Full-automatic goose feather sorting and ironing integrated system

A fully automatic, goose feather technology, used in sorting, moving accessories, optical testing flaws/defects, etc., can solve problems such as damage and affect the quality of goose feather shuttlecocks, and achieve a reasonable, compact, and intelligent measurement and control system. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

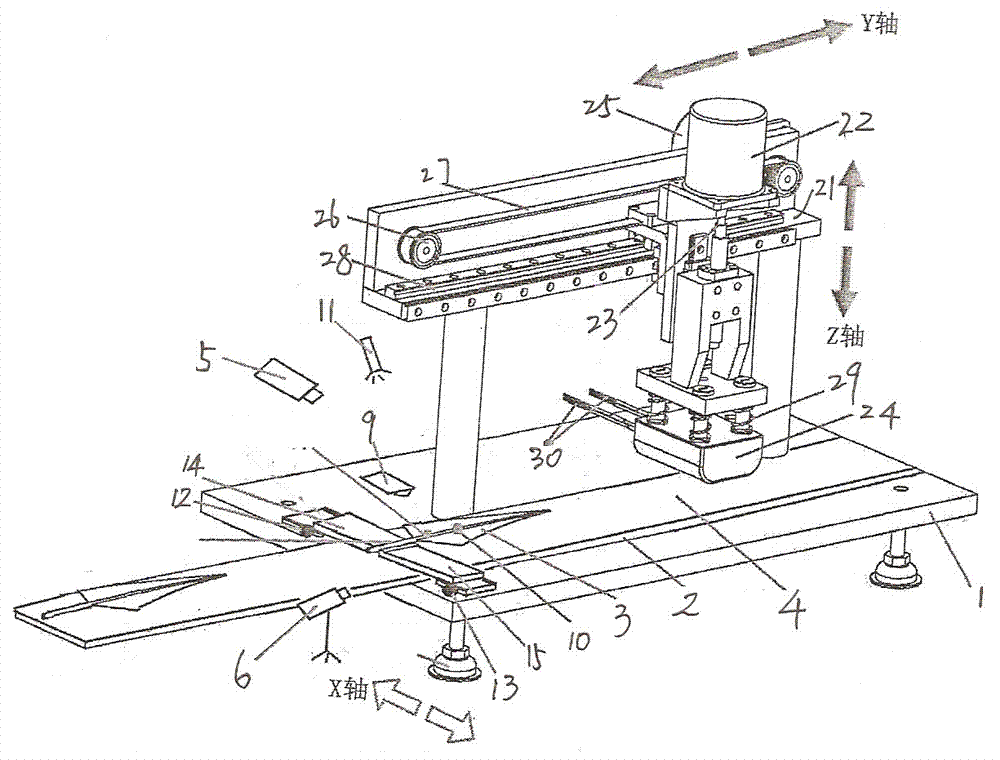

[0030] A fully automatic goose feather sorting and ironing integrated system, comprising a base 1, on which an ironing board 2 is arranged, a conveyor belt 4 for transporting goose feathers 3 is arranged above the ironing board, and a goose feather bar clamping device is arranged above the conveyor belt, After the goose feather rod clamping device, a pressing and flattening device for ironing and finishing of goose feathers is installed; a color CCD camera A5 for sorting goose feathers is installed above the front and top of the goose feather rod clamping device, and a color CCD camera A5 is installed on the side of the conveyor belt for ironing and finishing. Color CCD camera B6 for quality inspection of processed goose feathers, camera A, camera B are connected to FPGA7, and FPGA is connected to single-chip microcomputer 8; after the goose feather rod clamping device, an air blowing system 9 that blows away unqualified goose feathers is set;

[0031] A field programmable gate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com