Preparation method of keratin complex fiber

A composite fiber and keratin technology is applied in the field of preparation of keratin composite fibers, which can solve the problems of high brittleness, low strength and low use value, and achieve the improvement of strength and elongation at break, reduce pollution and increase use value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] To a 1000 ml round-bottomed flask, first add 1.5 g of 50 mesh chicken feather keratin powder, add 600 g of 1-butyl-3-methylimidazolium chloride, dissolve at 120°C for 30 minutes to obtain a clear and transparent keratin ionic liquid solution , then cooled to 60° C. and then added 30 g of bamboo pulp, dissolved for 12 hours to obtain a uniform and transparent composite solution, and the solution was prepared by wet spinning to obtain keratin / cellulose composite fibers.

[0023] The specific spinning process parameters are as follows:

[0024] Spinning pressure: 0.2MPa; spinning temperature: 120°C, coagulation bath composition: distilled water; coagulation bath temperature: 60°C; water washing temperature: 80°C; spinning speed: 5m / min

Embodiment 2

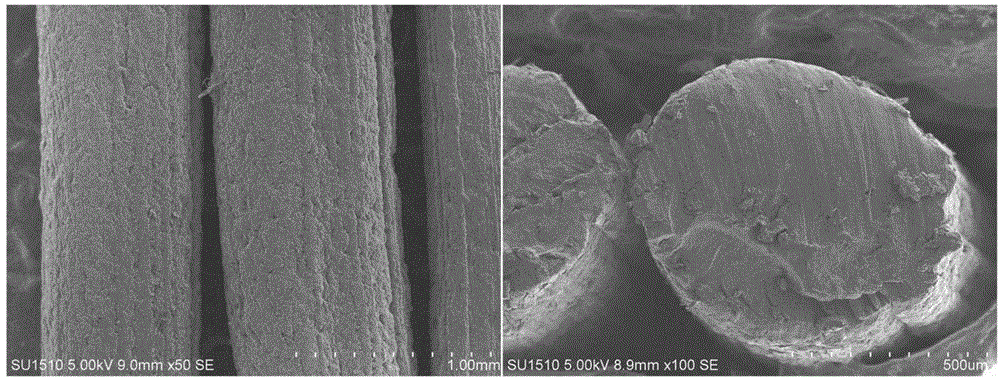

[0026] Add 30g of 100 mesh wool keratin powder to a 1000ml round-bottomed flask, add 600g of 1-allyl-3-methylimidazolium chloride, dissolve at 130°C for 2 hours to obtain a clear and transparent keratin ionic liquid solution , then cooled to 80°C and then added 30g of hemp pulp, dissolved for 10 hours to obtain a uniform and transparent composite solution, and the solution was prepared by wet spinning to obtain keratin / cellulose composite fibers. The SEM photo is as follows figure 1 shown.

[0027] The specific spinning process parameters are as follows:

[0028] Spinning pressure: 0.4MPa; spinning temperature: 70°C; coagulation bath composition: anhydrous ethanol aqueous solution (V / V=1:1); coagulation bath temperature: 20°C; water washing temperature: 50°C; spinning speed: 10m / min

Embodiment 3

[0030] Add 60g of 200 mesh duck feather keratin powder to a 1000ml round-bottomed flask, add 600g of 1-ethyl-3-methylimidazolium chloride, dissolve at 130°C for 5 hours to obtain a clear and transparent keratin ionic liquid solution , then cooled to 90° C. and then added 30 g of cotton linters, dissolved for 5 hours to obtain a uniform and transparent composite solution, and the solution was prepared by dry-jet wet spinning to obtain keratin / cellulose composite fibers.

[0031] The specific spinning process parameters are as follows:

[0032] Spinning pressure: 0.4MPa; spinning temperature: 100°C; air bath height: 1cm; coagulation bath composition: anhydrous ethanol aqueous solution (V / V=1:3); coagulation bath temperature: 10°C; water washing temperature: 30°C ; Spinning speed: 20m / min

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com