Patents

Literature

35results about How to "Processing economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

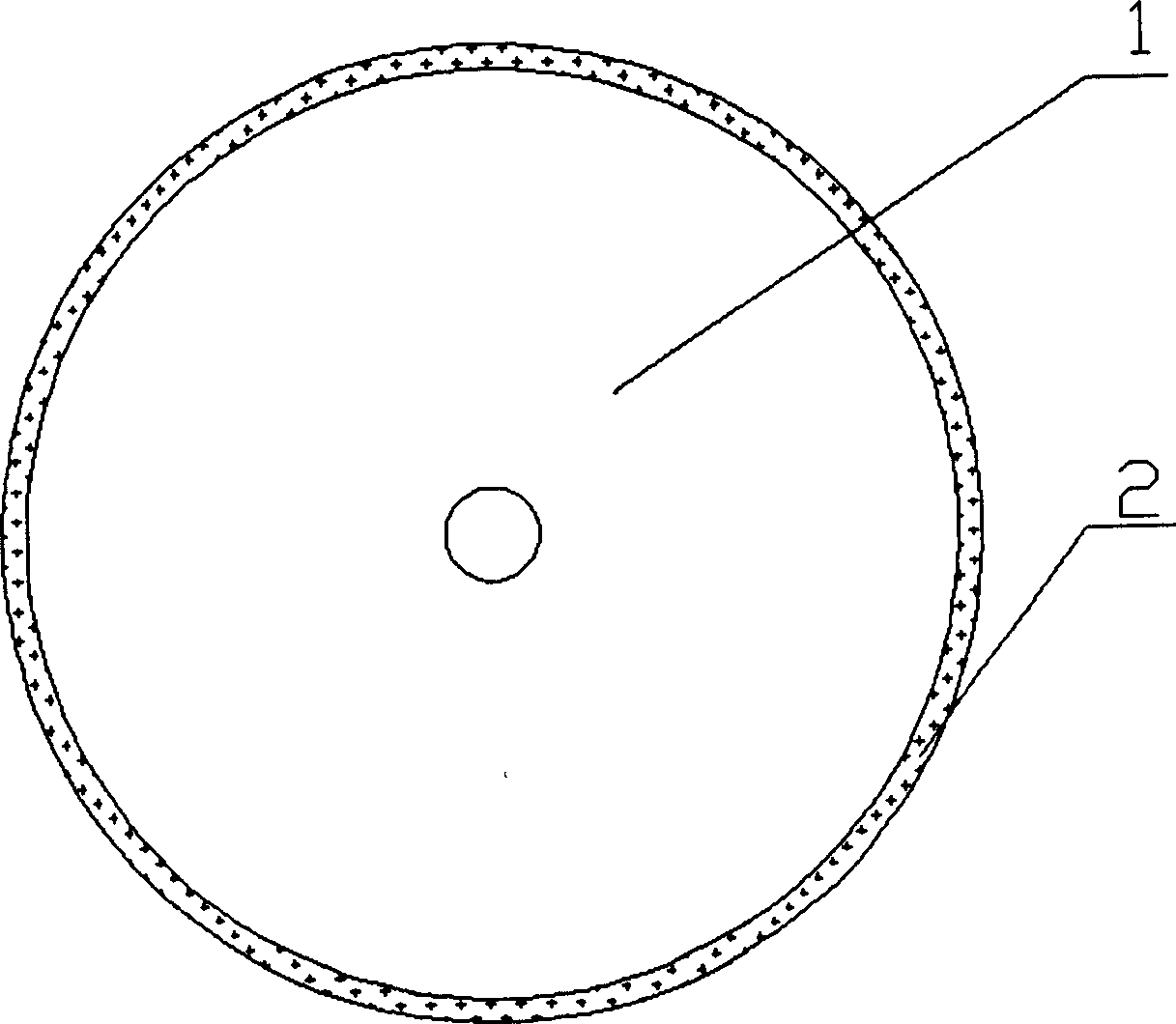

Dual-purpose saw web for cutting and grinding glass and its manufacturing method

InactiveCN1657454AHigh hardnessEfficient processingBonded abrasive wheelsGlass severing apparatusIron powderAlloy

Owner:HENAN HUANGHE WHIRLWIND CO LTD

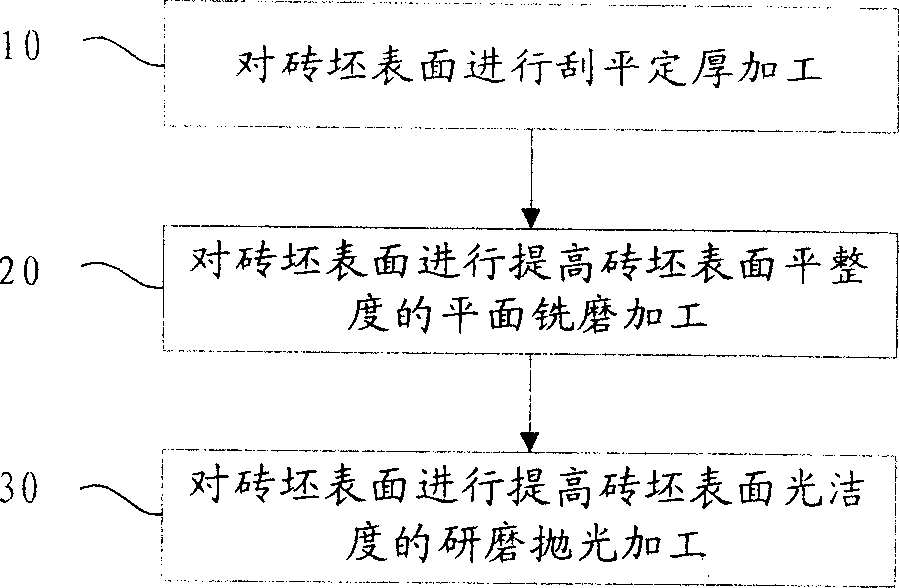

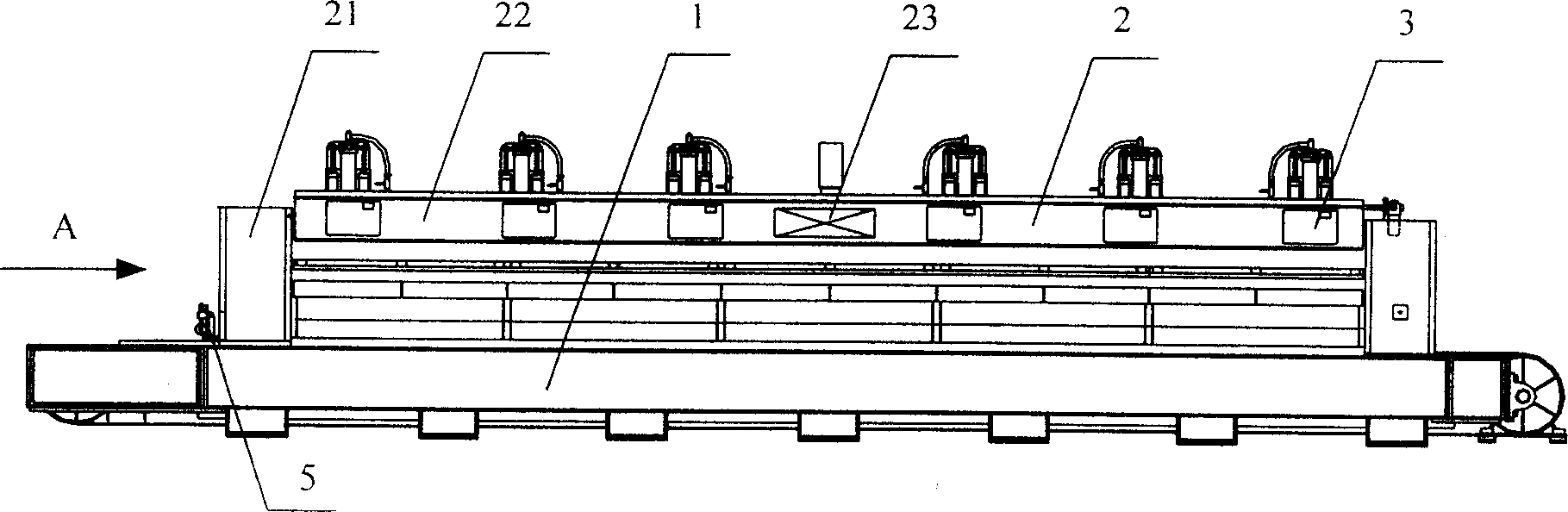

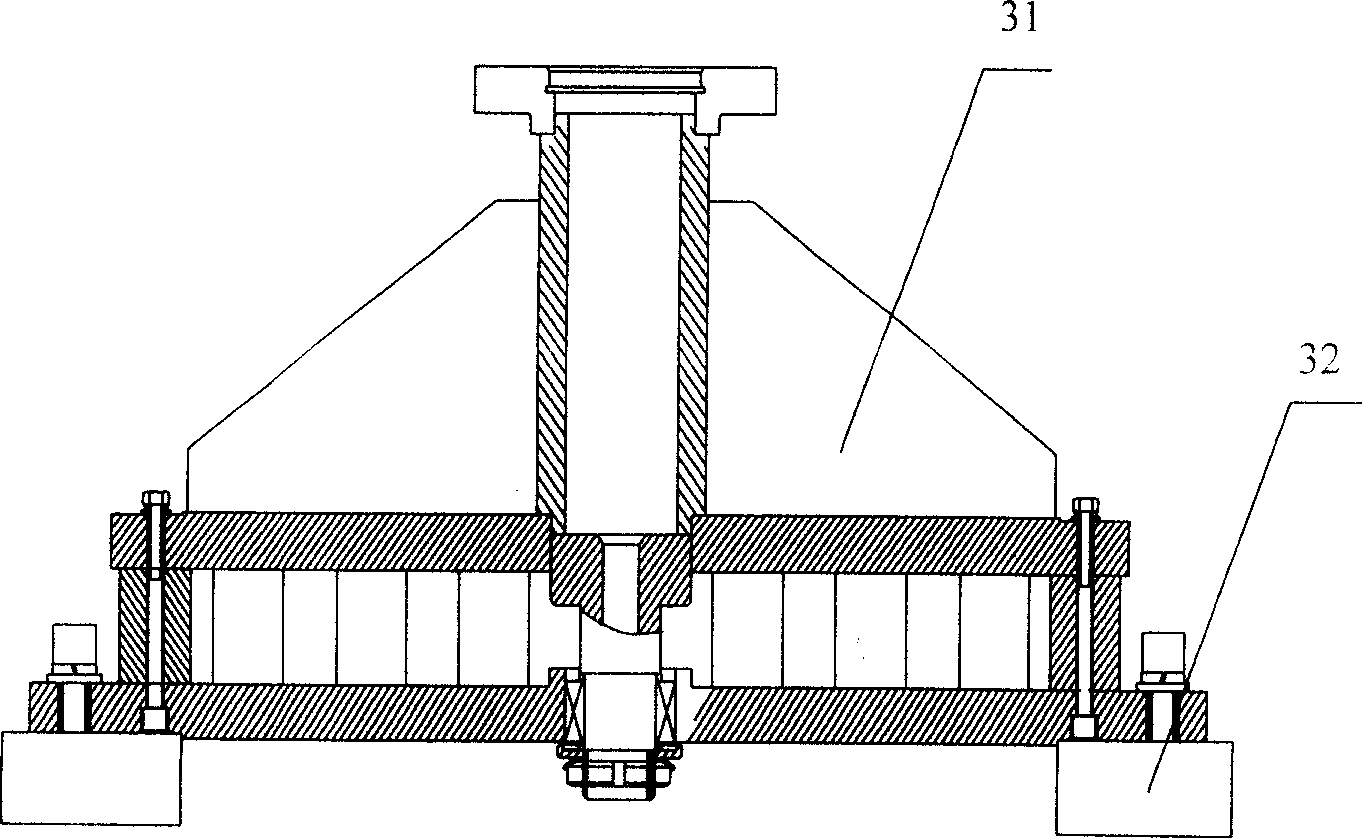

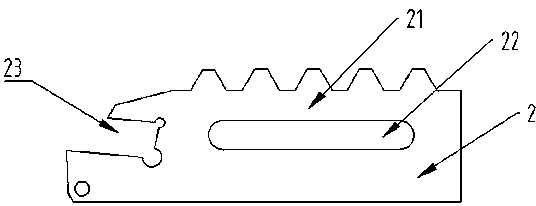

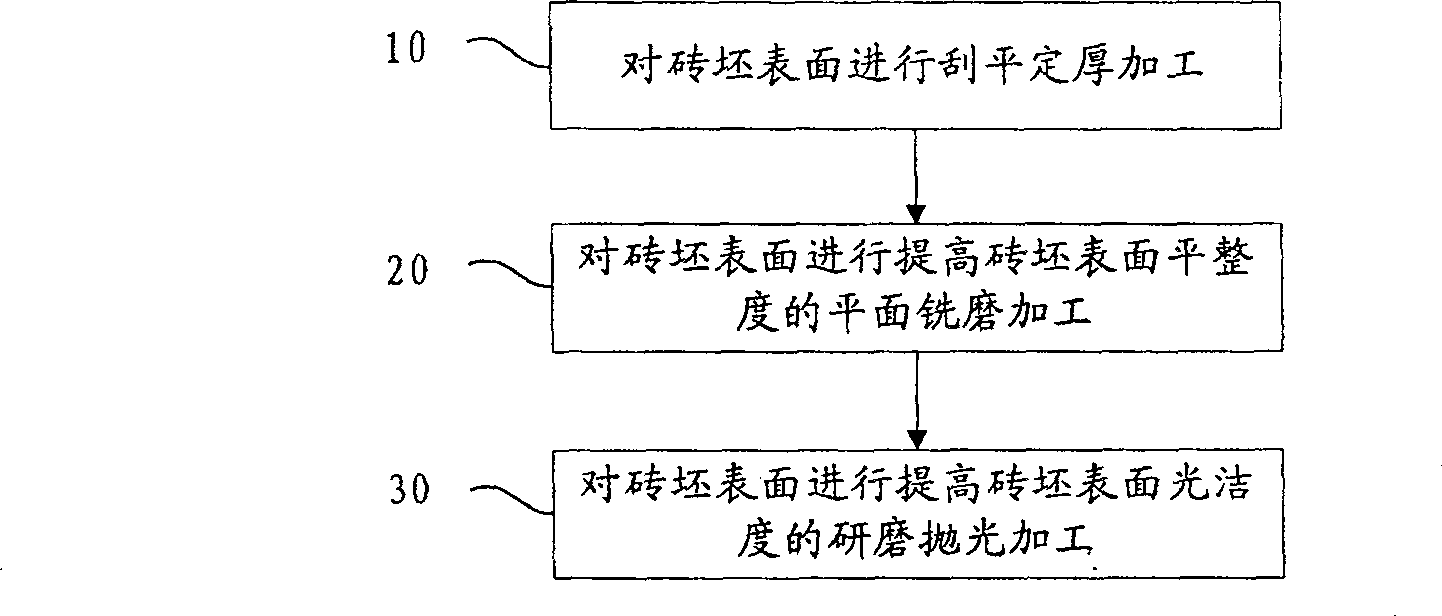

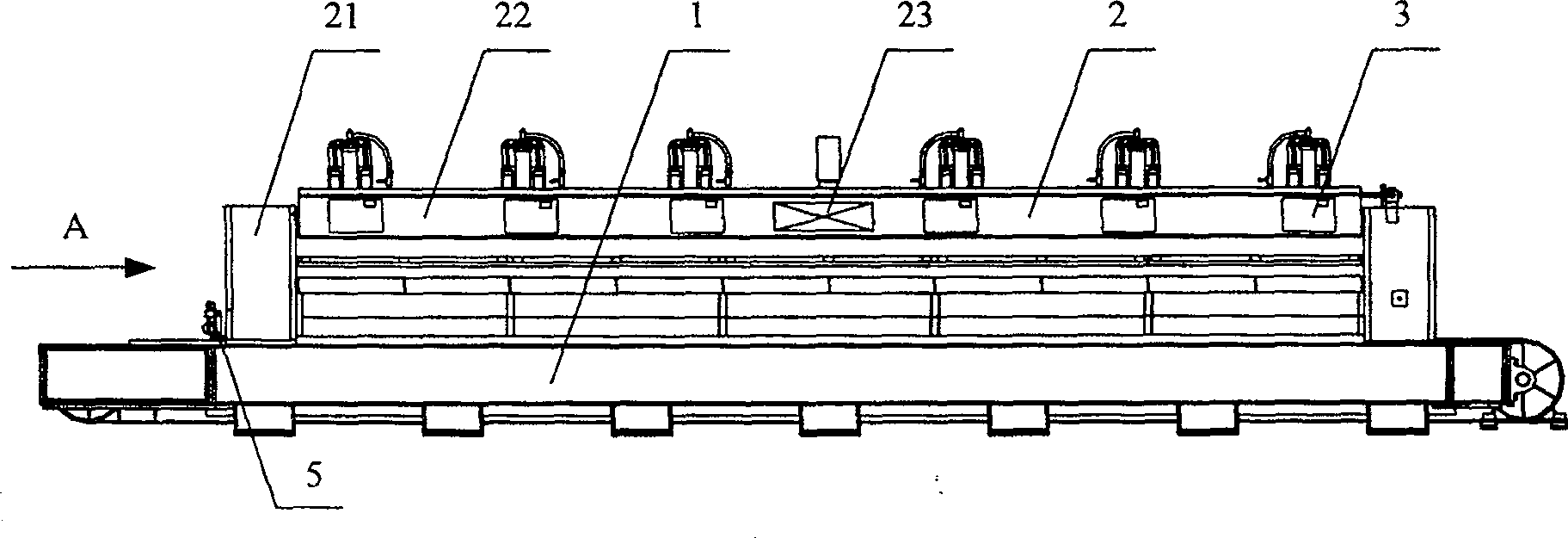

Method and apparatus for processing surface of ceramic polished brick

InactiveCN1843731AAvoid scratchesAvoid edge gnawingPolishing machinesCeramic shaping apparatusBrickEnergy consumption

The invention relates to a method for processing the surface of ceramic polished brick, and relative device. Wherein, said method comprises: flattening the surface and setting its thickness of brick; milling and grinding; and polishing. Wherein, the second step uses several grinders to rotationally mill the surface. Said special device comprises a flattening thickness setter, a surface miller and a grinding polisher, to process the surface of brick, while said surface miller comprises a frame, a beam vibrator, and a milling system; wherein, the milling system comprises several milling heads that fixed on the beam vibrator to rotate. The invention uses the devices in different efficiencies and accuracies to treat the surface of brick, therefore, it can improve the producing efficiency and quality, to reduce energy consumption and the cost of device.

Owner:KEDA INDUSTRIAL GROUP CO LTD

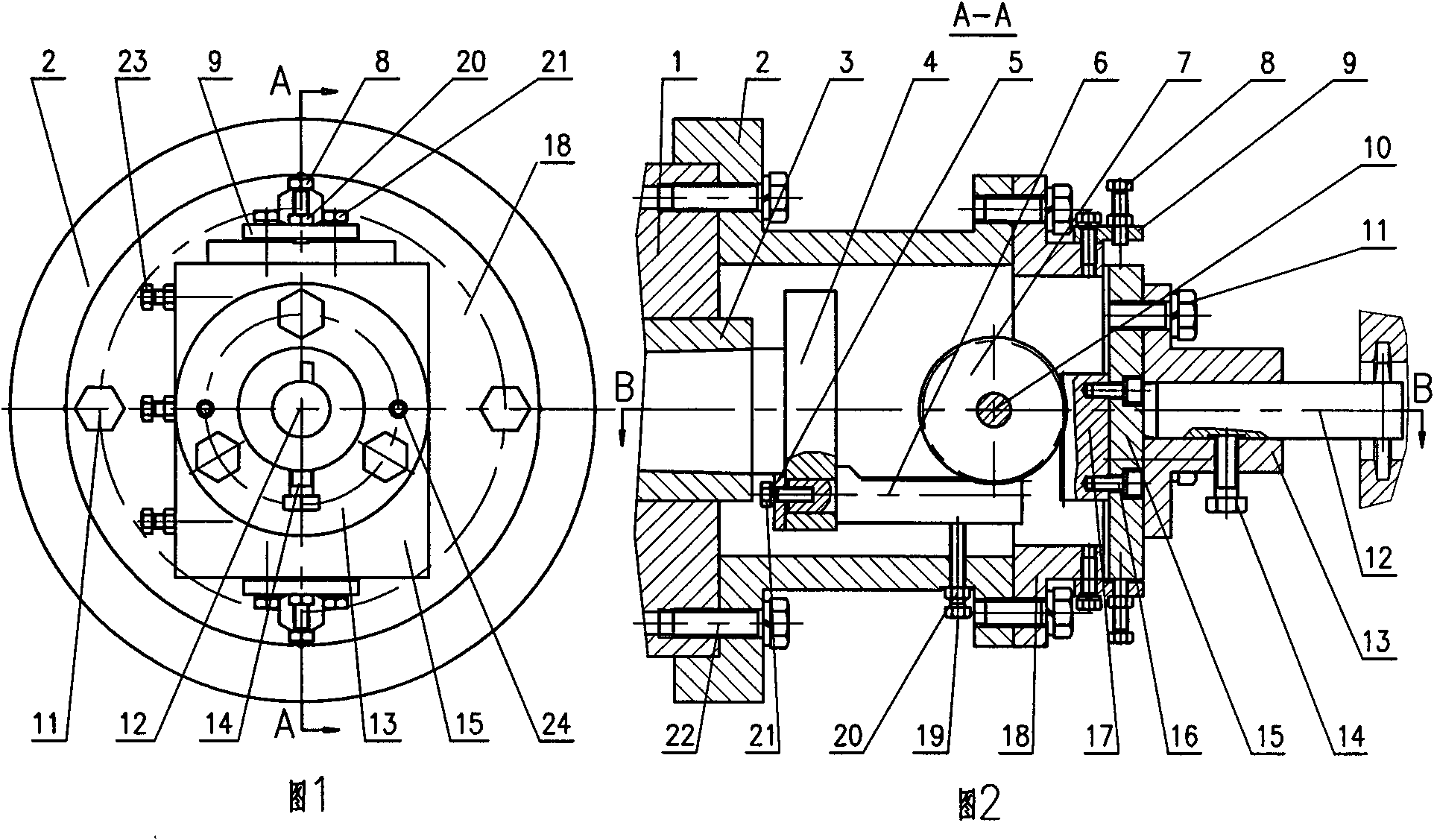

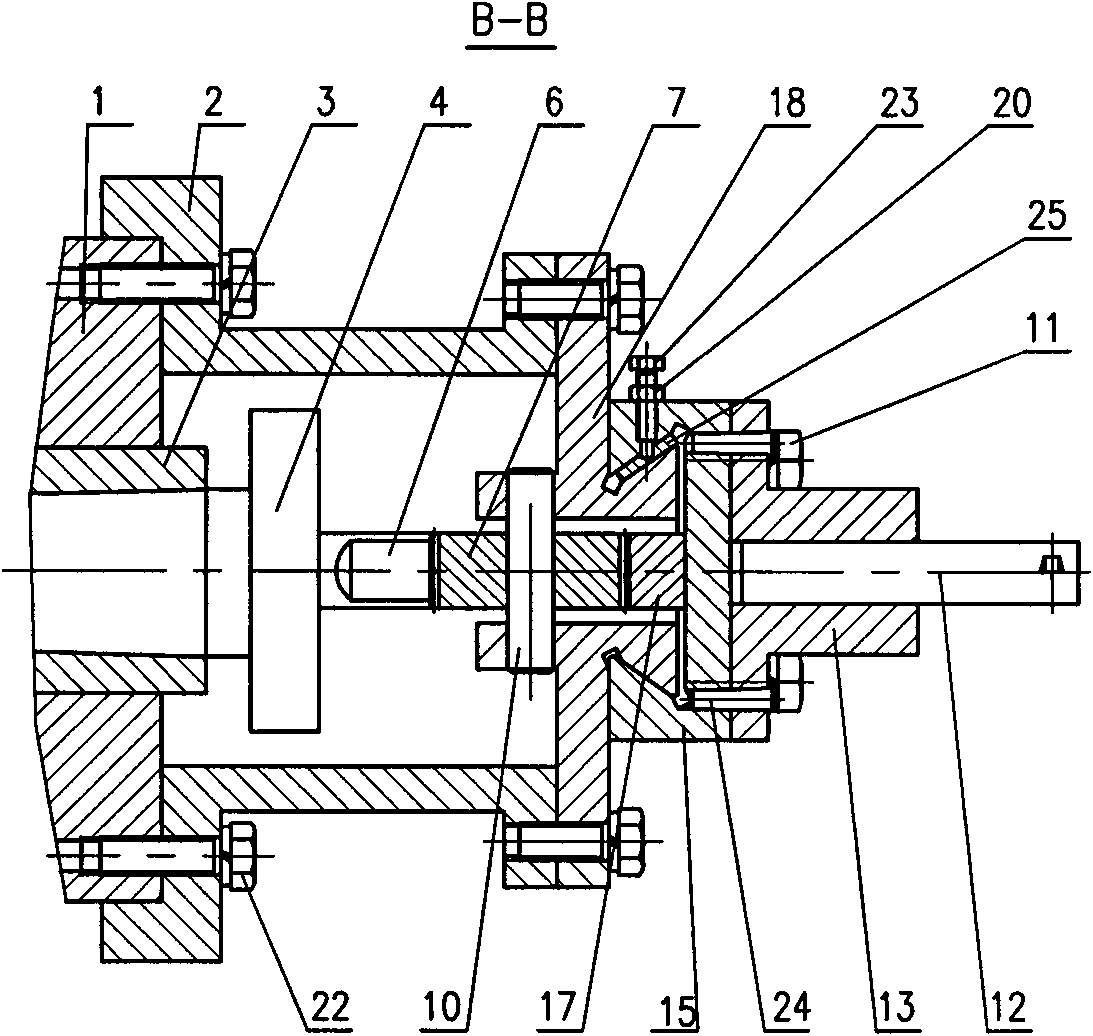

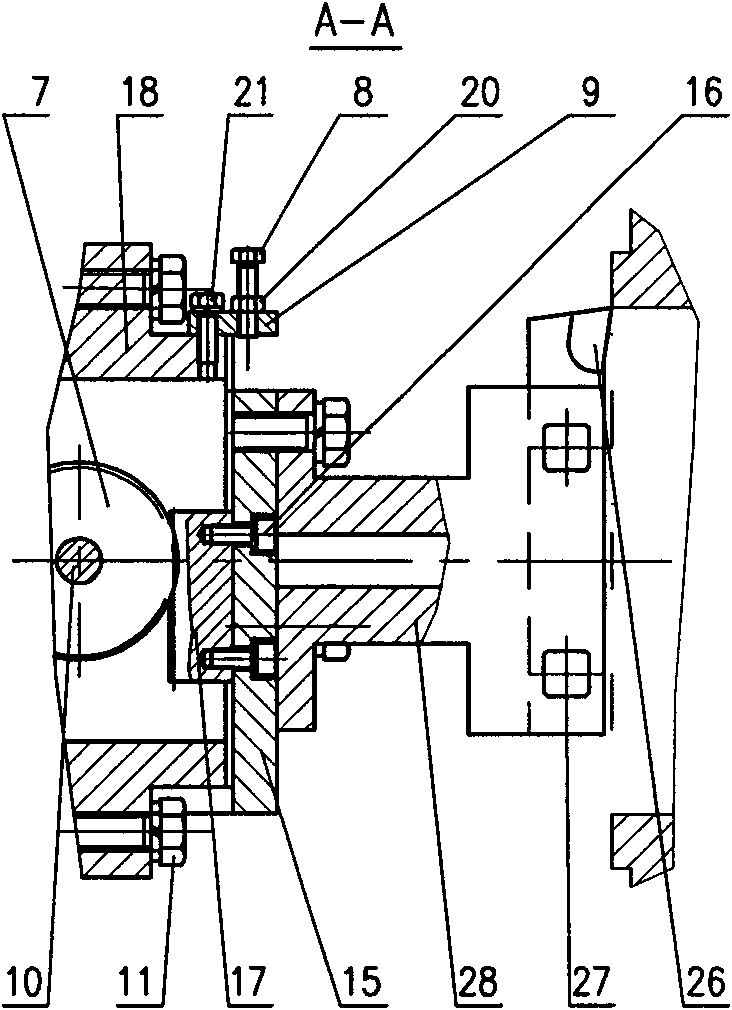

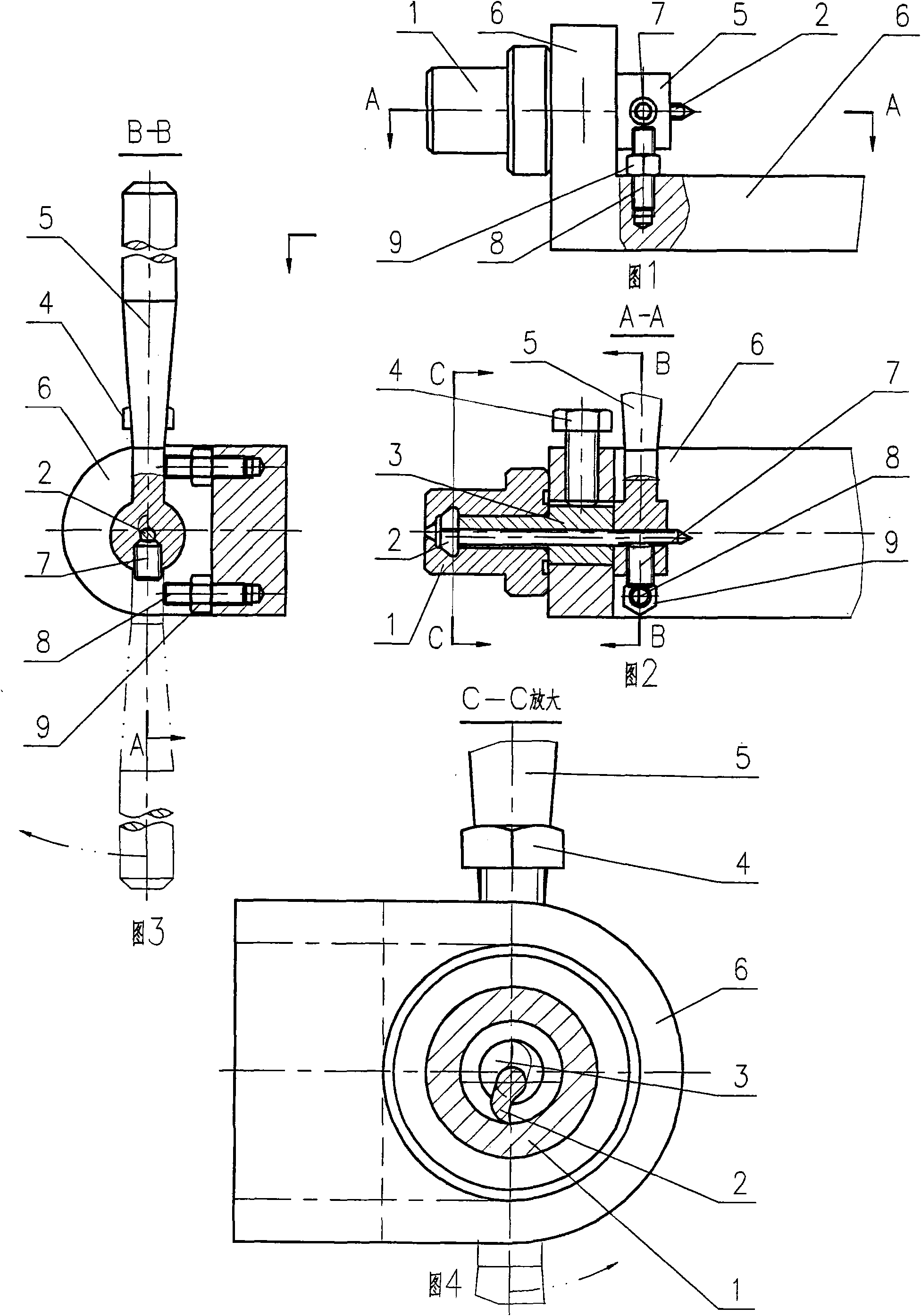

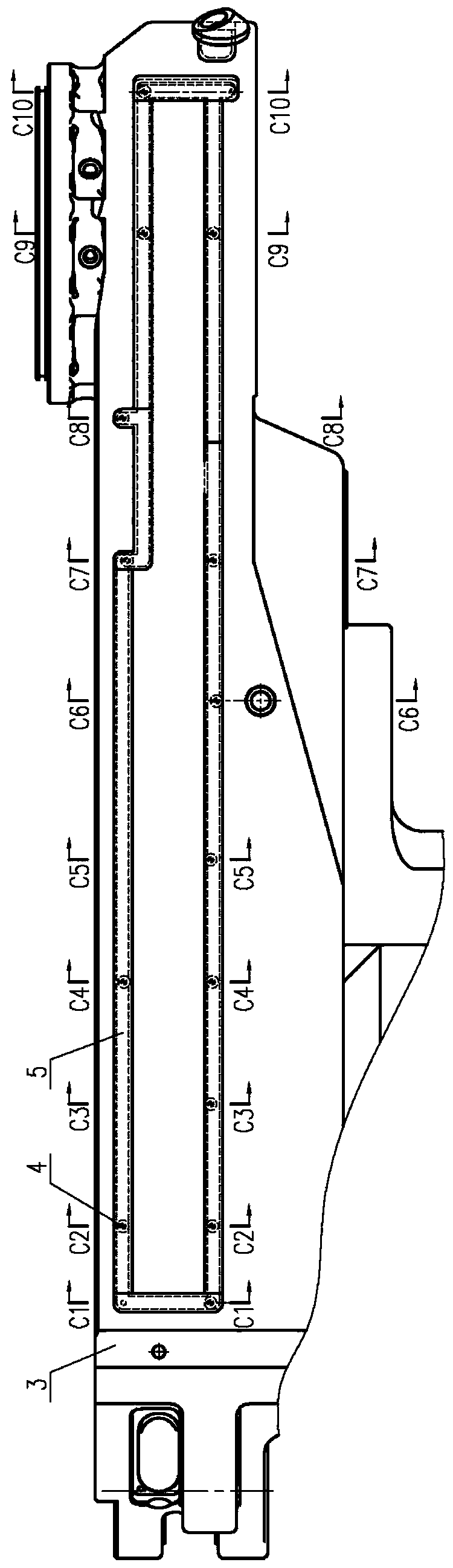

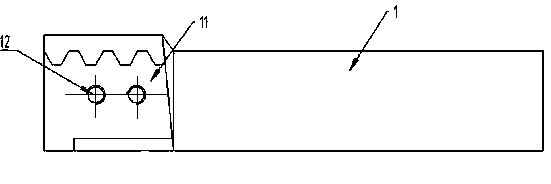

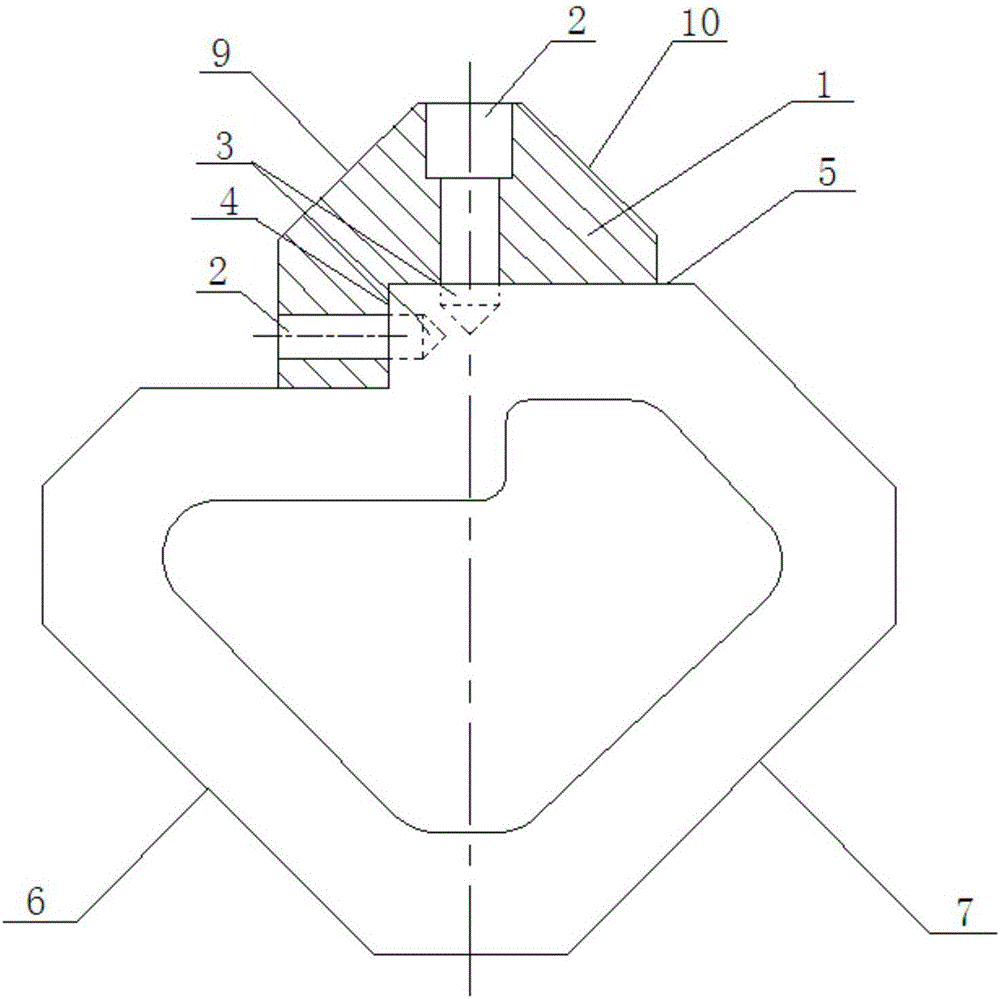

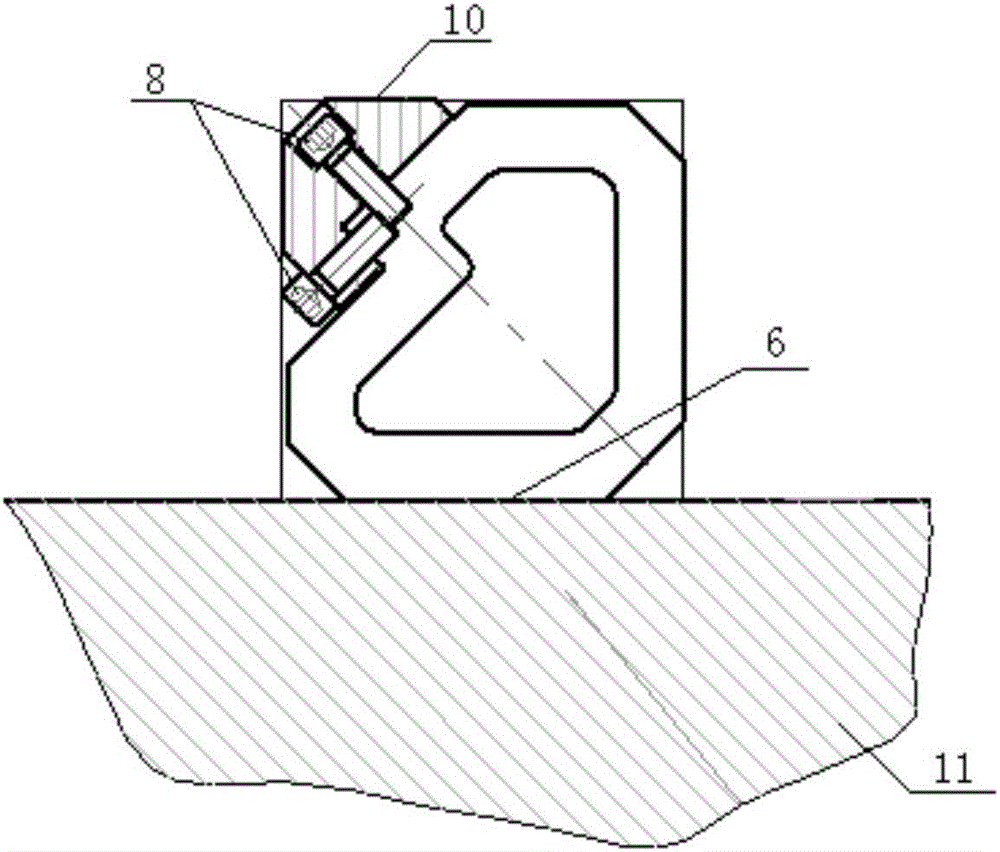

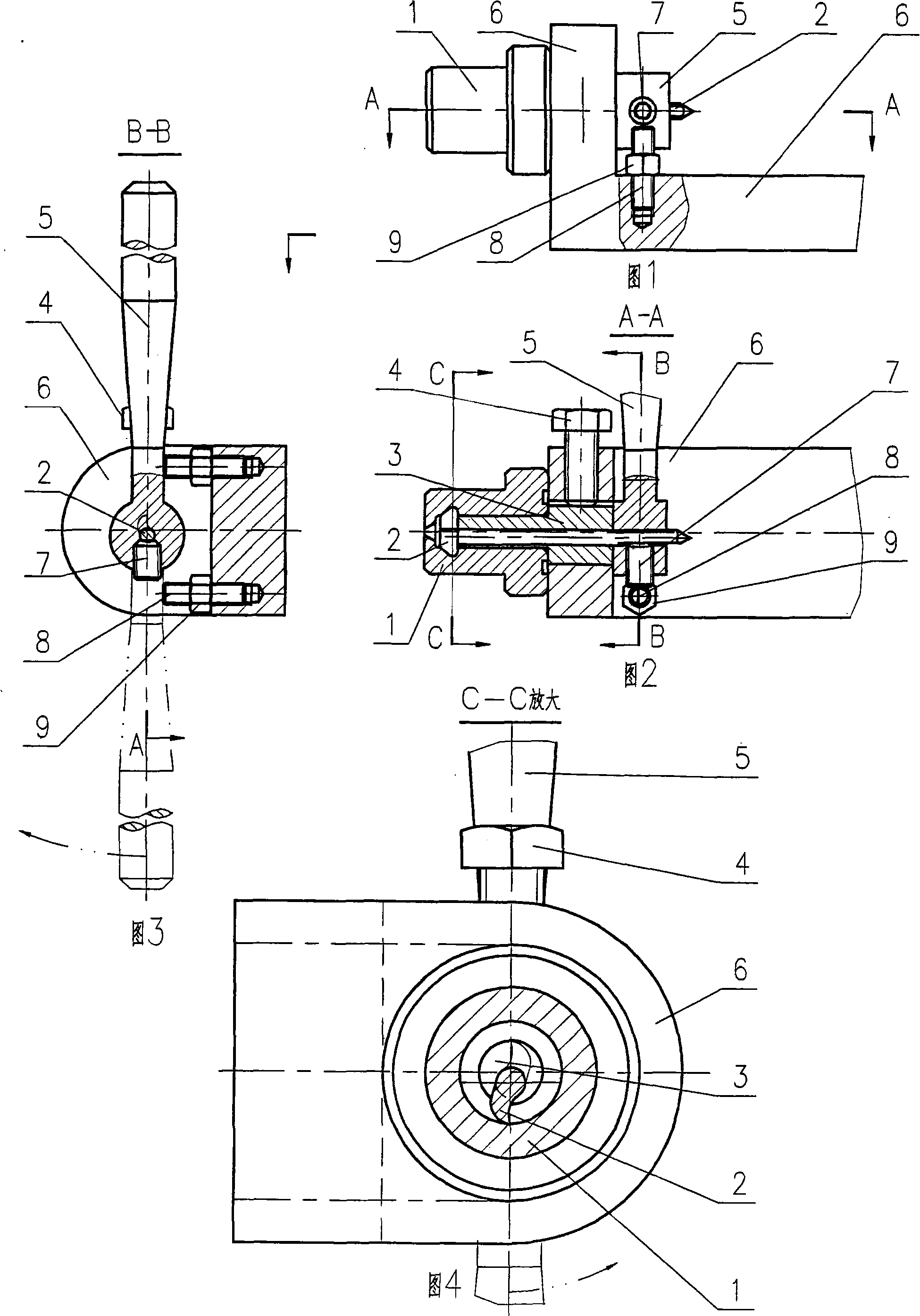

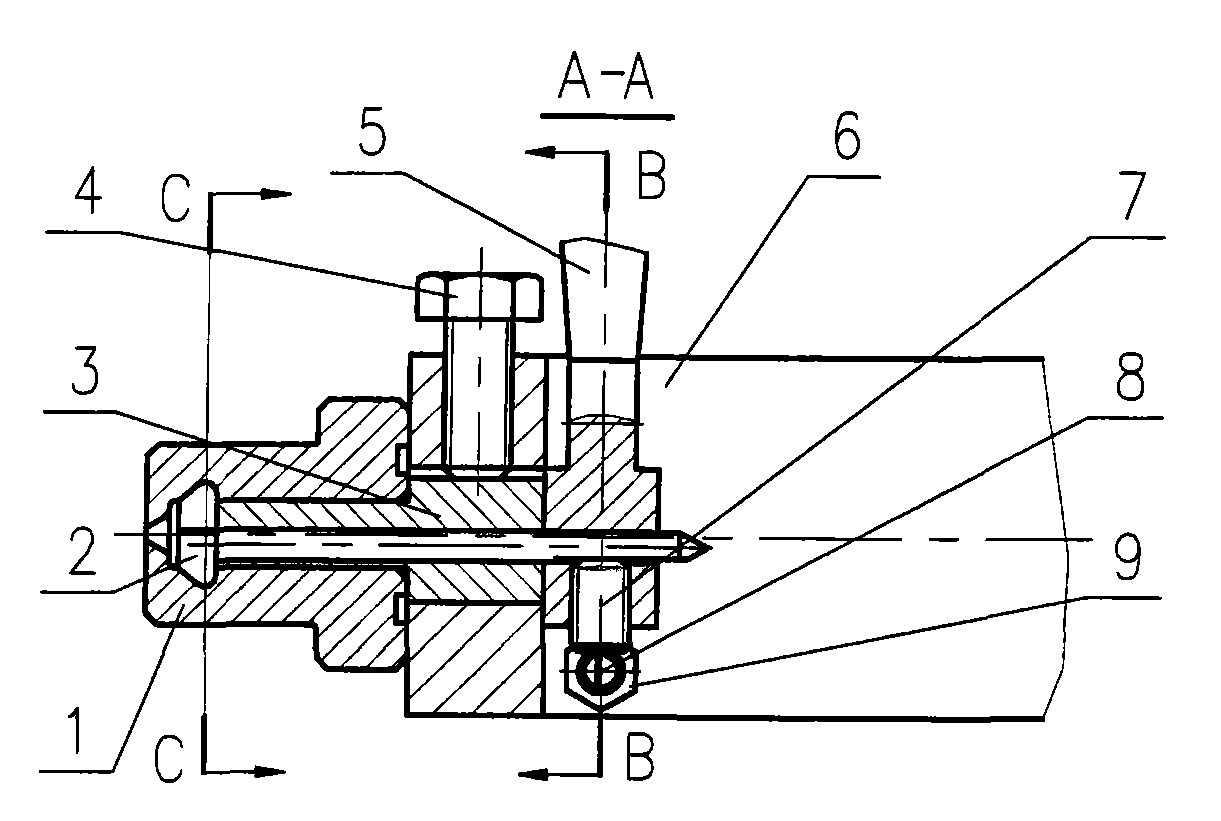

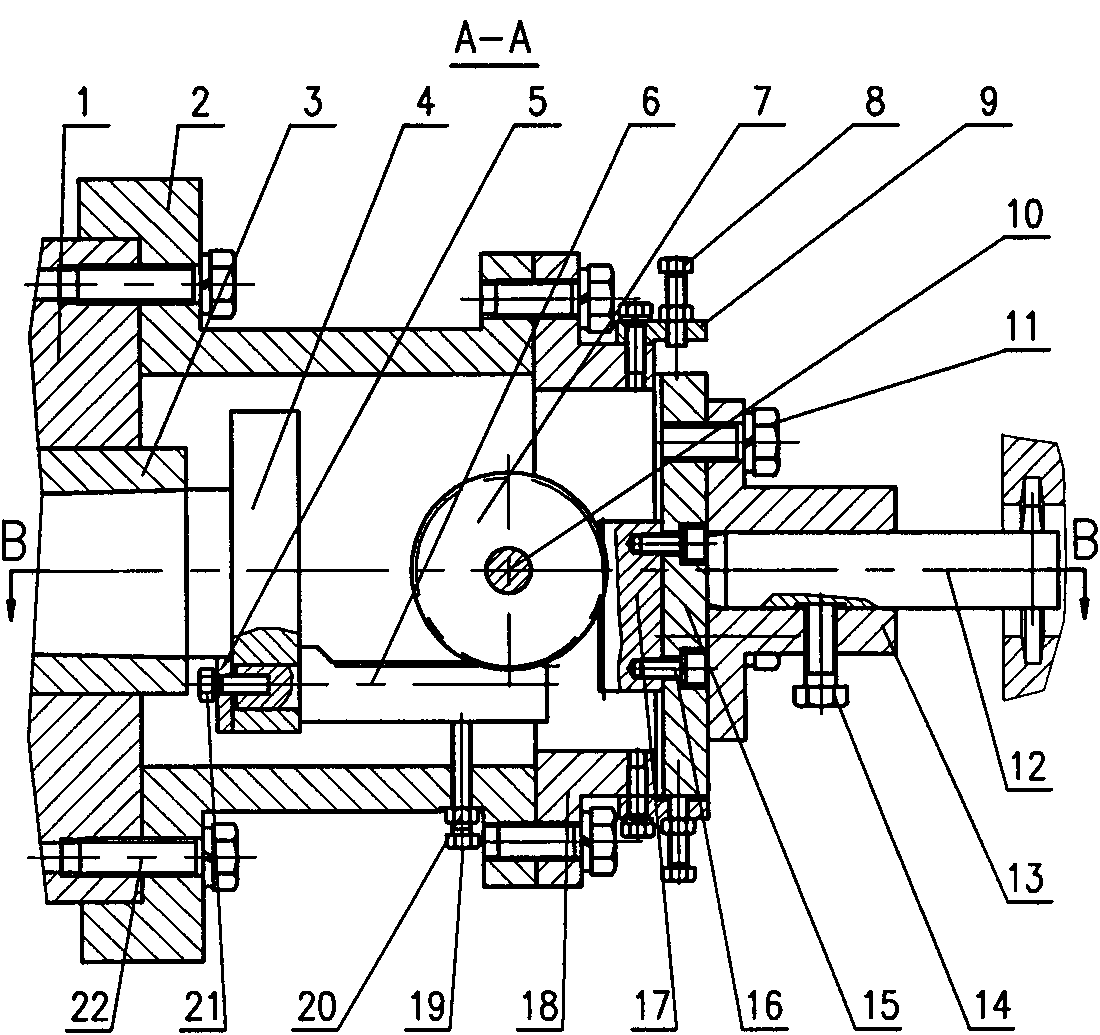

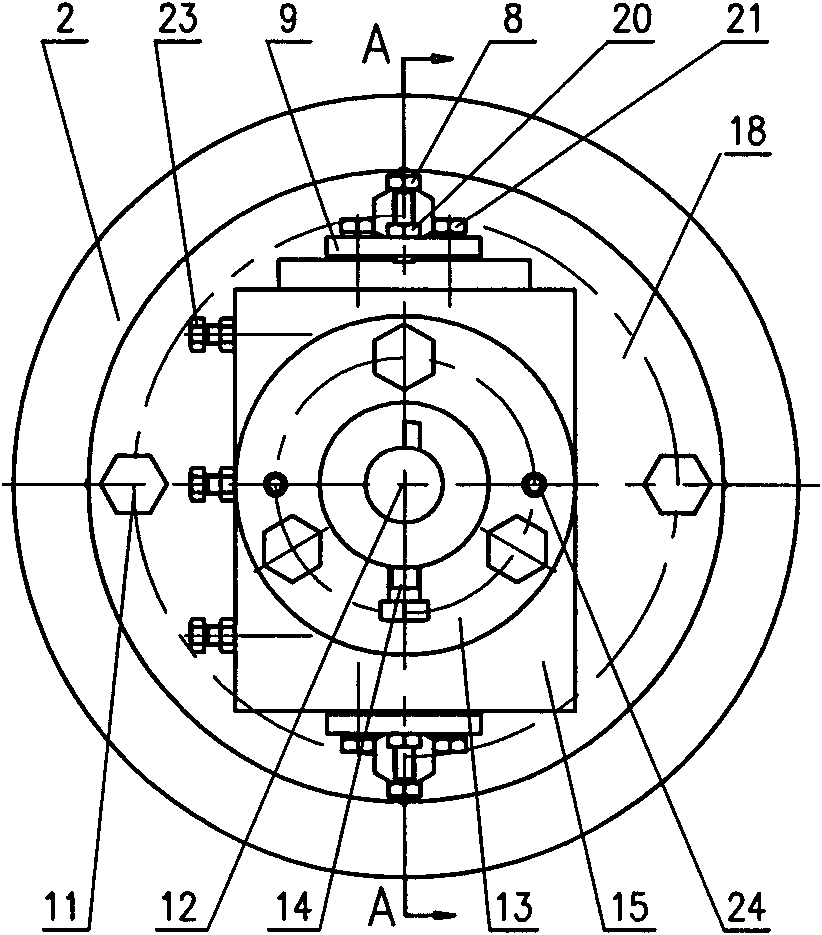

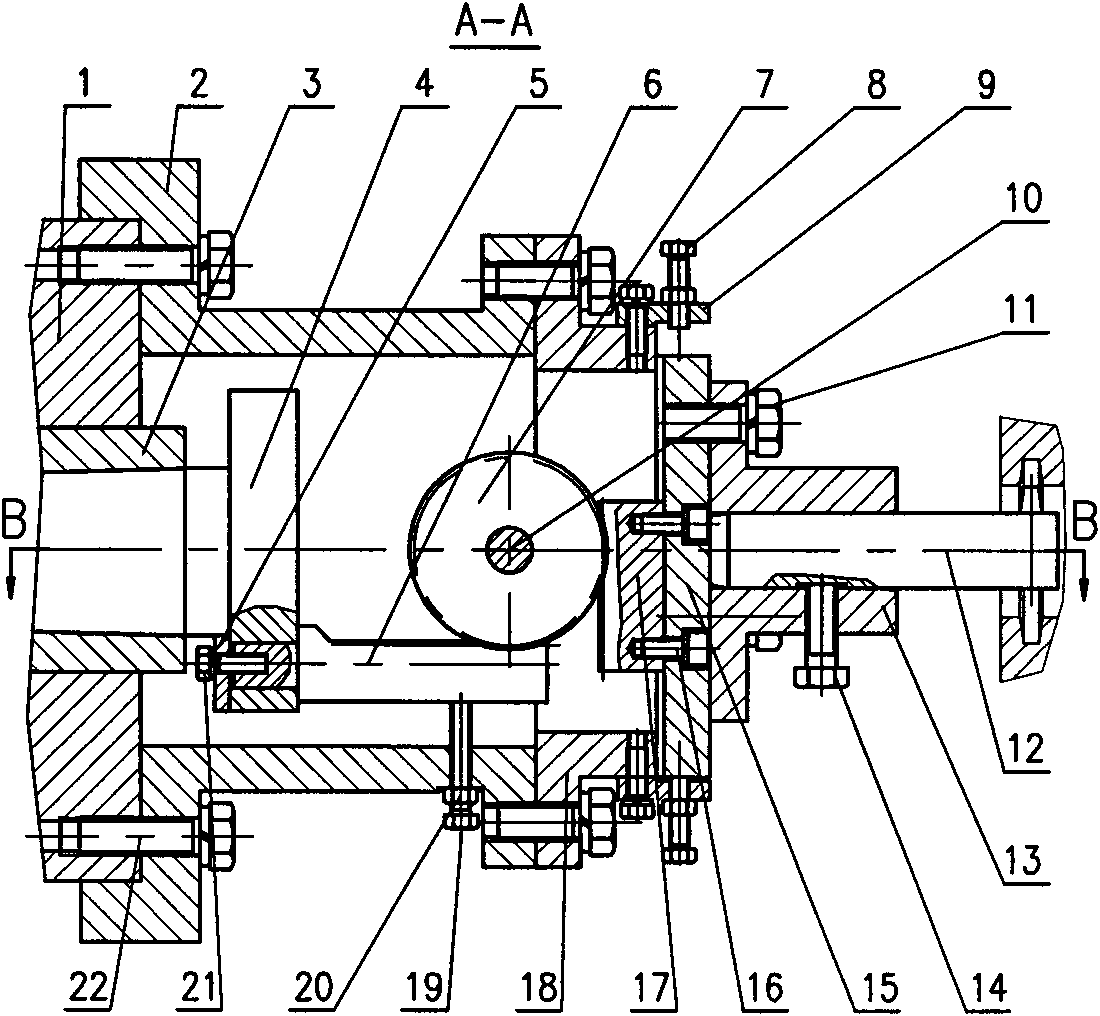

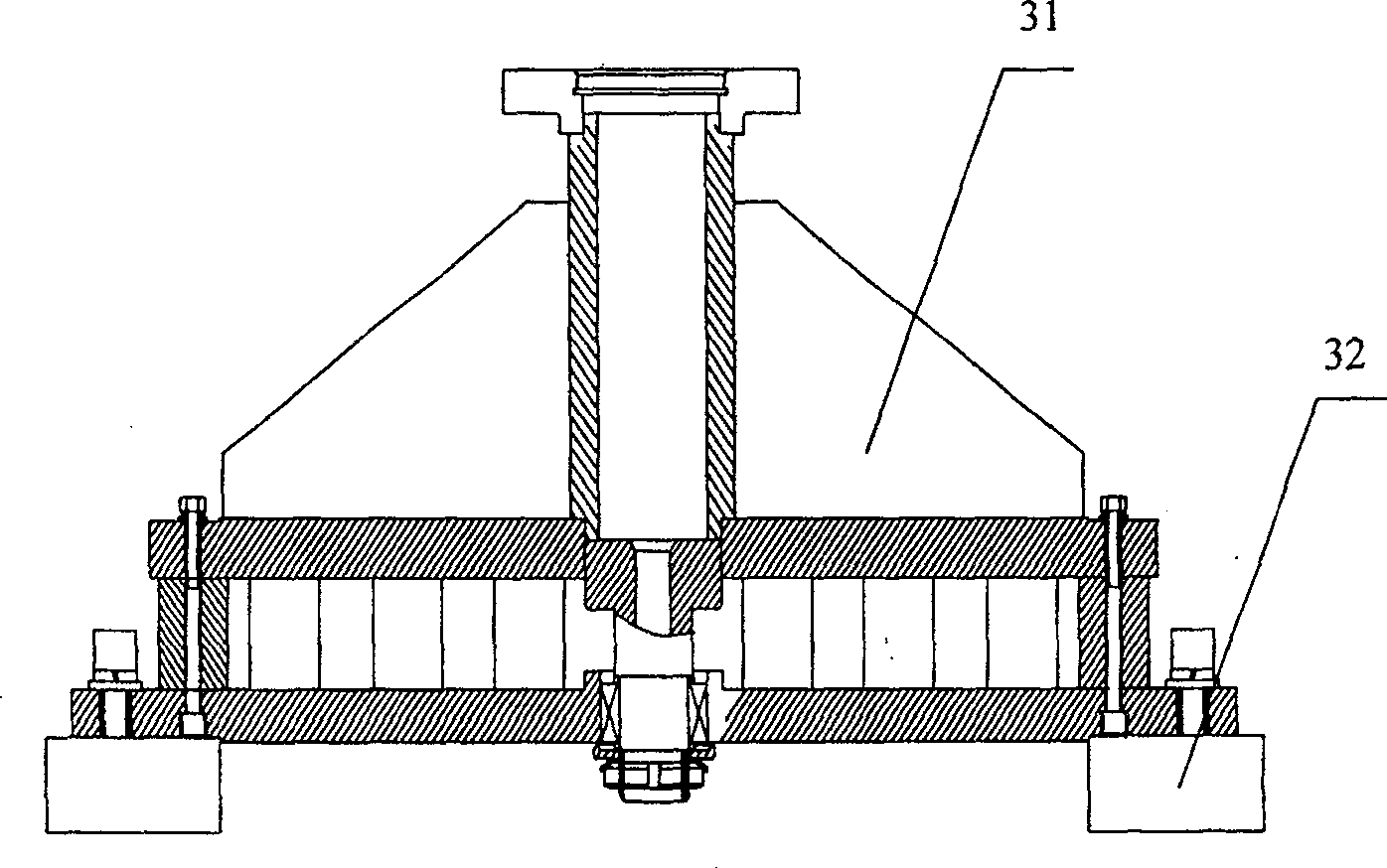

Radial feed mechanism

InactiveCN101607371AEasy to processProcessing economyFeeding apparatusBoring/drilling componentsHigh volume manufacturingGear wheel

The invention discloses a radial feed mechanism. A support is fixed on the front end of the main shaft of a boring lathe, a slide carriage seat is fixed on the support, a slide carriage is matched with the slide carriage seat by a dovetail groove, and a fit clearance between the slide carriage and the slide carriage seat is adjusted by an inserted bar; a cutting feed shaft is arranged in a taper hole on the front end of a boring lathe boring bar; an axial rack is arranged on a disk on the front end of the cutting feed shaft; a gear is arranged on the slide carriage seat by a mandrel to be meshed with the axial rack; a radial rack is fixed on the slide carriage to be meshed with the gear; the slide carriage seat is provided with a positioning mechanism which can limit the slide carriage to move, and the movement direction of the slide carriage is vertical to the rotary axis of the boring lathe; the cutter seat is fixed on the slide carriage, and the cutter is fixed on the cutter seat. The boring bar moves, and the axial rack drives the gear to rotate, so that the radial rack drives the slide carriage to move to realize radial feeding. When used, the radial feed mechanism can conveniently and economically process wider and deeper grooves in the inner bore of the part of a box body and the high-precision end surface in the inner bore of the part of the box body. The invention is especially suitable for mass production of parts.

Owner:吴淼东

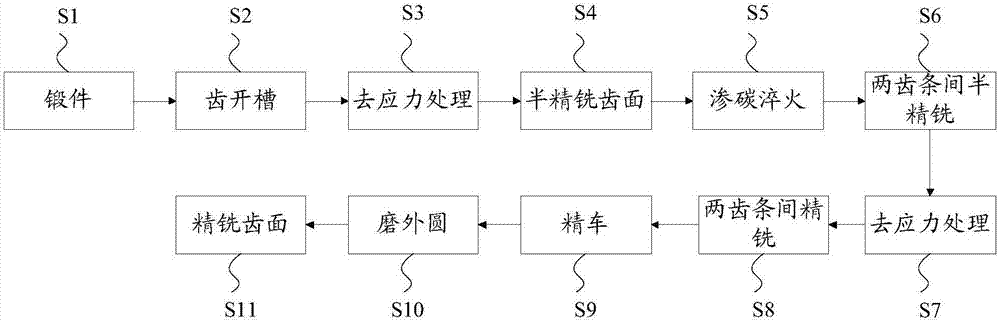

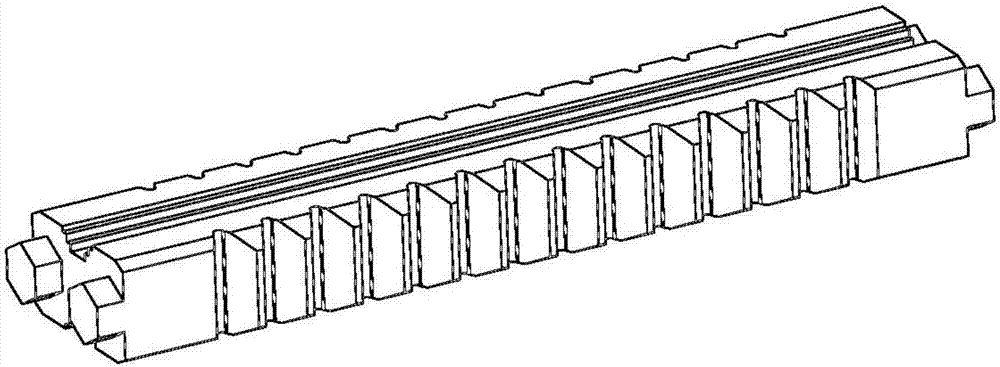

Processing method for hard-tooth-surface big-modulus cylindrical rack

The invention discloses a processing method for a hard-tooth-surface big-modulus cylindrical rack. The processing method comprises the following steps: S1: forging, according to the structure of the semicircle rack, performing the overall forging by using a blank corresponding to two racks; S2: tooth slotting, performing the tooth slotting to two sides of a forge piece; S3: destressing processing;S4: semi-finish-milling tooth surface, performing the half finish-milling tooth surface to two sides of the forge piece, wherein the working allowance is kept on the tooth surface; S5: carburizing and quenching; S6: semi-finish-milling between two racks; S7: destressing processing; S8: finish-milling between two racks, enabling two racks to be separated; S9: finish turning; S10: external grinding, finishing a product at the end face; and S11: finish-milling tooth surface, finishing a product at the tooth surface. The processing of the hard-tooth-surface big-modulus cylindrical rack is realized by the above technology. The uncontrollability of the cylindrical asymmetrical surface heat treatment deformation is overcome, and a special heat treatment device and a special gear grinding machineare not needed, so the processing is more simple and economic.

Owner:CHONGQING GEARBOX

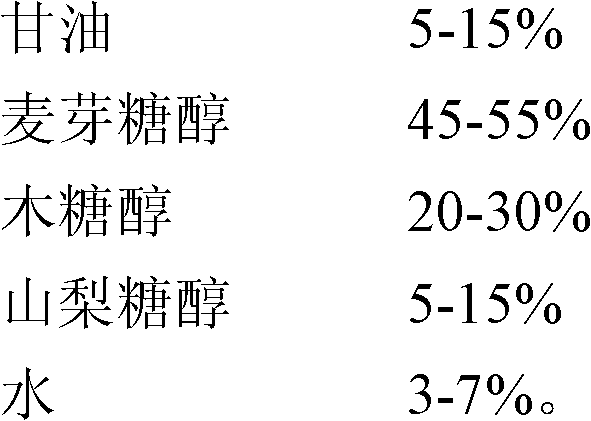

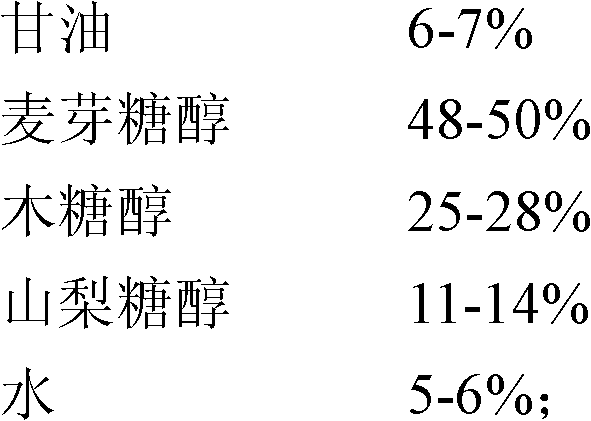

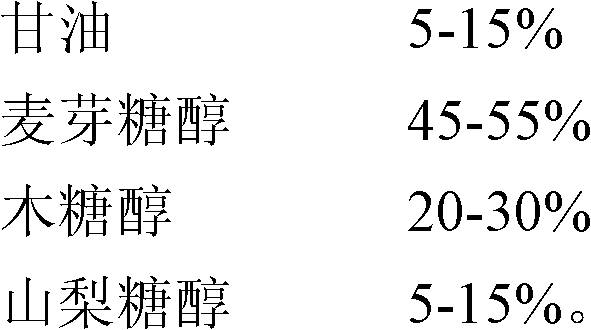

Compound moisturizing agent for foods and preparation method thereof

The invention discloses a compound moisturizing agent for foods. The compound moisturizing agent consists of the following components in percentage by weight: 5 to 15 percent of glycerol, 45 to 55 percent of maltitol, 20 to 30 percent of xylitol, 5 to 15 percent of sorbitol and 3 to 7 percent of water. The invention also discloses a method for preparing the compound moisturizing agent for foods. The method comprises the following steps of: (1) adding solid materials such as the maltitol, the xylitol and the sorbitol into water in a ratio, heating for dissolution, adding the glycerol, and uniformly stirring; and (2) filtering the obtained mixture, ensuring that insoluble matters in the filtrate is less than 10 milligrams / kilogram, and concentrating the filtrate until the water in the concentrated solution is 3 to 7 weight percent. The compound moisturizing agent for foods can be directly added into various foods according to requirements of processing technologies, and has a good moisturizing property, low sugar, low heat and rich health-care effects; and compound moisturizing agent meets the requirements of food processing technologies, and is convenient to use.

Owner:ZHEJIANG HUAKANG PHARMA

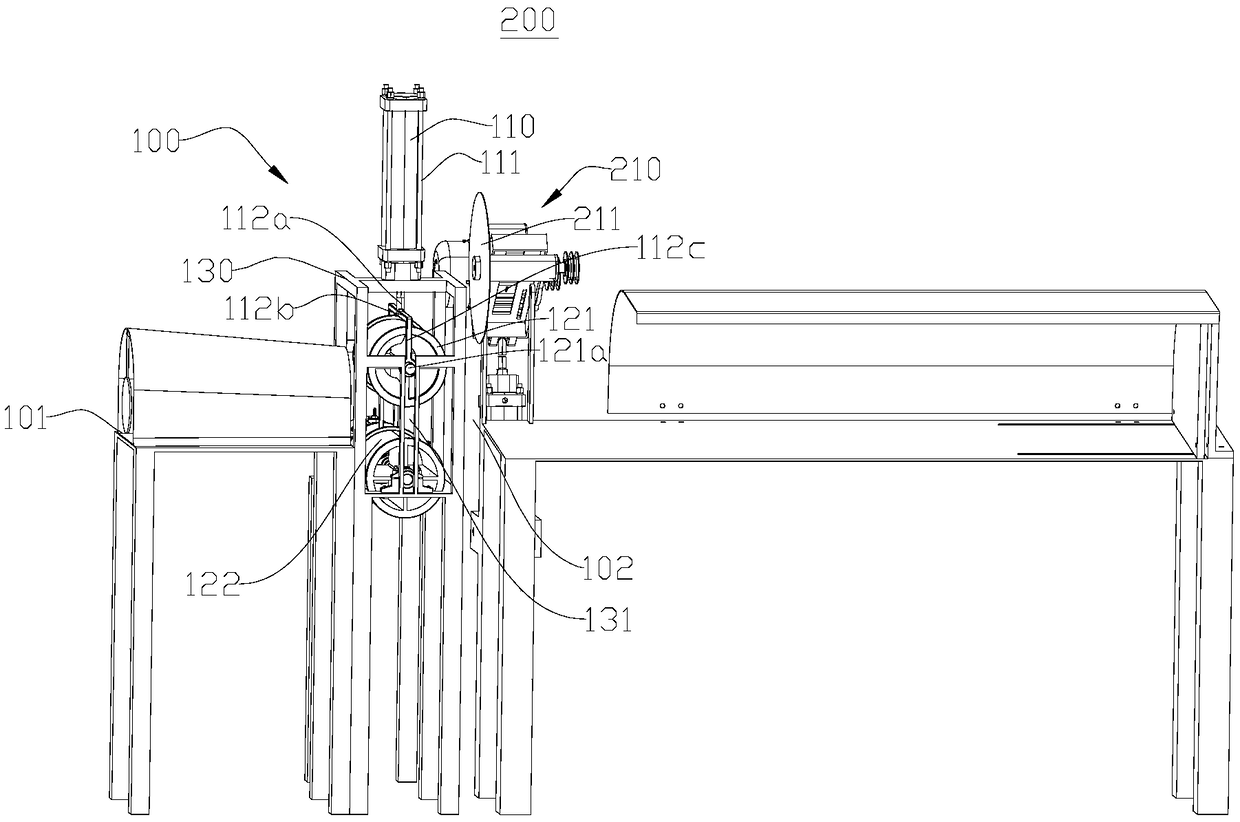

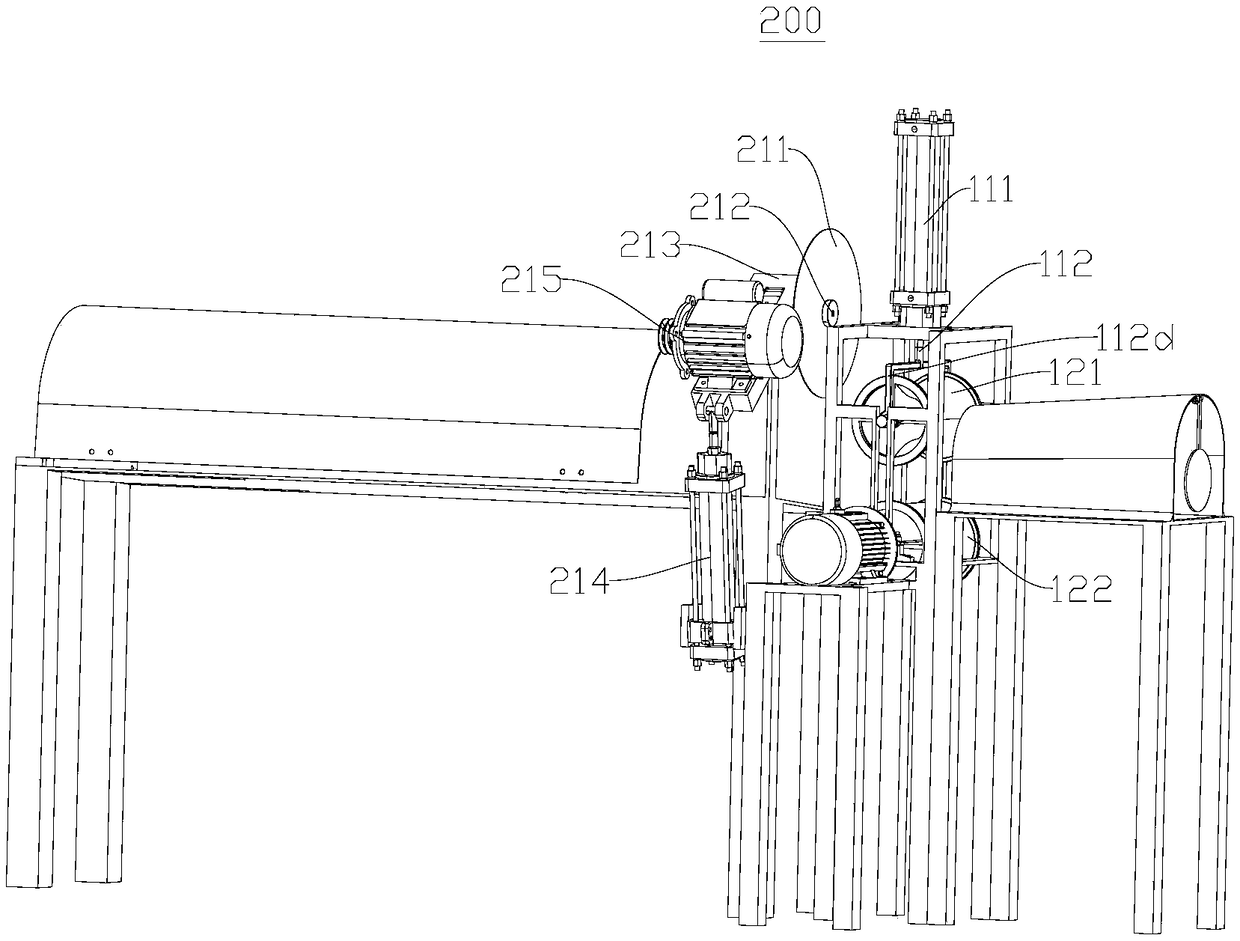

Clamping and feeding device for moso bamboo cutting machine, moso bamboo cutting machine and moso bamboo cutting system

PendingCN109129771AHigh degree of automationSave manpower and material resourcesFeeding devicesCane mechanical workingMaterial resourcesEngineering

The invention provides a clamping and feeding device for a moso bamboo cutting machine, the moso bamboo cutting machine and a moso bamboo cutting system. The clamping and feeding device comprises a moving assembly and a clamping assembly; the clamping assembly comprises a first roller and a second roller which are arranged in the vertical direction, and the first roller and the second roller are mutually matched for use; the moving assembly is connected with the first roller and drives the first roller to get close to or get away from the second roller in the vertical direction; a moso bamboois placed between the first roller and the second roller, thus the moso bamboo is clamped by the first roller and the second roller; and meanwhile, when the first roller and the second roller rotate relatively, the moso bamboo is pushed to move forwards. According to the clamping and feeding device, automatic clamping and feeding of the moso bamboo is achieved, the automatic degree is high, manpower and material resources are greatly saved, and meanwhile, the danger brought by manual operation is also avoided. The moso bamboo cutting machine comprises a cutting device and the clamping and feeding device used for the moso bamboo cutting machine. The moso bamboo cutting system comprises the moso bamboo cutting machine and is convenient to use and high in working efficiency.

Owner:SANMING UNIV

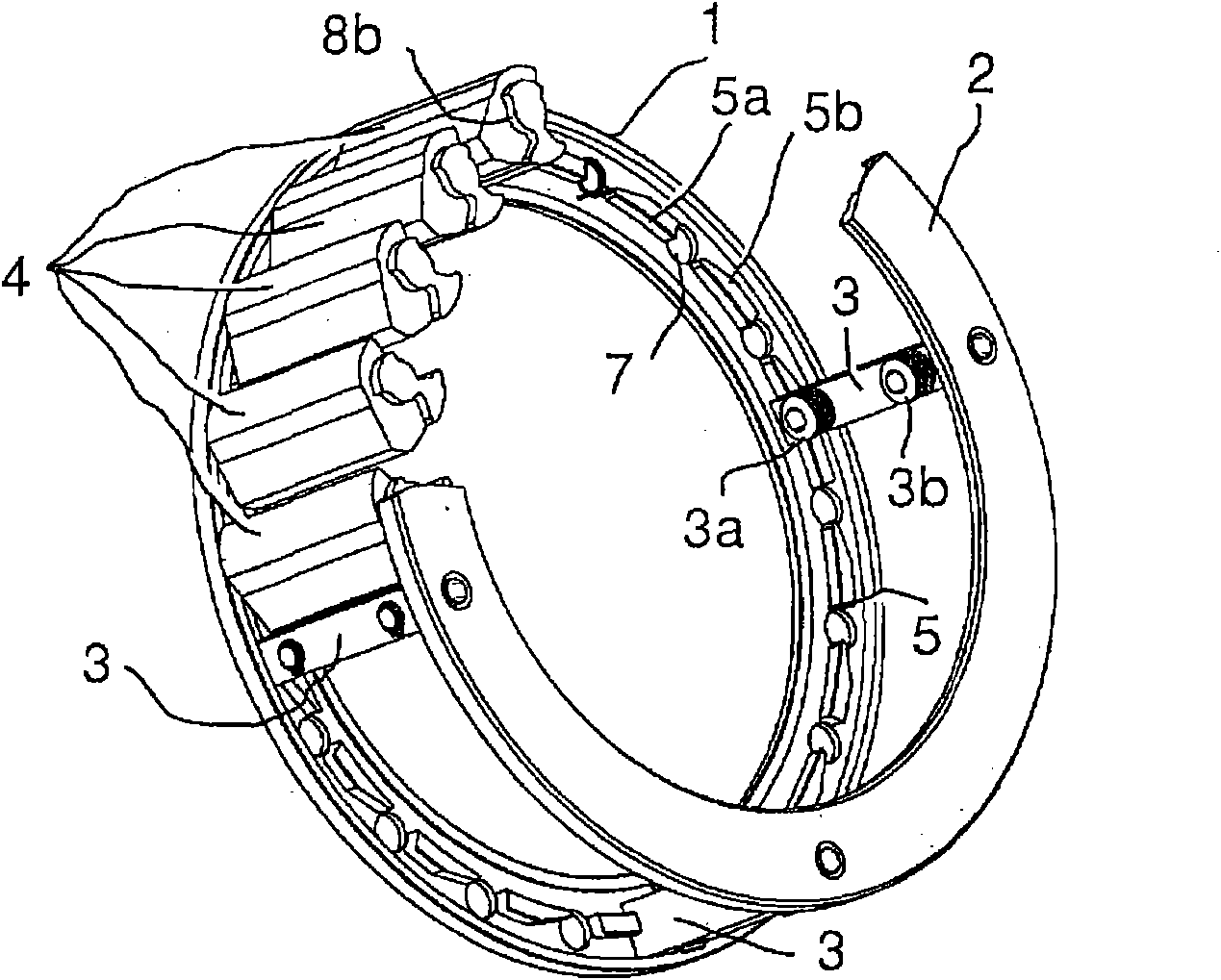

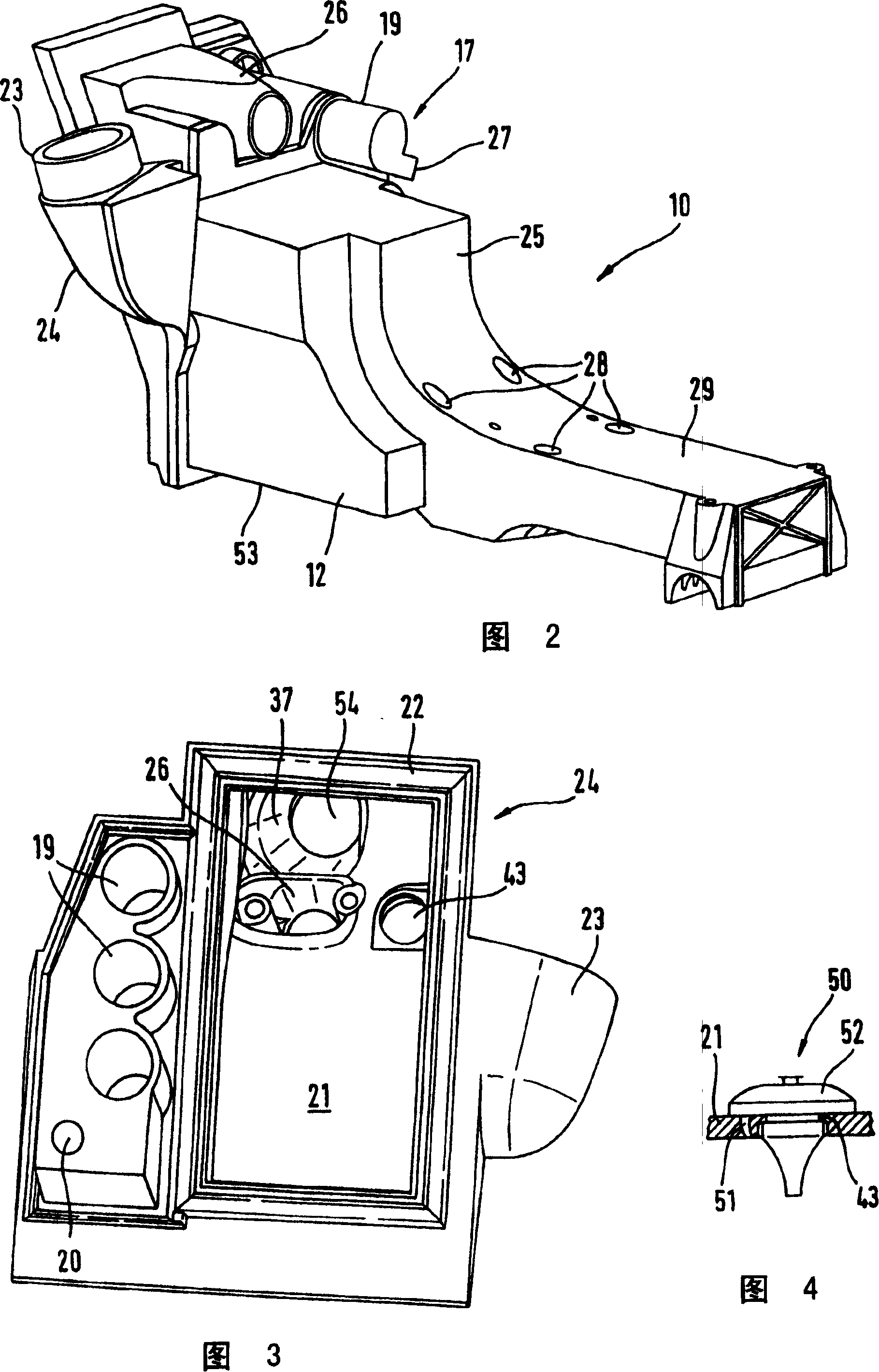

Free-wheel cage ring with centrifugal-force lifting

ActiveCN101936347AHigh positioning accuracyAccurate and firm configurationFreewheel clutchesCentrifugal forceTorsion spring

The invention relates to a one-way clutch retainer, which comprises two circular flanged disks (1,2; 11,12); the flanged disks are connected with each other and arranged with an axial gap; action bodies (4; 14) are disposed there between; the action bodies can be arranged in the retainer by a swinging way and is pre-tightened on the joint direction by a spiral torsion spring; the action bodies perform the acting swinging motion on the separation direction against the spring under the effect of centrifugal force; at least two guiding surfaces (5c,5d; 15) are arranged for each action body in its axial extension; a guiding surface is joined on the regions on the end peripheries of the action bodies, can guide the action body at least on the circumferential direction of the flanged disk and has a fracture on at least the radial inner side; the action body is passed throught the fracture and is extended towards an action surface on the radial inner side; the axial length of the action surface on the radial inner side of the action body is equal to the total length of the action body. According to the invention, The guiding surfaces are each formed integrally by recesses on opposite end faces of the flanged disks.

Owner:RINGSPANN

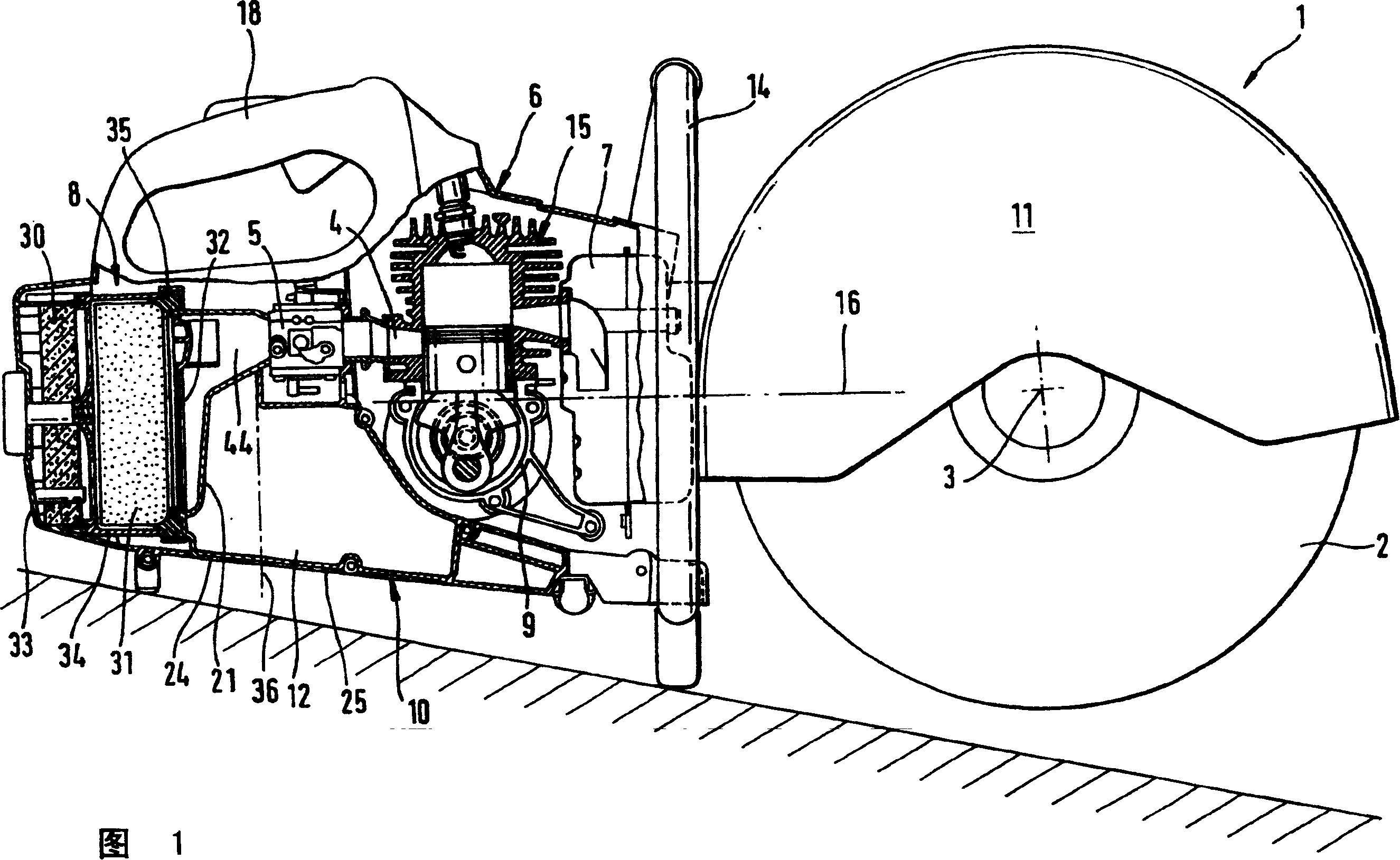

Manually operated tool

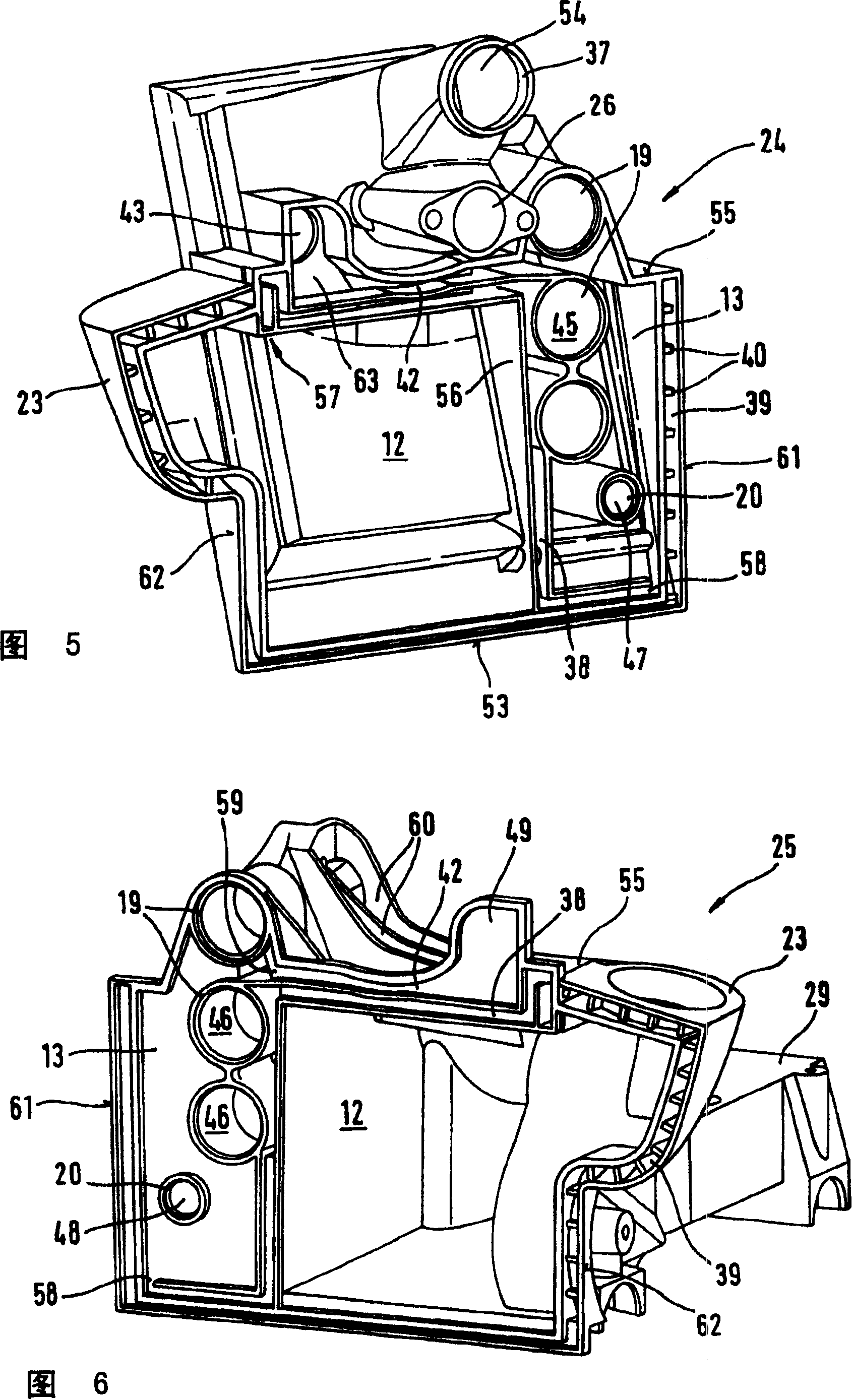

ActiveCN100377845CWon't leakPrevent leakageMetal sawing devicesNon-fuel substance addition to fuelAir cleaningFuel tank

A manually operated tool such as a parting-off grinder, chainsaw or similar device has a tank housing which contains a fuel tank. The tool has an air cleaning unit, the tank housing being connected to the clean air side of the air cleaning unit via a bleed device. A simple design in which leaks are avoided results if a reservoir wall of the tank housing and a housing wall of the air cleaning unit are positioned adjacent to one another and the bleed device comprises a bleed opening which passes through the reservoir wall and the housing wall.

Owner:ANDREAS STIHL AG & CO KG

Dual-purpose saw web for cutting and grinding glass and its manufacturing method

InactiveCN100404448CHigh hardnessEfficient processingBonded abrasive wheelsGlass severing apparatusIron powderAlloy

Owner:HENAN HUANGHE WHIRLWIND CO LTD

Small inner bore lathe grooving tool

The invention relates to a small inner bore lathe grooving tool. A tool tip of a turning tool shelters in an eccentric sleeve small excircle and enters a component inner bore, the turning tool rotates in the eccentric sleeve, and the tool tip gradually reaches out of the eccentric sleeve small excircle to cut the component so as to process a groove in the inner bore. The eccentric sleeve is fixed in the bore in front of the tool body, the turning tool is arranged in an eccentric bore of the eccentric sleeve, a handle is fixed at the rear end of the tool holder of the turning tool, the tool tip of the turning tool and the handle are respectively arranged at two sides of the axle center of the tool holder; when the tool tip is within the eccentric sleeve small excircle, a small cylinder of the handle leans against the end face of a locating screw; when the turning tool rotates, the tool tip cuts the component outside the eccentric sleeve small excircle, when the other side of the small cylinder leans against the end face of the locating screw, the inner diameter formed by the tool tip processing component is the size needed by the component inner bore groove. The eccentric sleeve small excircle and the component inner bore have a clearance of 0.02-0.04 millimeter. The small inner bore lathe grooving tool can process the groove in the component small inner bore conveniently, precisely and economically, thus solving the challenge in machining.

Owner:吴淼东

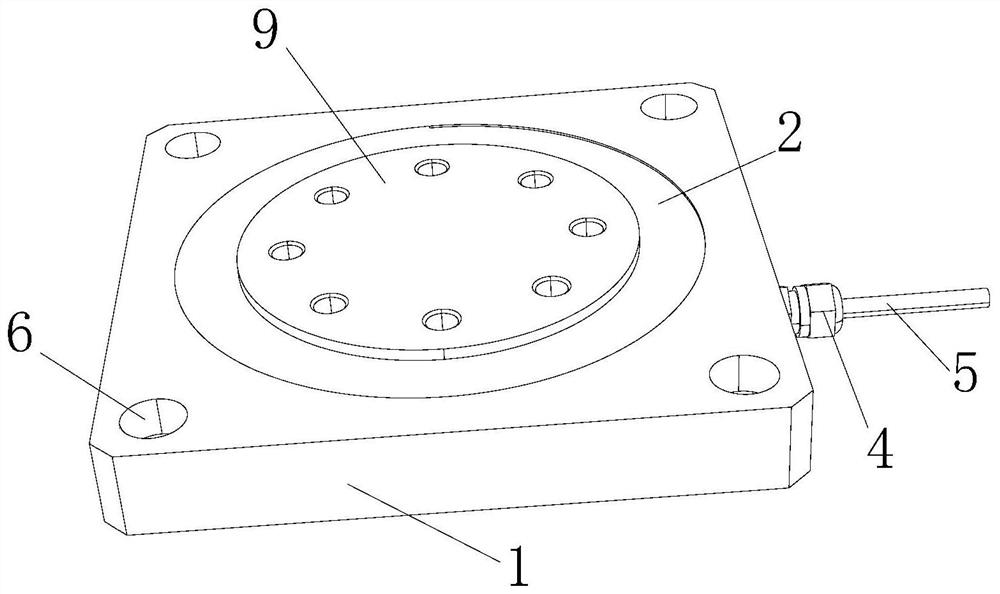

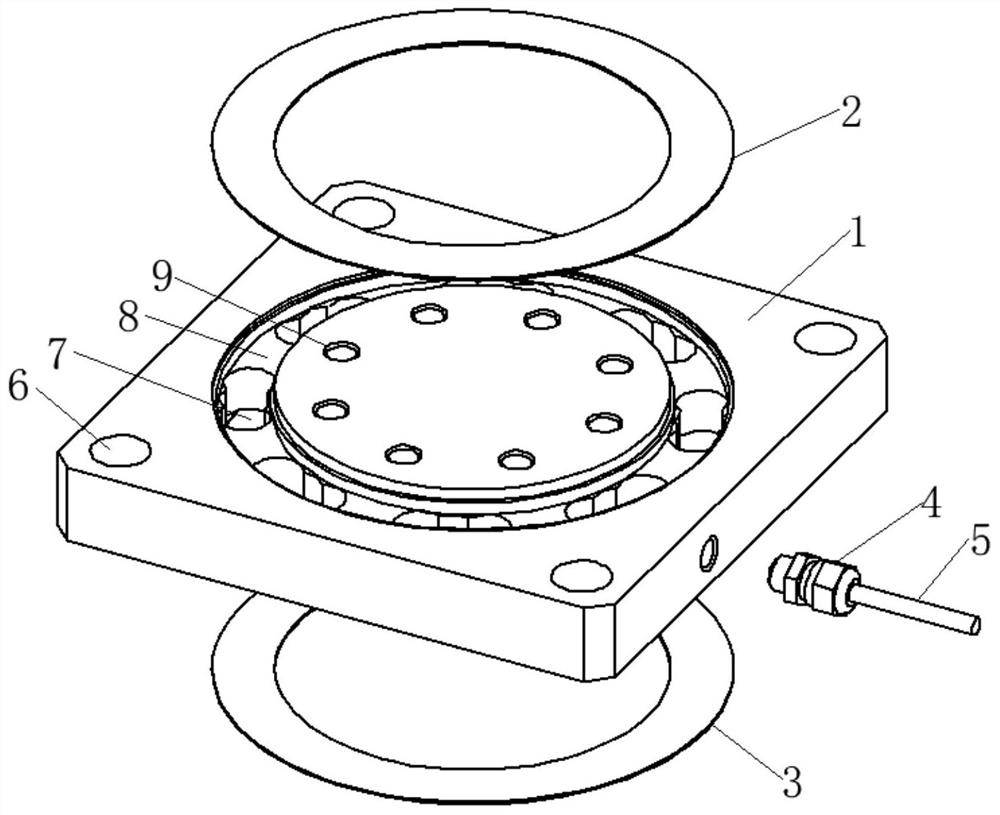

Strain pressure sensor

PendingCN112284241AReduce the overall heightLarge measuring rangeForce measurement using piezo-electric devicesElectrical/magnetic solid deformation measurementElastomerLoad resistance

The invention relates to the technical field of sensors, and discloses a strain pressure sensor which comprises an elastomer, a patch beam is arranged in the middle of the elastomer, a bearing table is connected with the middle of the patch beam, a strain gauge is attached to the upper surface of the patch beam, and the strain gauge and the patch beam form a Wheatstone bridge; a cable is arrangedon one side of the elastomer, one end of the cable is connected with the Wheatstone bridge, and the other end of the cable is connected with an external display device. The patch beam with the annulargroove design is adopted to be connected with the bearing table, the two sides of the patch beam are in circular arc transition, force can be stably transmitted in the force transmission process, thestructure is high in eccentric load resistance and lateral load resistance, machining is more economical, and the sensor is low in overall height, large in measurement range and high in precision.

Owner:深圳市鑫精诚科技有限公司

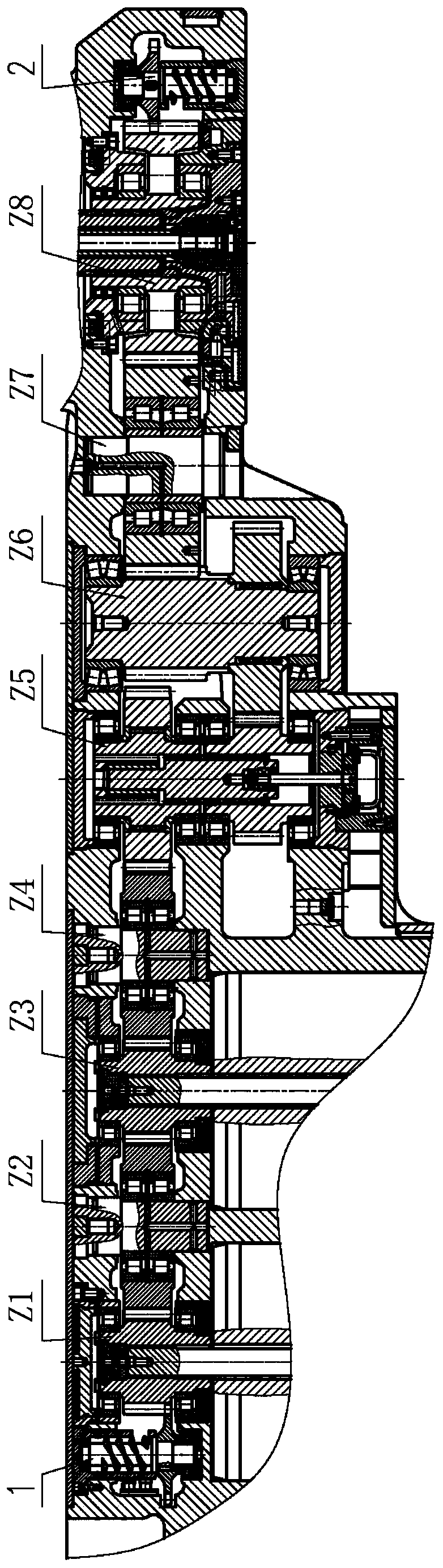

Efficient forced lubrication system with circulating lubrication function for coal mining machine

The invention relates to an efficient forced lubrication system with a circulating lubrication function for a coal mining machine. The efficient forced lubrication system comprises a high speed end lubrication pump, a low speed end lubrication pump and a lubrication oil passage, wherein the high speed end lubrication pump and the low speed end lubrication pump are arranged in a transmission case of a rocker arm; the lubrication oil passage is arranged in a transmission case housing of the rocker arm and comprises a main oil passage and multiple groups of branched oil passages; the main oil passage is communicated with the high speed end lubrication pump, the low speed end lubrication pump and lubricating points of all shaft assemblies of a diving system of the rocker arm, and is also communicated with oil discharge outlets of the high speed end lubrication pump and the low speed end lubrication pump. In the efficient forced lubrication system disclosed by the invention, one of the high speed end lubrication pump and the low speed end lubrication pump is always at low position at each time and can supply oil to the main oil channel, so that the main oil passage is always filled with oil; the oil is supplied to the high speed end lubrication pump, the low speed end lubrication pump and the lubricating points of all the shaft assemblies of the diving system of the rocker arm in real time through all the branched oil passages; even if the coal mining machine works on the work face with a large dip angle, all parts of the driving system of the rocker arm do not lack oil; the efficient forced lubrication system has high applicability.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +1

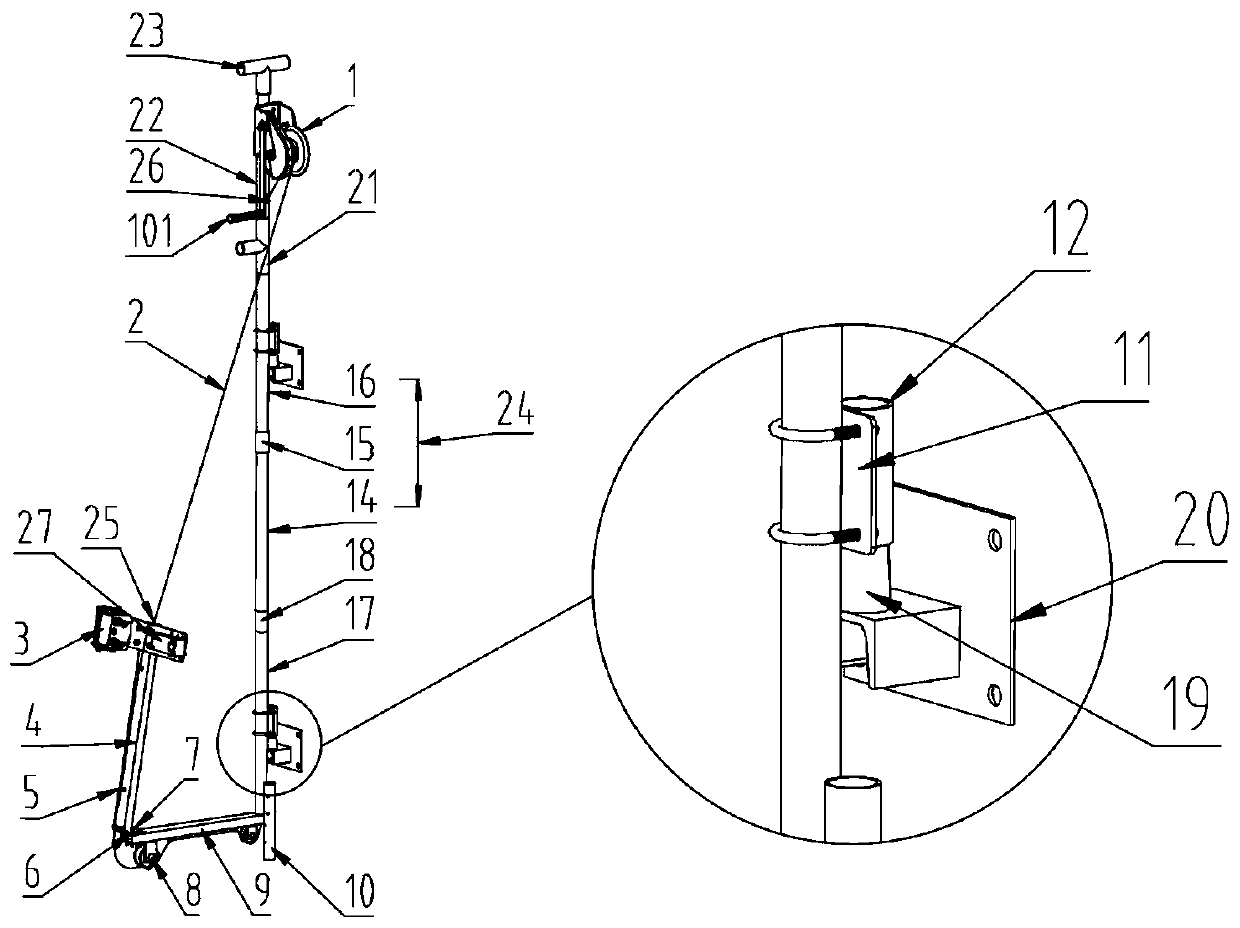

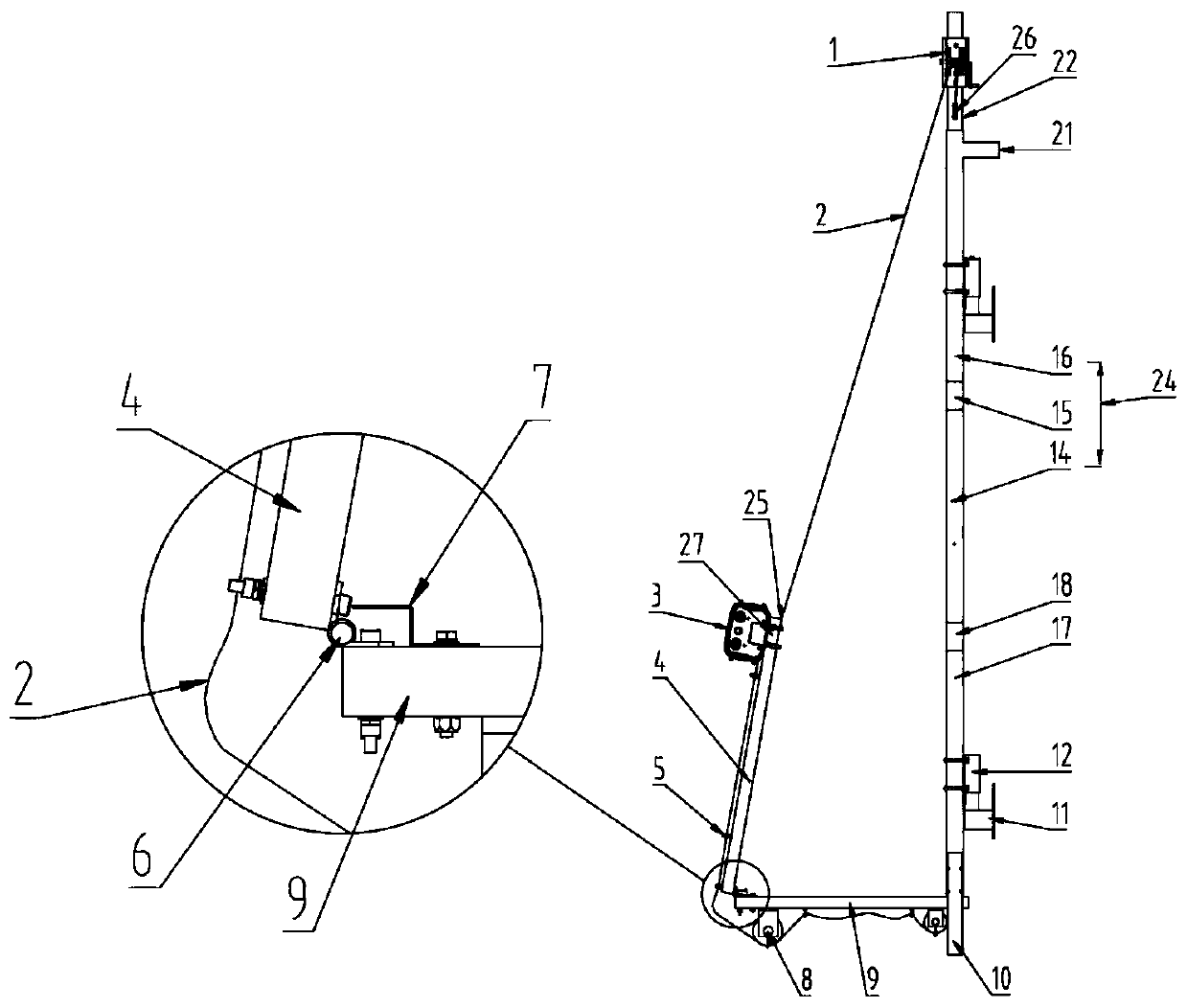

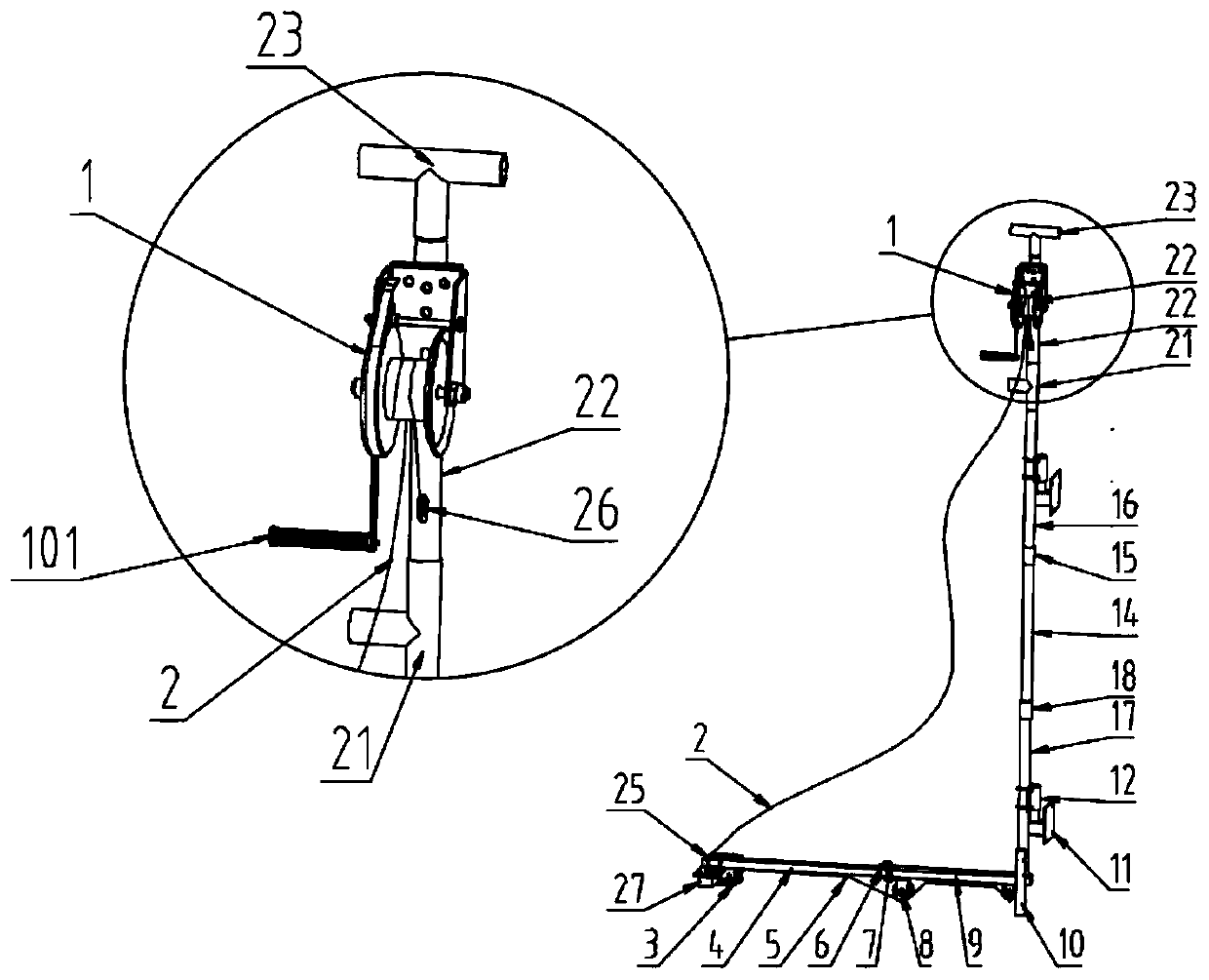

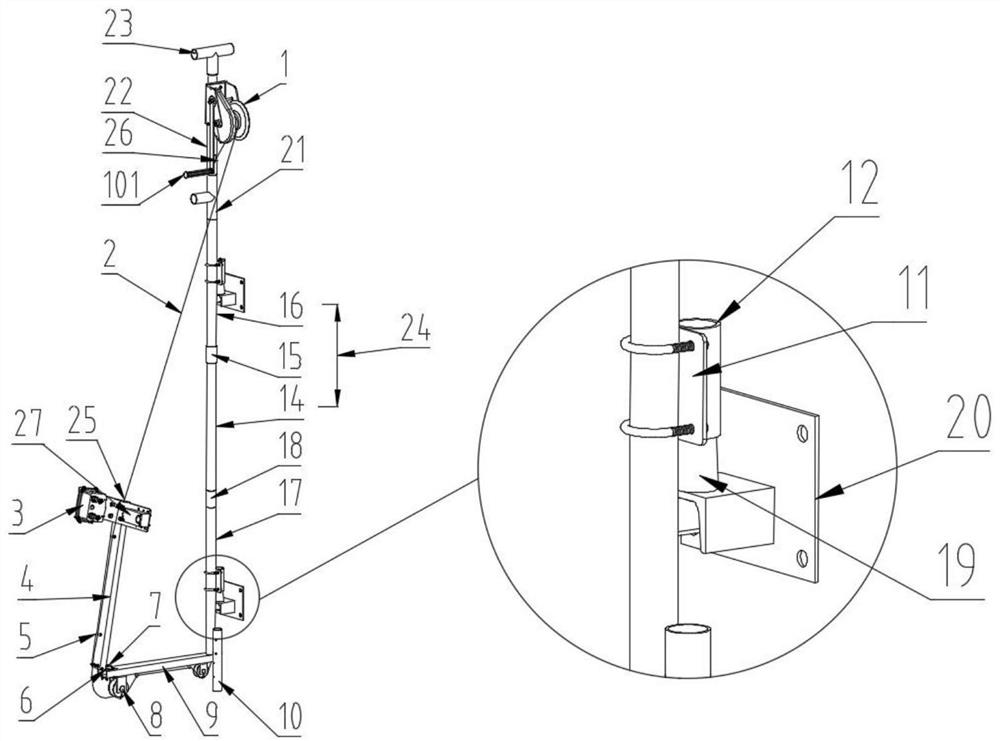

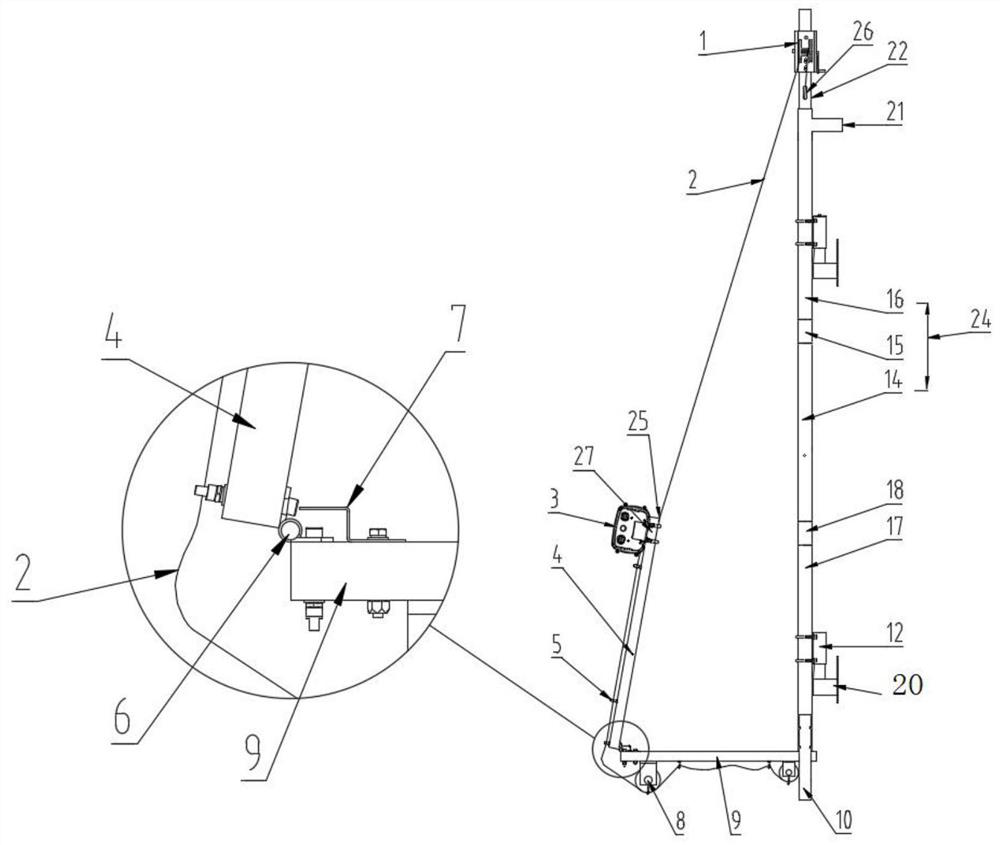

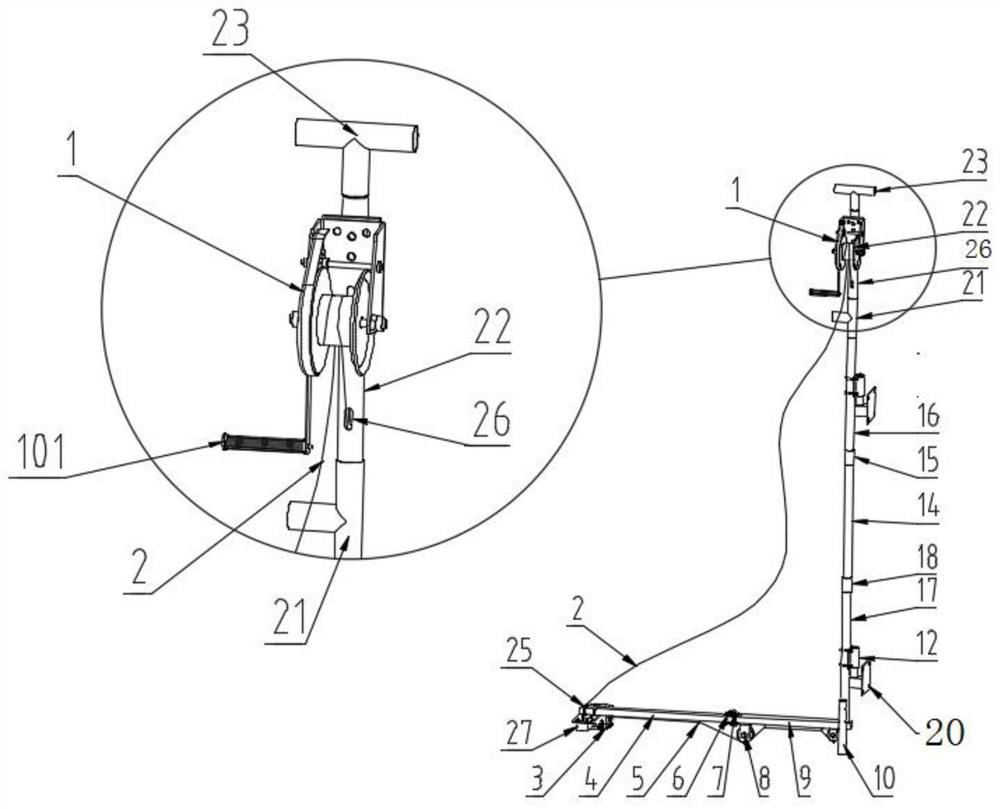

Mounting frame for online monitoring equipment of urban drainage pipe network

ActiveCN110848518AReduce the risk of downhole operationsGood value for moneyMachines/enginesPipeline systemsThreaded pipeDrainage tubes

The invention discloses a mounting frame for online monitoring equipment of an urban drainage pipe network. The mounting frame comprises a hollow telescopic rod, wherein a three-way pipe is connectedto the upper end of the telescopic rod, a winding frame is arranged at the upper end of the three-way pipe, a winch is fixed on the winding frame, and a steel wire rope is arranged on the winch; the lower end of the telescopic rod is connected with a hollow supporting rod through a lower internal thread pipe, the lower end of the supporting rod is fixedly connected with a transverse pipe, the transverse pipe is vertically connected with the supporting rod, and the other end of the transverse pipe is connected with a movable rod through a hinge; the other end part of the movable rod is providedwith a through hole, one end part of the steel wire rope is fixed in the through hole, so that the movable rod moves upwards or downwards under the driving of the steel wire rope; and a baffle is fixed on the upper side surface of the transverse pipe, and the baffle can block the movable rod when the movable rod rotates upwards to the maximum direction. The mounting frame for the online monitoring equipment of the urban drainage pipe network is reasonable in structure, the length of the telescopic rod can be adjusted, the mounting frame is convenient to use, manual underwater operation is notneeded, and collection and installation are facilitated.

Owner:无锡航征科技有限公司

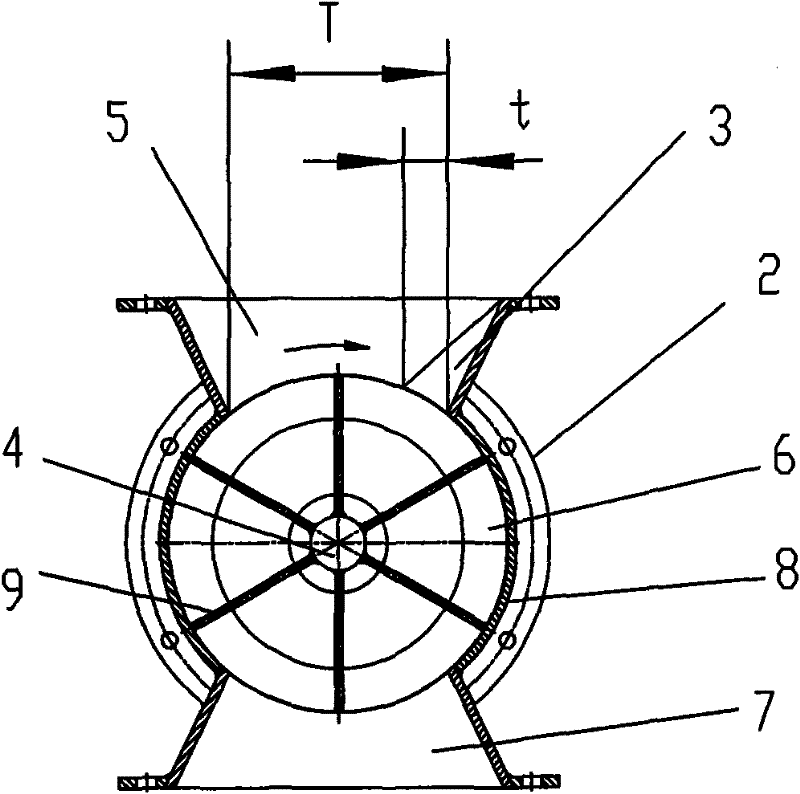

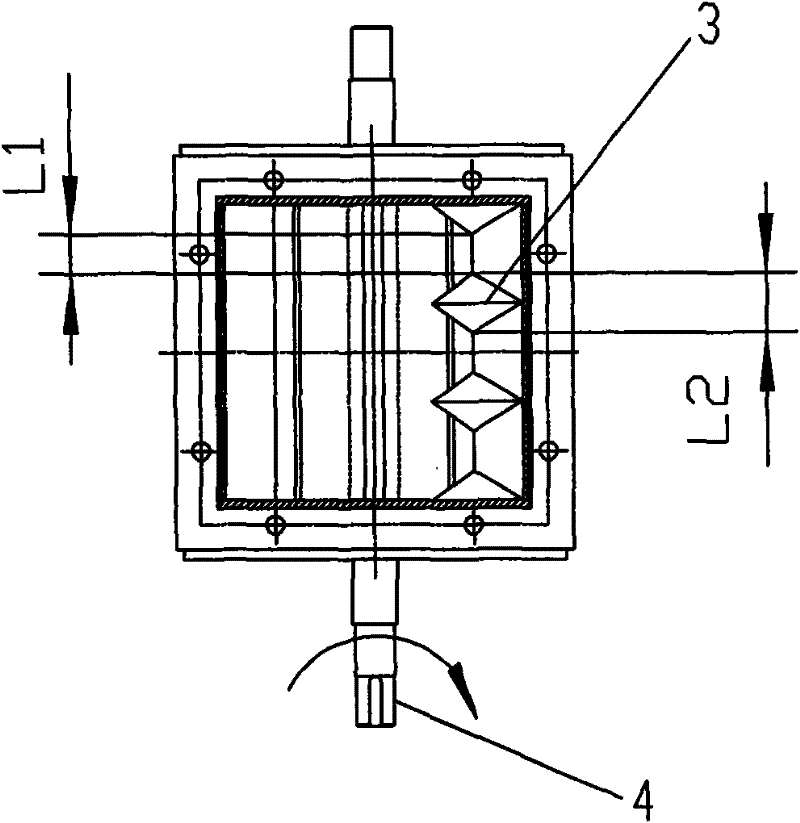

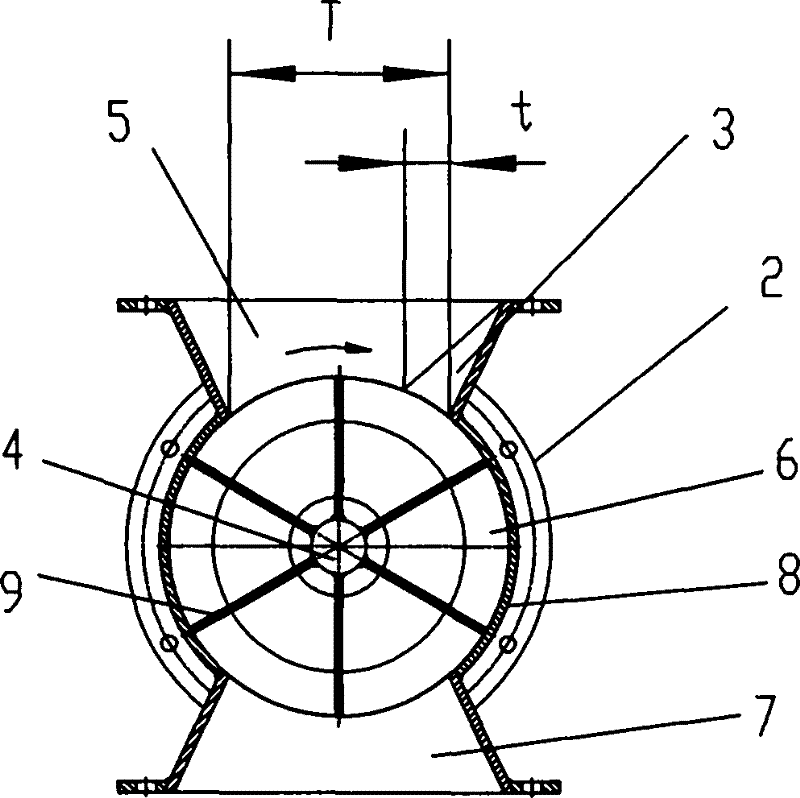

Antilocking mechanism of star feeder

The invention relates to an antilocking mechanism by discharged ash of a star feeder, comprising a feed inlet, a casing and a feed outlet, wherein the upper end of the casing is a funneled feed inlet; the lower end of the casing is a funneled feed outlet; an inner chamber is arranged inside the casing; the inner chamber is provided with star wheel rotors with equant structures; the star wheel rotors are connected with a transmission shaft. The invention is characterized in that a plurality of V-shaped bosses are arranged on the inner wall of one side of the feed inlet which has the same rotating direction with the star wheel rotors; the distance between the V-shaped bosses is L1; the width of the V-shaped boss is L2 and the length is t; the diameter of the lower end of the feed inlet is Tand T is greater than t; and a layer of outer cover casing is arranged outside the casing. The invention has simple structure, economic processing, and is beneficial for the smooth falling off of thepowder from the outlet.

Owner:WUXI XITONG ENG MACHINERY

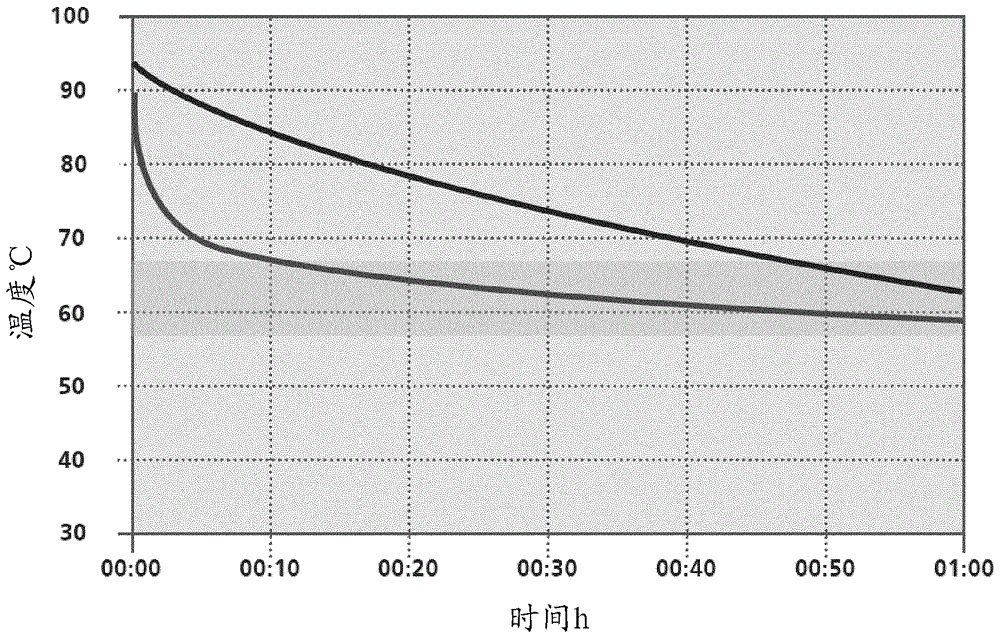

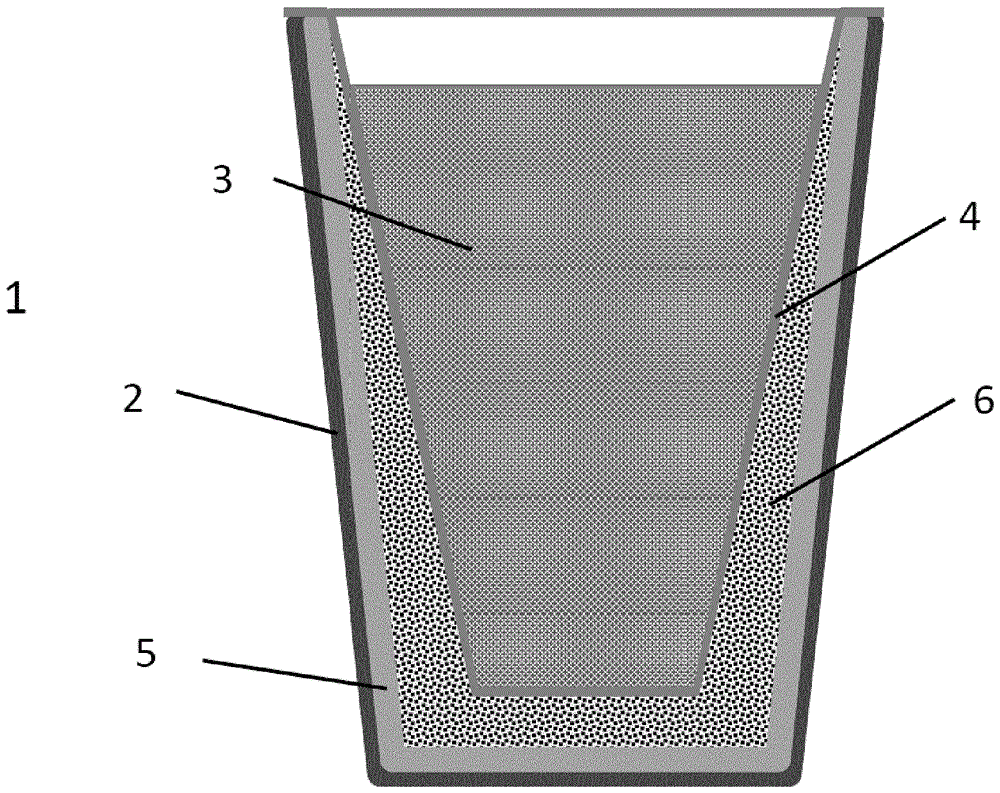

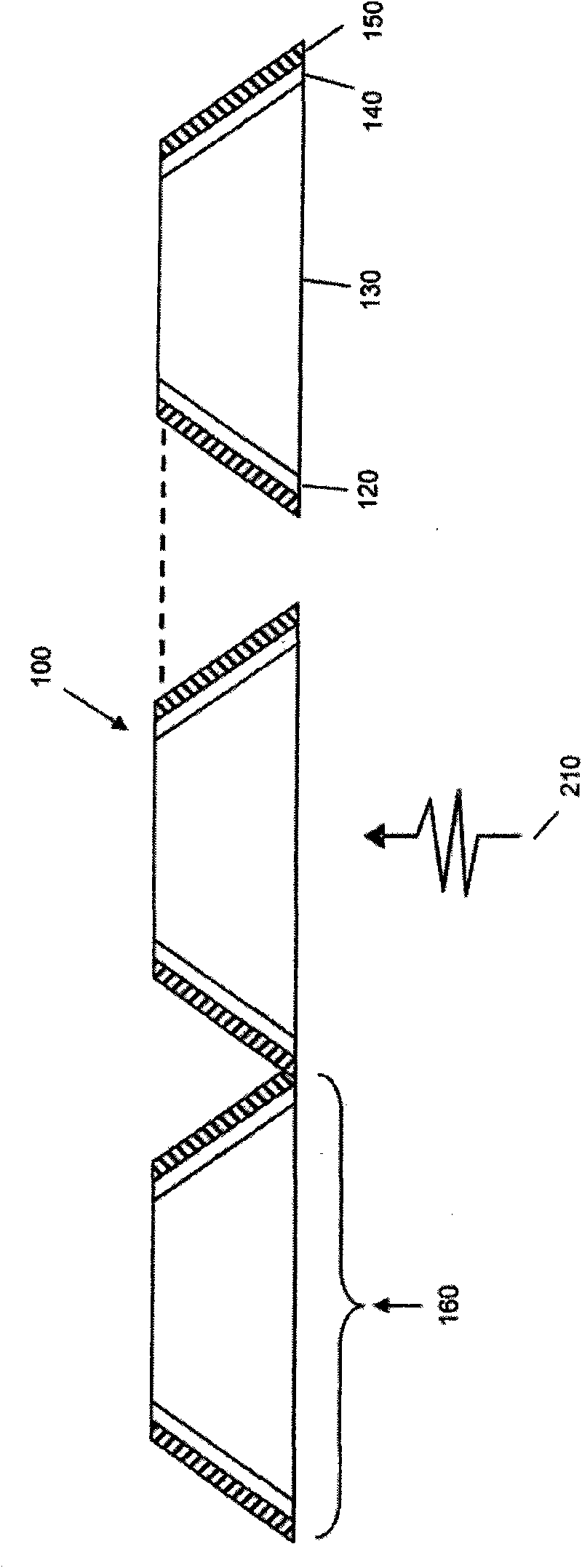

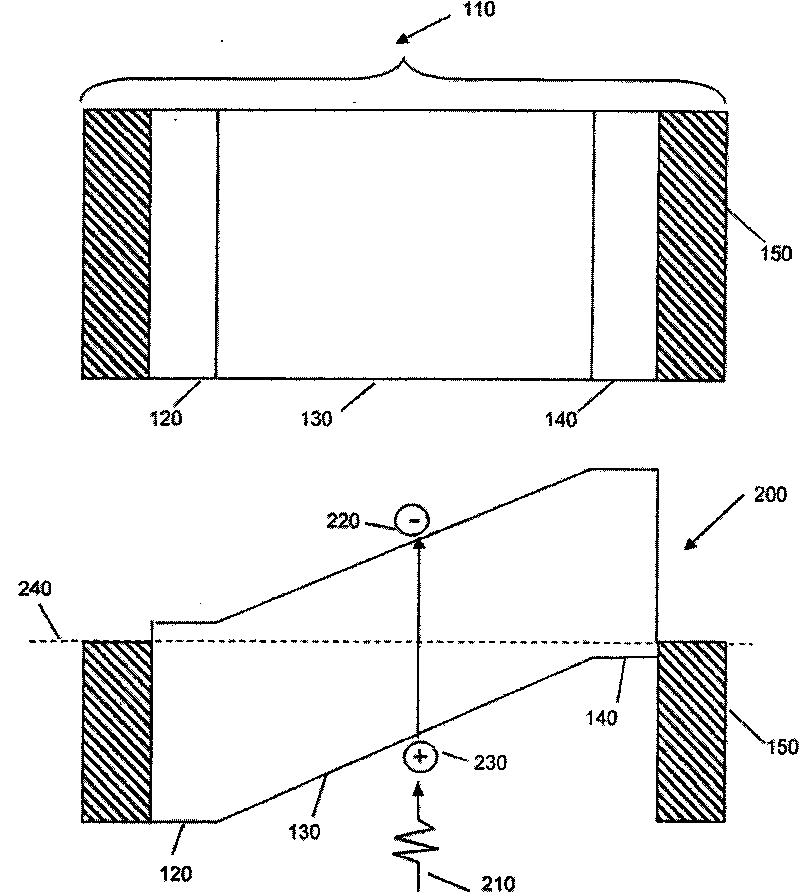

Container having a mixture of phase-change material and graphite powder

ActiveCN106061863AProcessing economyDomestic cooling apparatusThermal insulationGraphitePhase-change material

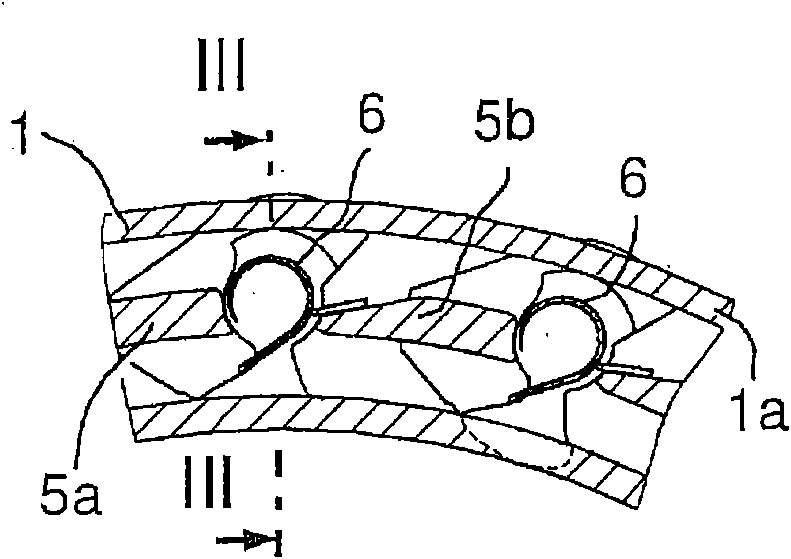

The invention relates to a container (1), in particular a beverage container, comprising an inner container wall (4) and an outer container wall (2) and an intermediate space (5) lying between the container walls (2, 4), wherein the intermediate space (5) is filled with a mixture (6), which contains phase-change material and graphite powder, wherein the graphite powder is introduced into the phase-change material in such a way that the mixture (6) has a pulpy consistency at a temperature at which the phase-change material is liquid. The invention further relates to a method for producing a container (1), in particular a container (1) according to one of the preceding claims, comprising the following steps: A) providing an inner container wall (4) and an outer container wall (2); B) applying a mixture (6) of graphite powder and phase-change material to the inside of the outer container wall (2) and / or the outside of the inner container wall (4); C) joining the outer container wall (2) and the inner container wall (4).

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Adjustable cutting-depth cutter bar

The invention discloses an adjustable cutting-depth cutter bar, particularly relates to a grooving cutter bar with adjustable cutting depth and solves the technical problems of resource waste and low working efficiency by traditional groove machining. The adjustable cutting-depth cutter bar comprises a rod-shaped cutter handle, and the rod-shaped cutter handle is connected with a cutter head clamping piece. The adjustable cutting-depth cutter bar has the advantages that the structure is simple, the replacement is convenient, the number of cutter handles and relevant components is small, high-quality efficient and economical groove machining can be finished, the cutter head clamping piece can be matched with grooving cutters such as hard alloy coated cutting tools, ceramic cutting tools and polycrystalline cubic boron nitride (PcBN) composite piece welding cutters, and machining of grooves with different cutting depths and different widths can be conveniently achieved by the aid of different cutter head clamping pieces.

Owner:ZHENGZHOU BERLT HARD MATERIALS

Method for preparing super-microporous polymer material without surface gas traces

The invention provides a method for preparing a super-microporous polymer material without surface gas traces. The method comprises the following steps: (1) synthesizing polymer nano core-shell particles by adopting a one-step emulsion polymerization method, wherein microspheres are in a core-shell structure and have the sizes in the range of 80-400nm, the structure is uniform, and the shell layer has a chemical cross-linking structure; and (2) compounding the core-shell particles and a polymer matrix through a melt blending or in-situ polymerization method, wherein the material has a closed pore structure. According to the super-microporous polymer material prepared by adopting the process, the porous size distribution ranges from 100 to 400nm, the number of pores in unit volume reaches 10<12> cells / cm<3>, and the polymer material has typical microporous polymer structural characteristics. According to the method, gas diffusion can be effectively limited, and gas traces on the material surface are avoided; the processing process is simple, fast and economic, the processing window is wide, and the pore structure is easily controlled; and high pressure and high pressure drop rate are not needed, the cost can be reduced, and the production efficiency is improved; molding is performed through a traditional polymer processing method, special equipment is not needed, and the cost is low.

Owner:姜明

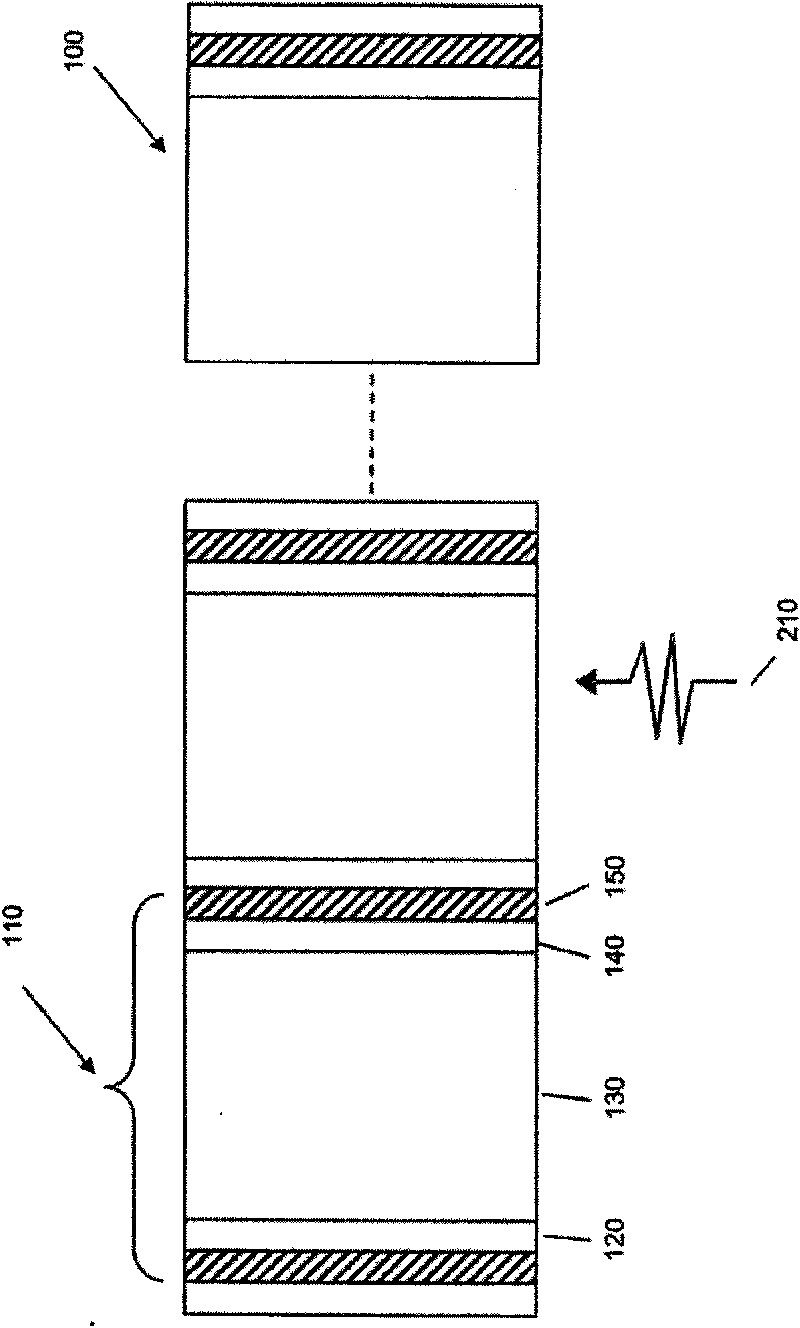

Solar converter and compound converter

InactiveCN101728440AAvoid defectsProcessing economyPhotovoltaic energy generationSemiconductor devicesInfraredIndium

The invention relates to a multi-node multi-spectrum solar converter and a production method for converting solar energy into electric energy by using same. The solar converter is processed by diamond, aluminum arsenide, silicon, gallium phosphide, indium gallium phosphorus, gallium arsenide, germanium, silicon, indium gallium arsenic, indium carbide or any substrate sensitive to one or a plurality of solar spectrum zones and comprises one to thousands of parallel nodes illuminated by solar light. As an optimal embodiment, in order to obtain high converting efficiency, adjacent nodes are electrically connected by conductive layers for reducing serial resistance in the converter; a plurality of converters with different substrates of different band gaps are assembled into a compound converter. The compound converter has a multi-spectrum multi-node converting function and is used for converting the solar energy of the whole spectrum from ultraviolet ray to infrared ray.

Owner:NOVARTIS SPECTRUM

Large-modulus and small-tooth-number gear machining method

The invention discloses a large-modulus and small-tooth-number gear machining method. The large-modulus and small-tooth-number gear machining method comprises piece forging, annealing treatment for casting stress removal, rough turning, semi finish turning, carburizing and quenching, finish turning, fine control shot blasting, flaw detection and final inspection. The large-modulus and small-tooth-number gear machining method has the advantages that large-modulus and small-tooth-number gear machining can be achieved, and the problems that machining is difficult and serious deformation is likelyto happen during machining are solved; and special design of a gear tool is not needed, complex tooth face rough and finish machining can be finished through a square shoulder disc milling tool bar tool, and machining is more simple and economical.

Owner:衡山同远机械有限公司

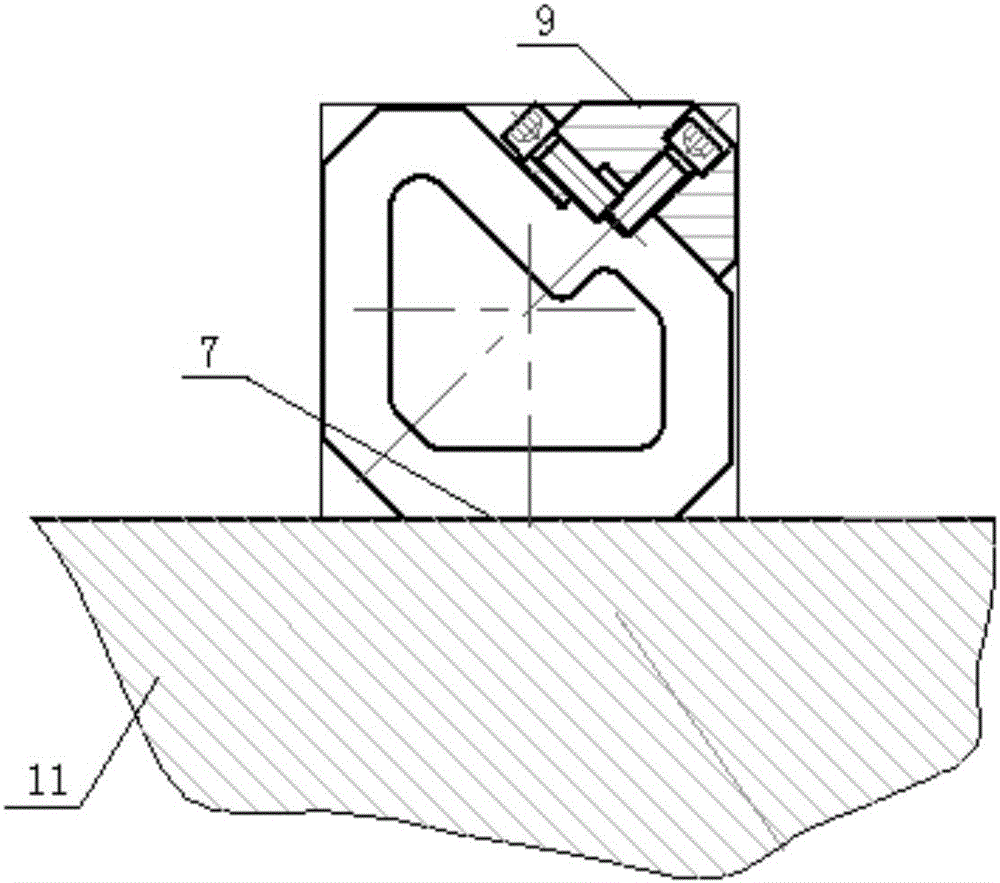

Machining tool for steel-inlaid guide rail shaped like Chinese character Shan

InactiveCN106112802ARealize batch processingProcessing economyGrinding machinesGrinding work supportsChinese charactersMachined surface

The invention discloses a machining tool for a steel-inlaid guide rail shaped like a Chinese character Shan. The section of the tool is of a polygonal structure; the polygonal structure comprises a first mounting surface, a second mounting surface, a first reference surface and a second reference surface, and the first mounting surface is perpendicular to the second mounting surface; the first reference surface is perpendicular to the second reference surface, the first reference surface and the first mounting surface form a 45-DEG included angle, and the second reference surface and the second mounting surface form a 45-DEG included angle; internal threaded holes which are perpendicular to each other are formed in the first reference surface and the second reference surface; the guide rail shaped like the Chinese character Shan is connected with the internal threaded holes by using bolts after passing through assembling holes formed in the guide rail; the guide rail shaped like the Chinese character Shan is fixedly arranged on the first reference surface and the second reference surface, the first to-be-machined surface of the guide rail shaped like the Chinese character Shan is kept parallel to the second mounting surface, and the second to-be-machined surface of the guide rail shaped like the Chinese character Shan is kept parallel to the first mounting surface. By using the machining tool, the qualified precise guide rail shaped like the Chinese character Shan can be economically and efficiently machined, and batch machining of the precise guide rail shaped like the Chinese character Shan can be realized.

Owner:宝鸡市广环机床有限责任公司

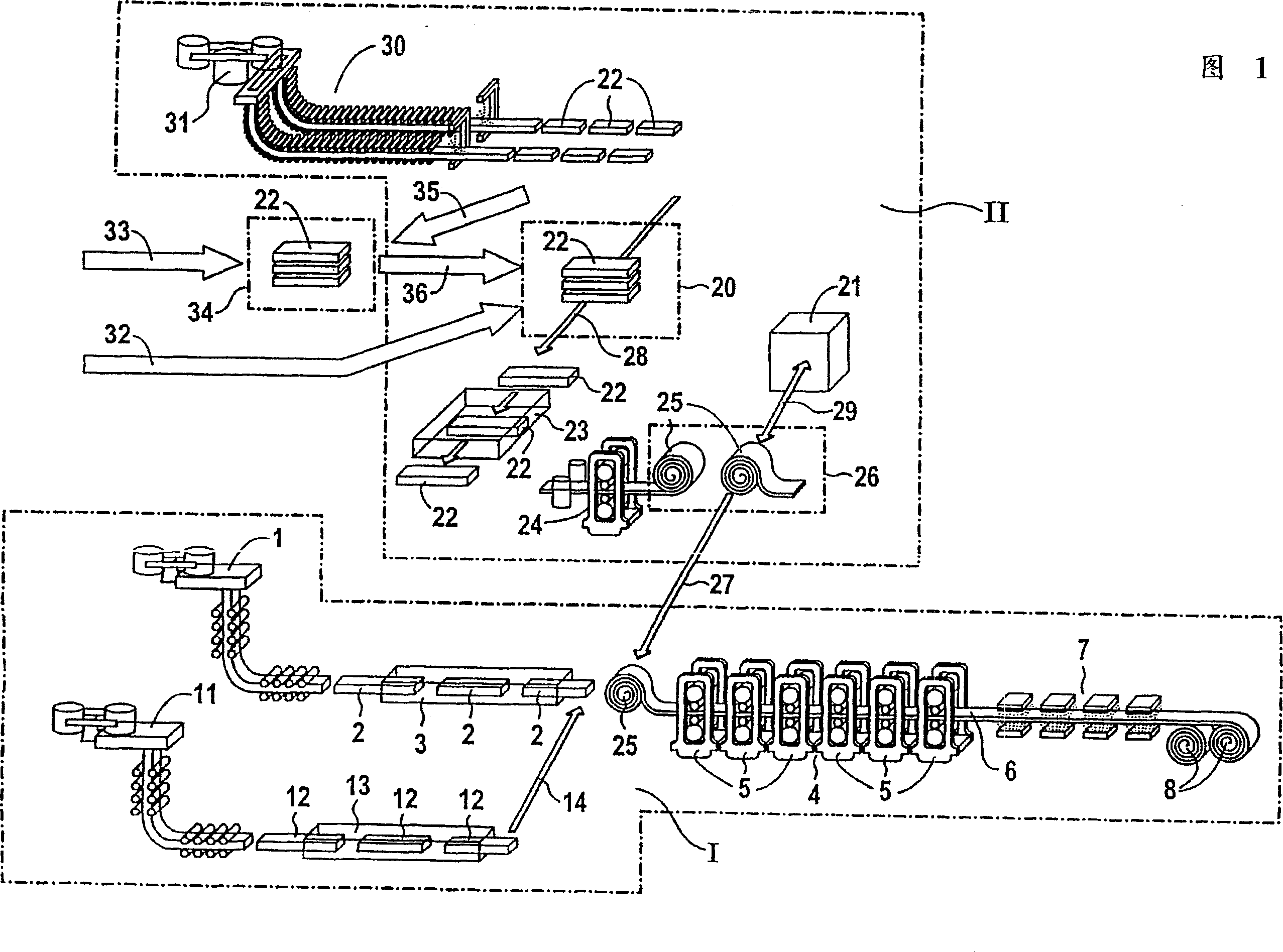

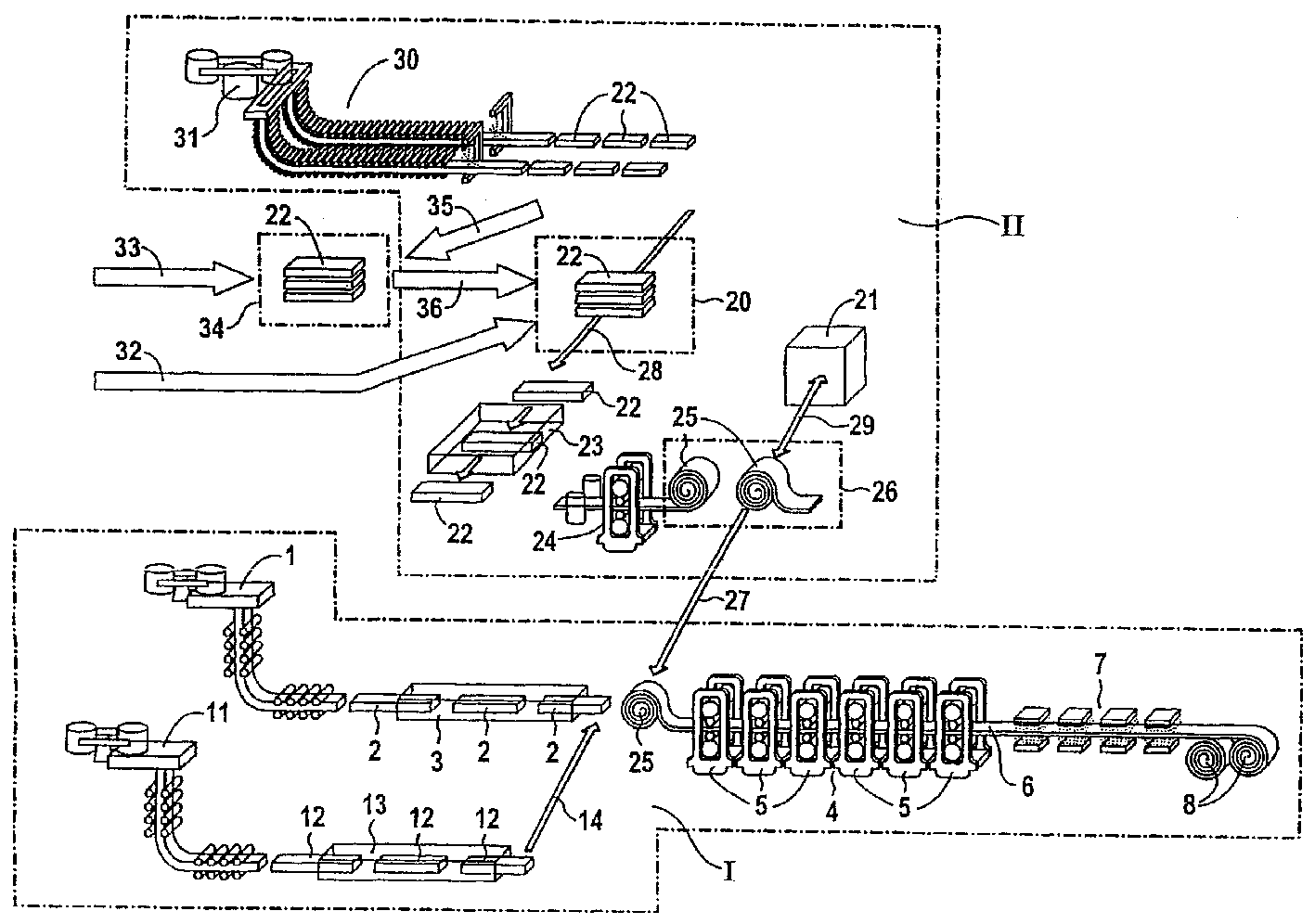

Foundry rolling unit

InactiveCN1268450CRealize processingEconomical processingMetal rolling arrangementsFoundryProduction line

The invention relates to a foundry rolling unit, comprising a first production line (I), with at least one casting machine (1, 11), the thin slabs (2, 12) of which may be introduced into at least one tunnel furnace (3, 13), whereby said tunnel furnace (3, 13) opens out into at least one finishing train (4), with at least one mill stand (5). After leaving the finishing train (4) the rolled hot strips may be introduced into at least one cooling run (7) and may be rolled on at least one coiler (8). The foundry rolling unit furthermore comprises a second production line (II) arranged in an at least partly parallel manner in terms of production, with at least one slab introducing device (20), through which the slabs (22) may be introduced into at least one reheating oven (23) and at least one cogging stand (24) arranged thereafter. The rolled pre-strips may be obtained as coils (25) from at least one coil-box (26). The foundry rolling unit further comprises a coil transport device (27), by means of which the coils (25) may be transferred before the finishing train (4), from the second production line (II) to the first production line (I). The coils (25) may be removed from the coil box (26) and transported to the input of the finishing train (4), in order to carry out introduction of the pre-strips. By means of the above it is possible to produce a complete spectrum of different steel types, in particular stainless steel and high-alloyed steel, whilst achieving a corresponding high throughput.

Owner:PRIMETALS TECH GERMANY

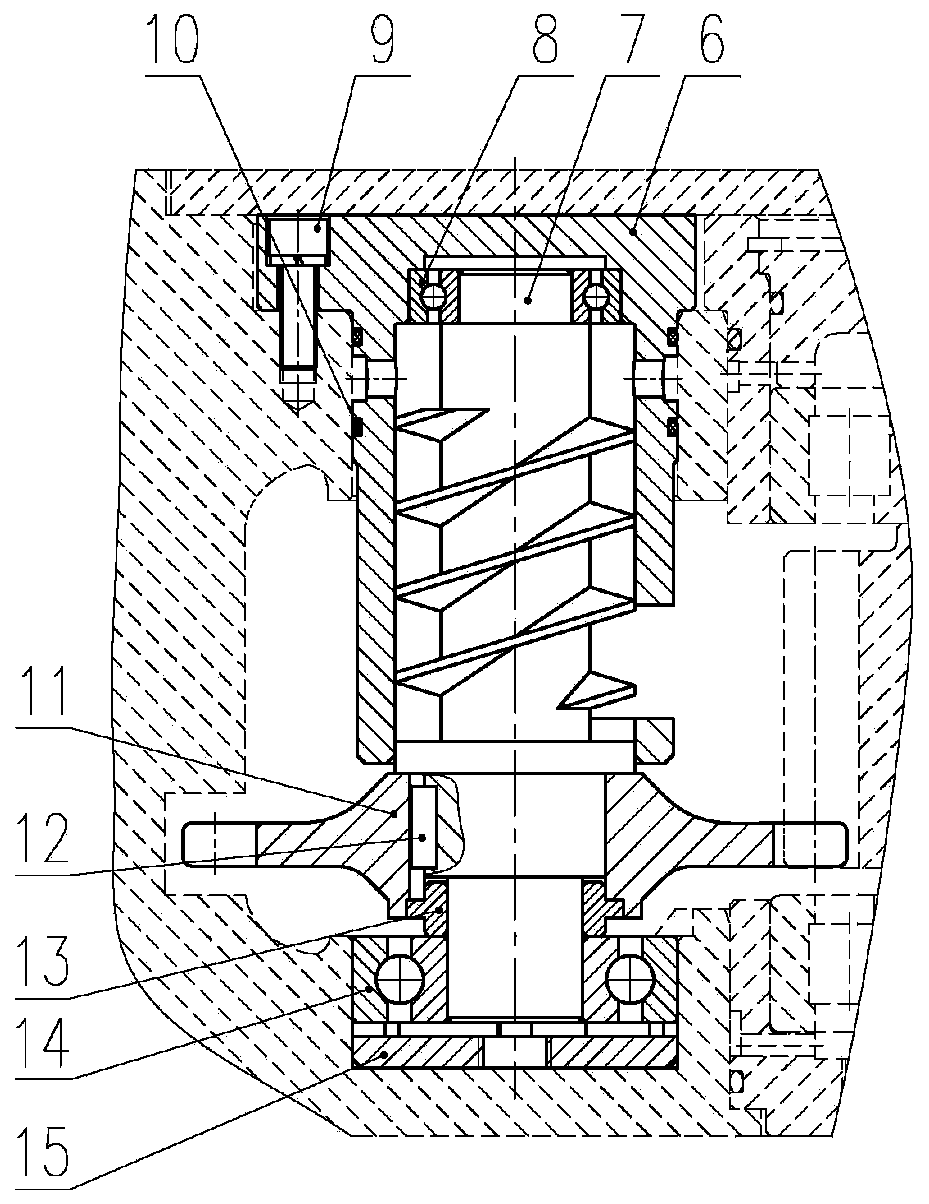

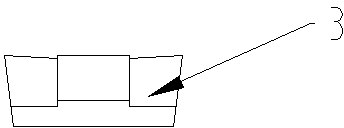

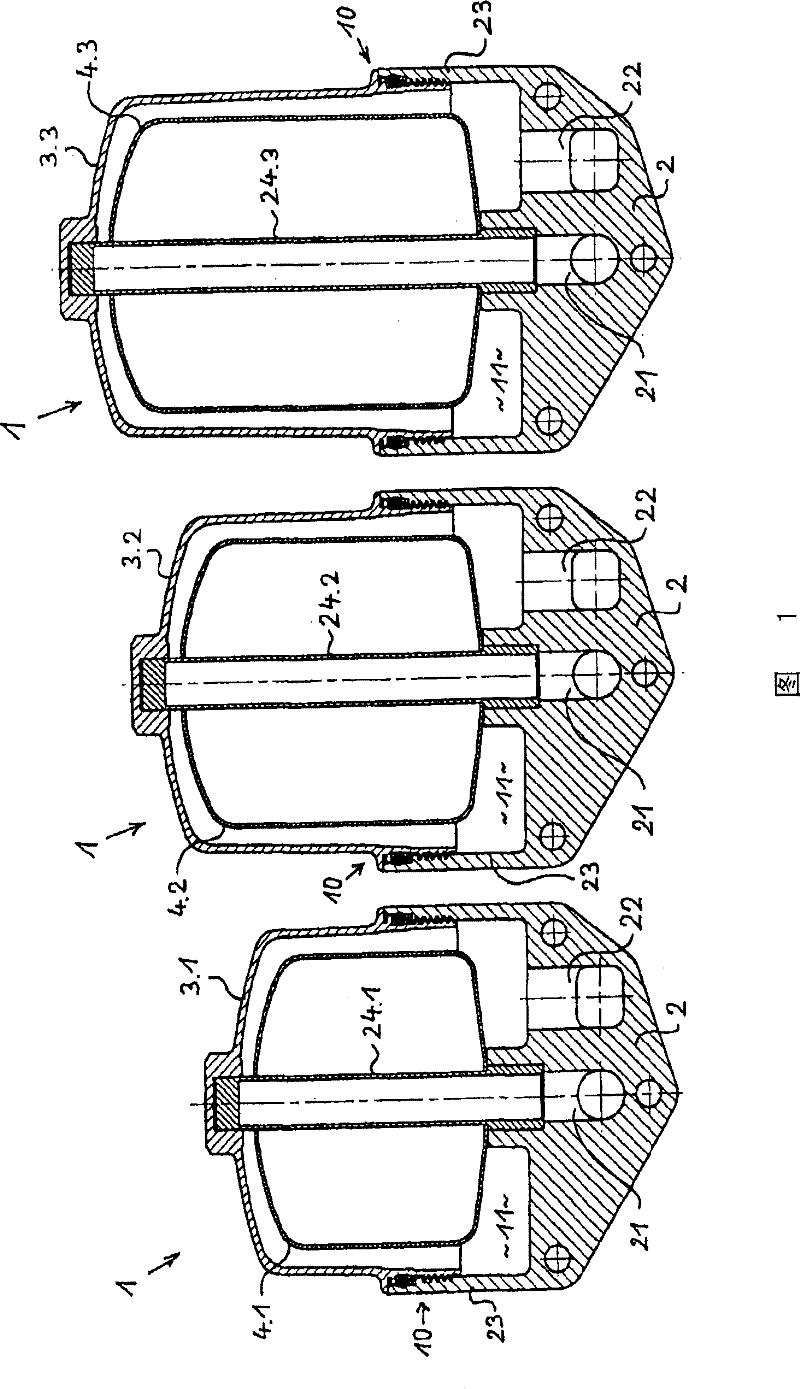

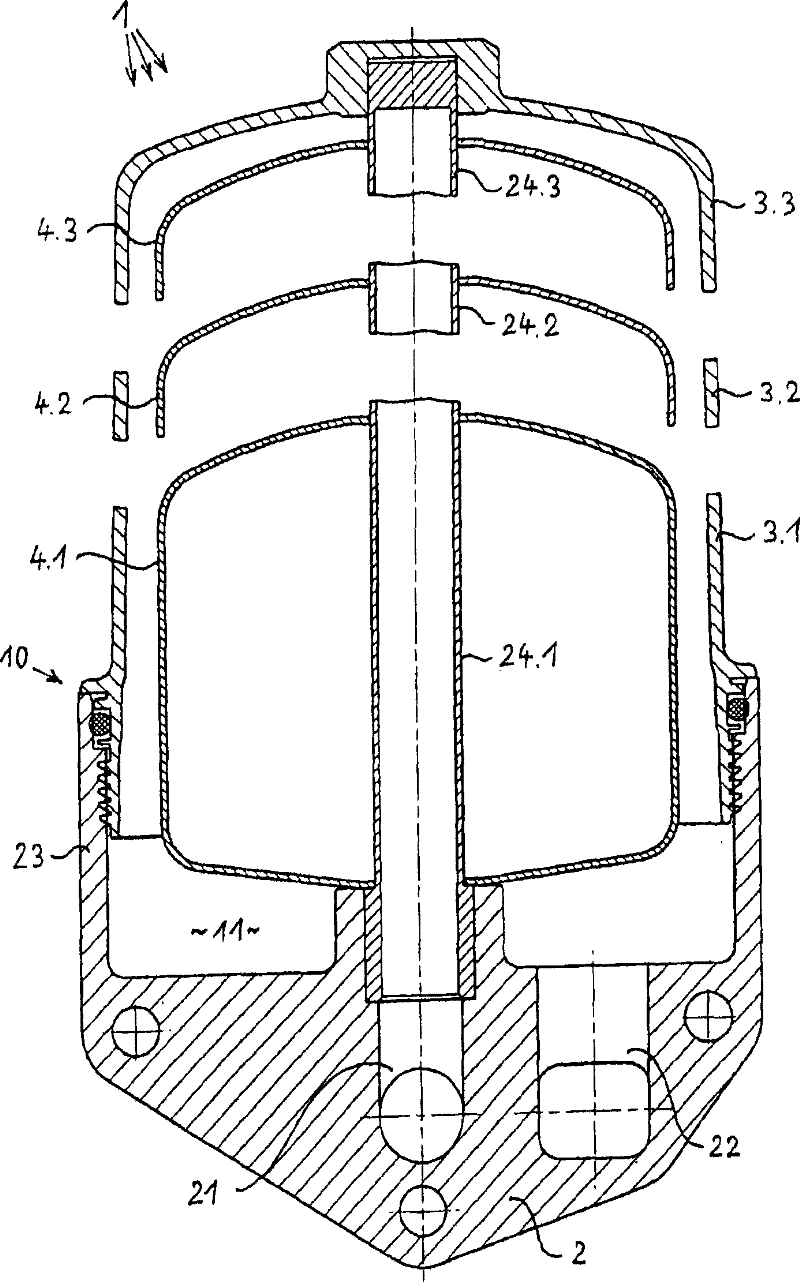

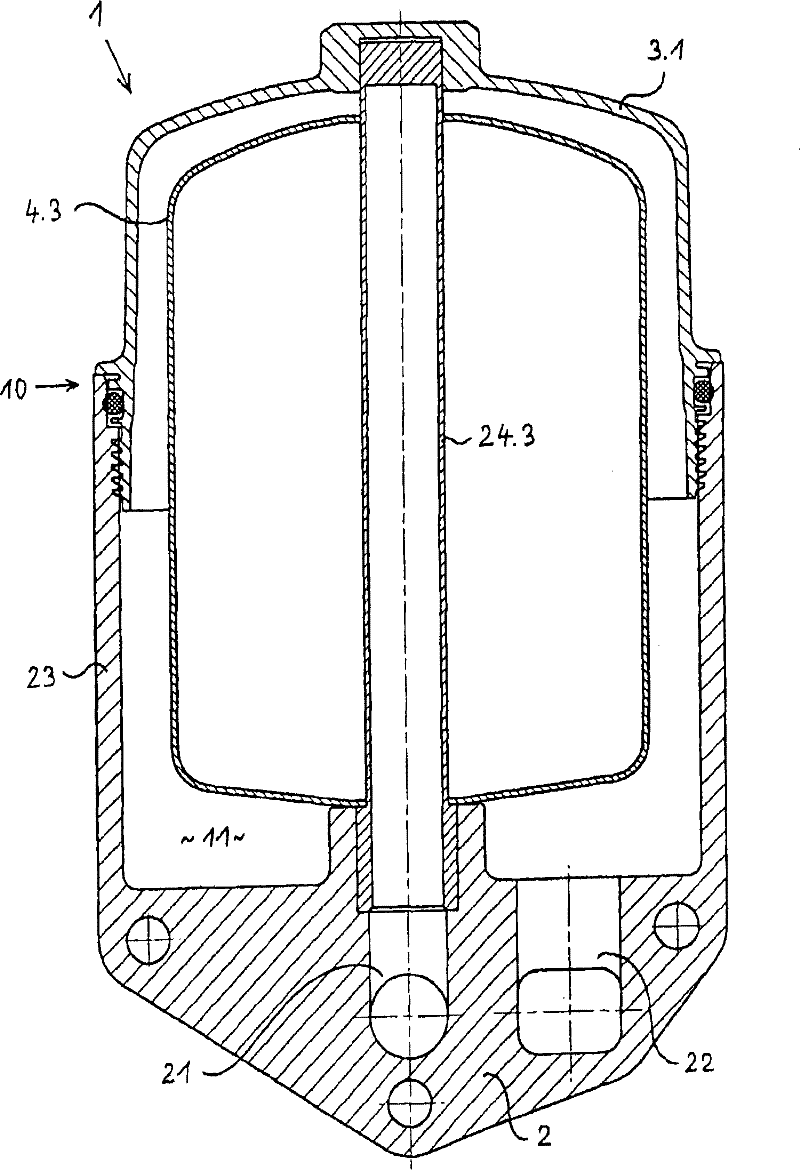

Centrifuges, in particular, for a lubricant oil in an internal combustion engine

ActiveCN101304811BProcessing economySimplify the management processMachines/enginesCentrifugesModular unitInternal combustion engine

Centrifuges (1), in particular for a lubricant oil in an internal combustion engine, are provided with a housing (10) which comprises a base (2), a lid (3) forming the second part of the housing and connectable to the base (2) and a rotor (4) arrangeable in the housing (10). The inventive centrifuges (1) are characterised in that each centrifuge (1) is embodied in the form of a modular unit whichis assembled with the aid of modular system parts, wherein said modular system comprises different bases (2, 2.1 - 2.n) and / or different lids (3, 3.1 - 3.n) and / or different rotors (4, 4.1 - 4.n) which can be assembled in the form of different combinations in such a way that different centrifuges are obtained.

Owner:HENGST FILTER SYST (KUNSHAN) CO LTD

Small inner bore lathe grooving tool

The invention relates to a small inner bore lathe grooving tool. A tool tip of a turning tool shelters in an eccentric sleeve small excircle and enters a component inner bore, the turning tool rotates in the eccentric sleeve, and the tool tip gradually reaches out of the eccentric sleeve small excircle to cut the component so as to process a groove in the inner bore. The eccentric sleeve is fixedin the bore in front of the tool body, the turning tool is arranged in an eccentric bore of the eccentric sleeve, a handle is fixed at the rear end of the tool holder of the turning tool, the tool tip of the turning tool and the handle are respectively arranged at two sides of the axle center of the tool holder; when the tool tip is within the eccentric sleeve small excircle, a small cylinder of the handle leans against the end face of a locating screw; when the turning tool rotates, the tool tip cuts the component outside the eccentric sleeve small excircle, when the other side of the small cylinder leans against the end face of the locating screw, the inner diameter formed by the tool tip processing component is the size needed by the component inner bore groove. The eccentric sleeve small excircle and the component inner bore have a clearance of 0.02-0.04 millimeter. The small inner bore lathe grooving tool can process the groove in the component small inner bore conveniently, precisely and economically, thus solving the challenge in machining.

Owner:吴淼东

Radial feed mechanism

InactiveCN101607371BEasy to processProcessing economyFeeding apparatusBoring/drilling componentsHigh volume manufacturingEngineering

The invention discloses a radial feed mechanism. A support is fixed on the front end of the main shaft of a boring lathe, a slide carriage seat is fixed on the support, a slide carriage is matched with the slide carriage seat by a dovetail groove, and a fit clearance between the slide carriage and the slide carriage seat is adjusted by an inserted bar; a cutting feed shaft is arranged in a taper hole on the front end of a boring lathe boring bar; an axial rack is arranged on a disk on the front end of the cutting feed shaft; a gear is arranged on the slide carriage seat by a mandrel to be meshed with the axial rack; a radial rack is fixed on the slide carriage to be meshed with the gear; the slide carriage seat is provided with a positioning mechanism which can limit the slide carriage tomove, and the movement direction of the slide carriage is vertical to the rotary axis of the boring lathe; the cutter seat is fixed on the slide carriage, and the cutter is fixed on the cutter seat. The boring bar moves, and the axial rack drives the gear to rotate, so that the radial rack drives the slide carriage to move to realize radial feeding. When used, the radial feed mechanism can conveniently and economically process wider and deeper grooves in the inner bore of the part of a box body and the high-precision end surface in the inner bore of the part of the box body. The invention is especially suitable for mass production of parts.

Owner:吴淼东

Method and apparatus for processing surface of ceramic polished brick

InactiveCN100532041CProcess jumps smoothlyProcessing economyPolishing machinesCeramic shaping apparatusBrickMetallurgy

The invention relates to a method and device for processing the surface of porcelain polished tiles. The processing method includes successively performing scraping and thickness determination on the surface of the brick adobe, plane milling and grinding and polishing, wherein the plane milling is performed by several milling heads on the brick body. The surface is milled while rotating and oscillating. The processing device includes a scraper and thickness gauge machine, a plane milling machine and a grinding and polishing machine for sequentially processing the surface of the adobe. The plane milling machine includes a frame, a beam swing system and a milling system. The milling system consists of several A grinding head that swings back and forth while rotating on the swing system. The present invention uses equipment with different processing efficiencies and processing precisions to carry out the most economical and effective processing on the surface of brick adobes at different stages, so that the process jump between rough processing and finishing processing in the prior art can be smoothed, reducing inefficiency and ineffectiveness Processing, improve production efficiency and product quality, and achieve the purpose of reducing energy consumption and abrasive wear, and reducing production costs.

Owner:KEDA INDUSTRIAL GROUP CO LTD

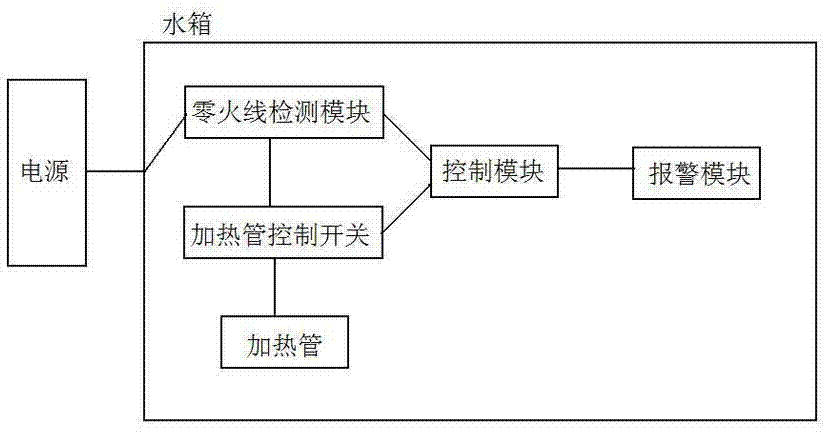

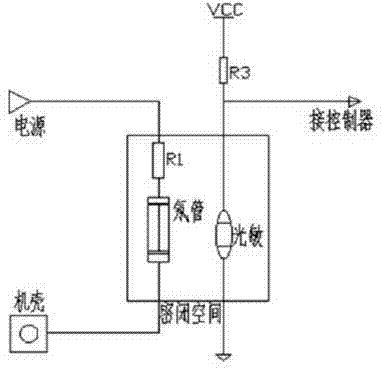

Galvanized steel sheet water heater antirust water tank and corrosion prevention method thereof

The invention discloses a galvanized steel sheet water heater antirust water tank. According to the galvanized steel sheet water heater antirust water tank, a zero line / fire line detection module is additionally arranged, and meanwhile, when the galvanized steel sheet water heater antirust water tank is stopped from being heated, the purpose of rust corrosion prevention of the heating water tank is achieved through a mode of connecting a heating tube with a zero line of an external power supply. The galvanized steel sheet water heater antirust water tank has the advantages of slowing the oxidation process of a metal zinc welding line of the galvanized steel sheet water heater antirust water tank, prolonging the service life of the heating water tank and overcoming the defect of easy rust corrosion of the galvanized steel sheet water heater antirust water tank and is not easy to subjected to rust corrosion and economic and convenient to machine; and meanwhile, the manufacturing cost is low, and the cost performance of the water tank is improved.

Owner:苏州新亚科技有限公司

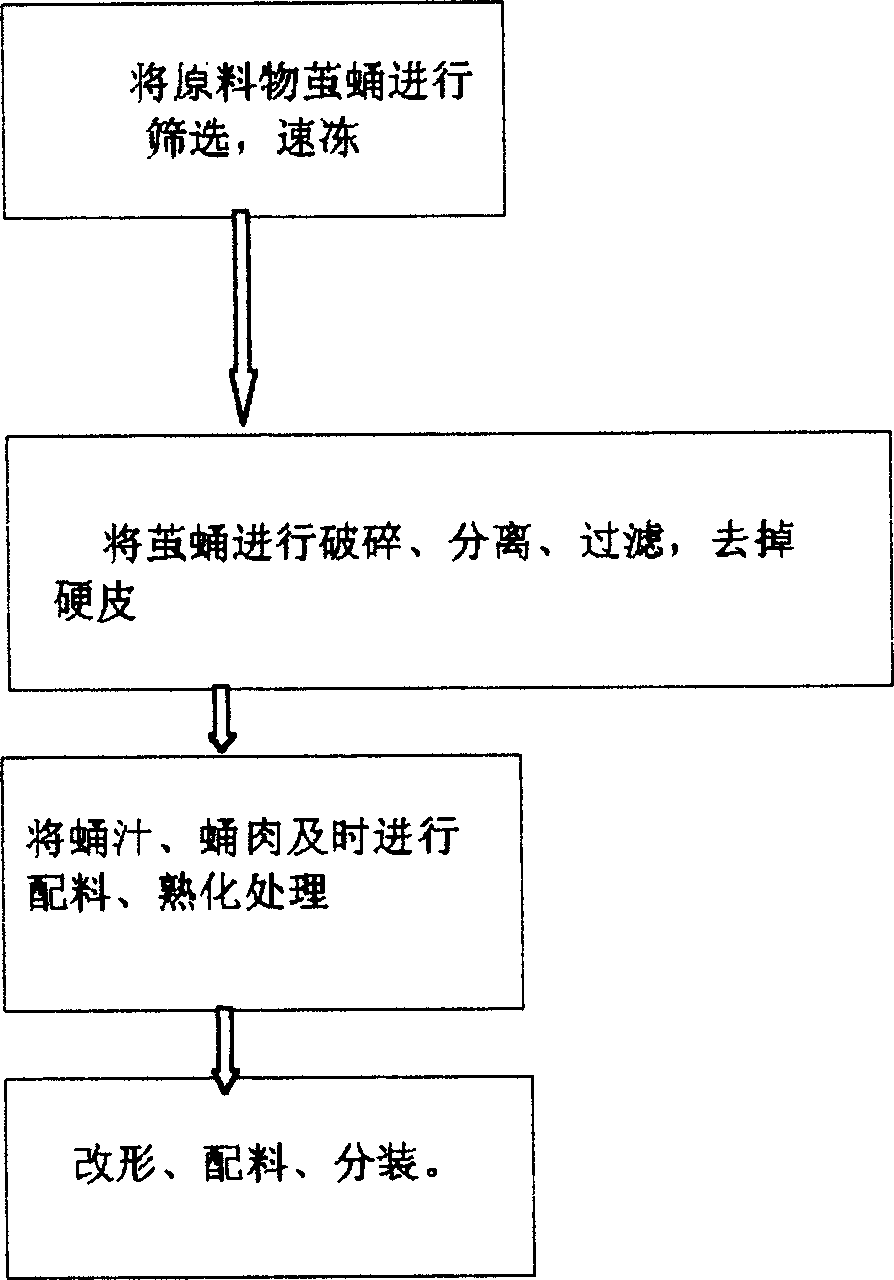

Process for preparing food using silkworm chrysalides as basic material

A food based on silkworm chrysalis is prepared through screening silkworm chrysalises, quick freezing, crushing, separating shell, filtering, proportioning with other raw materials, heating and shaping.

Owner:郭建国

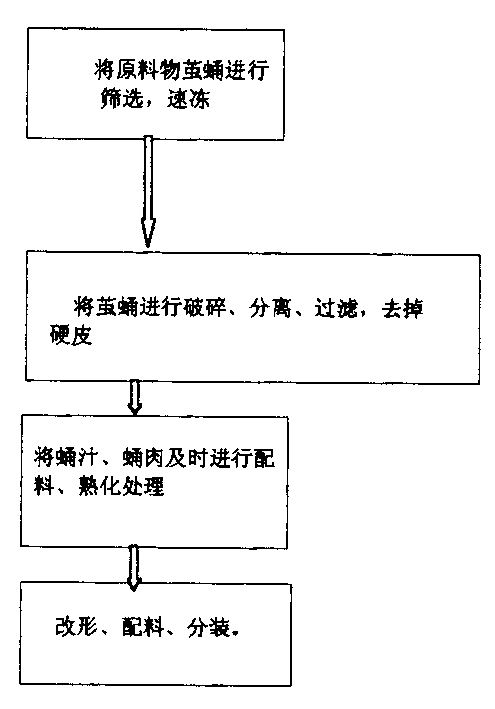

Formula and preparation method for cable with good acid and alkali resistance and high temperature resistance

InactiveCN111518351AShort molding cycleProcessing economyPlastic/resin/waxes insulatorsDiaminePoly ether ether ketone

The invention discloses a formula and preparation method for a cable with good acid and alkali resistance and high temperature resistance. The formula comprises the following raw materials in parts byweight: 80-120 parts of matrix resin, 6-8 parts of a calcium / zinc composite stabilizer, 50-60 parts of a plasticizer, 3-5 parts of a filler, 1-2 parts of a lubricant, 0.5-1 part of a bisphenol A antioxidant, 1-3 parts of a carbon black colorant, 3-4 parts of a dispersing agent and 10-15 parts of a composite flame retardant. By arranging polytetrafluoroethylene resin, polyether-ether-ketone resin,polyadipoyl butanediamine resin and various mixed auxiliaries, the acid and alkali resistance and the high temperature resistance of the prepared cable are obviously improved; and the material ratioof each layer in the cable can be finely adjusted, so the cable with higher economic benefit and better comprehensive performance is prepared.

Owner:四川威鹏电缆制造股份有限公司

An installation frame for online monitoring equipment of urban drainage pipe network

ActiveCN110848518BReduce the risk of downhole operationsGood value for moneyMachines/enginesPipeline systemsControl theoryWinch

The invention discloses a mounting frame for on-line monitoring equipment of urban drainage pipe network. The mounting frame includes a hollow telescopic rod. The upper end of the telescopic rod is connected with a tee pipe. A winch is fixed, and the winch is equipped with a wire rope; the lower end of the telescopic rod is connected to a hollow support rod through the lower inner wire tube; the lower end of the support rod is fixedly connected to a horizontal tube, and the horizontal tube is vertically connected to the support rod; the other end of the horizontal tube is connected through a hinge A movable rod is connected; the other end of the movable rod has a through hole, and one end of the wire rope is fixed in the through hole, so that the movable rod moves upward or downward under the drive of the wire rope; the upper side of the horizontal tube is fixed with a baffle, The plate is capable of blocking the travel rod when the travel rod is turned upward to the maximum direction. The invention has a reasonable structure, can adjust the length of the telescopic rod, is convenient to use, does not need manual underwater work, and is convenient to collect and install.

Owner:无锡航征科技有限公司

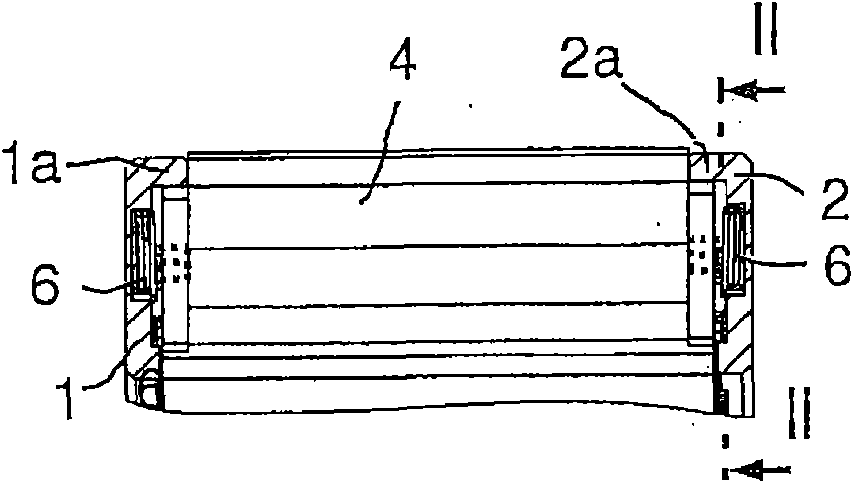

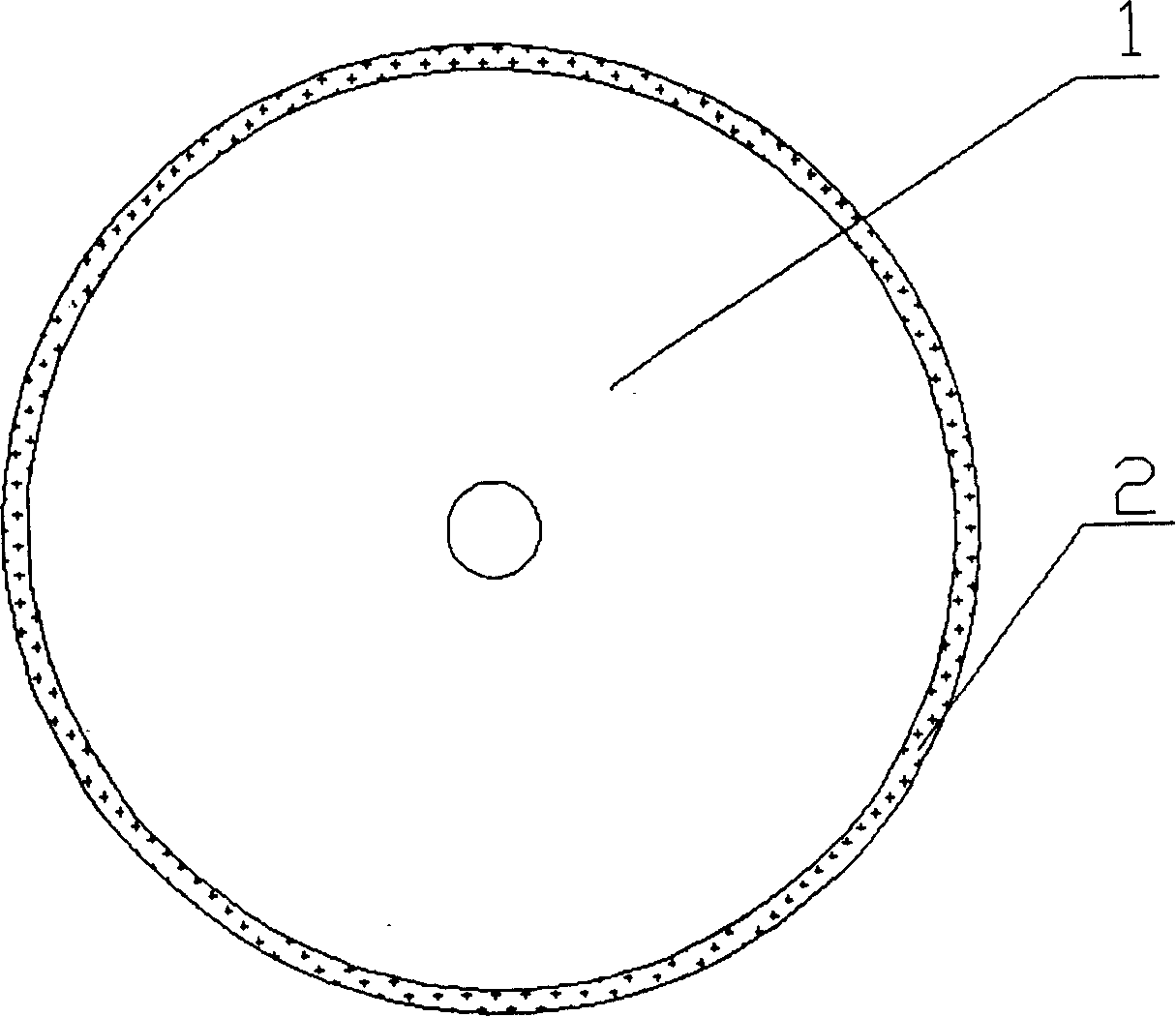

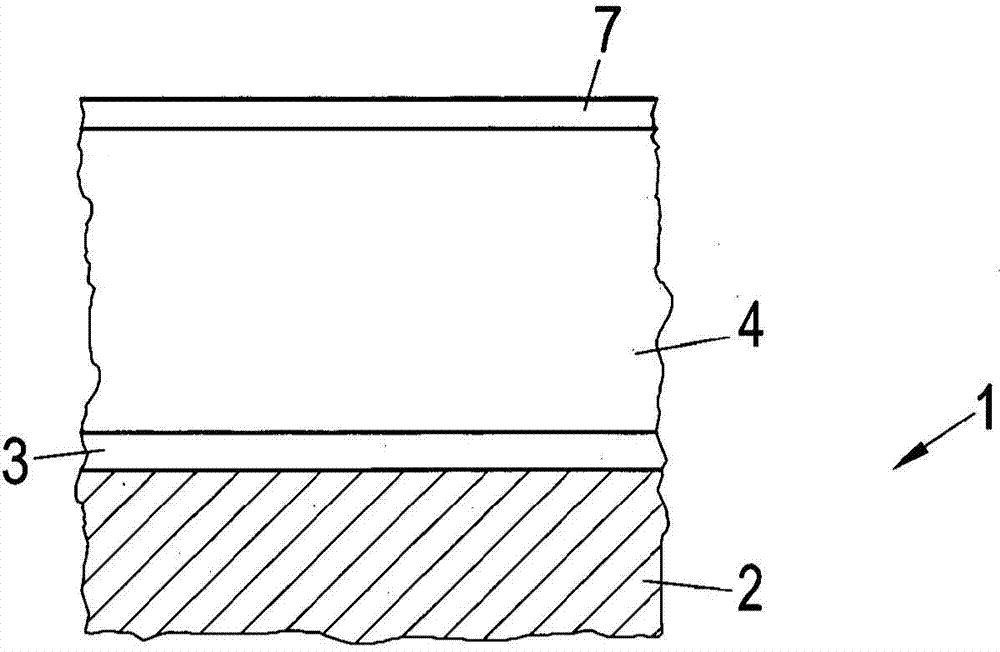

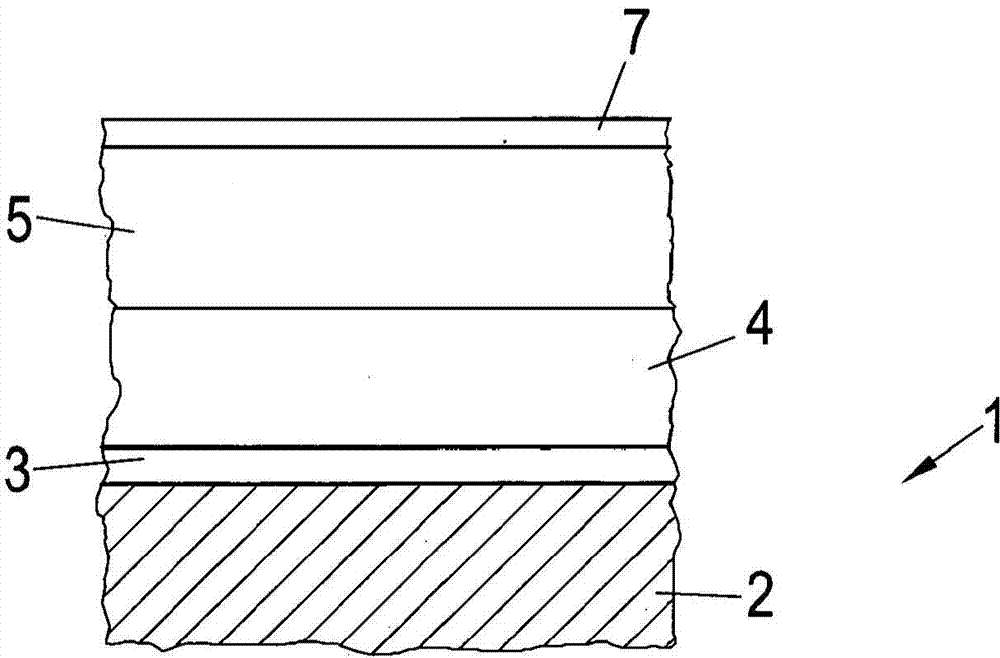

Roll and method for producing a roll

InactiveCN104520505AShorten manufacturing timeReduce process costsCalendersPress sectionCardboardMixed oxide

The invention relates to a roll (1) for use in a machine for producing or finishing a web of fibrous material such as a paper, cardboard or tissue web comprising a roll core (2), at least one adhesion layer (3) formed thereon, and at least one ceramic layer (4) formed on the at least one adhesion layer (3). The at least one ceramic layer (4) contains an oxide compound in the form of a mixed oxide ceramic, at least in parts.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com