Patents

Literature

250results about How to "Flat cutting surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond rope saw static force cutting method

InactiveCN101768926AImprove cutting efficiencySimple construction processBuilding repairsGrinding machinesHydraulic motorReinforced concrete

The invention provides a diamond rope saw static force cutting method, relating to a diamond cutting method. In the invention, an adopted hydraulic pressure diamond rope saw is driven by an hydraulic motor to move at a high speed around the cut surface of a cutting object (4) so as to cut the cutting object (4); the grinding material of diamond rope saw (5) is diamond particles, so the diamond rope saw can be used for cutting stone, reinforced concrete or other hard materials; the power source of the cutting is the hydraulic motor, a hydraulic pump is driven by the hydraulic motor to operate smoothly; and the hydraulic motor can be distantly controlled by a high-pressure oil pipe to reduce vibration and noise in cutting process and enable the cutting object (4) is cut and separated stably. The invention has the advantages of high safety and efficiency and environment protection.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

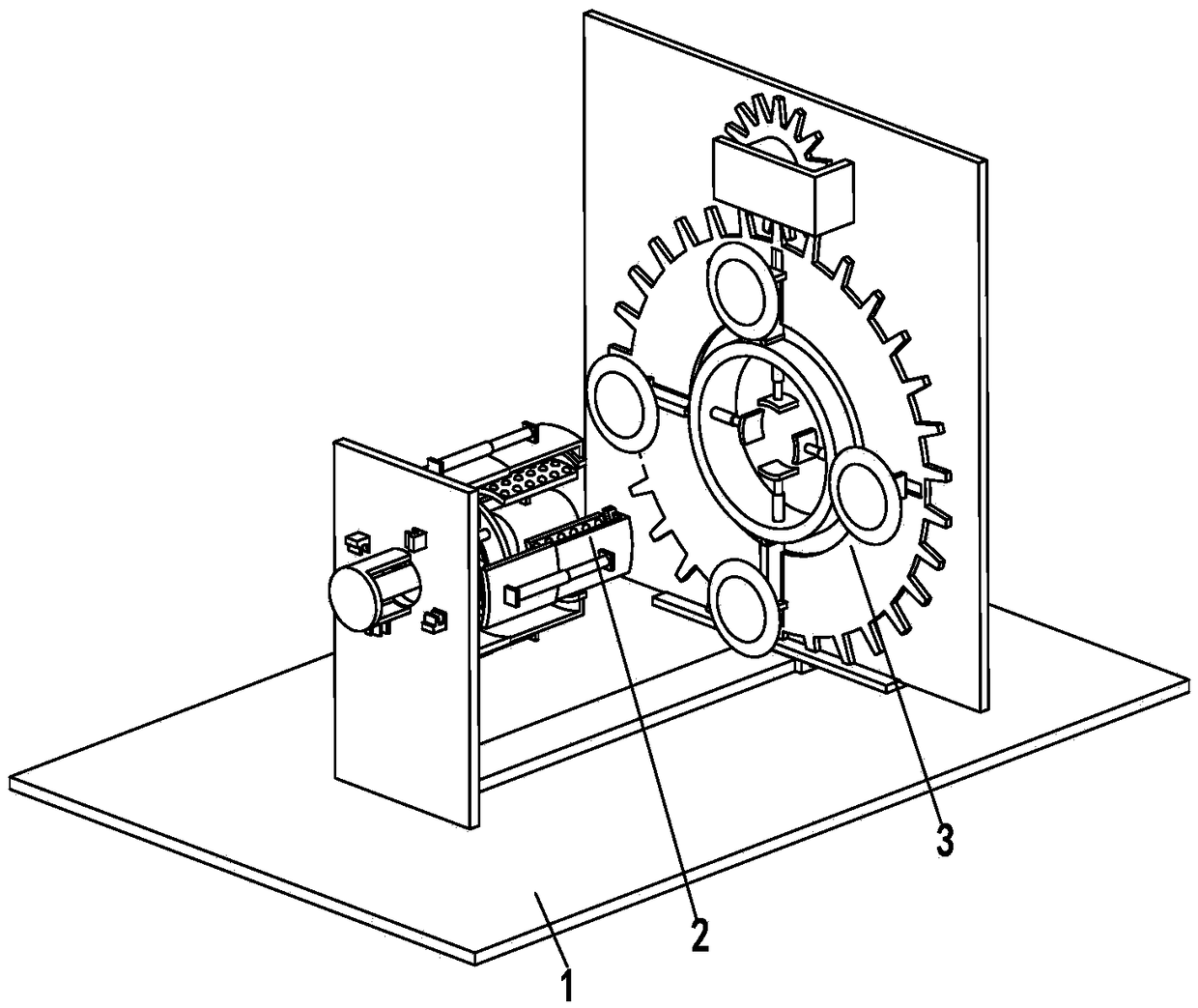

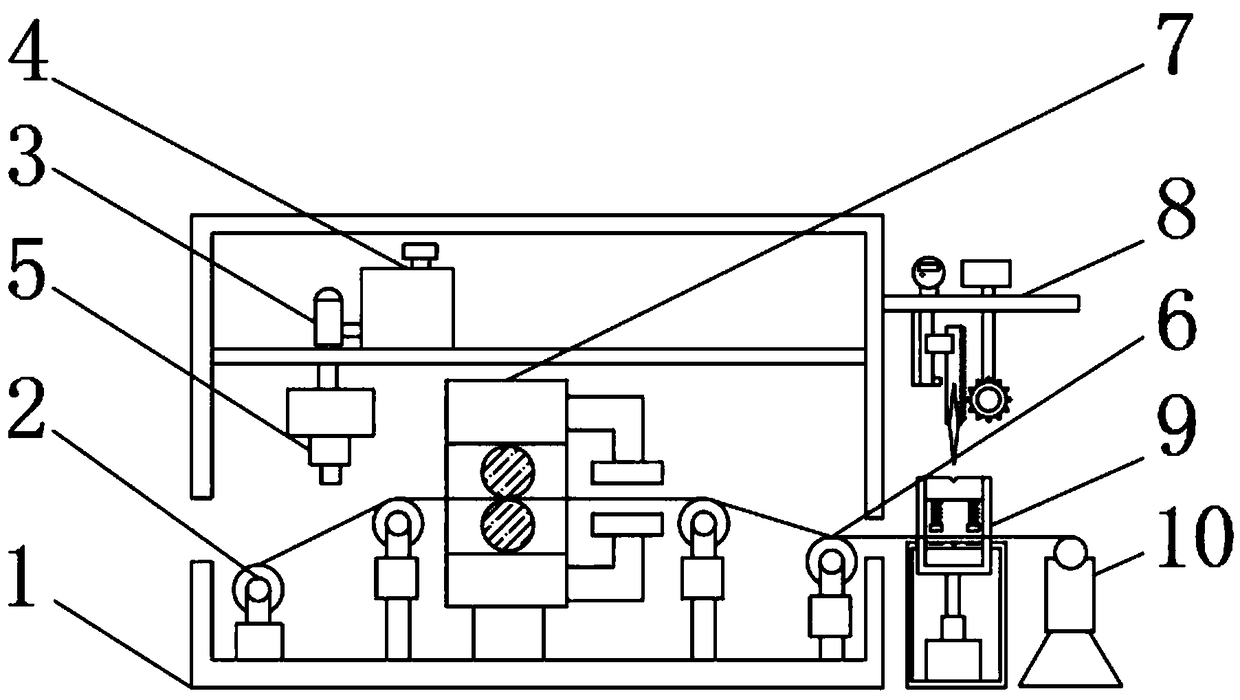

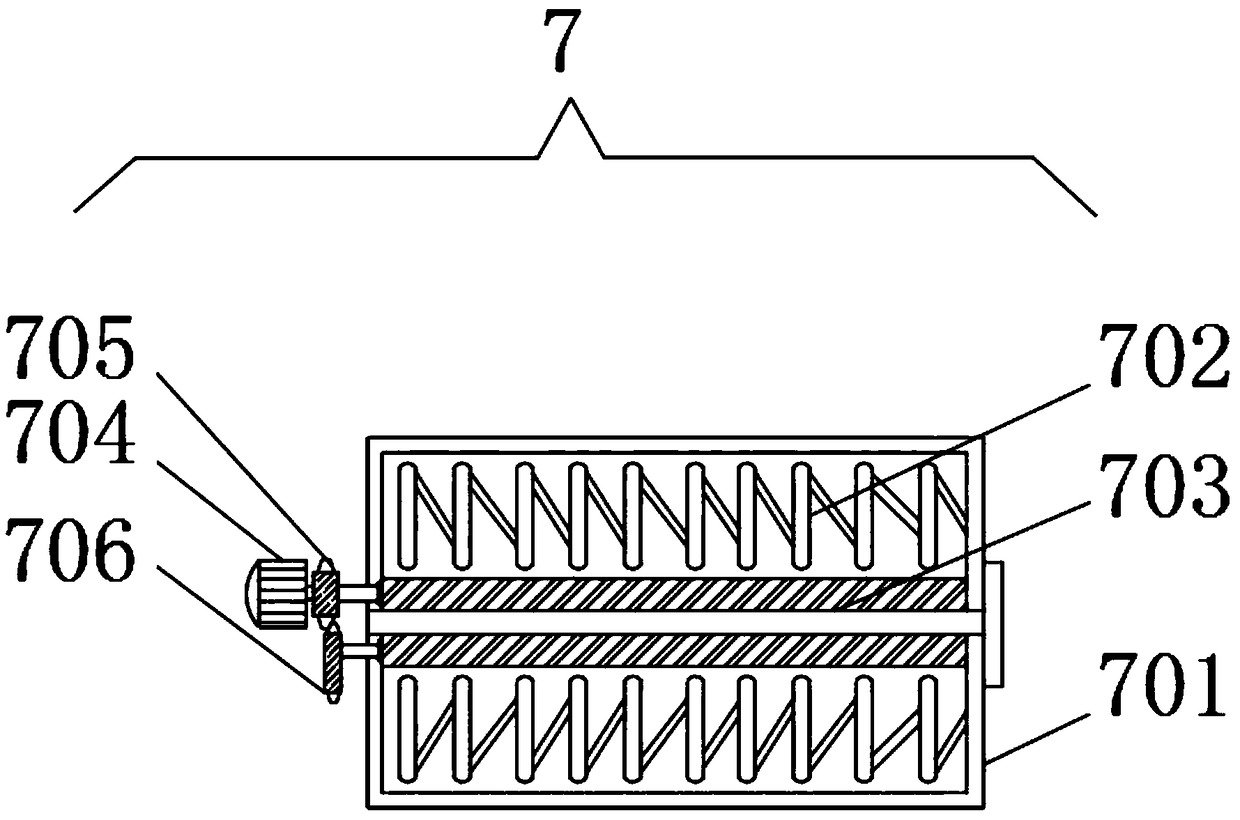

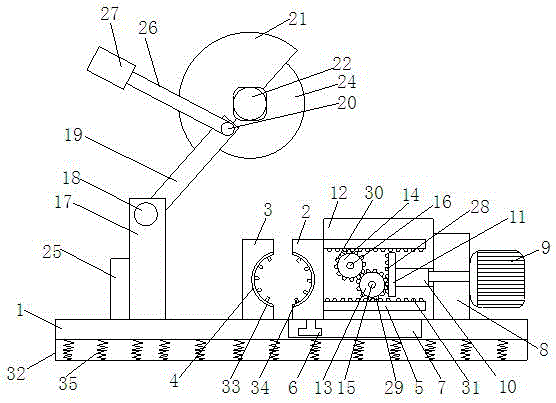

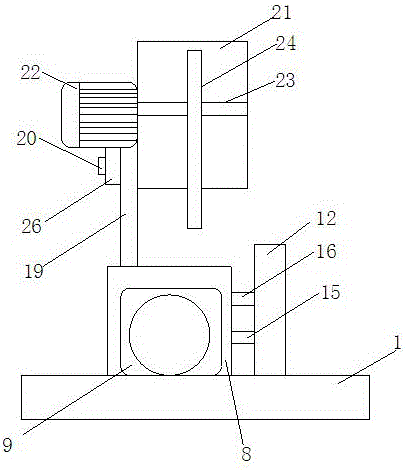

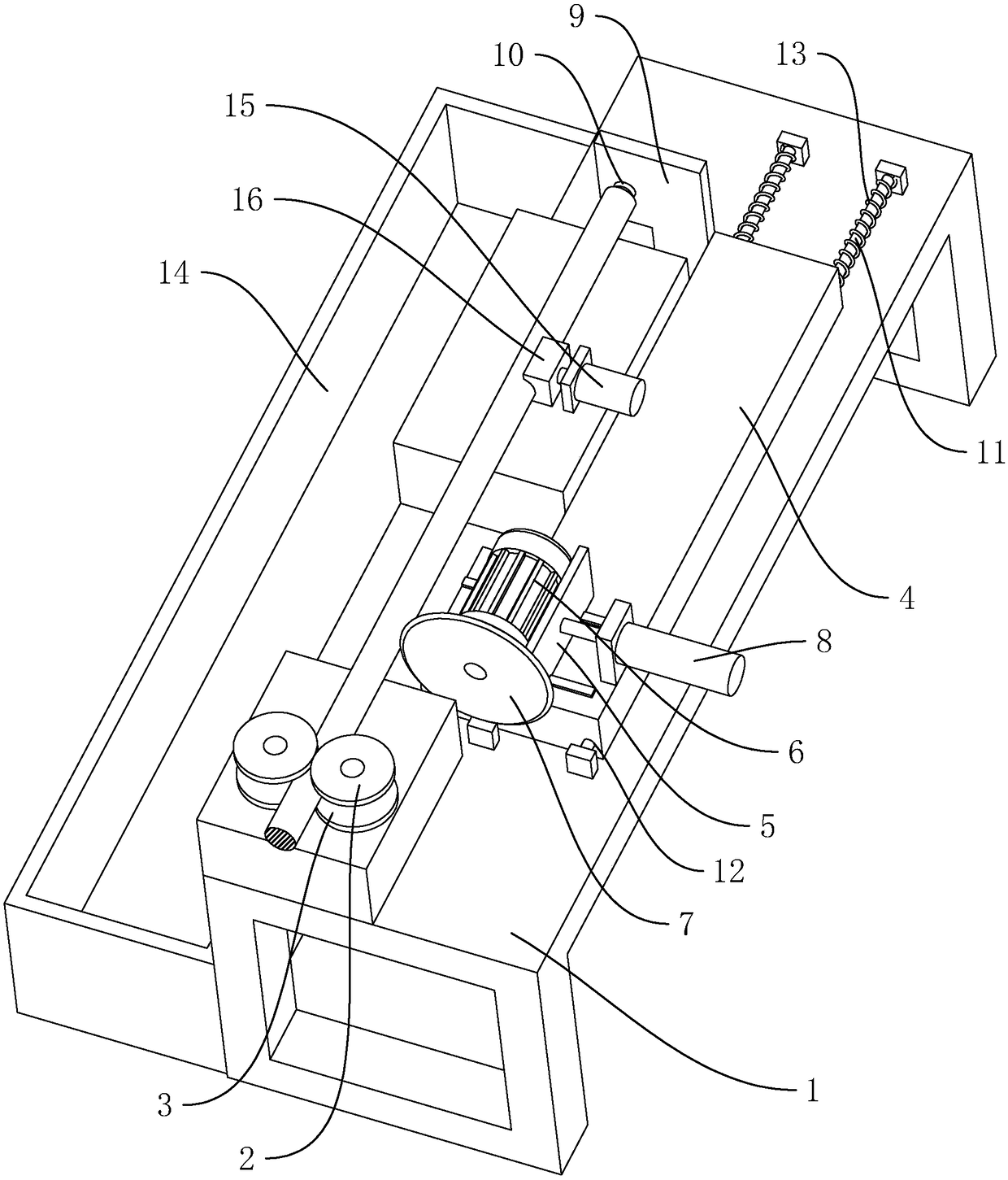

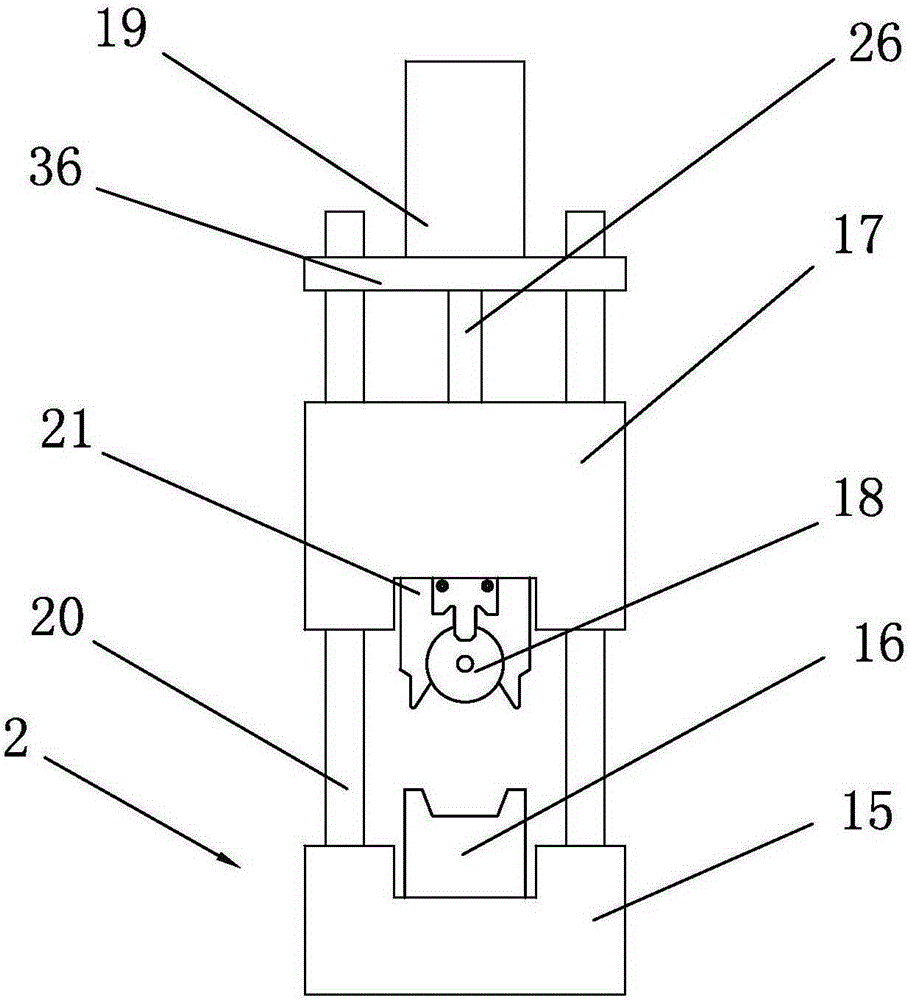

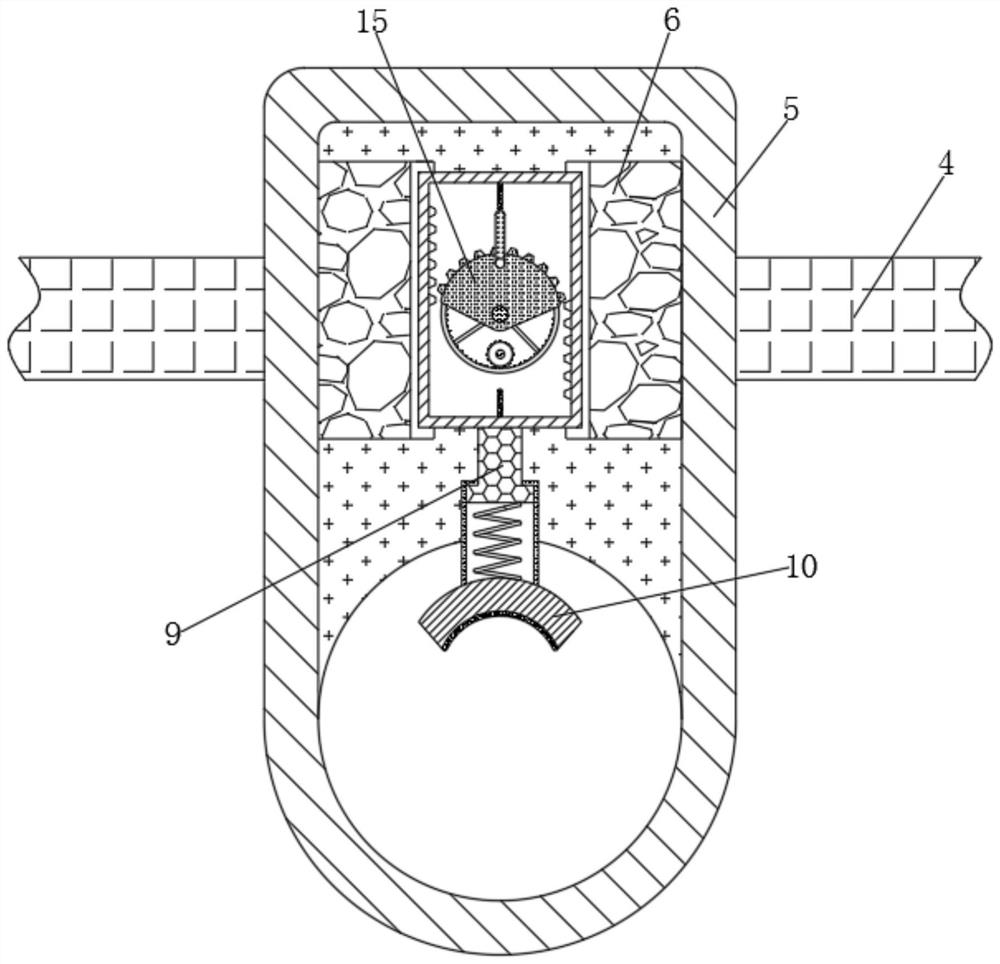

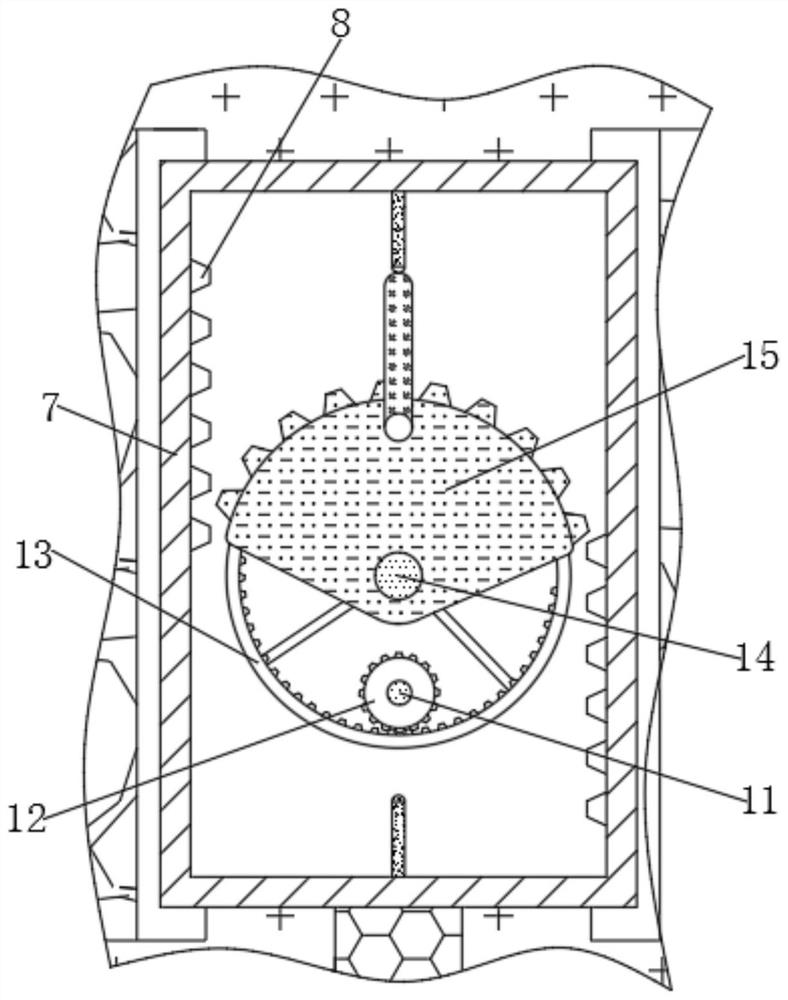

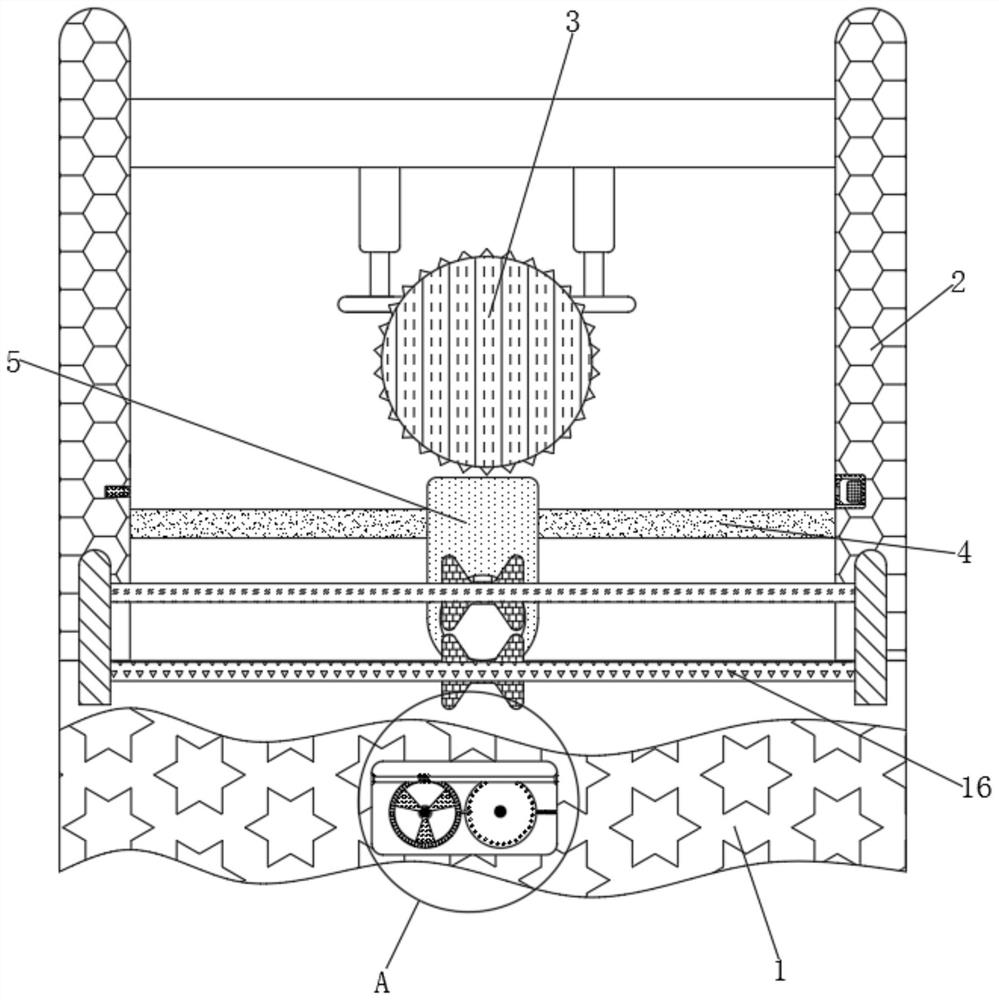

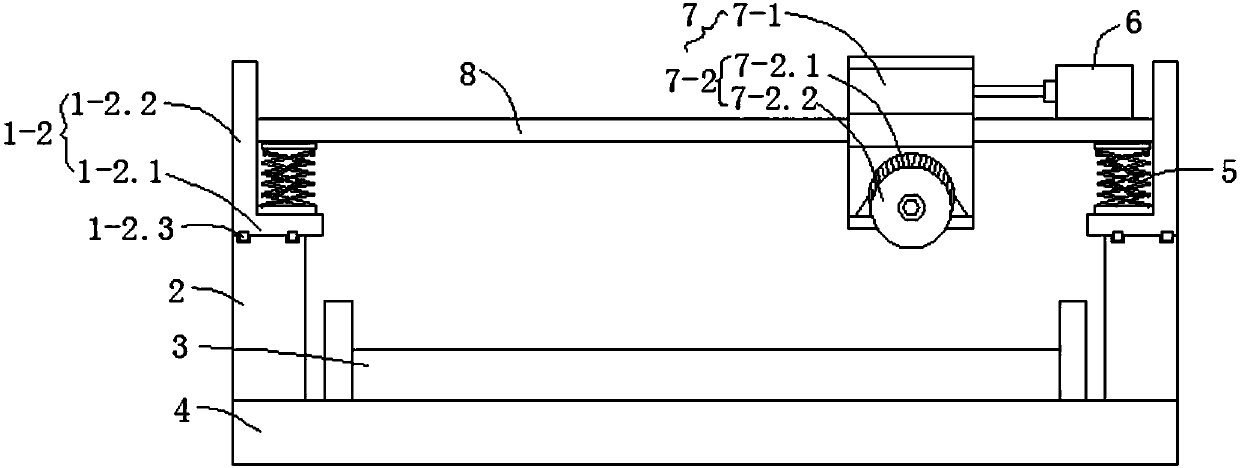

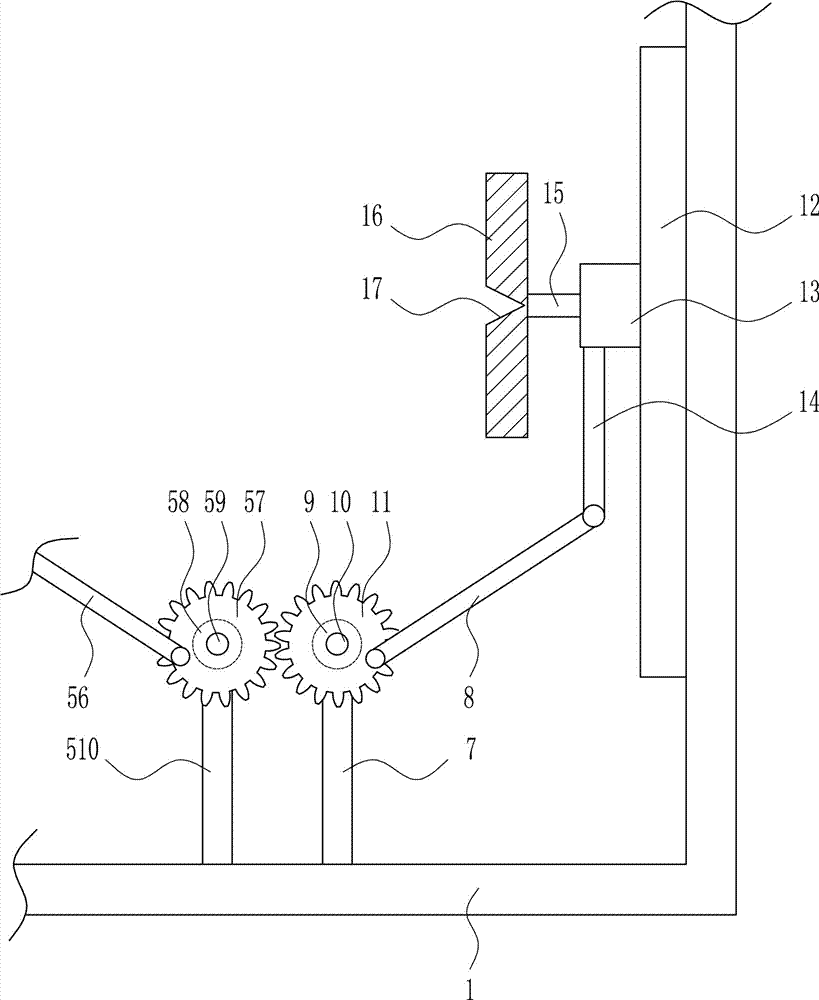

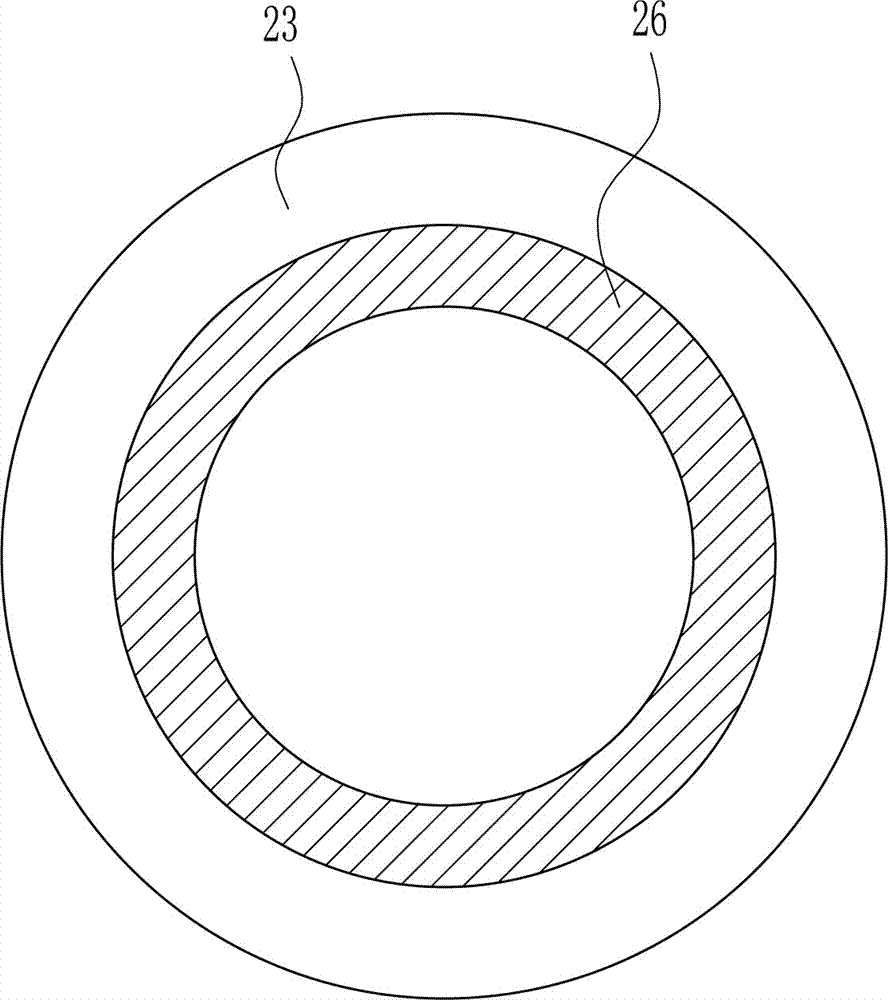

Automatic rubber hose cutting equipment and automatic rubber hose cutting technology

ActiveCN109227674ARealize automatic cuttingNot easy to scratchMetal working apparatusGear wheelFixed frame

The invention relates to automatic rubber hose cutting equipment and an automatic rubber hose cutting technology. The automatic rubber hose cutting equipment comprises a bottom plate, a supporting device and a cutting device, and the supporting device and the cutting device are sequentially installed on the bottom plate from left to right; the supporting device comprises a fixing plate, a fixed frame, a movable air cylinder, an inner wall supporting mechanism and an outer wall supporting mechanism; the cutting device comprises a linear guide rail, an electric sliding block, a working plate, aworking gear, a driving gear, a driving motor, a rotating ring, a rotating gear, a rotating motor, a supporting air cylinder, a supporting plate, a rotating rod, a sliding frame, a mounting frame, a cutting motor and a cutting blade. The invention further provides a using method of the automatic rubber hose cutting equipment. The equipment and the technology can solve the problems that in an existing rubber hose cutting process, the labor cost is high, the working efficiency is low, the cutting surface is not smooth, safety hidden hazards exist and the surface of a rubber hose is easily scratched, and the function of automatically cutting the rubber hose can be achieved.

Owner:中金液压胶管股份有限公司

Gauze cutting machine enabling good cutting effect

InactiveCN108998950AImprove cleanlinessConvenient for subsequent cutting and storageSevering textilesTextile shapingYarnSprayer

The invention provides a gauze cutting machine enabling a good cutting effect, and belongs to the gauze cutting machine technical field. The gauze cutting machine enabling a good cutting effect comprises a housing; a first cloth roller is fixedly mounted on the left side of the interior of the housing; a water pump is fixedly mounted at the upper part of the interior of the housing; a water tank is fixedly mounted to the right side of the water pump; and a sprayer is fixedly mounted below the water pump. With the gauze cutting machine enabling a good cutting effect adopted, gauze can be quickly dried and flattened; wrinkled gauze can be ironed to be flat, so that subsequent cutting and storage work can be facilitated; the gauze can be disinfected; and the cleanness of the gauze can be improved; the cutting device can perform automatic cutting, so that manpower can be saved; the service life of a blade can be prolonged; the replacement of the blade can facilitated; cutting quality can be improved; a situation that a large number of yarn ends are left and need to be manually removed can be avoided; and the efficiency of the finished product production of gauze can be improved.

Owner:江西美宝利实业有限公司

Production method for seamless nickel sheet with microprism array

InactiveCN103009016AAvoid pollutionImprove stitching accuracyElectroforming processesElectroformingNickel plate

The invention relates to a production method for a seamless nickel sheet with a microprism array. The production method includes the steps of manufacturing unit nickel sheets of required amount; performing finish machining to and removing burrs of the unit nickel sheets, and cutting two sides of a front surface of each unit nickel sheets to form a cut surface with certain angle; arranging the machined nickel plates as required, and welding the unit sheets from reverse surfaces to be sequentially connected to form a required large nickel sheet matrix; bending the welded large nickel sheet matrix, selecting a plastic cylinder with smooth inner wall, and fixing the bent large nickel sheet matrix on the smooth inner wall of the plastic cylinder; and placing the plastic cylinder with the large nickel sheet matrix adhered into an electroforming groove for electroforming, and forming the required seamless nickel sheet on the front surface of the large nickel sheet matrix. Cutting precision and splicing precision of the unit nickel sheets are controlled strictly, the surface of a die for producing the large nickel sheet matrix of the nickel sheet is seamless by the aid of the cylinder, and accordingly production of the seamless nickel sheet is truly achieved.

Owner:CHANGZHOU HUA R SHENG REFLECTIVE MATERIAL

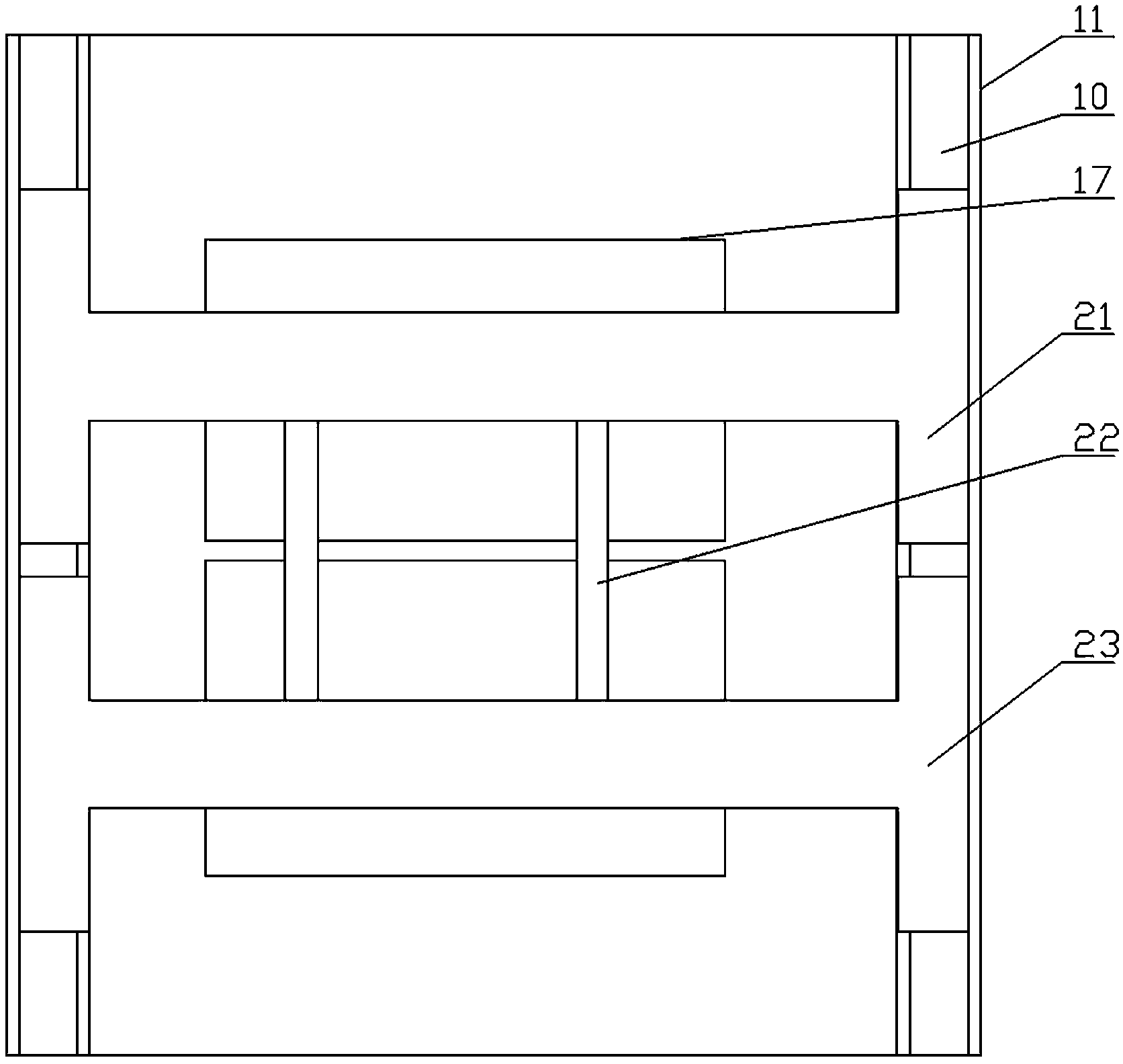

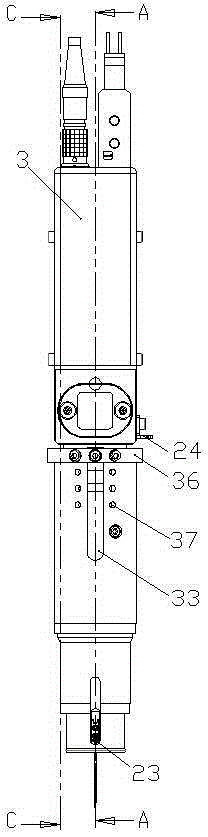

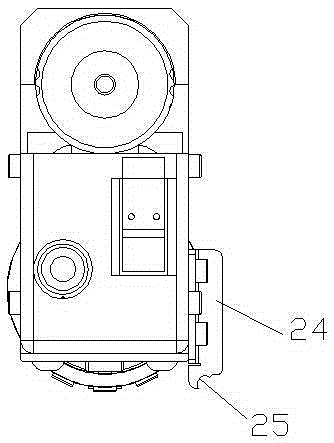

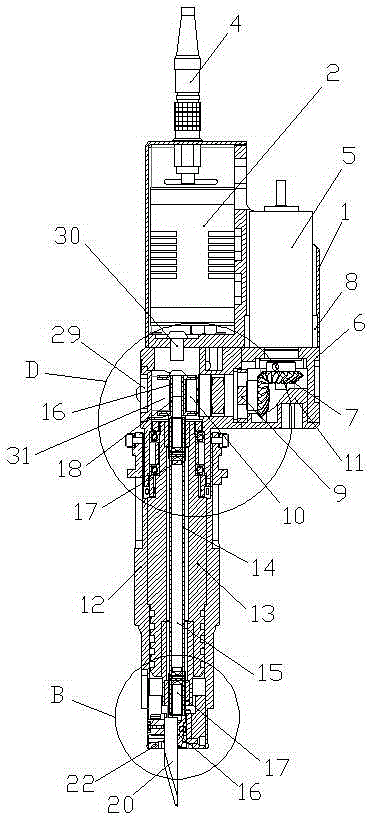

Multifunction high-precision numerical control plasma machining device

The invention relates to a multifunction high-precision numerical control plasma machining device comprising a base and a machining platform with a nail bed structure. A Y-axis transmission mechanism and an X-axis transmission device are respectively arranged above and below the machining platform, wherein the Y-axis transmission mechanism is connected with a sheet cutting torch unit and a medium plate cutting torch unit which can be alternately used and are provided with infrared locating real-time tracking devices; a cutting torch formed by extending a Y-axis cross beam is provided with a pipe cutting torch unit matched with a pipe rotating mechanism; the X-axis transmission device and the Y-axis transmission mechanism respectively comprise a ball screw and a servo motor; the sheet cutting torch unit comprises a sheet cutting torch with a water spray cover; the medium plate cutting torch unit comprises an automatic arc voltage boosting Z-axis actuating mechanism and an arc voltage boosting anticollision clamp; and the pipe rotating mechanism comprises a lifting open and close roller wheel followup device and a big-power bearing block servo motor. The invention not only has stronger comprehensiveness, lower production cost, higher cutting precision, low noise, small vibration, high stability and higher cutting quality but also facilitates fine blowdown.

Owner:武汉薪火智能切割机器有限公司

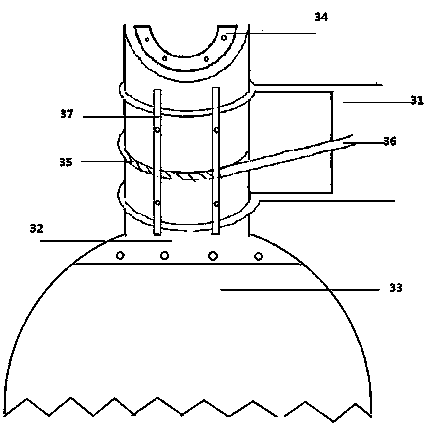

Device for automatically cutting and extracting stone for fruits

InactiveCN101214082ANo mechanical damageOrientation is accurateFruit stoningCircular discEngineering

A fruit automatic orientation slitting and coring device includes at least one independent channel. Two clamping belts are respectively wound on active belt rollers and positive belt rollers. A pair of active belt rollers rotates at the same speed and in reverse direction. The linear velocity and the direction of the tight sides of the two clamping belts are uniform. Two oriented belts are arranged under the clamping belts. The velocity difference is provided between the oriented belt and the clamping belt. The moving directions are uniform. The tight side of the oriented belt which is arranged in a V-shaped groove and moves levelly and straightly drives fruit to rotate. A milling is equipped with a disc sickle with sharp triangle teeth, the edge line of which coincides with the central line of the independent channel. A float cutting guide device is arranged above the disc sickle. When the disc sickle comes across a flinty kernel, the float cutting guide device moves upward. Therefore, the disc sickle is protected from being damaged. The disc sickle continuously applies forces on the kernel to lead to the loosening combination between the kernel and the flesh. And the kernel is separated from the flesh. The device is provided with high operation efficiency. Complete valves can be obtained. And the device is applied to the slitting and coring of fruits with kernels, such as the plums apricots, etc., with ovum shape.

Owner:INST OF AGRI MECHANIZATION XINJIANG AGRI INST

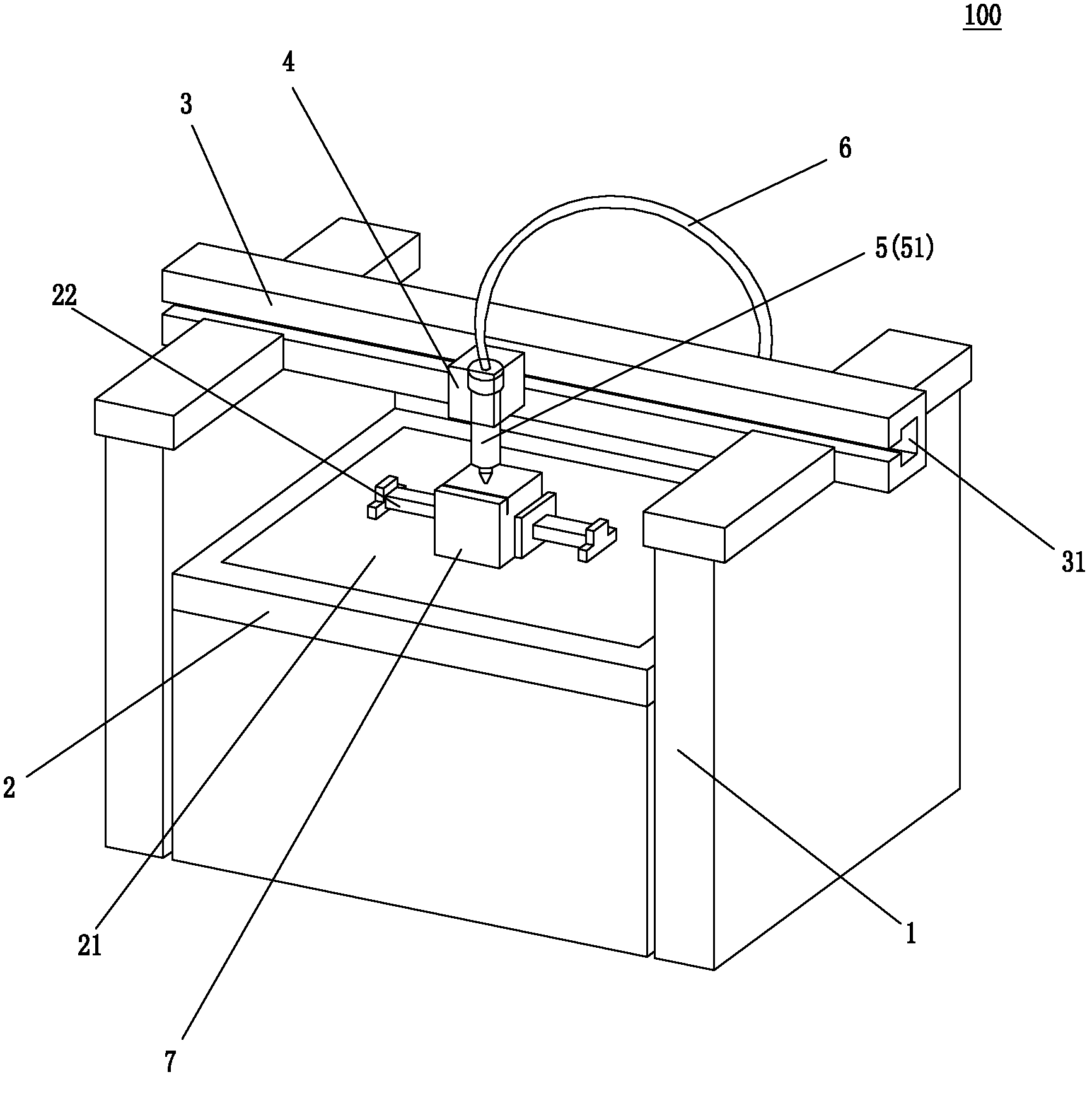

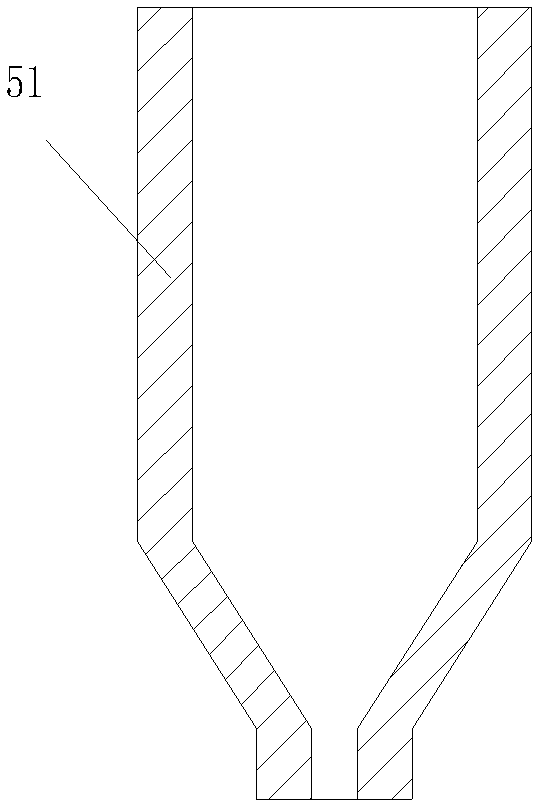

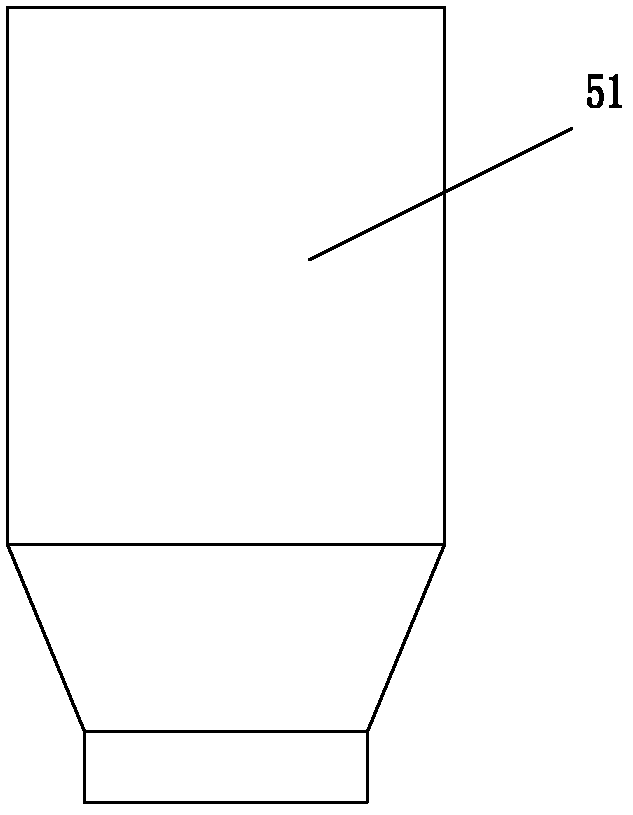

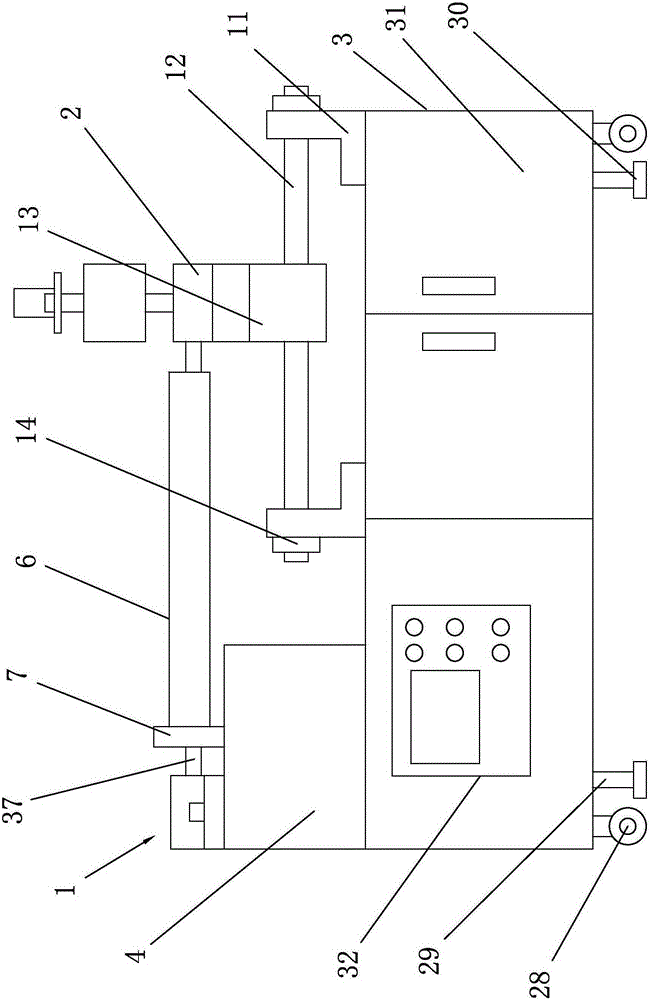

Cutting device for solar panel for environment-friendly power station

InactiveCN106695517AFlat cutting surfaceImprove work efficiencyGrinding drivesGrinding machinesPower stationGrinding wheel

The invention relates to a cutting device, and particularly relates to a cutting device for a solar panel for an environment-friendly power station. The technical problem to be solved by the invention is to provide a cutting device for a solar panel for an environment-friendly power station, which is capable of ensuring a smooth cutting surface, environment-friendly in cutting and high in working efficiency. In order to solve the abovementioned technical problem, the invention provides such a cutting device for a solar panel for an environment-friendly power station. The cutting device comprises a support, a collection frame, a support rod, a push device, a placement plate, a grinding wheel, a second motor and a lifting device, wherein the push device and the like are sequentially arranged at the bottom in the support from left to right; and the placement plate is arranged at the top end of the support rod, the lifting device is arranged at the right side of the top in the support, the second motor is arranged at the bottom of the lifting device, and the grinding wheel is connected to the left end of the second motor. The cutting device disclosed by the invention adopts the combination of the push action of the push device, the buffer action of a buffer device, the lifting action of the lifting device and a dust absorption action of a dust absorption device.

Owner:贾爱忠

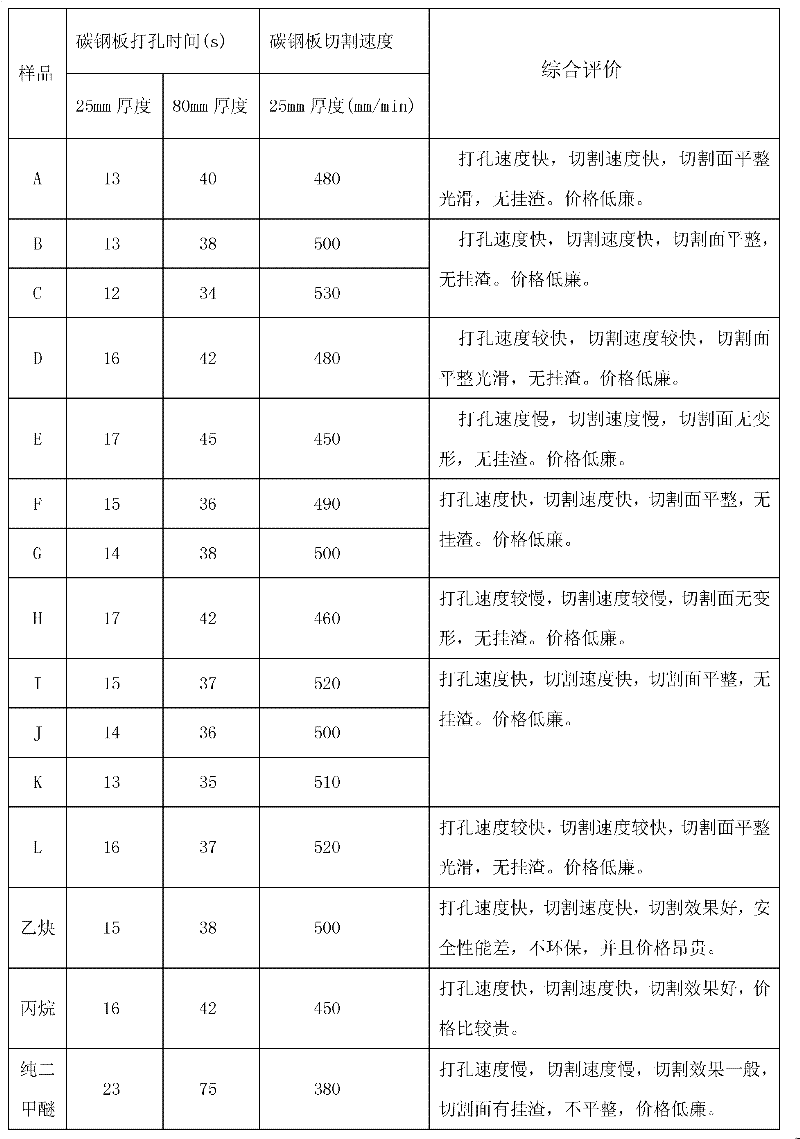

Industrial fuel gas for metal cutting and welding

This invention discloses an industrial fuel gas used for metal cutting and welding. Additive and dimethyl enther are added to cylinder to make-up the fuel, dimethyl enther is 40~99.9% and other rest additive. The additive is consisted by one or any several kind of following fuels as arbitrary proportion, petroleum liquefied gas, propane, butane, propylene, pentane, clean oil, methanol, ethanol. This invention has good burning property, security, environmental protection capability and extra high burning flame temperature. Comparing to acetylene, it is not easy to bomb, and its storage, transportation, using and management is more convenient and safe. There is no pollution to environment and operator. Its preheating and cutting velocity is fast, welding and welding line quality is good, oxygen consumption is low, so it improves work efficiency and reduces cost.

Owner:郑长同 +3

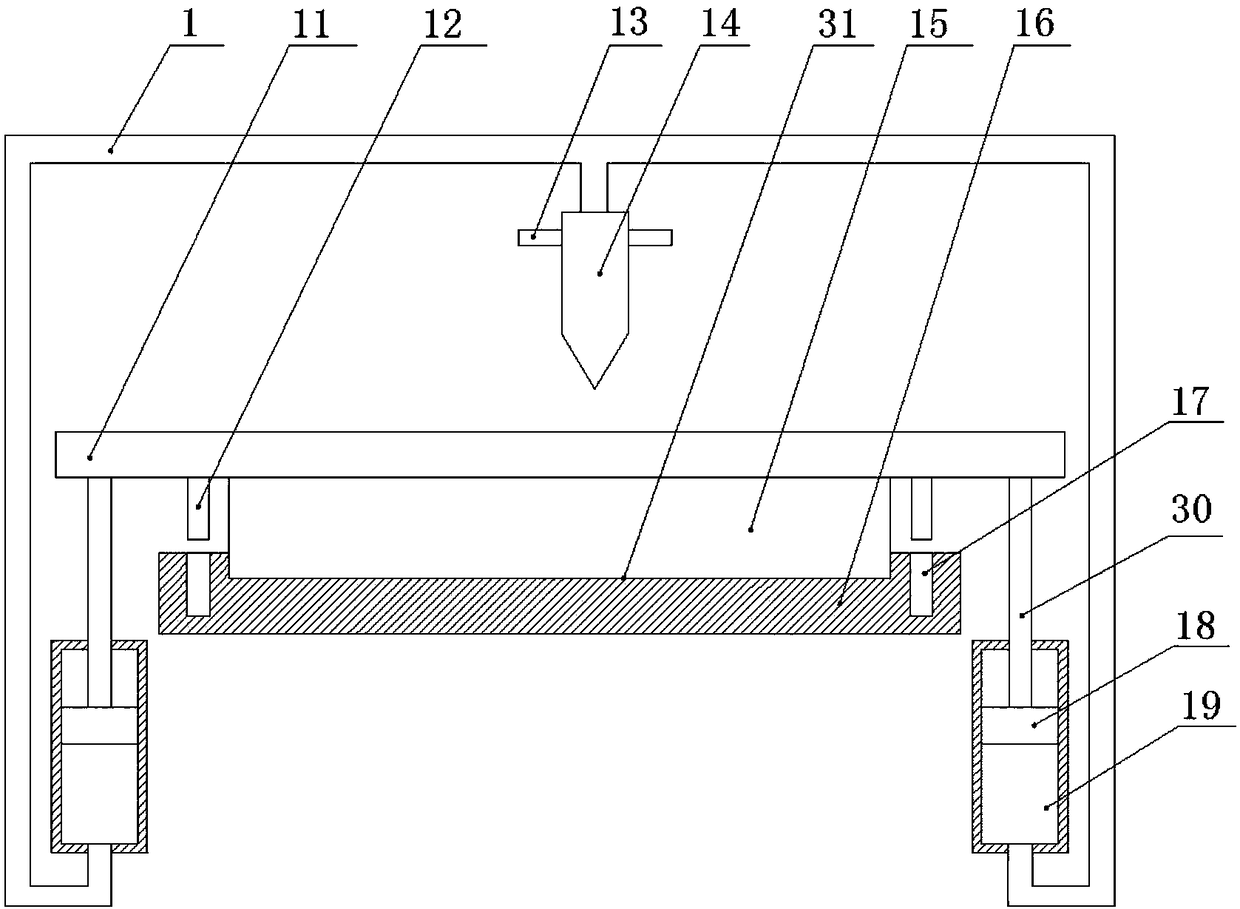

Coal sample preparation device for true three-dimensional permeability determination

InactiveCN102519769AReduced risk of breakageImprove molding ratePreparing sample for investigationStress concentrationJet flow

The invention relates to a coal sample preparation device for the true three-dimensional permeability determination. The preparation device comprises a fixed support, the fixed support is provided with a sample loading bench, and the sample loading bench is formed by a loading plane and a sample holder arranged on the loading plane; and a sliding guide rail is arranged over the sample loading bench, the sliding guide rail is slidingly provided with a sliding block, the sliding block is provided with a vertically downward jet nozzle, the jet nozzle is a flat seam nozzle, the flat seam of the flat seam nozzle and the sliding guide rail are arranged in a longitudinal parallel mode. The coal sample preparation device for the true three-dimensional permeability determination adopts the flat seam nozzle, so a jet flow jetted by the flat seam nozzle forms a plane type jet flow, and a stress concentration problem caused by the strong heterogeneity of the internal structure of coal can be maximally reduced, so the coal sample fragmentation risk is reduced, and the coal sample molding rate is improved; coal sample cutting is carried out in a plane type jet mode, so the cutting speed of a water jet flow is improved, thereby cutting surfaces are flattened, and the cutting effect is good.

Owner:CHINA UNITED COALBED METHANE +1

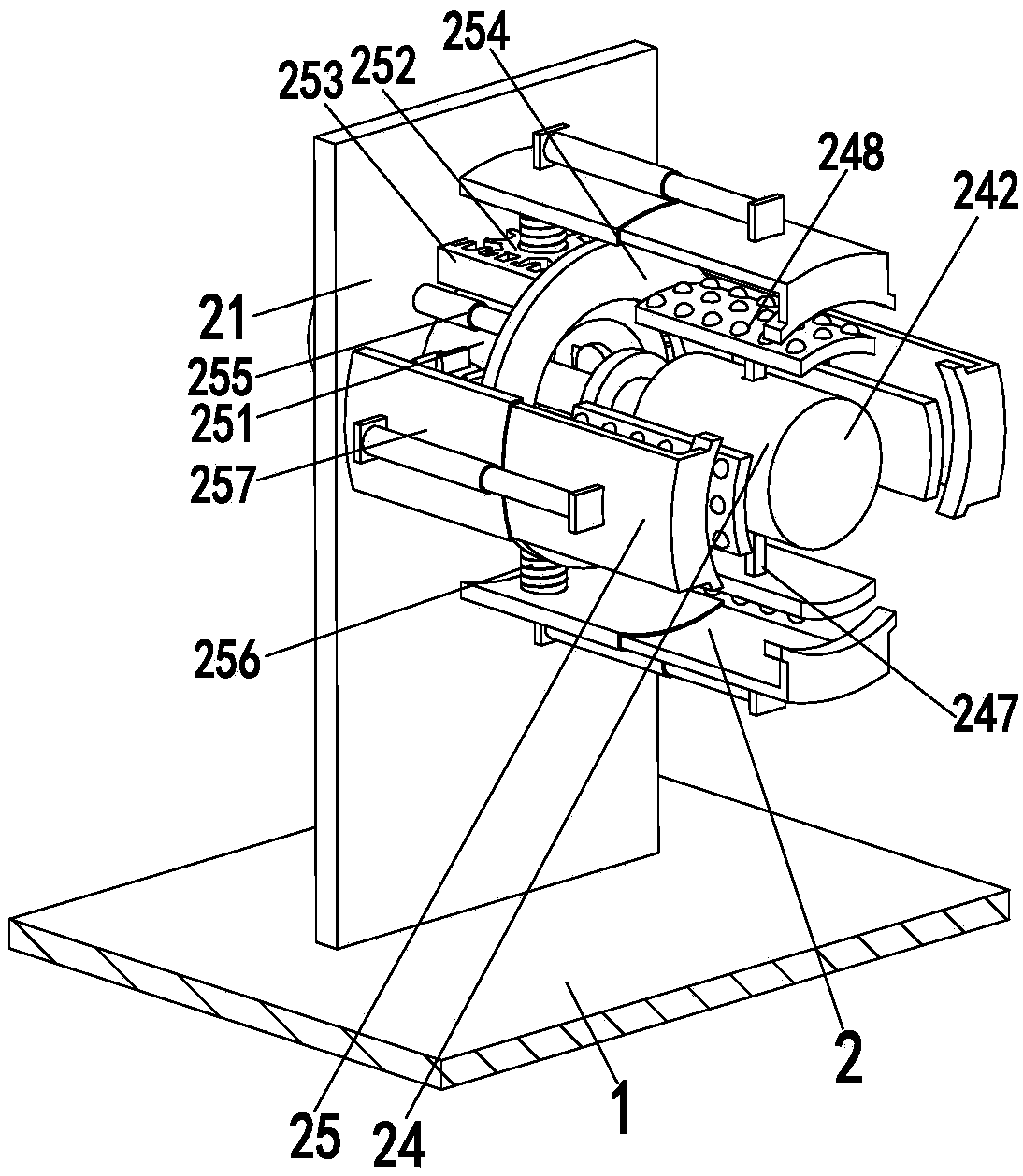

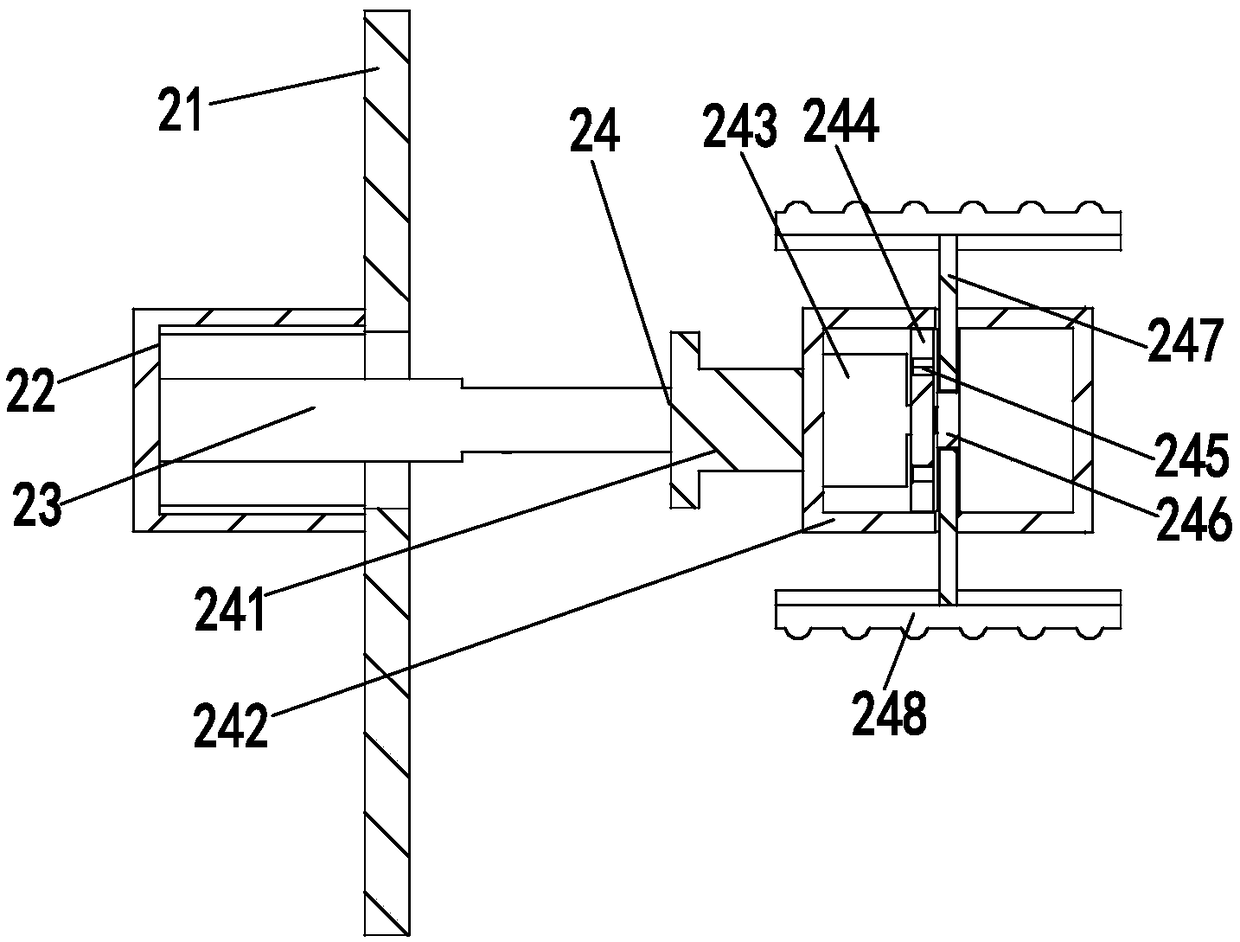

Steel pipe cutting machine high in clamping property

InactiveCN106624116AEnhanced clamping abilityClamping reachesTube shearing machinesShearing machine accessoriesArchitectural engineeringMachining

The invention provides a steel pipe cutting machine high in clamping property, and relates to the field of steel pipe machining. The steel pipe cutting machine high in clamping property comprises a base, an active block and a fixed block are arranged at a center shaft on the top of the base, the active block is located at the right side of the fixed block, clamping grooves are formed in the side, close to the fixed block, of the active block and the side, close to the active block, of the fixed block, two first support plates are fixedly connected to the right side of the active block, a sliding block is fixedly installed at the bottom of the active block, a sliding groove matched with the sliding block for use is formed in the position, corresponding to the sliding block, of the top of the base, a supporting block is fixedly installed on the right side of the top of the base, a first motor is fixedly installed on the right side of the supporting block, and a rotating shaft of the first motor penetrates through a supporting block and extends to the left side of the supporting block to be fixedly connected with a connection column which is located between the first support plates. The steel pipe cutting machine high in clamping property is not likely to slip, the cut surface of a cut workpiece is smooth, and use is convenient.

Owner:WUXI KONSTANT POWER TECH CO LTD

Continuous casting cutting slag cleaning method and slag cleaning device thereof

The invention discloses a continuous casting cutting slag cleaning method and a slag cleaning device thereof, which have the advantages that the simplicity is realized, the implementation is easy, the structure is simple, the installation and the use are convenient, and the slag cleaning effect is good. In the method, a blowing nozzle is arranged on a plane intersected with or vertical to the cutting surface, and ash at a cutting seam part is cleared by air through the blowing nozzle. The slag cleaning device comprises the blowing nozzle arranged on the plane vertical to the direction of a cutting nozzle through a U-shaped bent wall, and in addition, the blowing nozzle and the cutting nozzle are arranged at two opposite sides of billet steel.

Owner:陈寅明

Dual-purpose saw web for cutting and grinding glass and its manufacturing method

InactiveCN1657454AHigh hardnessEfficient processingBonded abrasive wheelsGlass severing apparatusIron powderAlloy

Owner:HENAN HUANGHE WHIRLWIND CO LTD

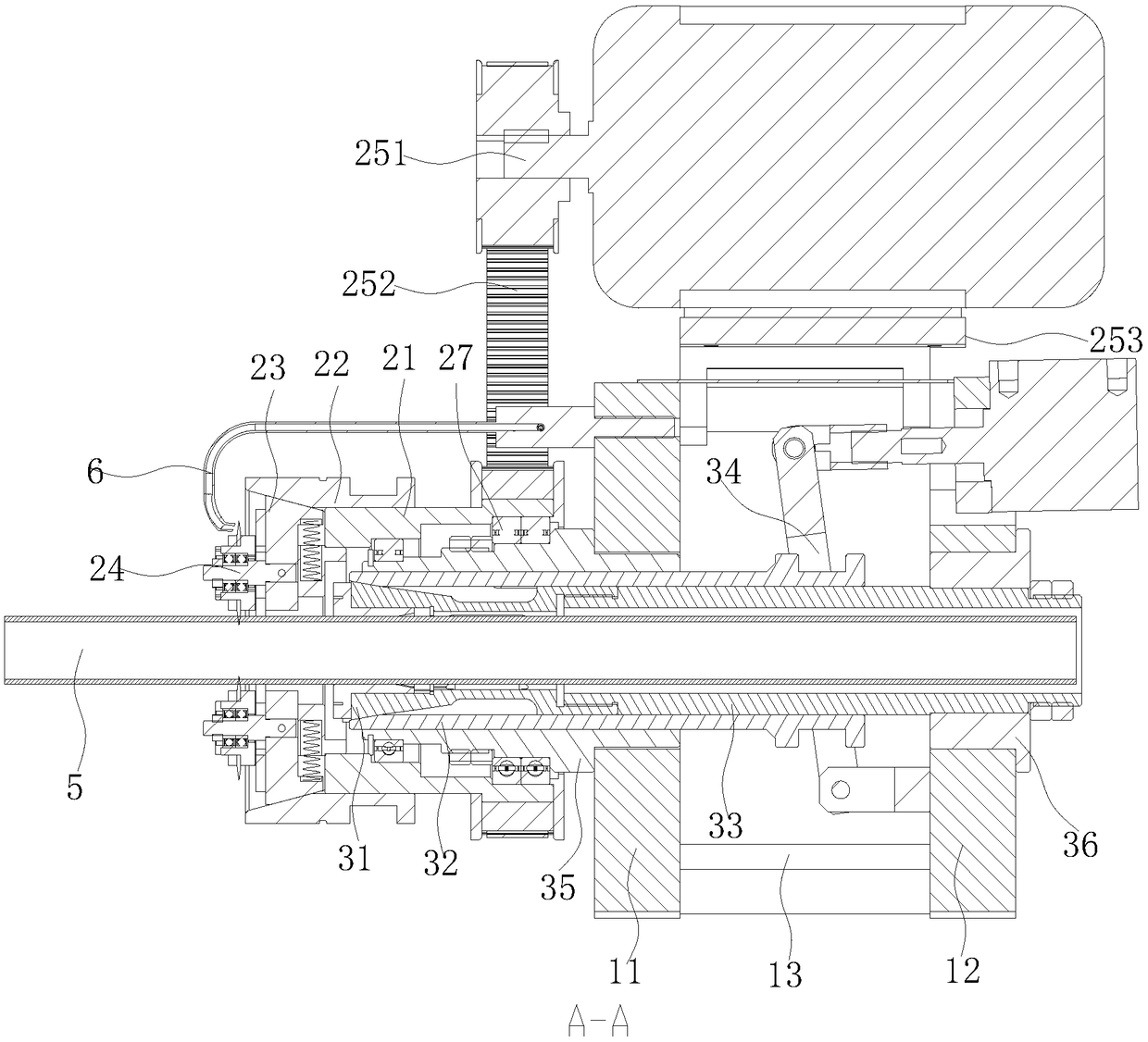

Copper bush machining technology and copper tube cutting device thereof

The invention discloses a copper bush machining technology and a copper tube cutting device of the copper bush machining technology. The copper bush machining technology and the copper tube cutting device of the copper bush machining technology aim to improve the copper bush machining and production efficiency. The copper bush machining technology is characterized by comprising the steps of preheating copper chips, melting the copper chips, manufacturing copper tubes, cutting off and collecting the copper tubes and machining the copper tubes into the copper bushes. The copper tube cutting device comprises a sliding frame. The upper end face of the sliding frame is connected with a sliding table in a sliding manner. The sliding table is provided with a cutting-off assembly cutting off the copper tubes. The cutting-off assembly comprises a sliding block connected to the upper end face of the sliding table in a sliding manner, a drive motor fixedly connected to the upper end face of the sliding block, a blade fixedly connected to an output shaft of the drive motor and a first air cylinder which is arranged on the sliding table and drives the sliding block to slide, wherein an output shaft of the first air cylinder is fixedly connected with the sliding block. By the adoption of the copper bush machining technology and the copper tube cutting device of the copper bush machining technology, the production efficiency of the copper bushes can be improved, and meanwhile, the copper tube cutting device can rapidly cut the copper tubes.

Owner:嘉善超盛五金材料股份有限公司

Cutting device applied to production and processing of tubular glass

InactiveCN105271686AEasy to installEasy to fixGlass severing apparatusMechanical engineeringEngineering

The invention discloses a cutting device applied to production and processing of tubular glass. The cutting device comprises a workbench, a clamping device, a sliding component and a cutting component, wherein the workbench comprises a first workbench and a second workbench; the clamping device comprises clamping blocks and clamping air cylinders; the sliding component comprises a support frame, a sliding bar and a sliding block; and the cutting component comprises a fixing block, a bracket, a moving block, a cutting knife and a telescopic air cylinder. The cutting device is simple in structure and strong in practicability; with the design of the clamping device, the tubular glass is more convenient and simpler to fix and clamp; the cutting stability of the tubular glass is improved; a cut surface after cutting is smoother; then, with the design of the sliding block component and the cutting component, the tubular glass is cut more automatically; furthermore, the position of the cutting knife can be adjusted by the sliding block component and the cutting component, so that the cutting device is applicable to cutting the tubular glass with different diameters; the application scope of the cutting device is enlarged; and the comprehensive utilization efficiency is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

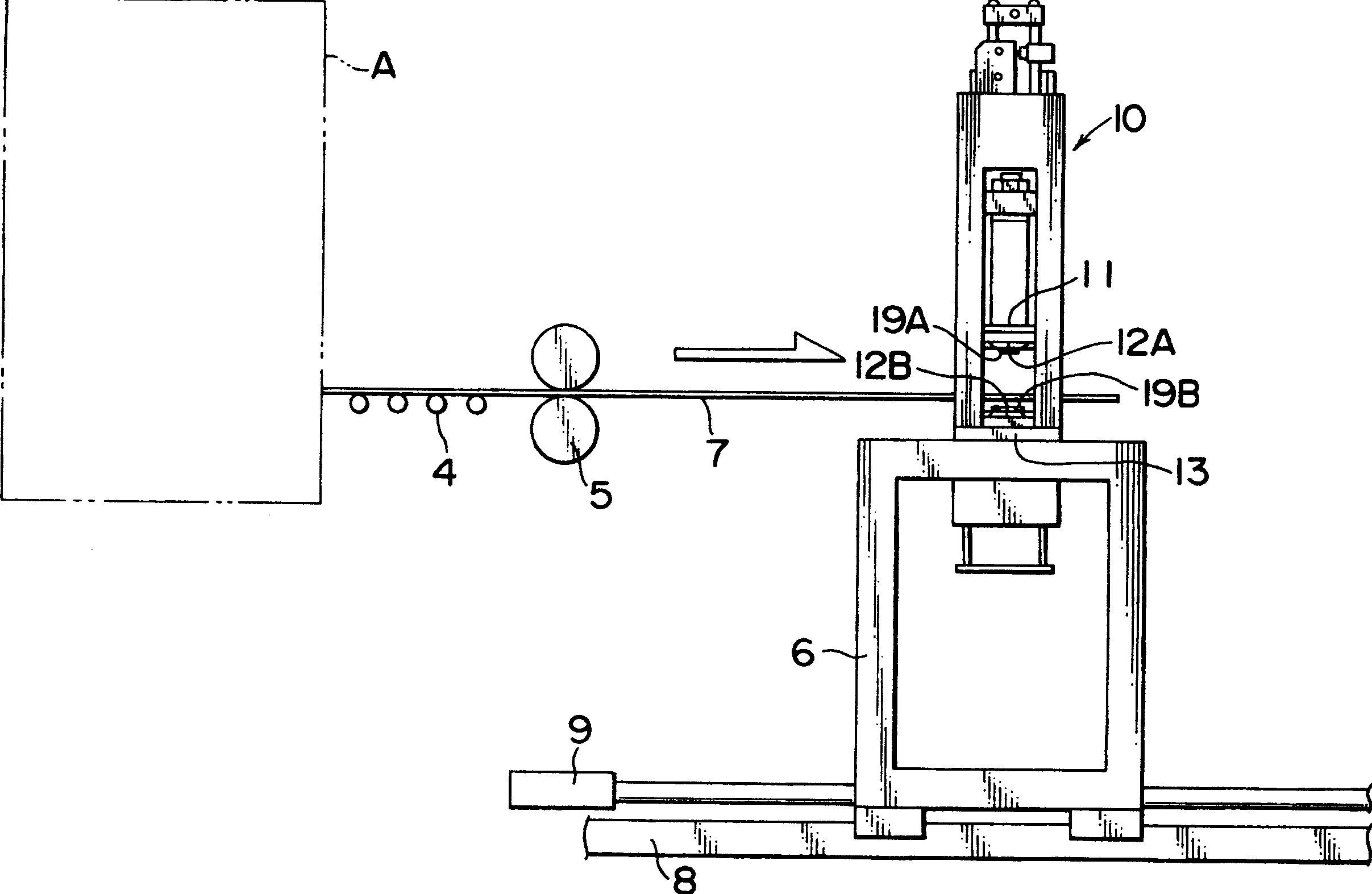

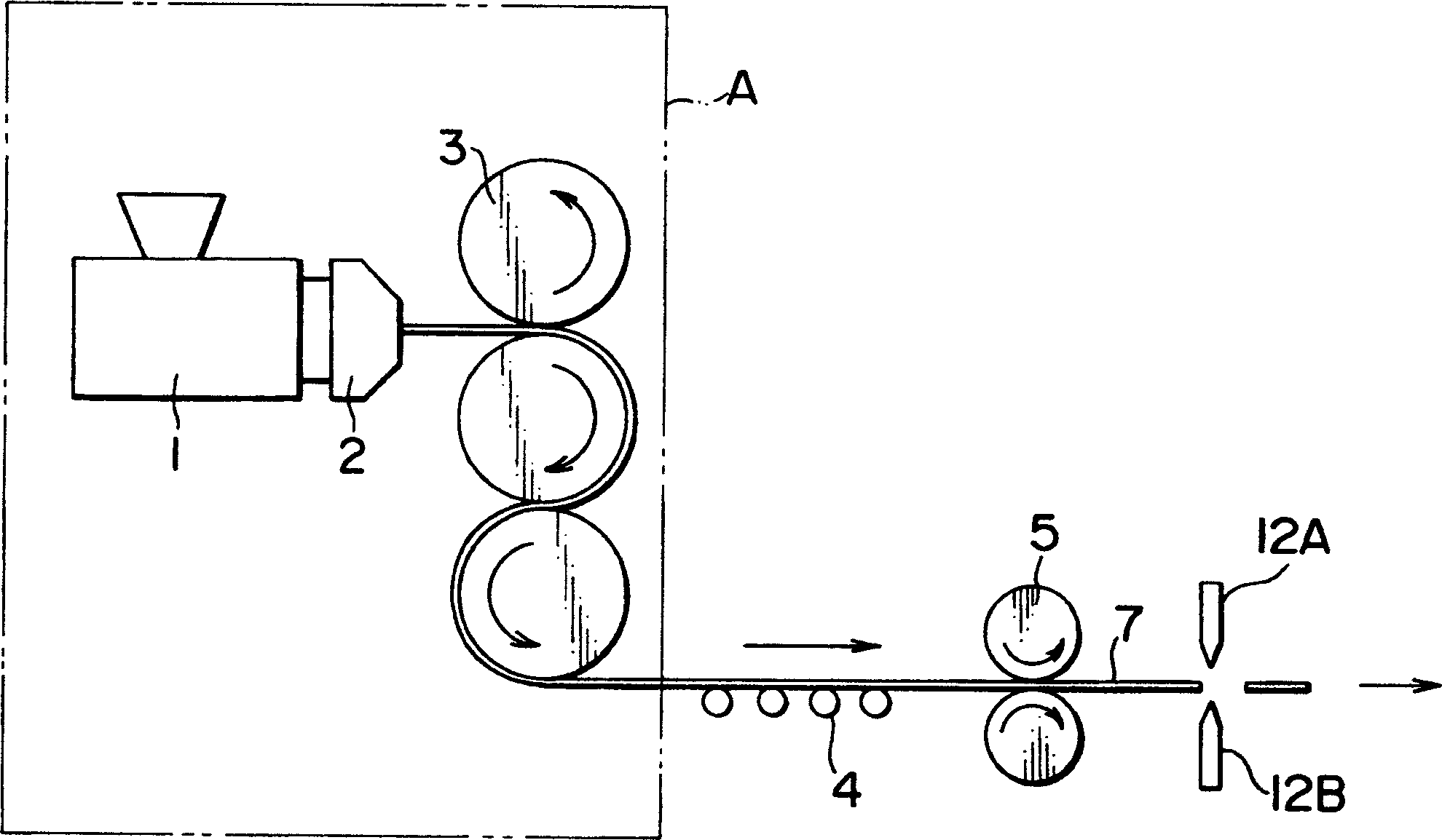

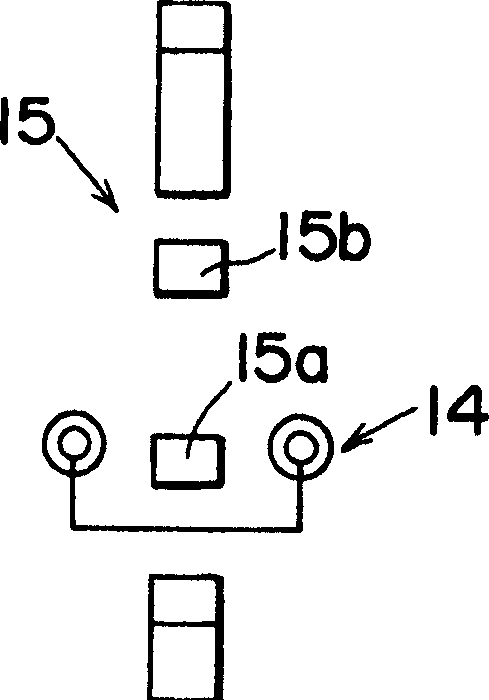

Cutting machine and manufacturing system for fixed size sheet

InactiveCN1757493AShort cutting timeImprove cutting accuracyMetal working apparatusElastic componentAcrylic resin

The invention provides a cutting machine capable of cutting rigid synthetic resin plate at high quality, in particular to the wide and thin rigid synthetic resin plate made from rubber and added with little acrylic resin or the like and provides a cutting machine capable of cutting out standard plate without chip from continuously flowing rigid synthetic resin plate. The cutting machine (10) comprises opposite an upper blade (12A) and a lower blade (12B), wherein two side faces of each blade are with elastic components (19A, 19B) protruded than the blades, while the elastic components can clamp rigid synthetic resin plate (7) when in cutting, the elastic components arranged on two side faces of the upper or lower blade are composed of an elastic portion near the blade and an elastic portion far from the blade, while the rigidity of the elastic portion near the blade is higher than the elastic portion far from the blade.

Owner:SUMITOMO CHEM CO LTD

Exhibition advertising board cutting device and cutting method thereof

InactiveCN111673825AWide applicabilityAchieve circular croppingMetal working apparatusEconomic benefitsEngineering

The invention discloses an exhibition advertising board cutting device and a cutting method thereof. The exhibition advertising board cutting device comprises a base. The two ends of the horizontal direction of the front and rear sides of the base are provided with folded edges. A left guide cavity and a right guide cavity are arranged inside the folded edges of the two ends of the front and rearside faces of the base correspondingly. A supporting platform is fixedly arranged over a table top of the base. A C-shaped clamping block I and a C-shaped clamping block II are arranged on the supporting platform. The ends of the folded edges at the two ends of the base are provided with vertical boards. A cutting platform is erected at the top ends of the vertical boards on the two sides. The cutting platform is provided with a cutting cavity. The exhibition advertising board cutting device is simple in structure, novel in design, reasonable in design, capable of realizing cutting of circularadvertising boards and square advertising boards and high in practicality. The two cutting modes are completed through one set of cutting device. The exhibition advertising board cutting device has great economic benefits.

Owner:马鞍山极趣信息技术股份有限公司

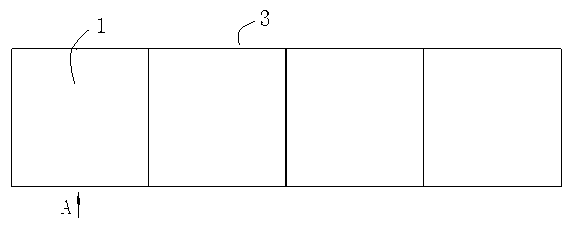

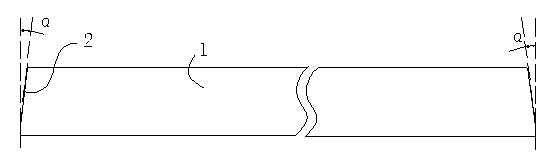

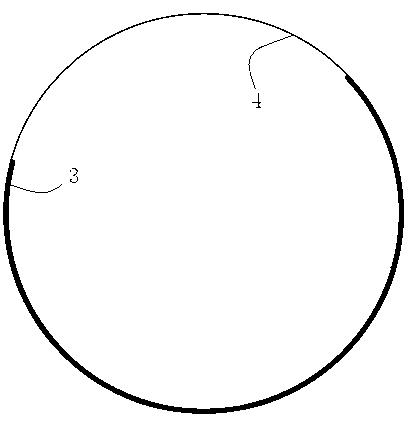

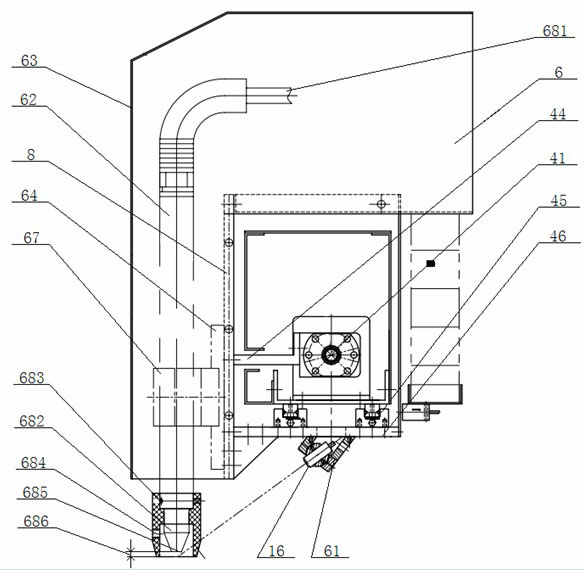

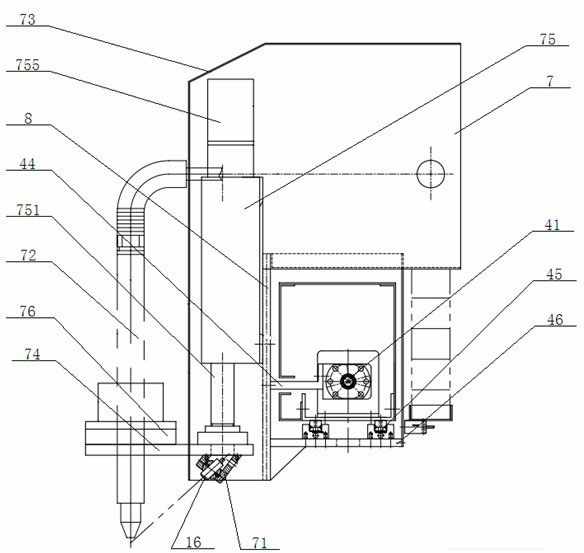

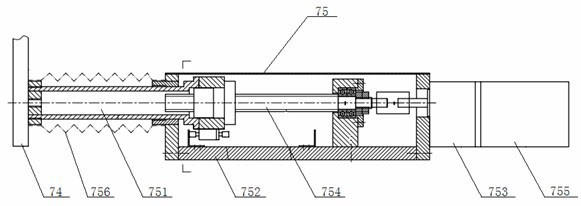

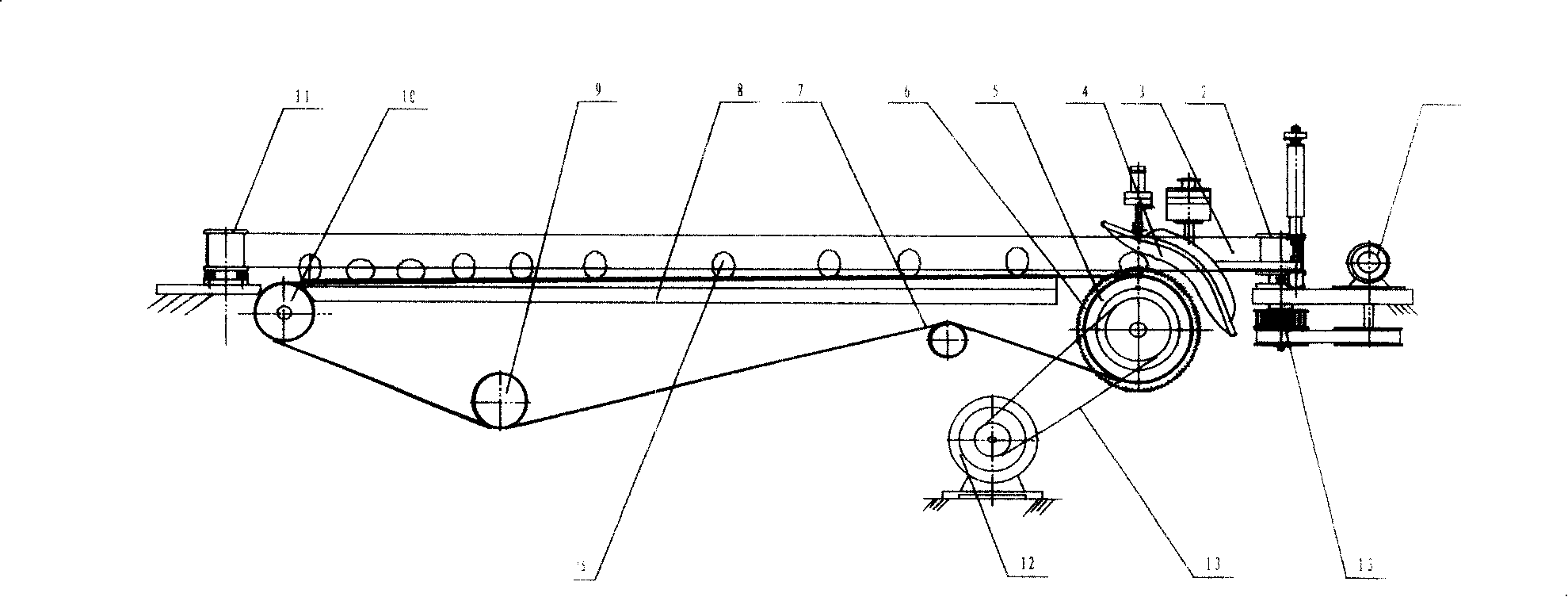

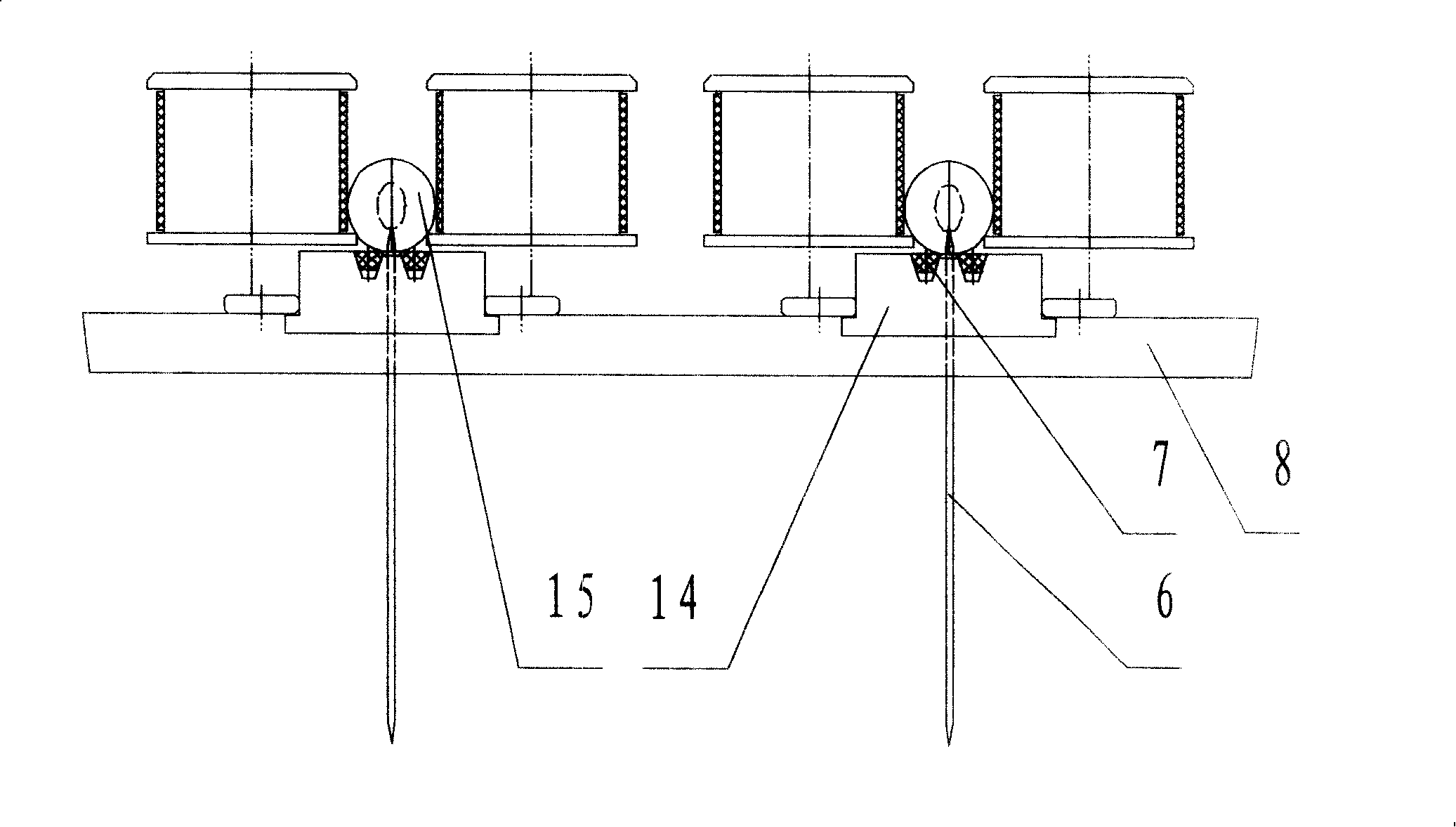

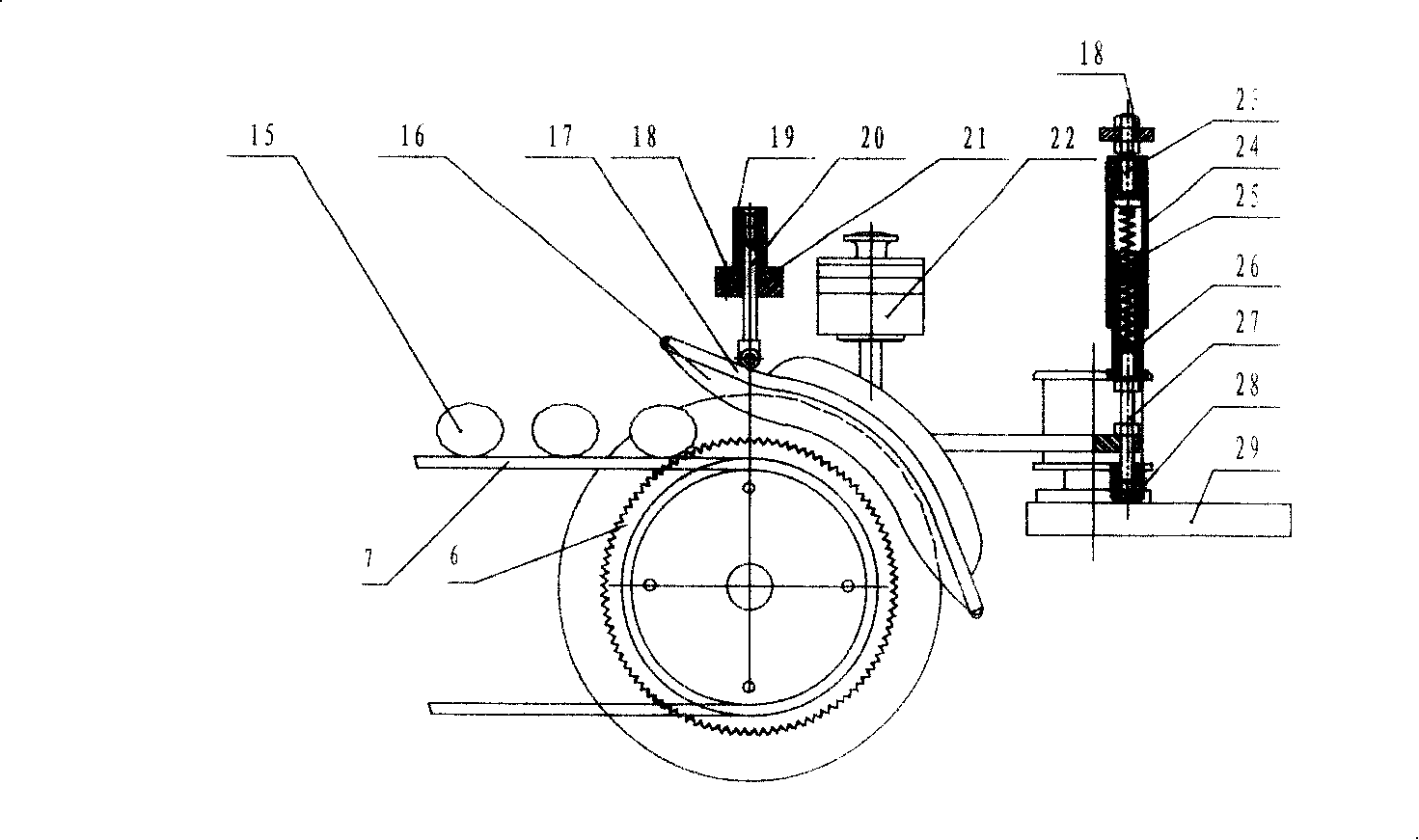

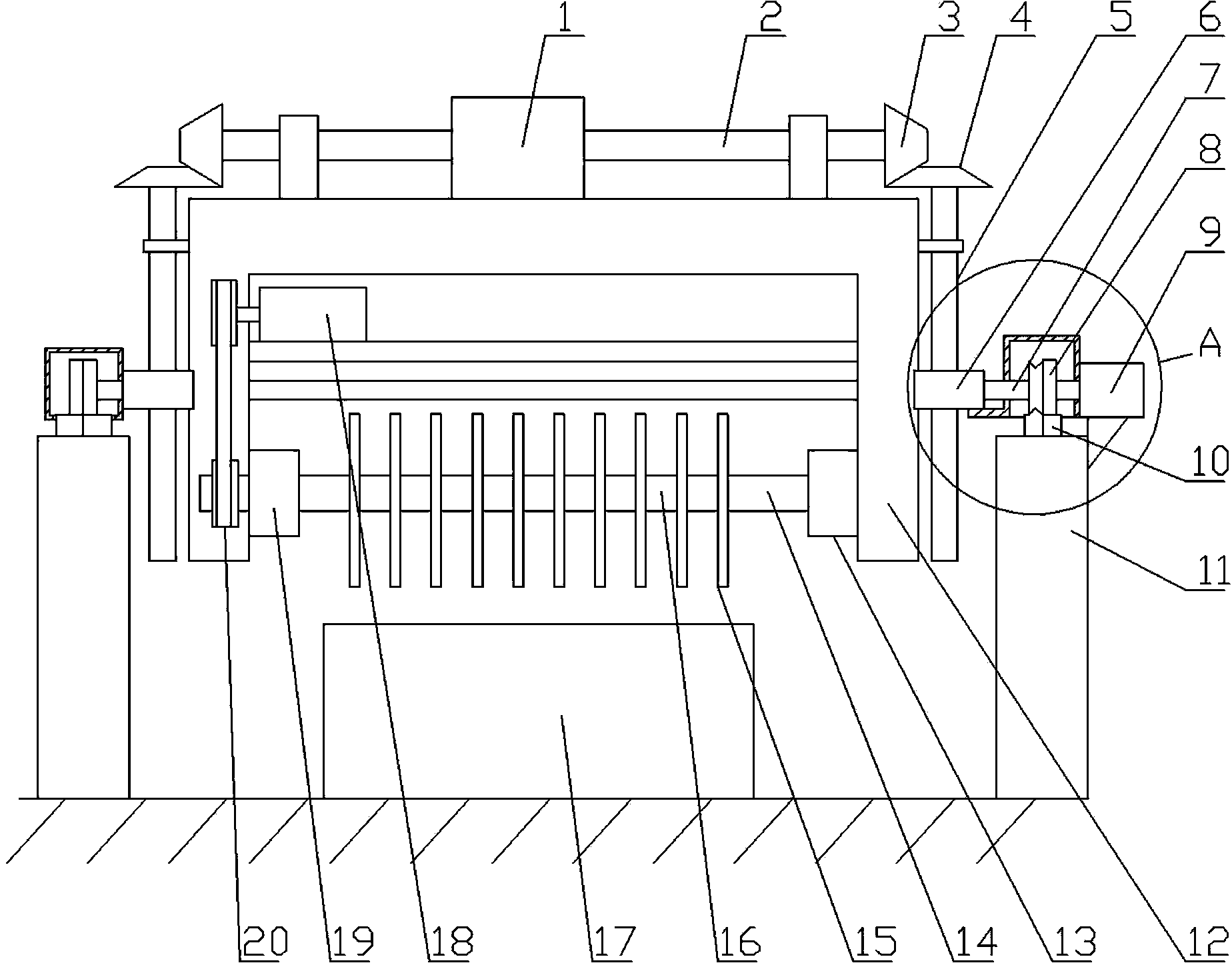

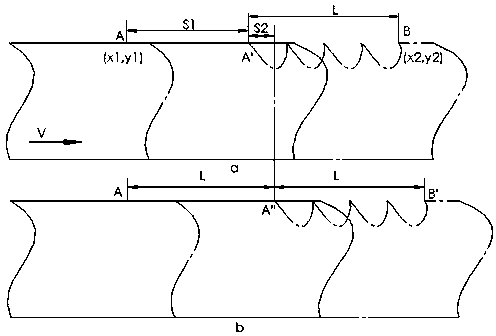

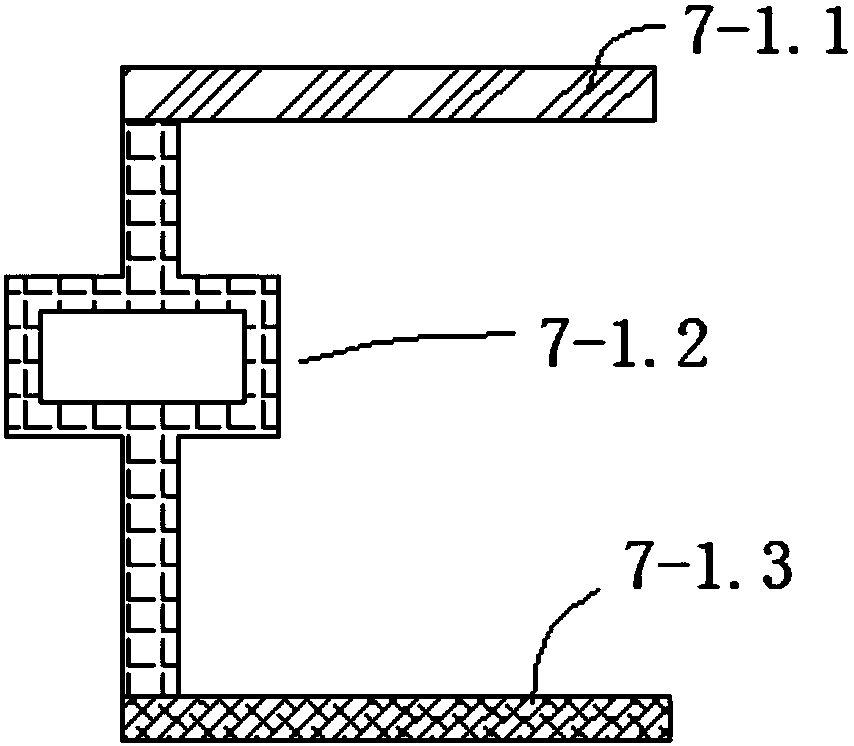

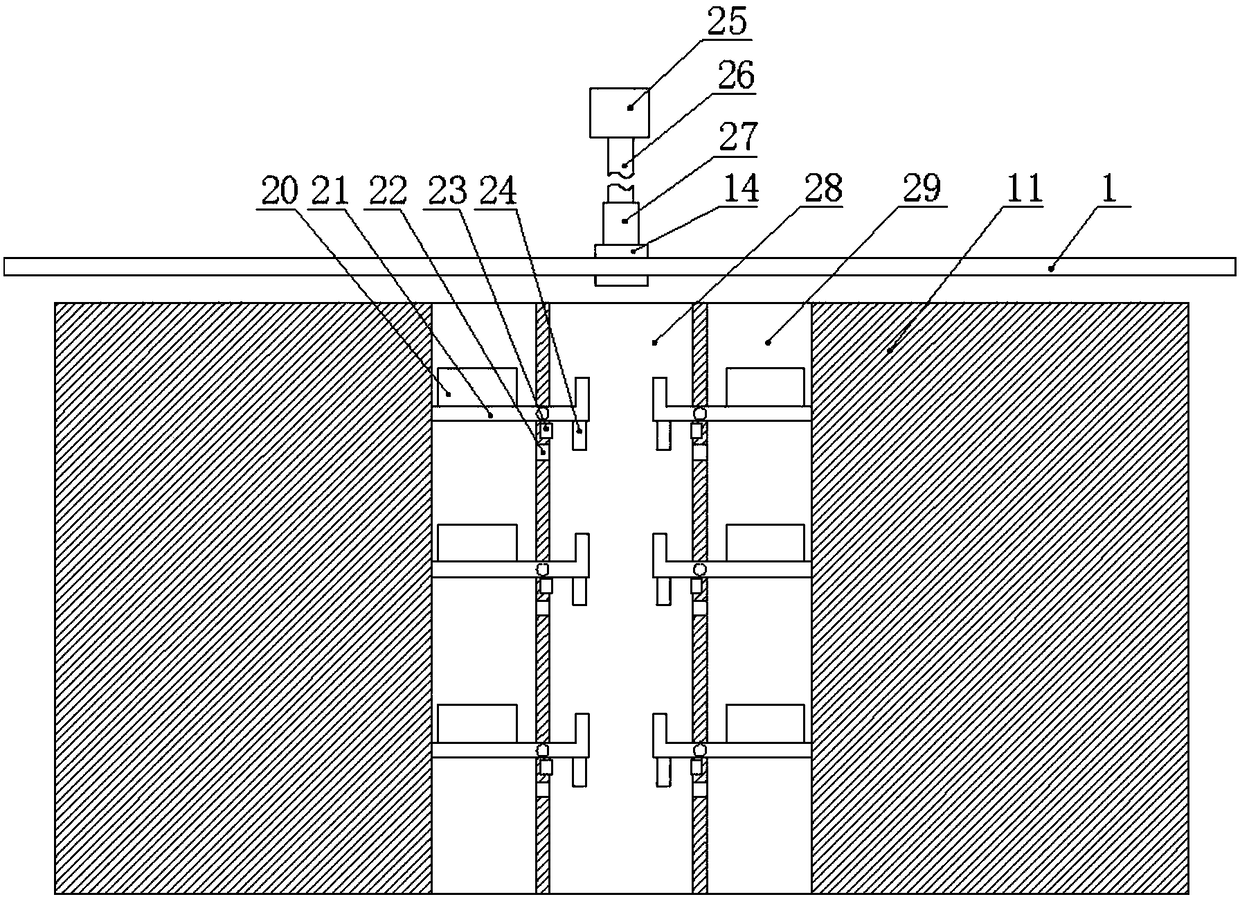

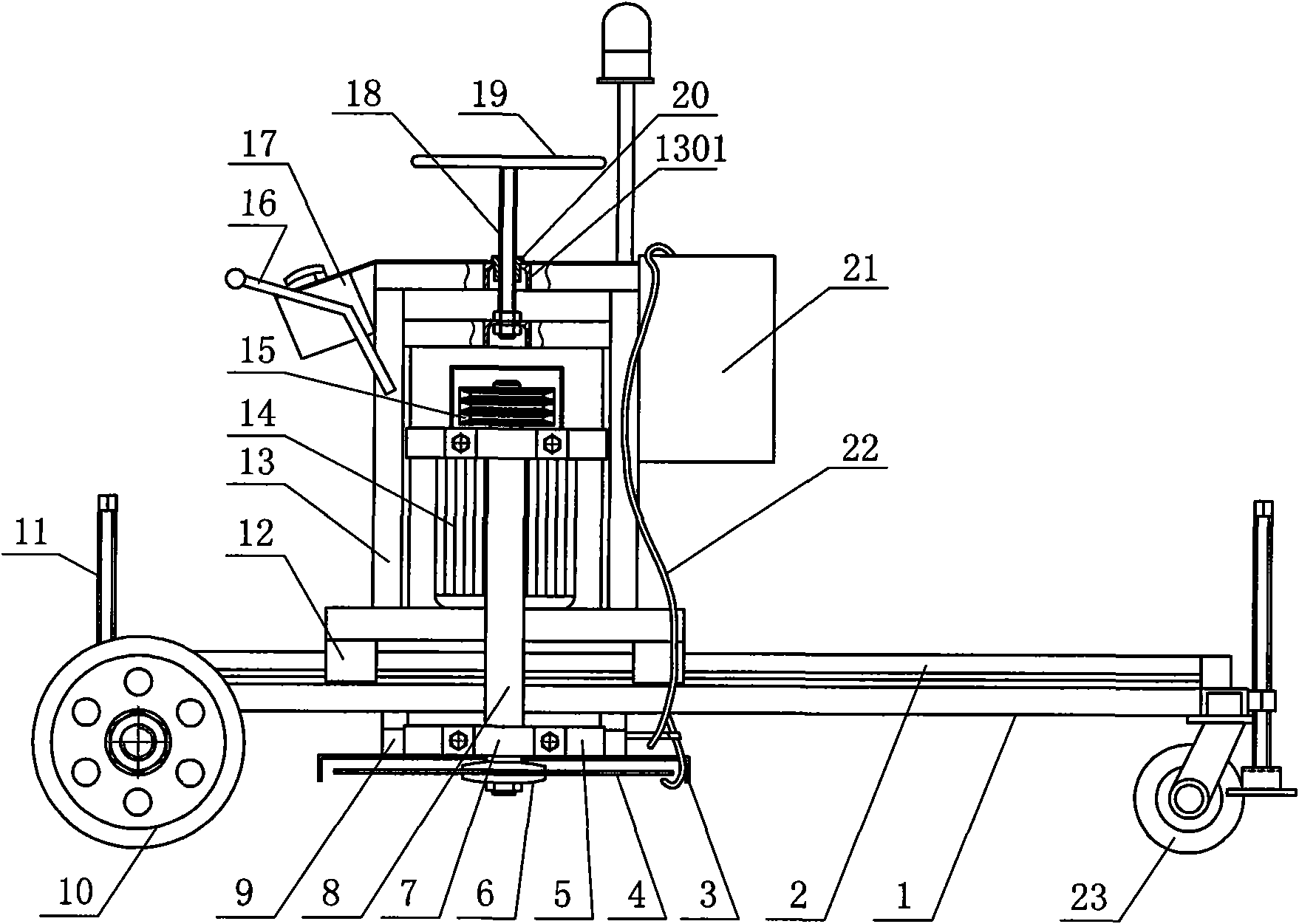

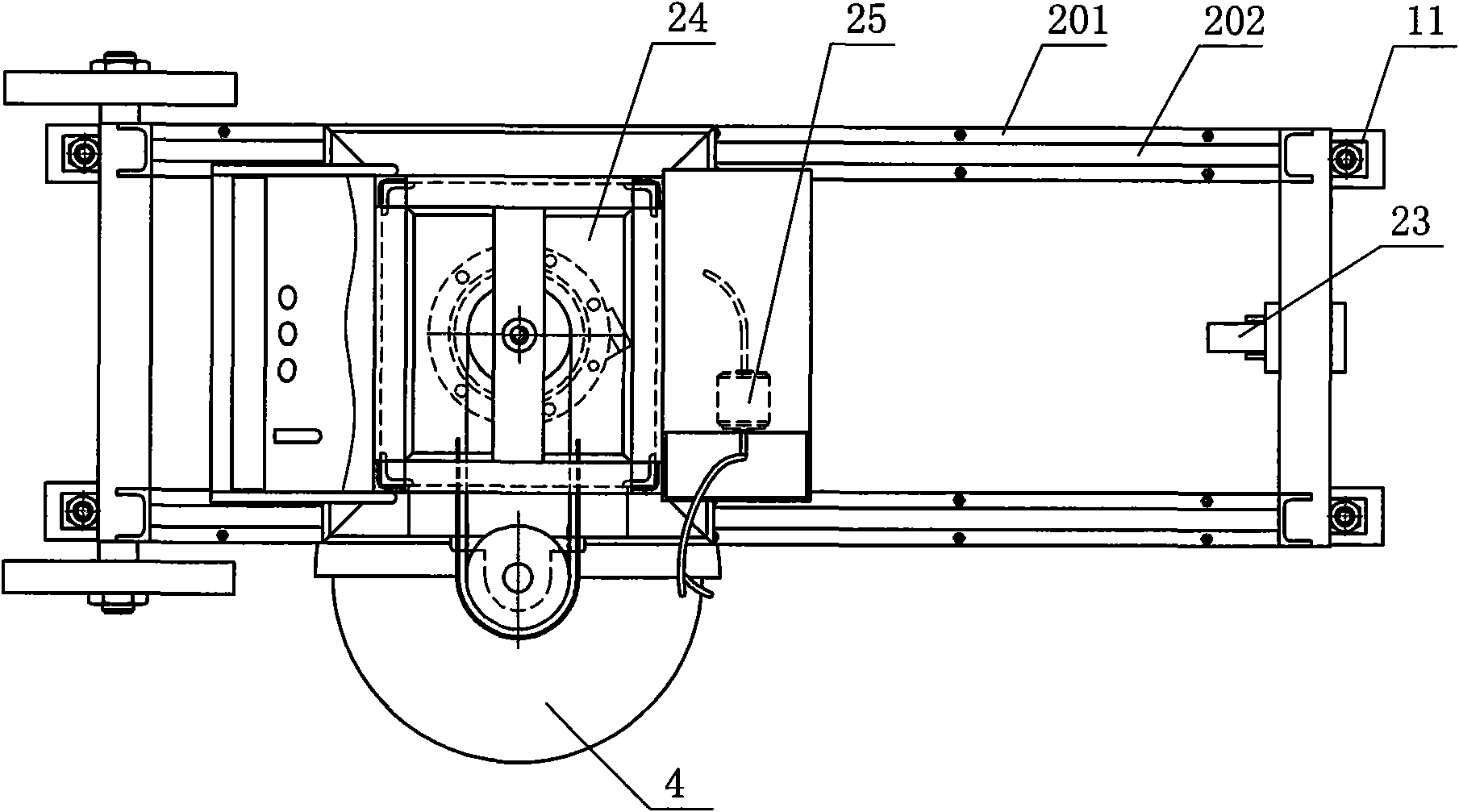

Ultrathin stone turning-free plate type flow line stone sawing machine and ultrathin stone cutting method

ActiveCN103465381AAvoid offsetFlat cutting surfaceStone-like material working toolsCircular discHost machine

The invention discloses an ultrathin stone turning-free plate type flow line stone sawing machine and an ultrathin stone cutting method. The ultrathin stone turning-free plate type flow line stone sawing machine comprises two parallel horizontal guide rails, two cutting host machines and a material frame, wherein the cutting host machines are cutting host machines with circular disc type saw blades, the two cutting host machines are respectively erected on the two guide rails, the material frame is arranged between the two guide rails and is positioned under the two cutting host machines, and the diameter of the saw blade of one cutting host machine is 1.5 to 2.5 times of the diameter of the cutting blade of the other cutting host machine. Through the arrangement of the two cutting host machines with cutters in different sizes, during the stone cutting, the two cutting host machines are respectively used for cutting the stone, the secondary cutting is formed for completing the stone cutting, the stone does not need to be turned, a cutting seam formed by the cutting for the first time has a position limiting effect on the cutter used for the cutting for the second time, the cutting tooth deviation during the cutting caused by greater dimension of the cutters and long distance between the cutting teeth and a main shaft can be prevented, the cutting precision is high, and the cutting plane is flat and smooth.

Owner:李政

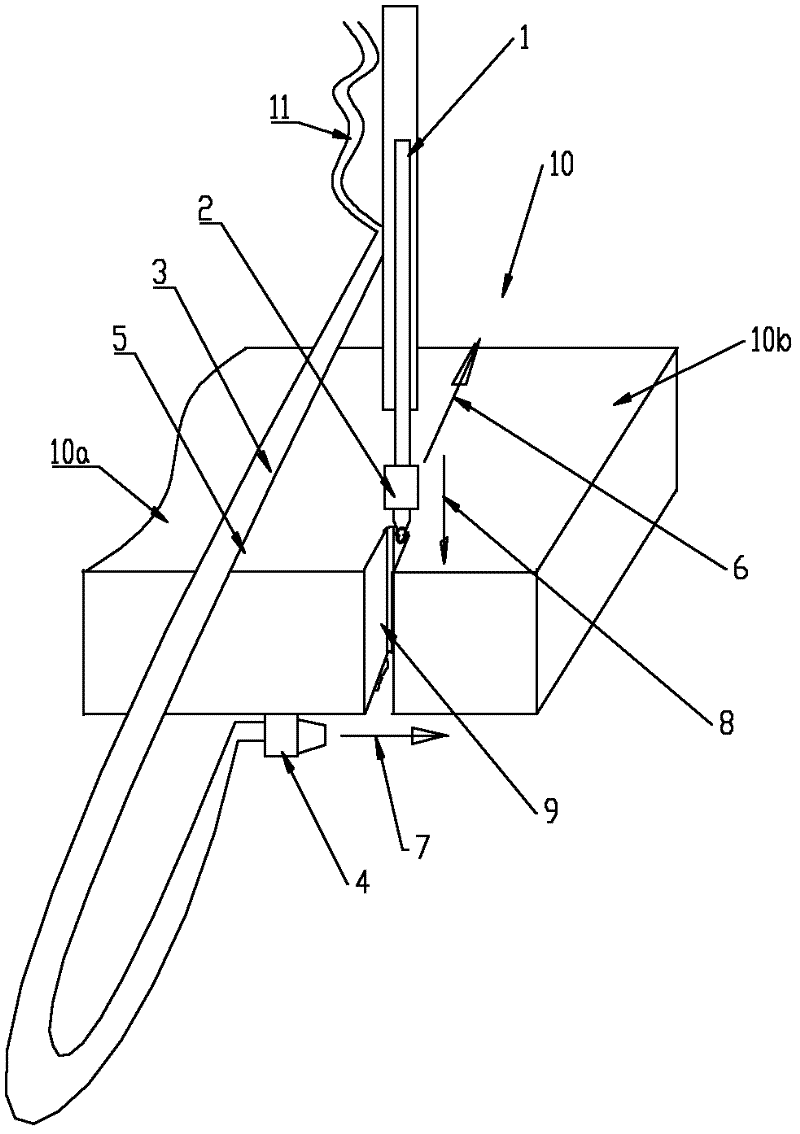

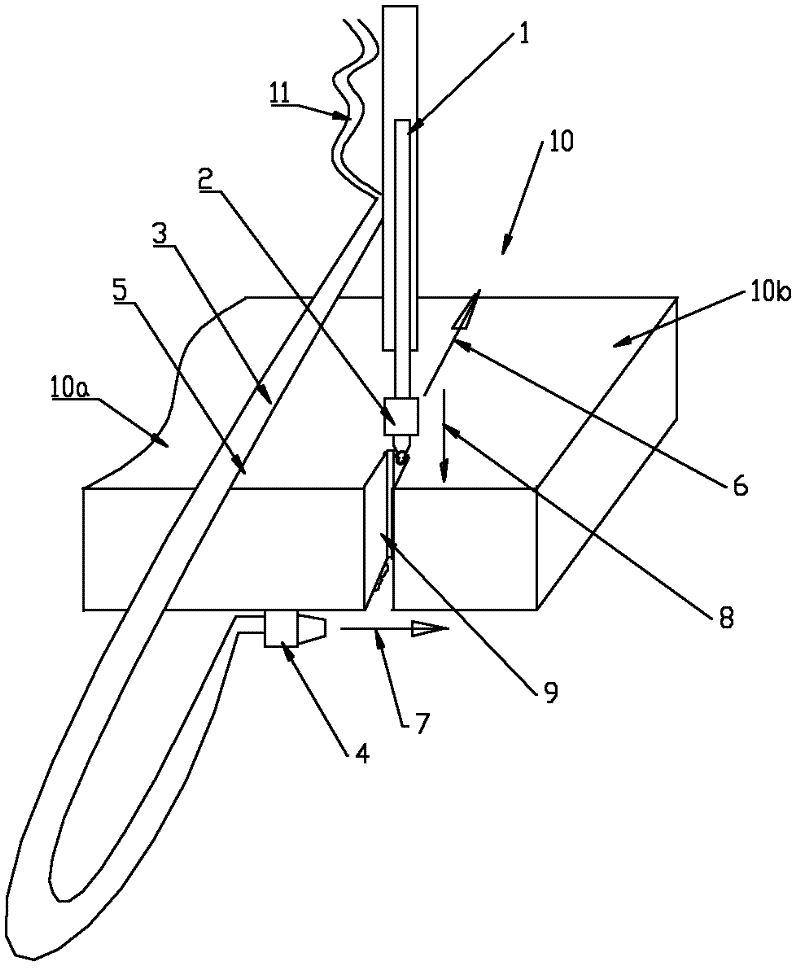

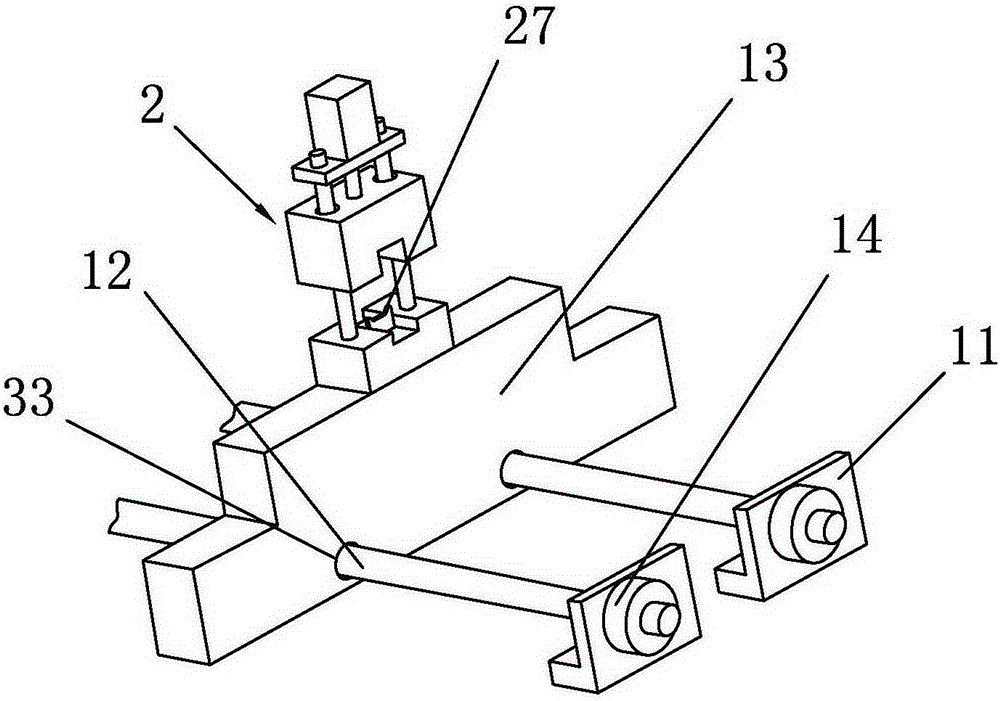

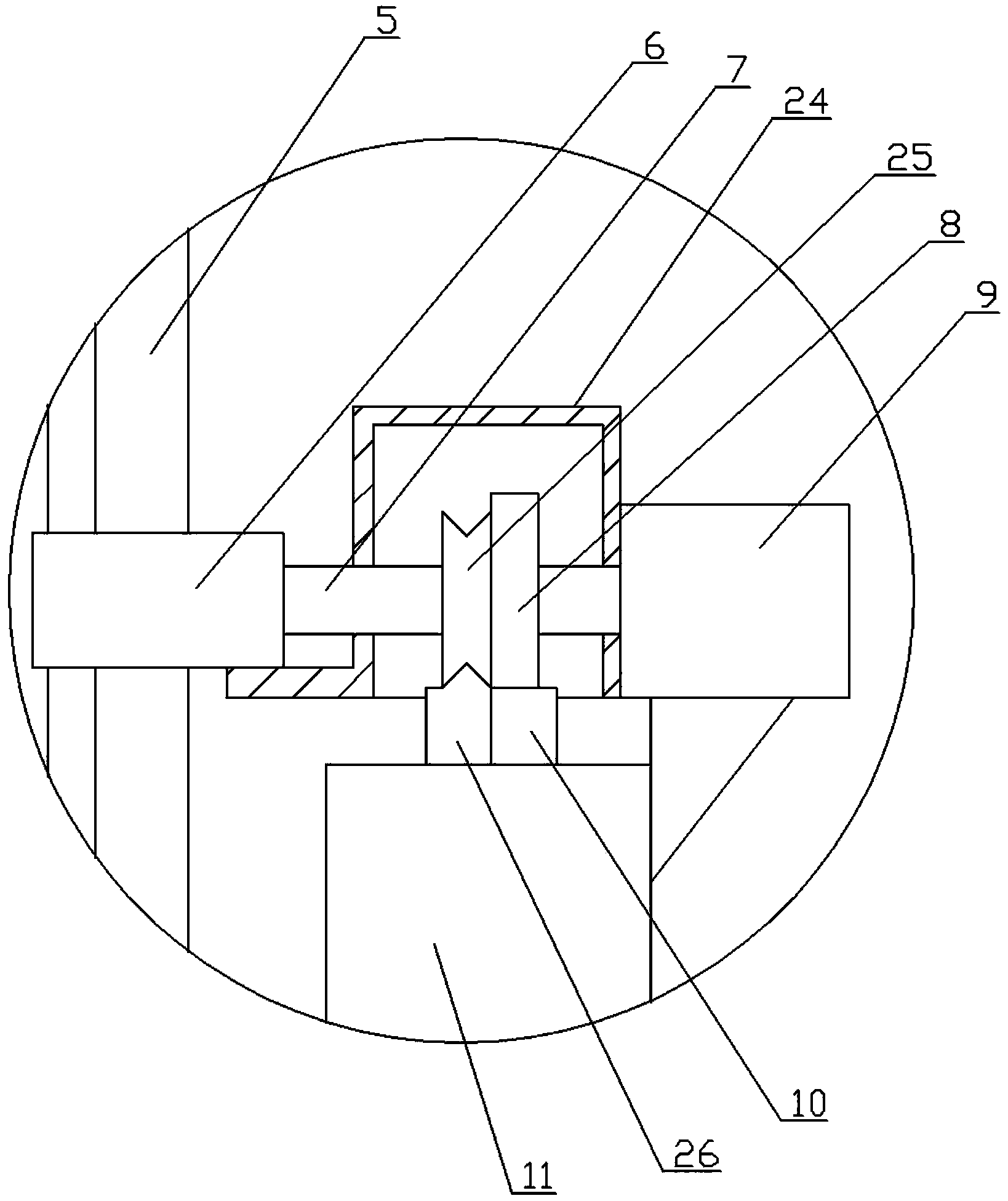

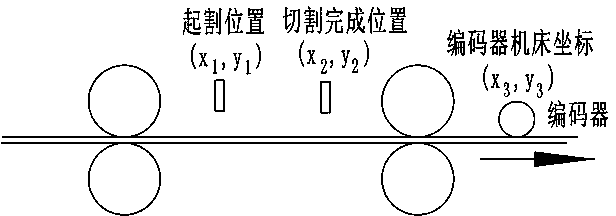

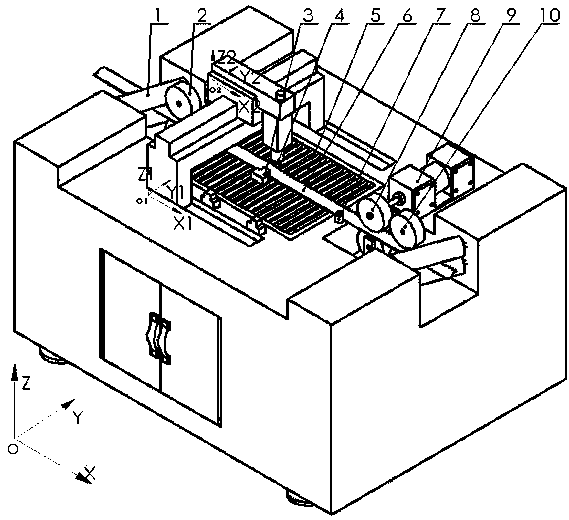

Laser continuous cutting device used for cutting saw belt and cutting method

ActiveCN104014938ANo thermal deformationNo damageWelding/soldering/cutting articlesMetal working apparatusMilling cutterLaser cutting

The invention discloses a laser continuous cutting device used for cutting a saw belt and a cutting method. The laser continuous cutting device aims to solve the problems that continuous cutting and forming of sawteeth can not be achieved, tool auxiliary time accounts for a high percentage, and cutting efficiency is low in the prior art. The laser continuous cutting device comprises a base which is sequentially provided with a driving friction roller used for regulating feeding speed of the saw belt, a pressing wheel set used for pressing the saw belt, a work platform and a driving wheel set driven by a driving device; a laser head which is arranged on a Z shaft for cutting the saw belt is arranged above the work platform; the work platform is provided with a feeler block and a transverse locating mechanism used for locating the saw belt; during cutting work, the speed of a sliding platform X1 is the same as the feeding speed of the saw belt. The laser cutting sawtooth continuous forming technique does not need a milling cutter, and the sawteeth in any two-dimensional shapes can be correspondingly manufactured very rapidly.

Owner:湖南泰嘉智能科技有限公司

Optical fiber cable cutting device based on light perception control principle

InactiveCN111958667AComplete cutAvoid slipping and offsetting situationsFibre mechanical structuresMetal working apparatusLight perceptionEngineering

The invention relates to the technical field of optical fibers, and discloses an optical fiber cable cutting device based on a light perception control principle. The optical fiber cable cutting device based on the light perception control principle comprises a workbench. A support is fixedly connected with the exterior of the workbench, a cutting assembly is movably connected with the exterior ofthe support, and supporting rods are fixedly connected with the exterior of the support. Limiting blocks are fixedly connected with the exteriors of the supporting rods, and limiting plates are fixedly connected with the interiors of the limiting blocks. Moving frames are movably connected with the exteriors of the limiting plates, teeth are arranged inside the moving frames, and connecting rodsare fixedly connected with the exteriors of the moving frames. By means of the interaction of the limiting blocks, the limiting plates, the moving frames, the teeth, first gears, second gears, gear rings, rotating shafts, rotary rods, the connecting rods and press plates, an optical fiber cable can be tightly pressed and fixed when the optical fiber cable is cut, the situation that the optical fiber cable slips and deviates in the cutting process is avoided, and therefore the optical fiber cable can be fully cut, and the cut surface is relatively flat.

Owner:杭州千耘贸易有限公司

Novel industrial cutting gas with dimethyl ether as main component

The invention discloses novel industrial cutting gas with dimethyl ether as a main component. The novel industrial cutting gas comprises (but not limited to) the following components in percentage by mass: 60-99.99% of the dimethyl ether, 0.01-40% of additives and the like, wherein the additive is prepared from tert-butylferrocene, diethyl ether, aromatic hydrocarbon, solvent oil No.6, tert-butyl alcohol and potassium permanganate according to a certain proportion. Auxiliary gas can also be added into the cutting gas and is one or some of acetylene, propane, propylene, butane and butylene. The novel industrial cutting gas disclosed by the invention presents strong advantages in the aspects of economy, safety, environment friendliness and cutting performance.

Owner:ENN XINNENG BEIJING TECH

Strong vibration cutter

ActiveCN105291171AIncrease speedLarge amplitudeMetal working apparatusEngineeringMechanical engineering

The invention relates to a strong vibration cutter which serves as a component of a high-speed cutting machine and is suitable for cutting all flexible materials. The cutting surface of the cutter is smoother, the cutting effect is better, and the efficiency is higher. A radiating seat is fixed on a motor seat, and a motor is placed inside the radiating seat; an eccentric shaft is rotationally installed in the motor seat and placed horizontally; a motor shaft of the motor is connected with the eccentric shaft through a gear set; the eccentric shaft is connected with a bearing; a cutter bar guiding seat is rotationally installed on the motor seat and fixed with a vibration cutter installation seat; end rod bodies are fixed at the lower end and the upper end of a middle rod body respectively; a connecting rod body fixedly sleeves the end rod body located at the upper end of the middle rod body; an inner hole is formed in an outer ring of the connecting rod body, and the bearing is installed in the inner hole movably; the inner hole is circular; a cutter bar limiting seat is arranged at the lower end of the vibration cutter installation seat fixedly; a blade installation seat is sleeved with the cutter bar limiting seat movably; and an air pipe joint, an air vent and a radiating hole are communicated sequentially, so that a cooling air channel is formed.

Owner:HANGZHOU ECHO SCI TECH

Liftable and movable type optical glass cutting device

InactiveCN107804961AWon't scratchSimple structureGlass severing apparatusAgricultural engineeringMovable type

The invention discloses a liftable and movable type optical glass cutting device, and relates to the technical field of optical glass processing equipment. The liftable and movable type optical glasscutting device comprises a base and a cutting mechanism, wherein the base is provided with a fixed cutting seat; the base is provided with two receiving plates which are symmetrically arranged at twosides of the fixed cutting seat; the two receiving plates are respectively provided with a moving mechanism, and the structures of the two moving mechanism are the same as each other; each moving mechanism comprises a drive cylinder and an L-shaped mounting plate fixedly connected with the drive cylinder; each L-shaped mounting plate comprises a horizontal part and a vertical part, wherein each horizontal part is provided with a shear fork lifting mechanism, and a horizontal support plate is connected between the two shear fork lifting mechanisms; one end of the horizontal support plate is provided with a telescopic cylinder; the cutting mechanism comprises a mounting frame and a cutting assembly; the mounting frame comprises an upper horizontal plate, a lower horizontal plate and a connecting part, and the connecting part sleeves the horizontal support plate; the cutting assembly is arranged on the lower horizontal plate. The liftable and movable type optical glass cutting device is simple in structure and good in stability, and can guarantee that the cut surface of cut optical glass is even and smooth.

Owner:CHENGDU KECHUANGGU TECH CO LTD

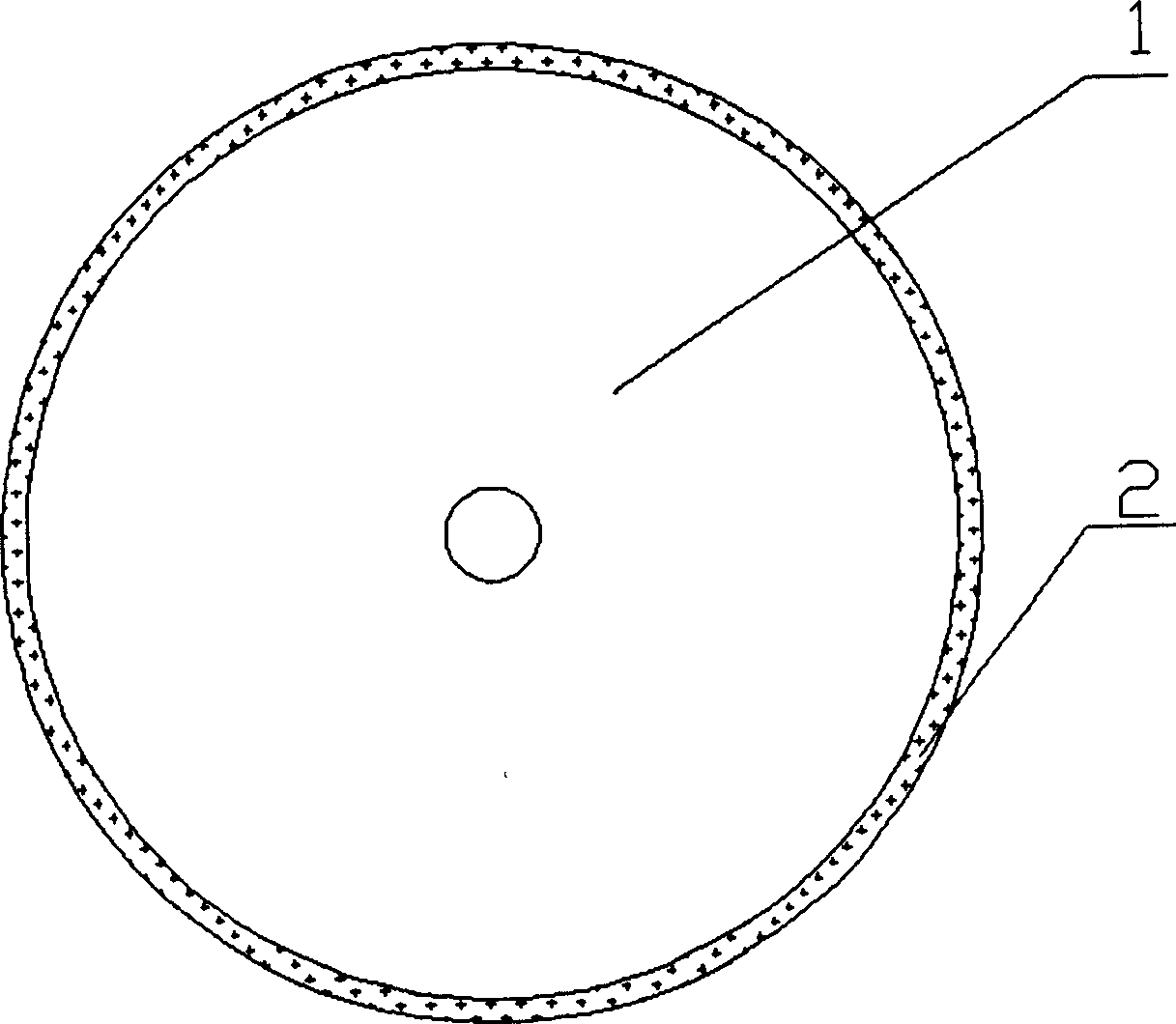

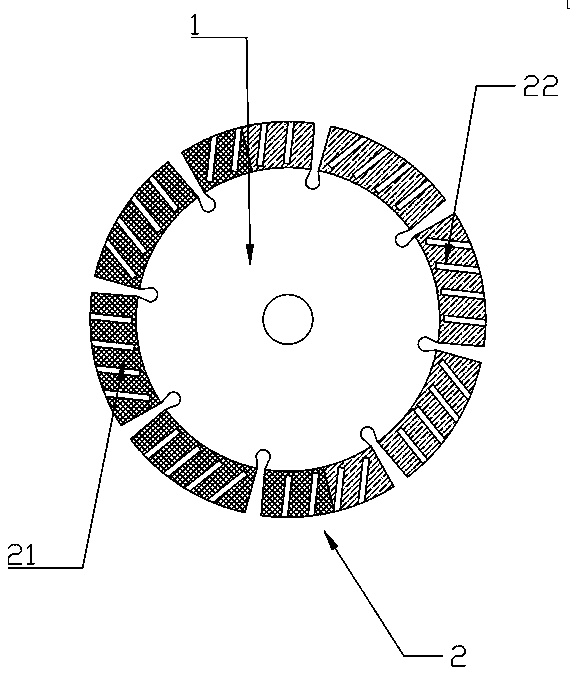

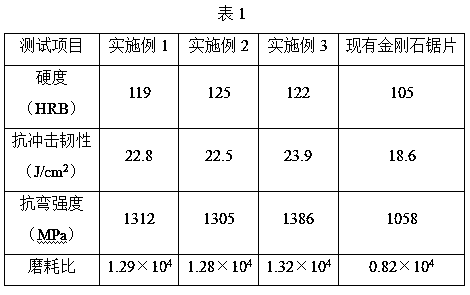

High-performance diamond saw blade and preparation method thereof

ActiveCN109175388AHigh hardnessImprove impact toughnessMetal sawing tool makingMetal sawing toolsIron powderBoron carbide

The invention discloses a high-performance diamond saw blade and a preparation method thereof. A tool bit of the high-performance diamond saw blade comprises a first cutting area and a second cuttingarea. The first cutting area comprises, by weight part, 8-14 parts of polycrystalline diamond particles, 48-55 parts of iron powder, 25-32 parts of copper powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-5 parts of tungsten carbide and titanium carbide mixture powder and 0.4-0.7 part of lanthanum pentanickel powder. The second cutting area comprises, by weight part, 10-16 parts of polycrystalline diamond and boron carbide mixture particles, 45-50 parts of iron powder, 27-33 parts of copper powder, 4-6 parts of zinc powder, 2-3 parts of tin powder, 1.5-2.5 parts of nickel powder, 2-3 parts of cobalt powder, 1.5-2 parts of manganese powder, 2.5-4 parts of titanium carbide powder and 0.4-0.7 part of lanthanum pentanickel powder. The high-performance diamond saw blade is excellent in comprehensive performance.

Owner:泉州市华兴超硬工具有限公司

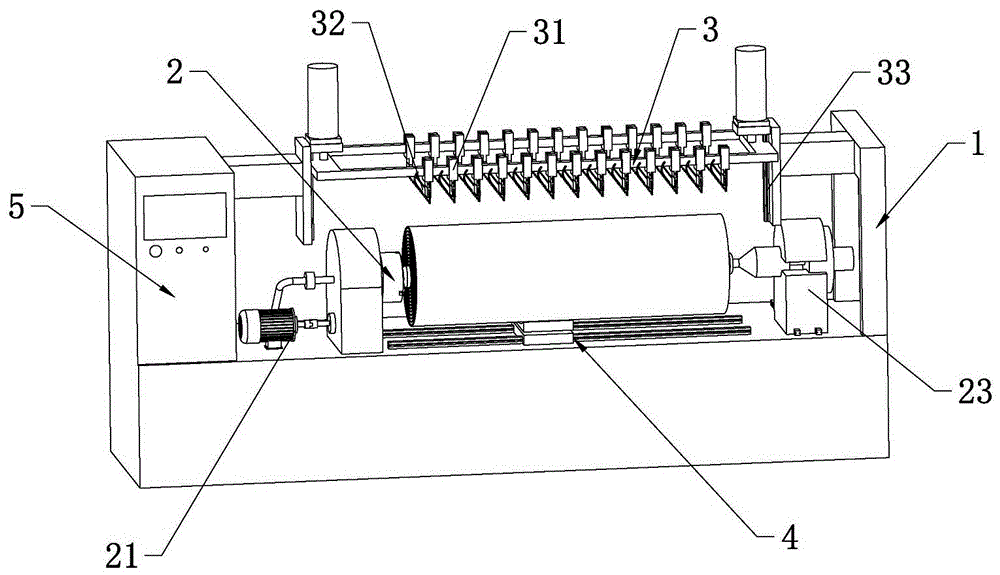

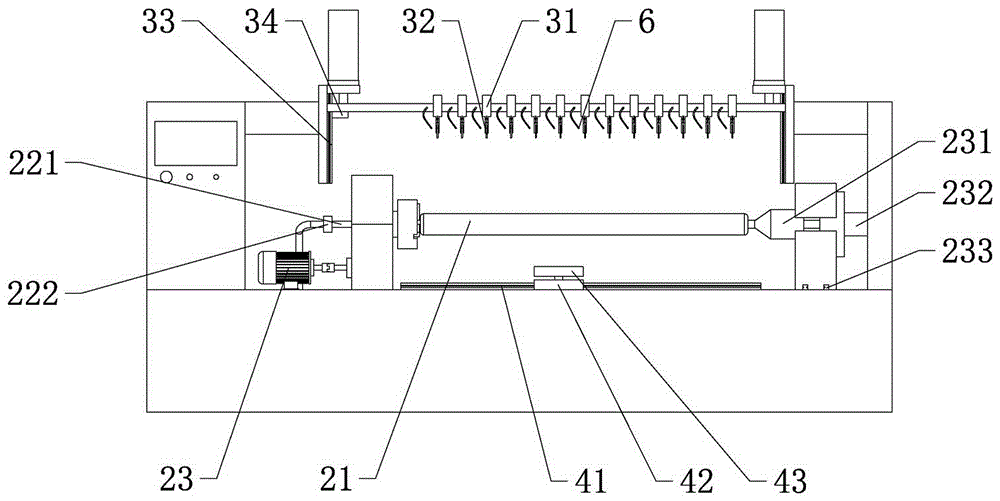

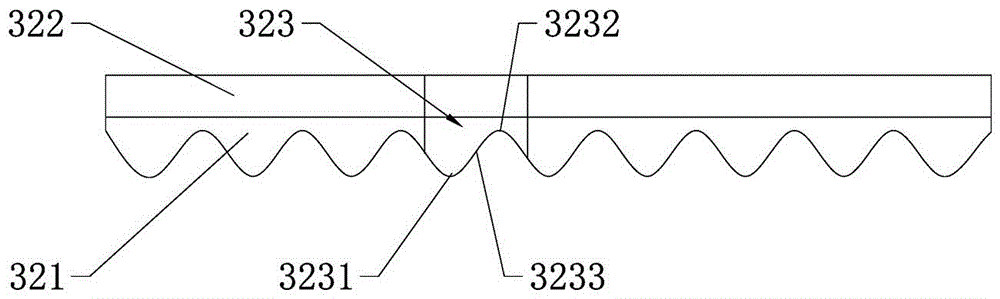

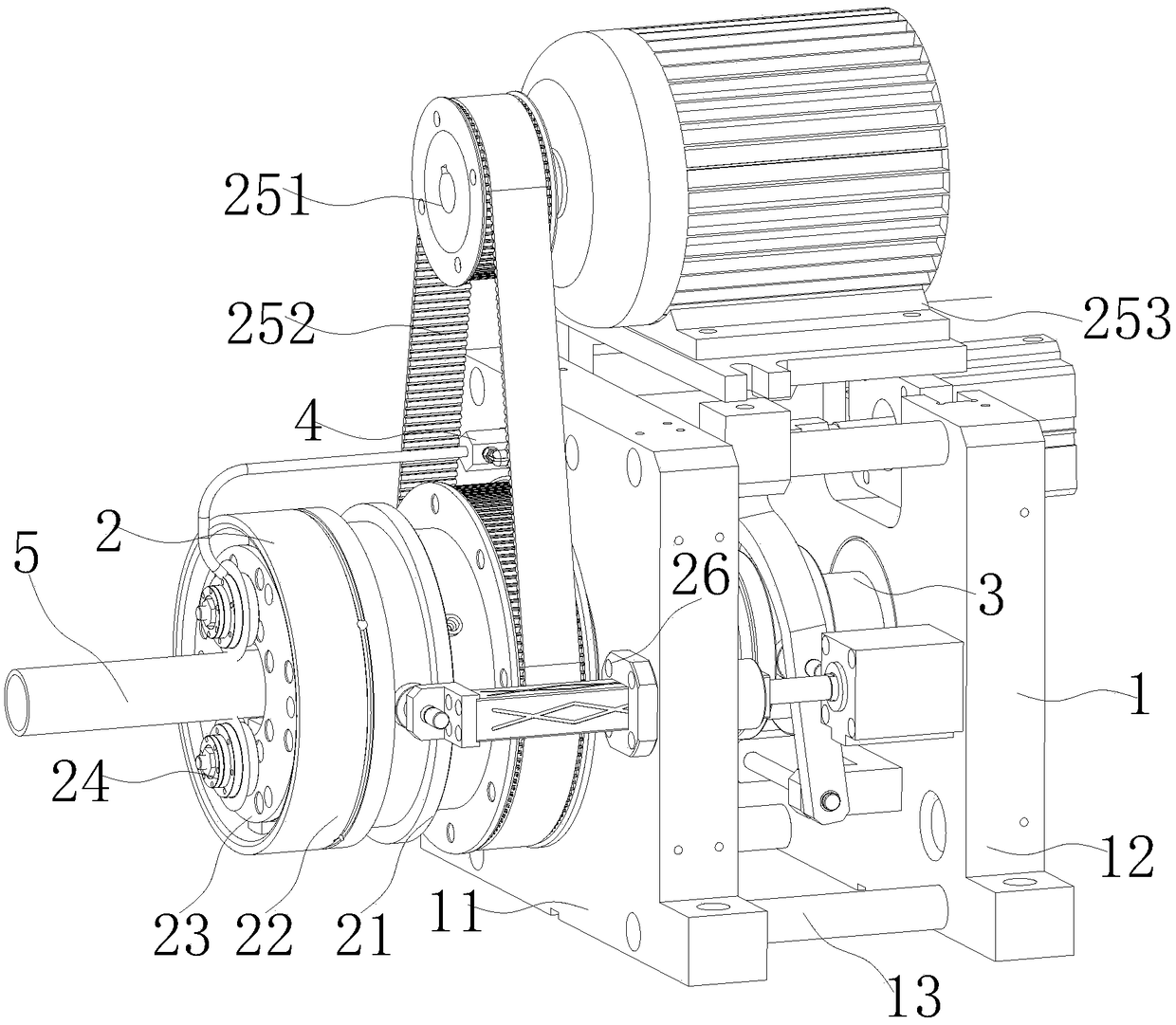

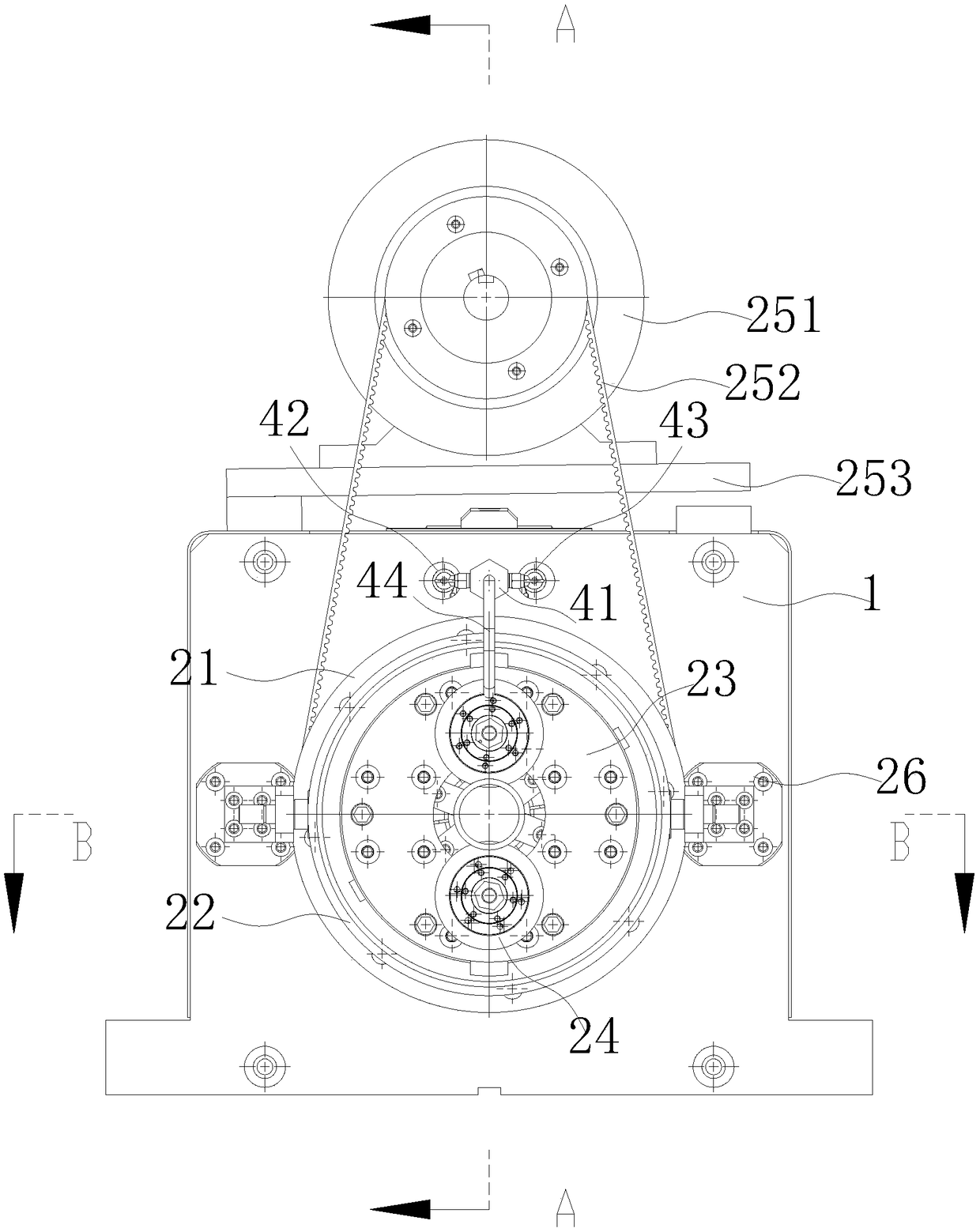

Mat splitting machine

ActiveCN105690457AImprove cutting efficiencyHigh speedMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of mat manufacturing, in particular to a mat splitting machine. The mat splitting machine comprises a machine frame, a rotary device used for driving materials, a cutting platform used for splitting the materials, a conveying device used for feeding and discharging the materials and a control mechanism used for controlling all the devices to operate coordinately. The rotary device comprises a driver fixed to the machine frame, a rotary shaft connected with the driver and a positioning mechanism used for supporting and positioning the rotary shaft. The cutting platform is provided with a plurality of cutter fixing frames provided with long-strip-shaped cutters, and the cutter fixing frames and the cutting platform are adjustably connected, so that the distance between the cutters is adjustable. A sliding mechanism is arranged between the cutting platform and the machine frame, and the cutting platform moves far away from or close to the rotary shaft through the sliding mechanism.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

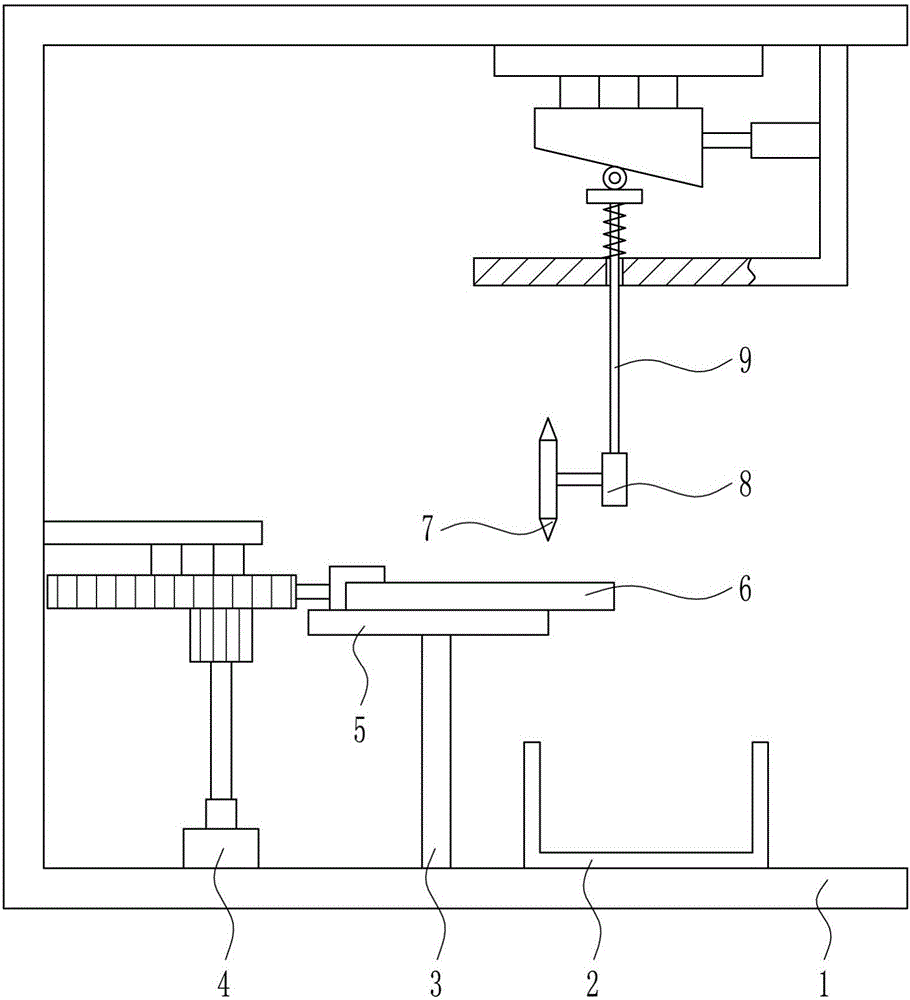

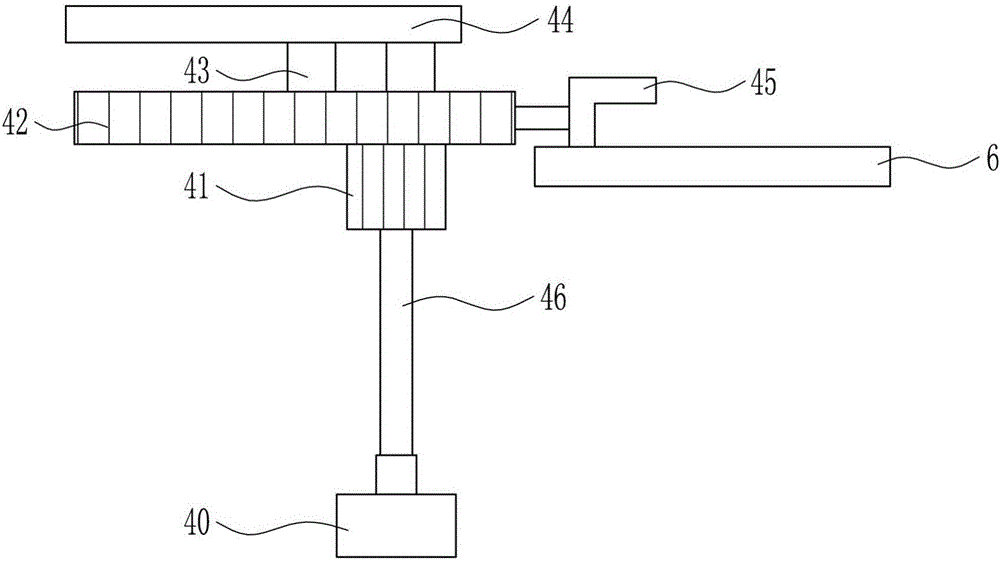

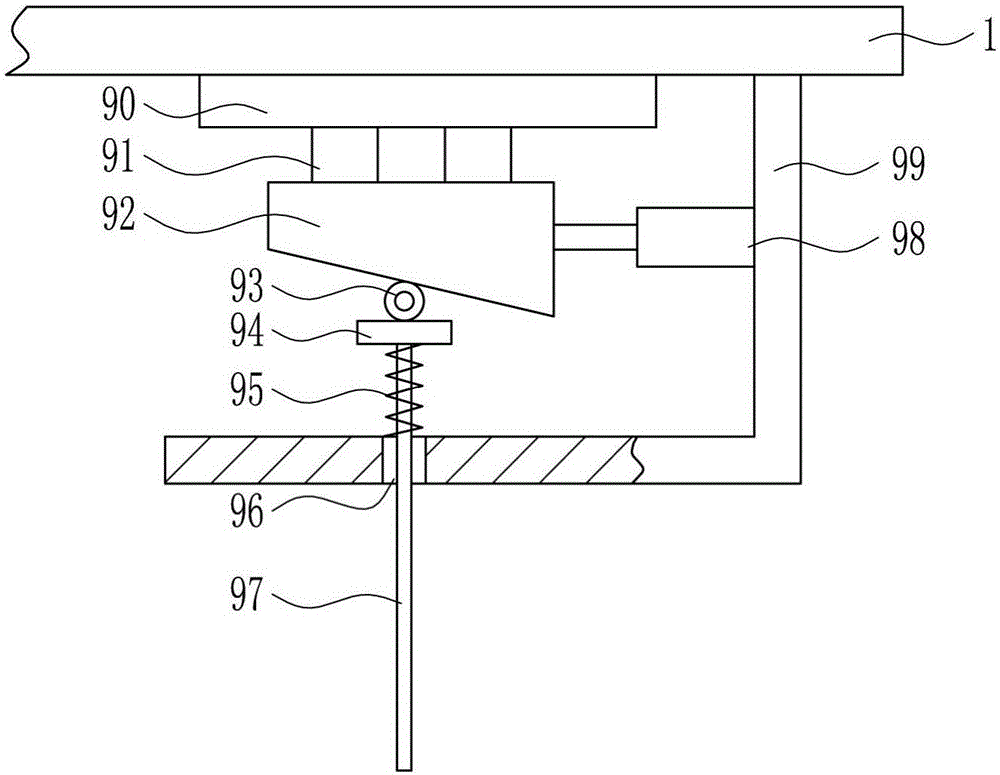

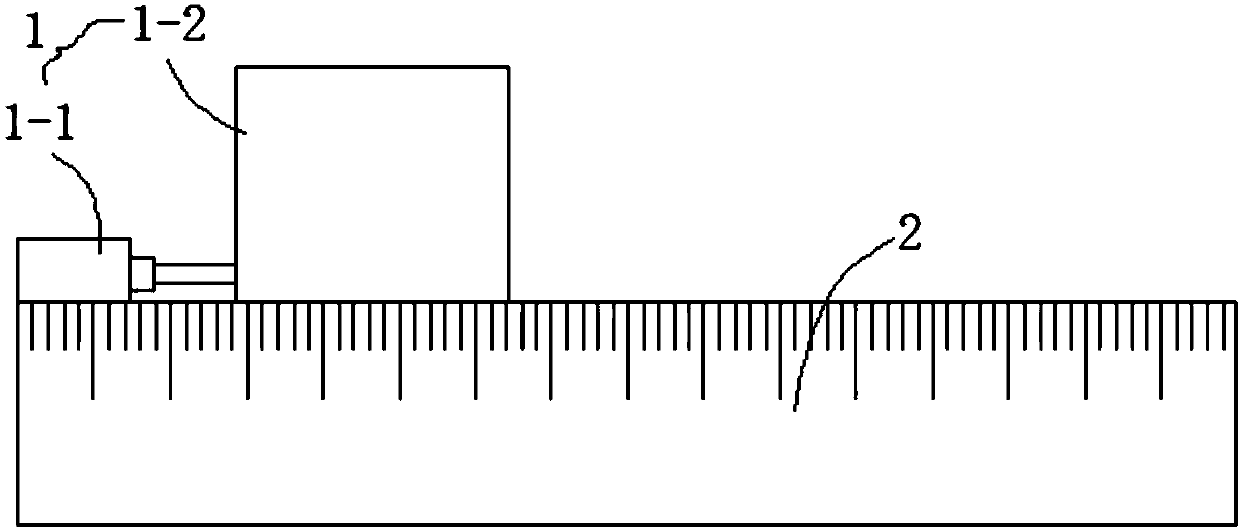

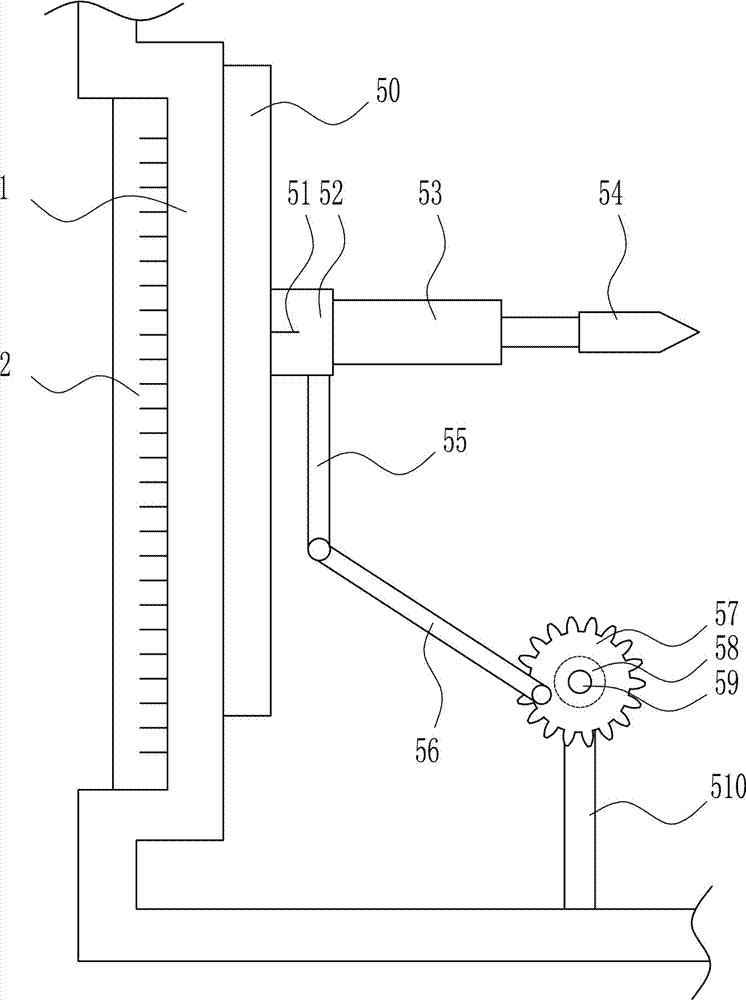

Stable quantitative cutting device for electric wires of electric power

ActiveCN106914566AContinuous quantitative cuttingImprove the efficiency of cutting wiresDirt cleaningMetal working apparatusElectric power systemEngineering

The invention relates to a cutting device, in particular to a stable quantitative cutting device for electric wires of electric power. According to the stable quantitative cutting device for the electric wires of the electric power, the cutting surface is flat, the cutting efficiency is high, and the cutting length can be quantitatively selected. The stable quantitative cutting device for the electric wires of the electric power comprises a support and the like. A graduated scale is arranged in the middle of the left wall of the support, a rotating device is arranged on the right side of the top of the support, a cutting device is arranged on the left wall in the support, and a collection frame is arranged on the right side of the bottom in the support and is located on the right side of the cutting device. According to the stable quantitative cutting device for the electric wires of the electric power, the effects that the cutting surface is flat, the cutting efficiency is high, and the cutting length can be quantitatively selected can be achieved. By arranging the graduated scale, the cutting length of the electric wires can be accurately measured.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ANYANG POWER SUPPLY

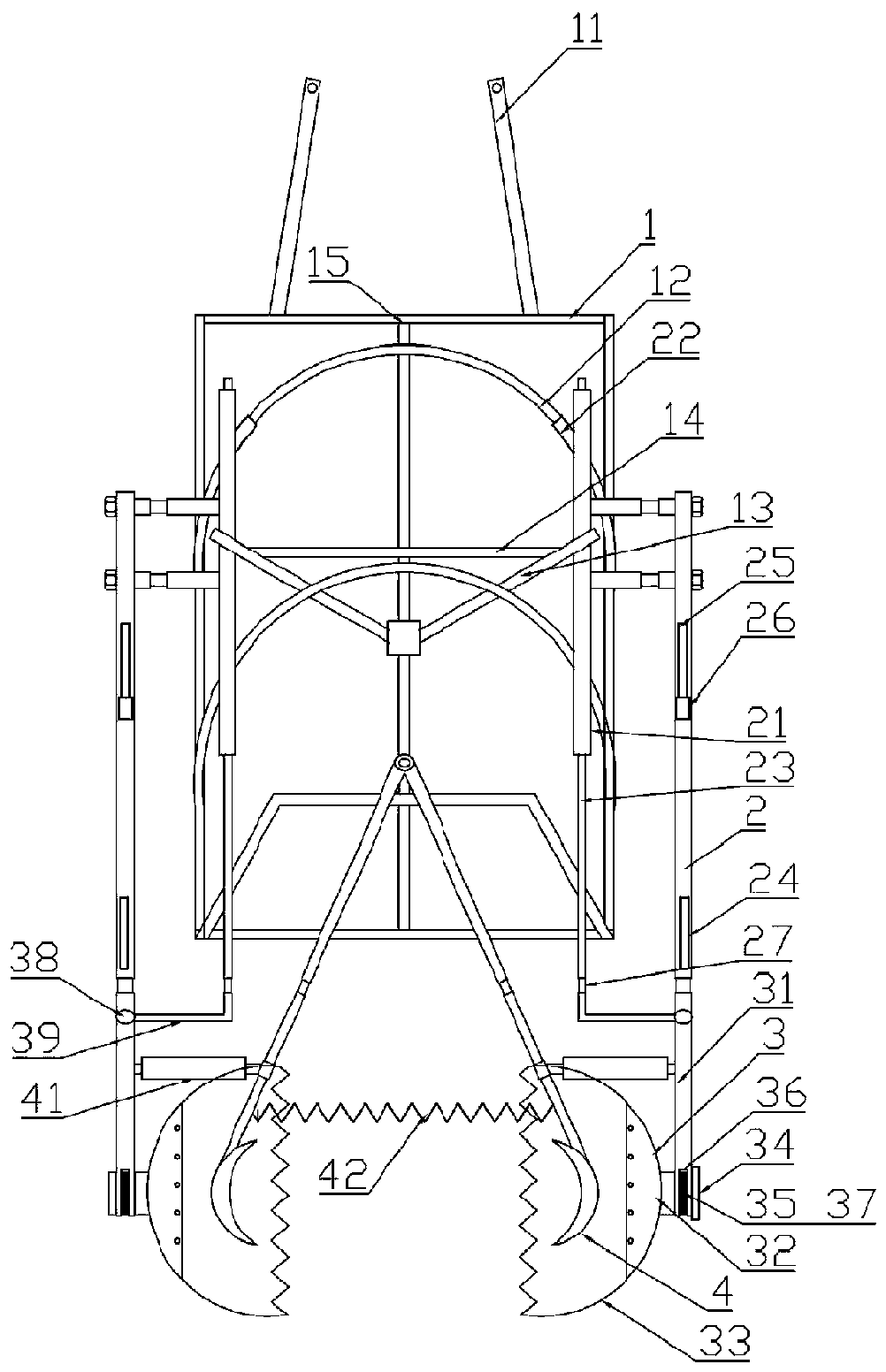

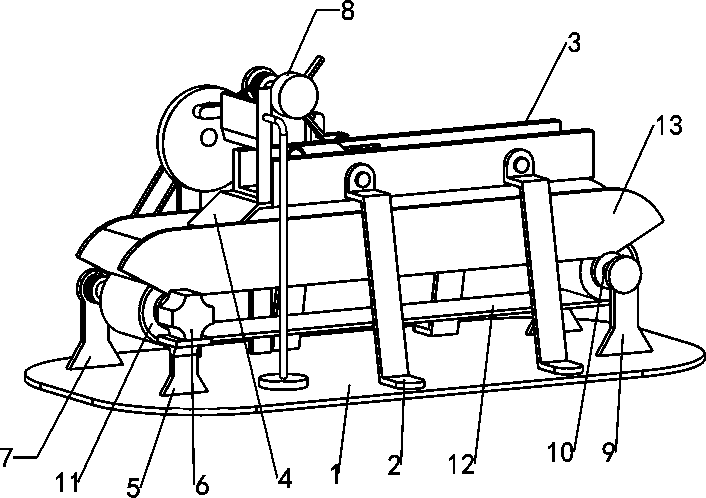

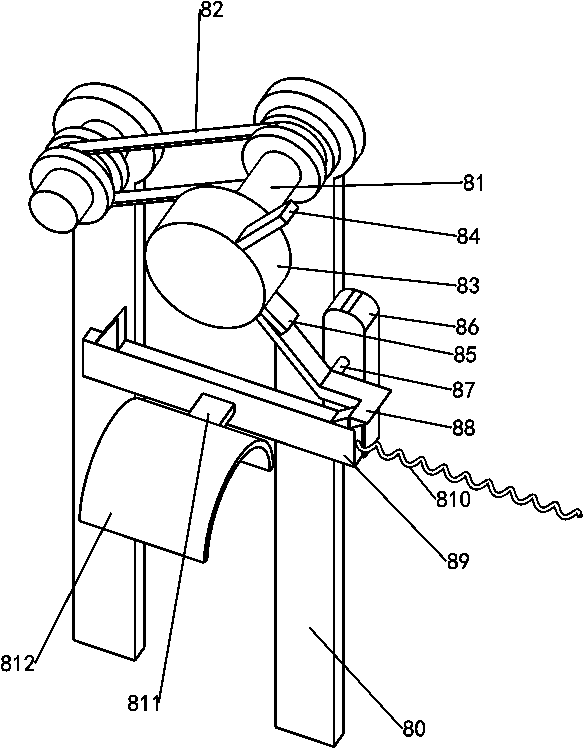

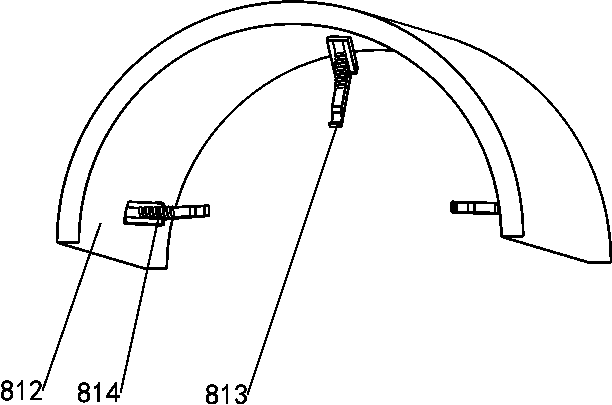

Saw-holding type soil ball-carried seedling transplantation machine

InactiveCN107593364AScientific and reasonable designSimple and fast operationTransplantingForestryTree rootEngineering

The invention discloses a saw-holding type soil ball-carried seedling transplantation machine comprising a machine body, a pair of mechanical arms attached to arc-shaped slide rails and equipped withsliding devices, a pair of digging paws and seedling straightening devices. The mechanical arms conduct arc-shaped movements along the arc-shaped slide rails via the sliding devices and with an axis of a driving wheel as a circle center and drives the digging paws mounted on the mechanical arms to move in an arc way; a hydraulic device mounted on the mechanical arms can control left-right openingand close of the digging paws and the seedling straightening device; when the pair of digging paws are closed, digging surfaces of two digging saws form hemispherical radian; arc-shaped saw rack and arc-shaped saw webs mounted on the digging paw racks swing and effectively cut and saw soil and tree roots off; a cutting shape is hemispherical; a connection distance between the mechanical arms withthe sliding devices and transmission sleeves can be adjusted; with the combination of the exchangeable and detachable arc-shaped saw webs, soil balls with different sizes can be cut as needed; the cutting surface is smooth and standard; and the saw-holding type soil ball-carried seedling transplantation machine has advantages in particular upon frozen earth work.

Owner:姚建峰

Sponge cutting device

ActiveCN108274505AFlat cutting surfaceImprove cut qualityDirt cleaningMetal working apparatusMechanical engineeringPiston

The invention relates to a cutting device, in particular to a sponge cutting device. The sponge cutting device comprises a storing plate made of an electromagnet. An iron press plate is slidably arranged above the storing plate. A fixing mechanism is arranged between the press plate and the storing plate. The two ends of the press plate are vertically provided with push rods. Water storage pipes are arranged below the push rods. The water storage pipes are internally and slidably provided with pistons. The pistons are connected with the push rods. A hollow cutting knife is slidably arranged above the press plate. A suction pipe is arranged between the cutting knife and the water storage pipes in a communicating mode. The cutting knife is provided with a fixed sleeve. One side of the pressplate is provided with an air cylinder. The air cylinder can be connected with the fixed sleeve. The press plate is provided with a through hole for allowing the cutting knife to penetrate through. The through hole is provided with a dedusting mechanism. The sponge cutting device can solve the problem that the cutting surface of sponge is uneven.

Owner:重庆致昌塑胶制品有限公司

Sectioning equipment for plastic binding rope

The invention relates to sectioning equipment, in particular to sectioning equipment for a plastic binding rope. The invention aims to provide the sectioning equipment for the plastic binding rope, which is capable of automatically transporting the plastic binding rope to a knife edge and has a flat cutting surface. The segmentation equipment for the plastic binding rope comprises a base, supporting frames and a placing frame; the base is in a long shape; the supporting frames are symmetrically and fixedly connected to the top of the base, and the number of the supporting frames is at least four; and the placing frame is connected between the upper parts of the supporting frames through bolts. According to the sectioning equipment for the plastic binding rope, the effects that the plasticbinding rope can be automatically conveyed to the knife edge, and the cutting face is smooth are achieved, and through clearance fit between a lifting lever and the plastic binding rope, the lifting rod can hook the plastic binding rope and drive the plastic binding rope to move leftwards together.

Owner:浙江奕乌侬食品有限公司

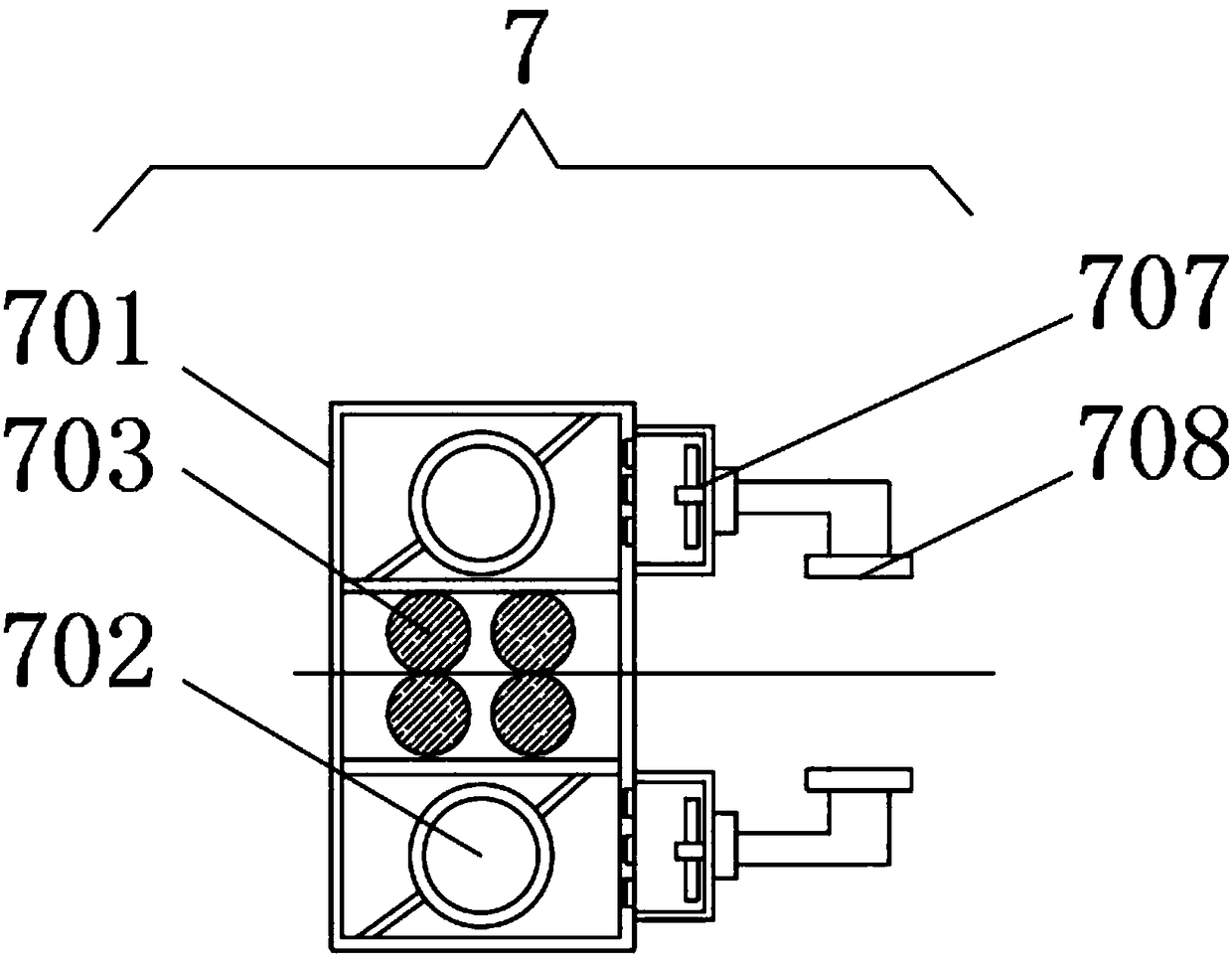

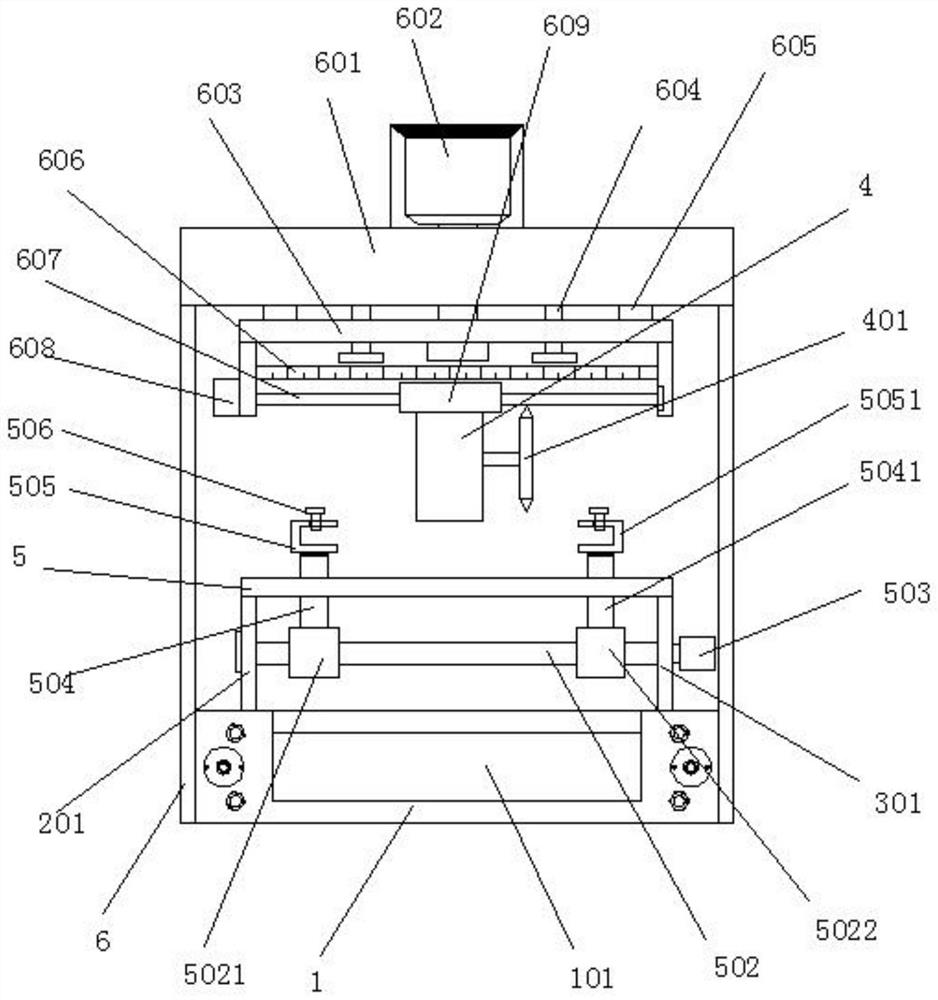

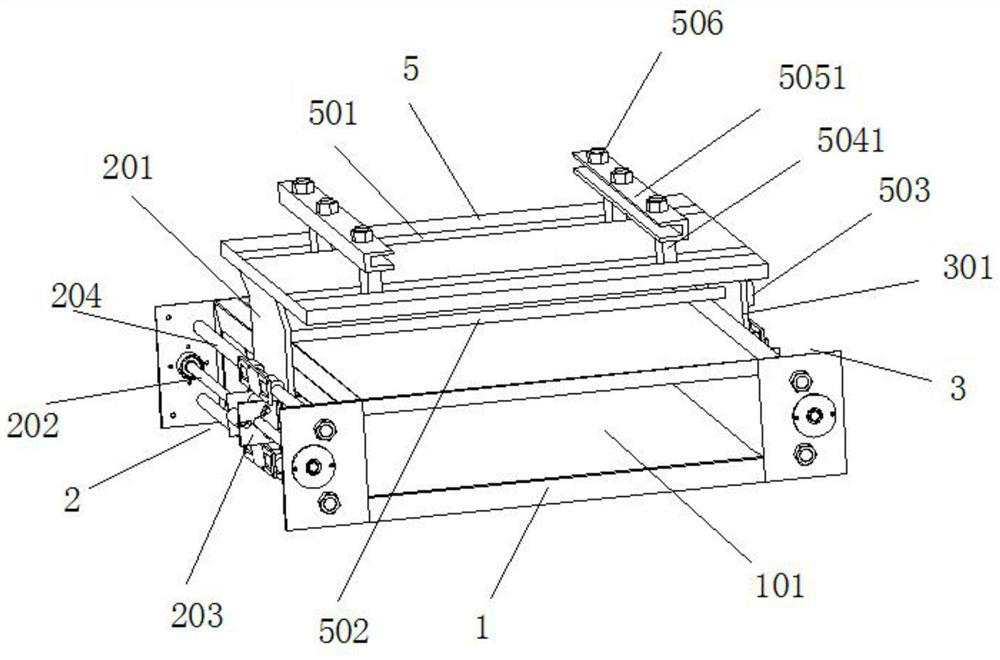

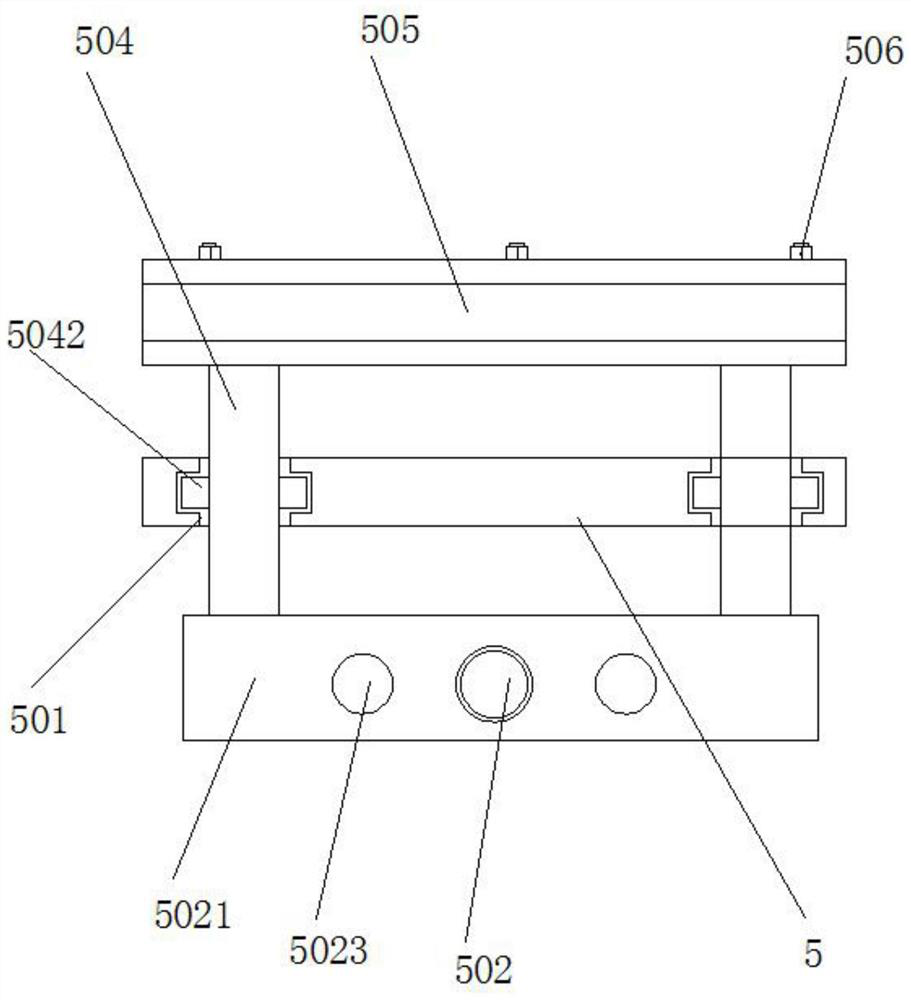

Chip-free rotating and cutting machine

PendingCN109227196AGuaranteed concentricityEven by forceFeeding apparatusPositioning apparatusPipe fittingEngineering

The invention discloses a chip-free rotating and cutting machine, which comprises a frame, a cutting device and a clamping device, wherein the cutting device and the clamping device are both arrangedon the frame; the cutting device comprises a transmission sleeve, an adjusting sleeve, an installation panel and a plurality of cutting mechanisms; the adjusting sleeve can drive a plurality of cutting mechanisms to synchronously move along the diameter direction of the installation panel. The device is used for cutting pipe fittings. The cutting device uses a taper extrusion mode to achieve synchronous feeding, and the synchronous feeding of the plurality of cutting mechanisms can be controlled through the driving of the adjusting sleeve, so that the stress of the cutting mechanisms is uniform, the service life of the cutting mechanisms is prolonged, and the cutting mechanisms are not easy to damage; the clamping device uses a taper extrusion mode to achieve clamping, the concentricity ofthe pipe fitting can be ensured in the cutting process, and the cutting surface is flat and does not incline.

Owner:黄建财

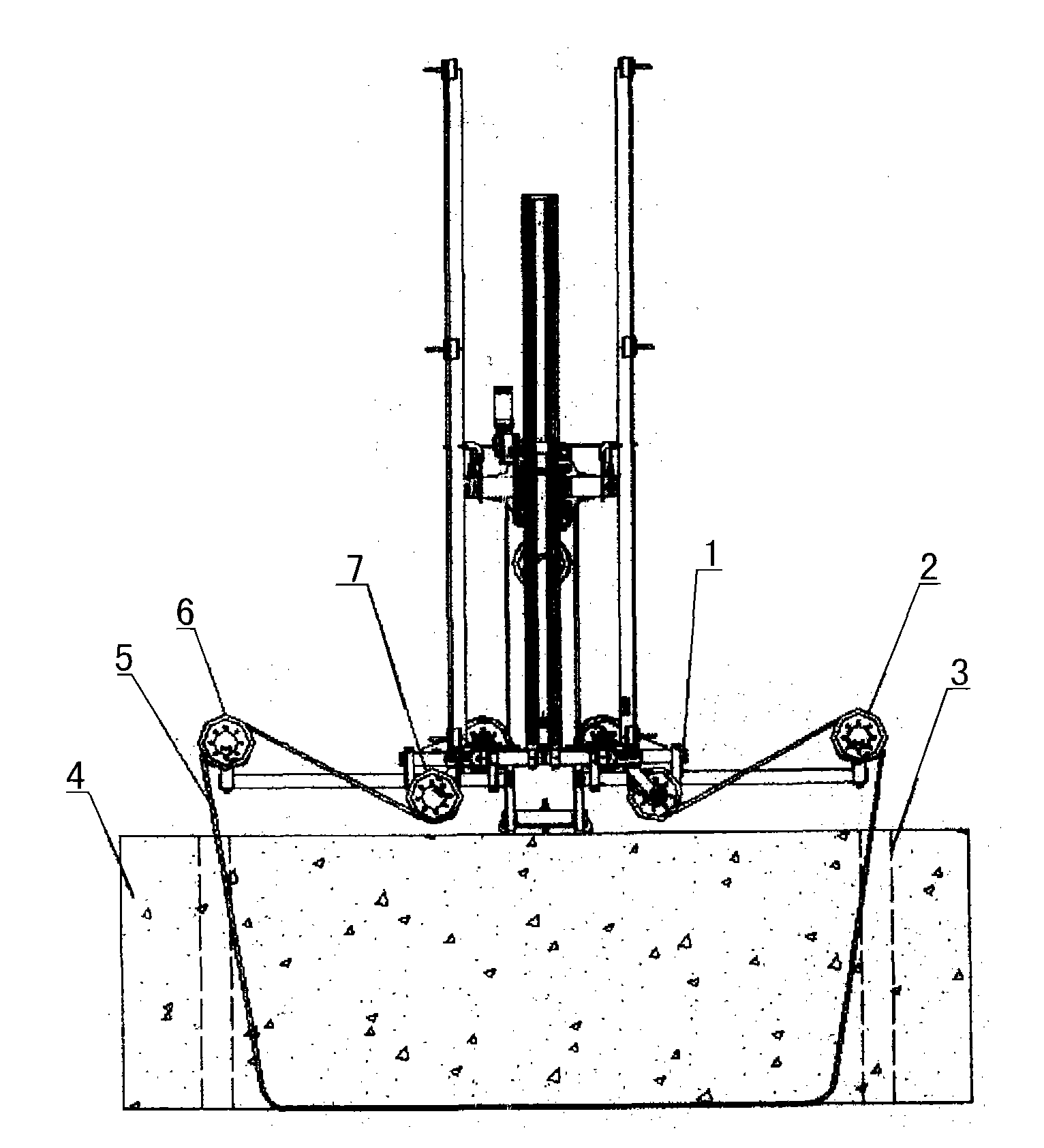

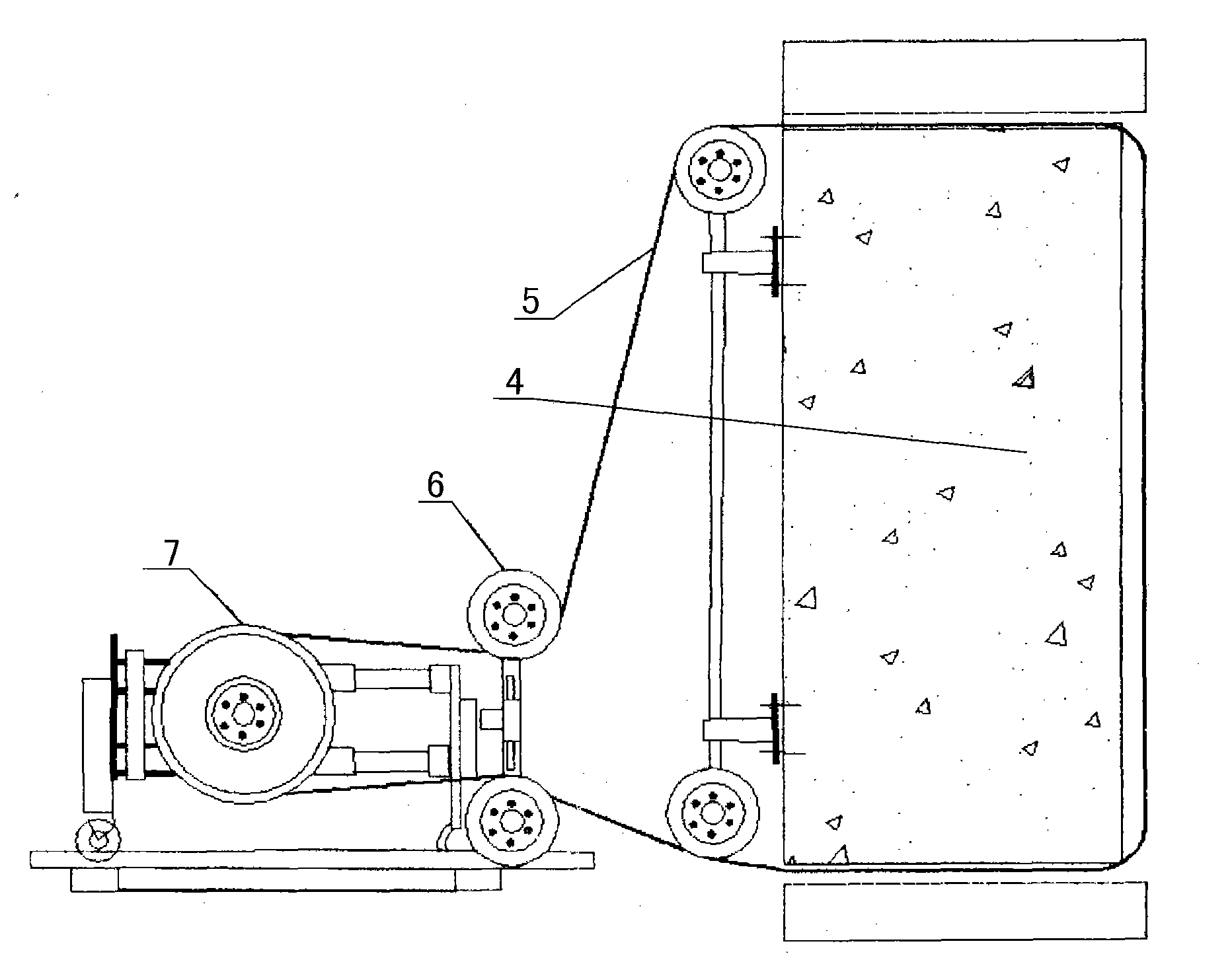

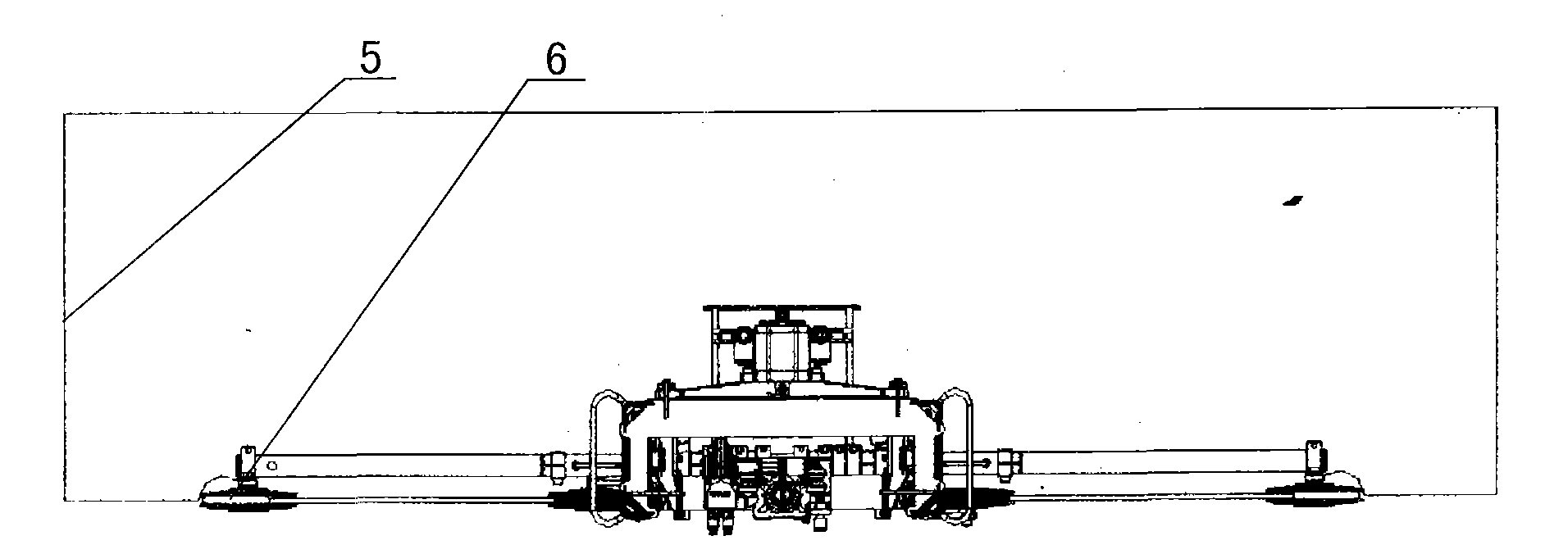

Plane-push lift type transverse cutting machine for concrete

InactiveCN101676081ASimple structureEasy to useStone-like material working toolsDrive shaftEngineering

The present invention provides a plane-push lift type transverse cutting machine for concrete which comprises a chassis rack, a ground wheel is arranged on the chassis rack. The plane-push lift type transverse cutting machine for concrete is characterized in that: a lift support seat is arranged on two ends of the chassis rack, a slideway is arranged on two sides of the chassis rack along the longitudinal direction, a machine frame is supported by the slideway, an inner rack is arranged in the machine frame, a lift mechanism is arranged on the machine frame, the lift mechanism connects with the inner rack, a motor is arranged on the inner rack, a vertically disposed transmission shaft is arranged on one side of the inner rack, the transmission shaft connects with an output shaft of the motor through a transmission mechanism, a saw blade is arranged on the down part of the transmission shaft. The plane-push lift type transverse cutting machine for cutter has advantages in that: 1. simple structure, easy use and maintenance, low manufacture cost; 2. convenient moving, stable cutting, safe use, high operating efficiency, flat and beautiful cutting surface; 3. wide purpose, the cuttingmachine can be used for transversely cutting various concrete pile heads in the base treatment, such as road, railway, bridge, etc.; dismounting small-sized storied house, bungalow and workshop; cutting and dismounting various concrete structure objects.

Owner:张帅 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com