Copper bush machining technology and copper tube cutting device thereof

A technology of processing technology and cutting device, applied in the field of copper sleeve processing technology and copper tube cutting device, can solve problems such as time-consuming and low efficiency of copper sleeve, improve production efficiency, maintain smoothness, and reduce waste generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0033] Embodiment 2: A copper sleeve processing technology, the difference from Embodiment 1 is: the heating temperature of the inner chamber of the preheating furnace is 250 ° C, and the copper scraps are preheated in the preheating furnace for 3 minutes, and then the copper scraps are transferred to Inside the electric furnace. When the inner cavity of the preheating furnace is heated to 250°C, the moisture in the copper shavings evaporates quickly to ensure that the copper shavings are dry.

Embodiment 3

[0034] Embodiment 3: A copper sleeve processing technology, the difference from Embodiment 1 is: the heating temperature of the electric furnace is 1200 ° C, and the copper scraps enter the electric furnace and melt into copper water; after the copper water flows into the copper tube forming mold, the copper tube is cooled Water cooling the copper tube forming mold, and the copper water is rapidly cooled and formed into copper tubes. And when the copper pipe is cut off, a section of the copper pipe is intercepted for hardness testing. If the measured Brinell hardness meets the requirements (the Brinell hardness value of the copper sleeve is HB80~110), the copper pipe enters the next step of processing. When the Brinell hardness exceeds the range value required by the copper tube, the batch of copper tubes shall be reprocessed.

Embodiment 4

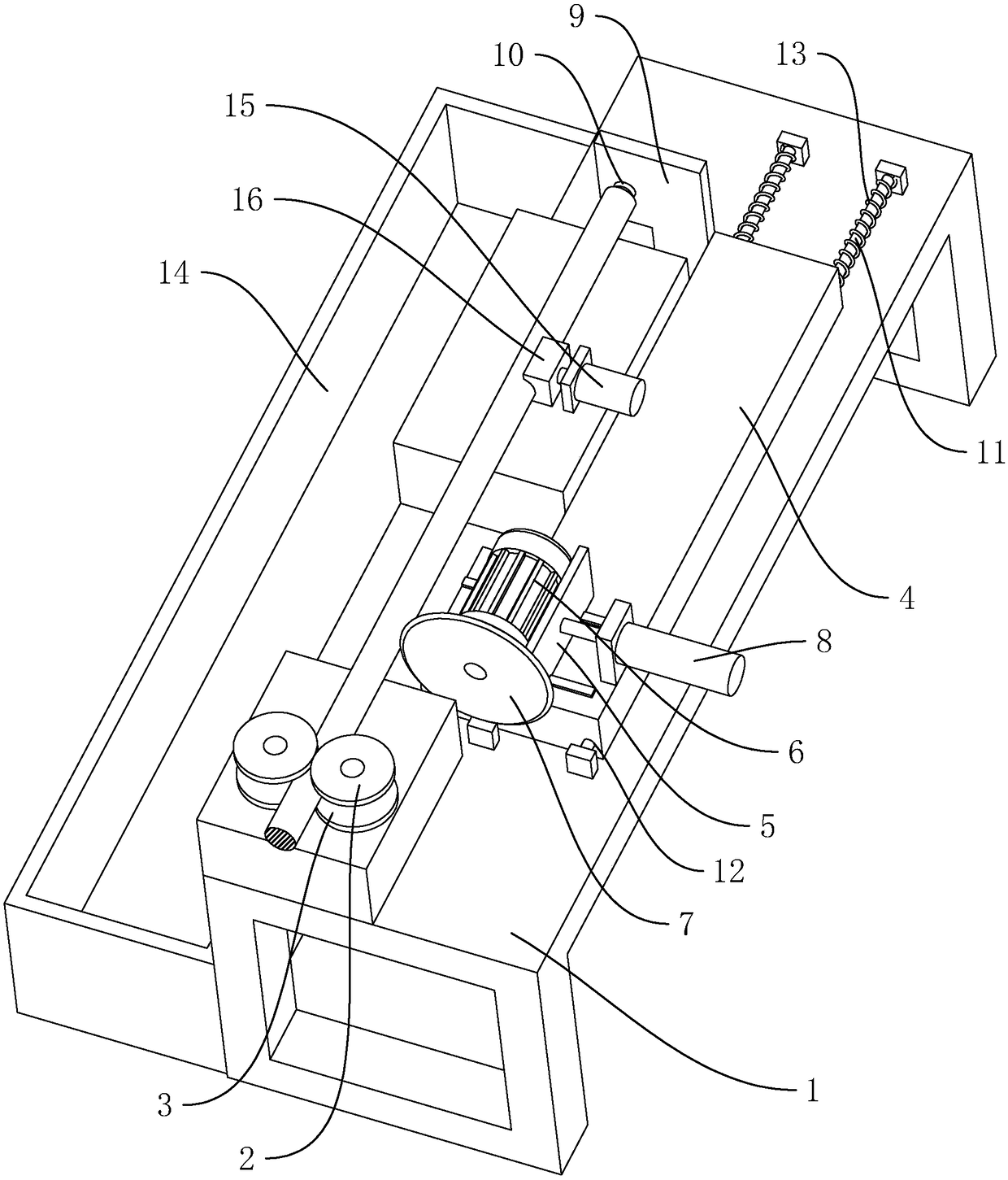

[0035] Embodiment four: as figure 1 As shown, the copper pipe cutting device includes a sliding frame 1, and two abutment wheels 2 abutting against the side wall of the copper pipe are arranged on the upper surface of the sliding frame 1. The rotation axis of the abutment wheels 2 is vertically arranged, and the two abutment wheels The connecting wheels 2 are arranged symmetrically on both sides of the copper pipe, and the side wall of the abutting wheel 2 is provided with an arc-shaped groove 3 corresponding to the side wall of the copper pipe, and the side wall of the copper pipe is clamped in the arc-shaped groove 3 . The position of the copper tube is fixed by the two abutment wheels 2, and the rotation of the two abutment wheels 2 facilitates the movement of the copper tube along the length direction of the copper tube.

[0036] The upper end surface of the sliding frame 1 is slidably connected with the sliding table 4 along the length direction of the copper pipe. The sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com