Dual-purpose saw web for cutting and grinding glass and its manufacturing method

A production method and technology of saw blades, which are applied in glass manufacturing equipment, glass cutting devices, grinding machines, etc., can solve problems such as rough sections and low work efficiency, achieve smooth cutting surfaces, improve processing efficiency, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

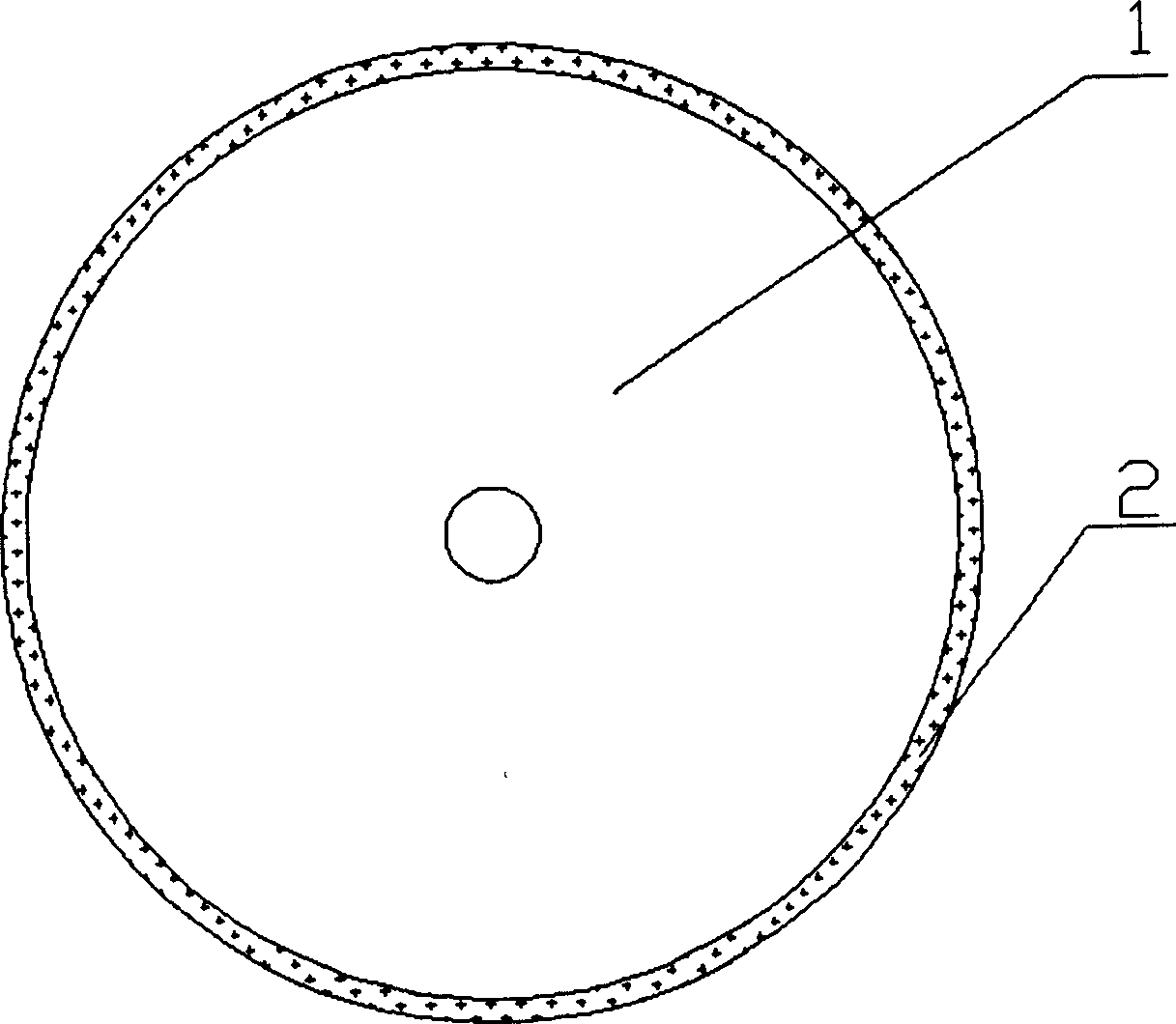

[0018] like figure 1 As shown, the glass cutting and grinding dual-purpose saw blade of the present invention is composed of a steel substrate 1 and an alloy cutter head 2 impregnated with diamond particles. The alloy cutter head 2 is composed of the following components by weight: 20 grams of iron powder, 45 grams of copper powder gram, 15 grams of tin powder, 8 grams of nickel powder, diamond 60 / 80MBD6, the alloy cutter head 2 is fixedly welded on the outer peripheral edge of the steel matrix 1.

[0019] The preparation method of the glass cutting and grinding dual-purpose saw blade of the present invention is as follows: 20 grams of iron powder, 45 grams of copper powder, 15 grams of tin powder, 8 grams of nickel powder, and diamond 60 / 80MBD6 are evenly mixed together, and put into the mold , heated at a temperature of 765°C, hot-pressed at a pressure of 30Mpa, and molded under a pressure of 300Mpa to obtain an alloy cutter head impregnated with diamond particles. Finally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com