water used in the dyeing process of unit textile can be reduced, the production cost is reduced, and environmental safety is guaranteed.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

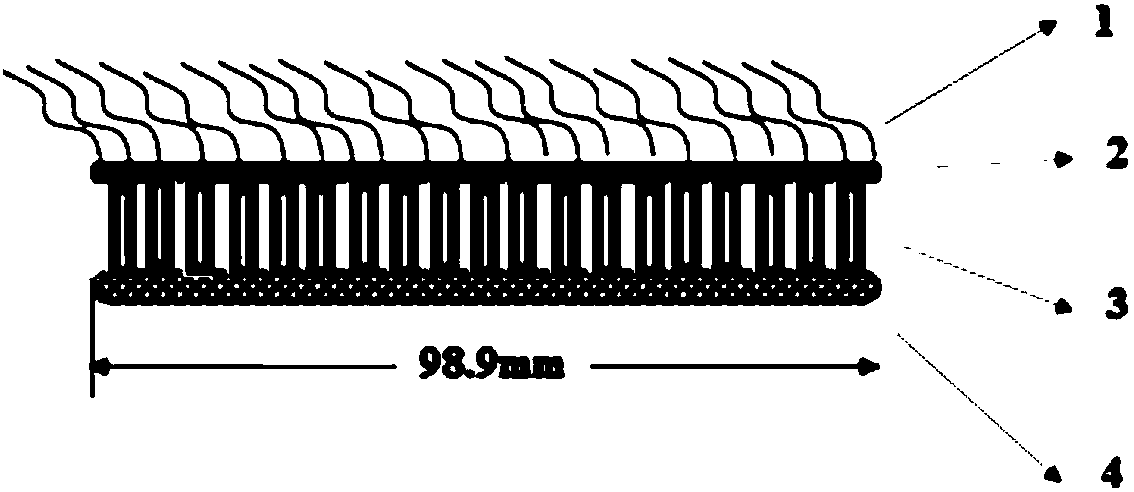

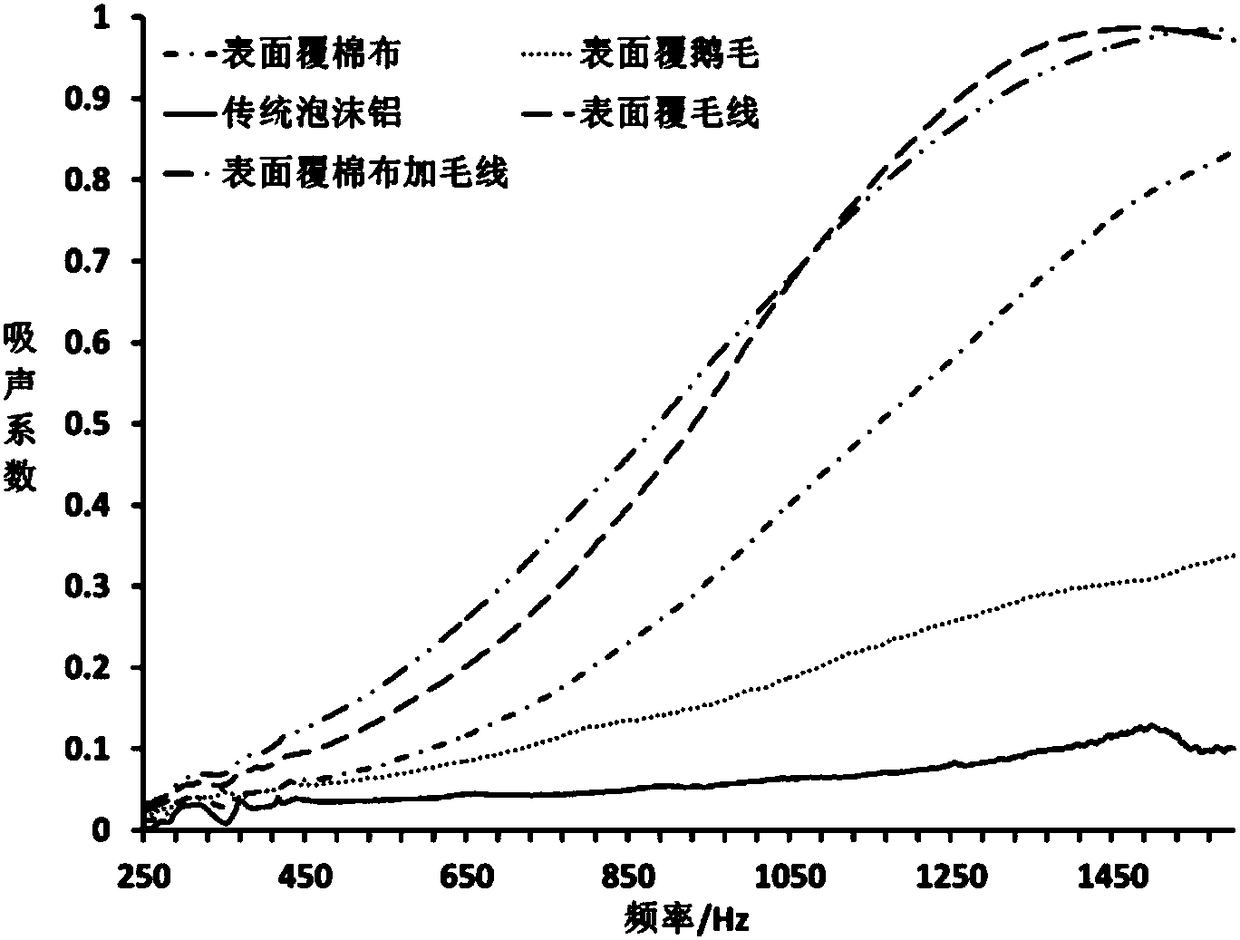

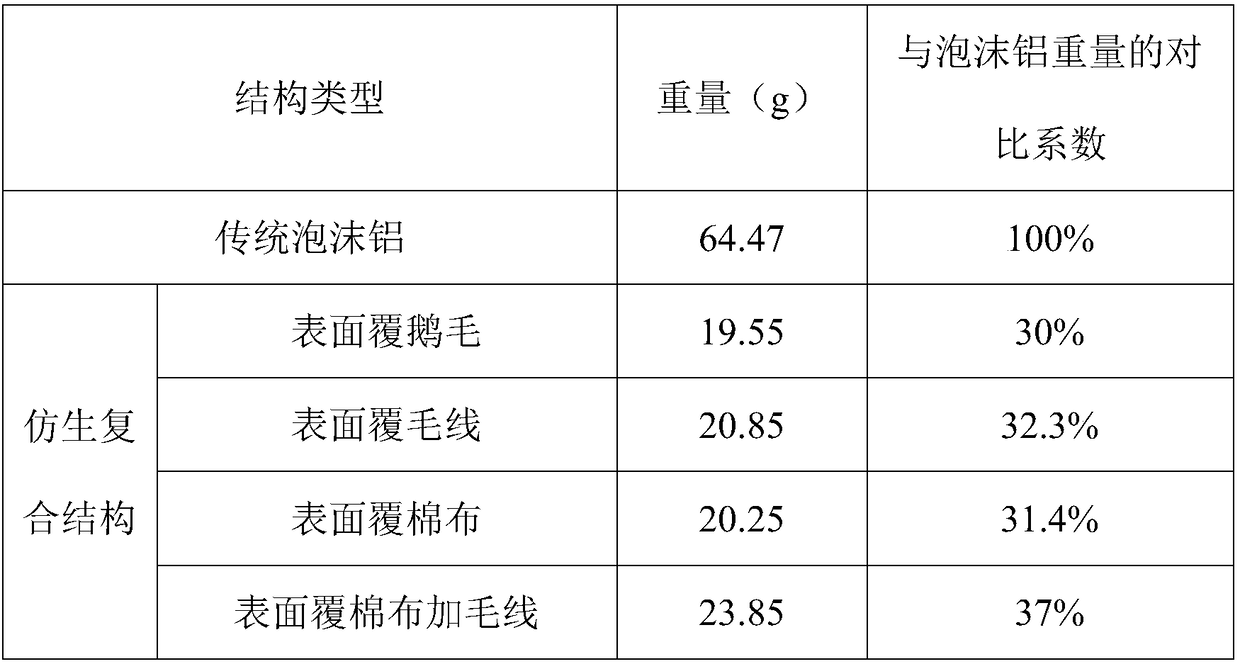

Novel bionic composite sound absorption structure

PendingCN108564938AImprove the sound absorption coefficientMain Factors for Accurate Sound Absorption CharacteristicsSynthetic resin layered productsSound producing devicesYarnFiber

The present invention provides a novel bionic composite sound absorption structure. The structure comprises four parts consisting of fibers, a film, a hollow cylinder body and porous foamed aluminum.The uppermost layer of the fibers can employ natural or inorganic or synthetic fibre materials such as goose feather, woolen yarn and cotton cloth to simulate the strigimorphae wing covert; the secondlayer is film materials to simulate the surface skin of the strigimorphae surface skin; the third layer is the hollow cylinder body to simulate the lower cavity structure of the skin of the strigimorphae, and the third layer is fixed with the second layer of film and the fourth layer of foamed aluminum in a gluing mode; and the downmost substrate structure is the porous foamed aluminum to simulate the lower skin tissue of the strigimorphae. The novel bionic composite sound absorption structure can more accurately simulate key factors influencing sound absorption features in long-eared owl skin and wing covert physiological structure, is better in the sound absorption effect compared to a known bionic structure, and effectively increases the low-frequency sound absorption coefficient whilegreatly reducing the cost and the weight compared to a current traditional foamed aluminum sound absorption structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com