Clamping and feeding device for moso bamboo cutting machine, moso bamboo cutting machine and moso bamboo cutting system

A technology of feeding device and cutting machine, which is applied in the direction of feeding device, sawing components, sawing equipment, etc., which can solve the problems of time-consuming, labor-intensive, dangerous costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

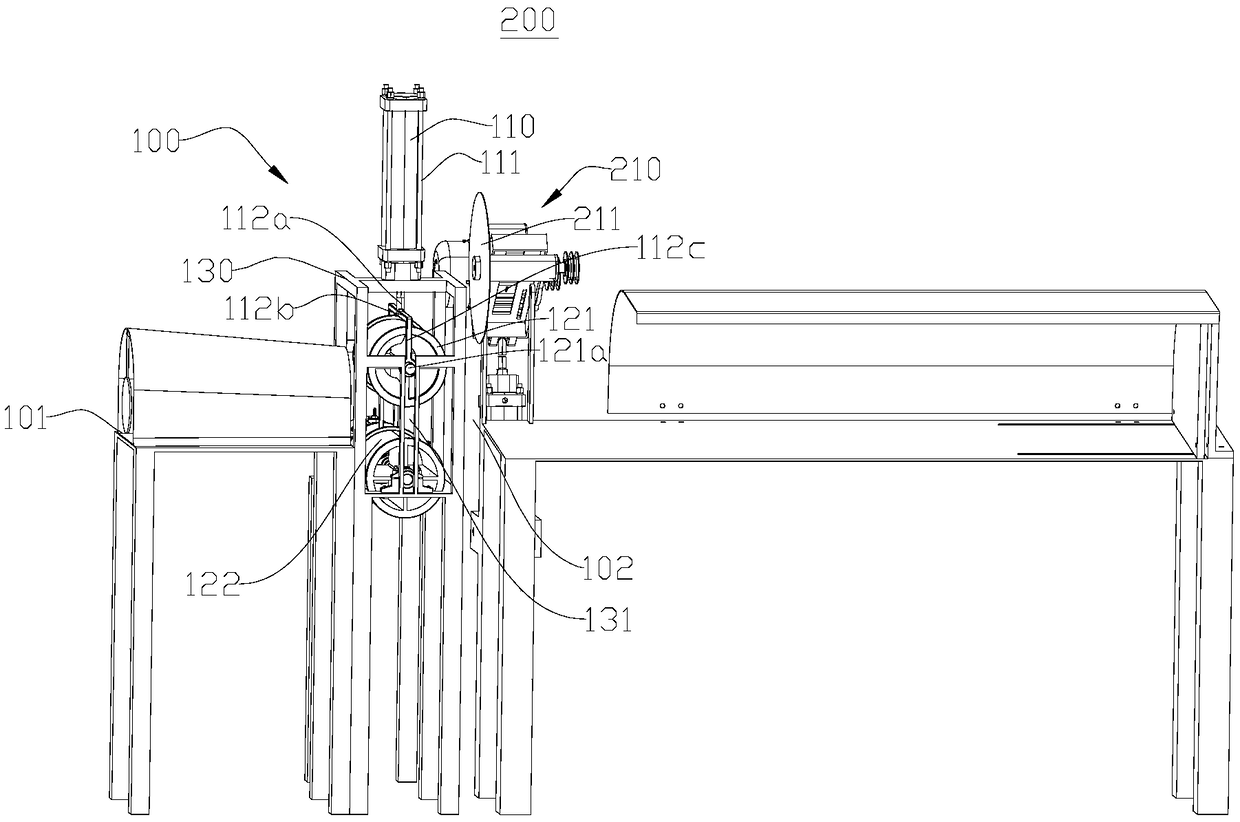

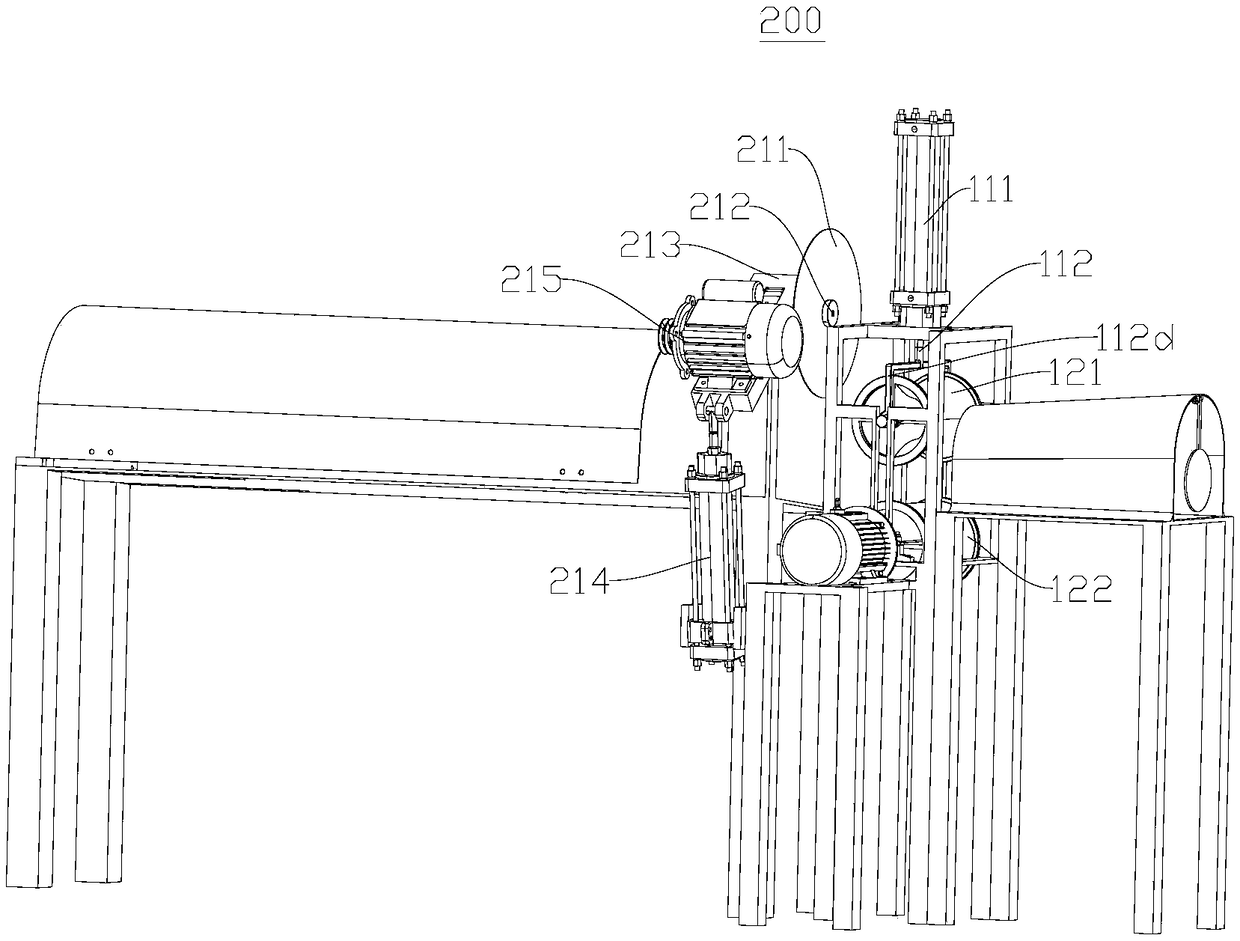

[0031] like figure 1 and figure 2 As shown, this embodiment provides a clamping and feeding device 100 for a moso bamboo cutting machine, including a main body.

[0032] The body includes a moving assembly 110 and a clamping assembly, wherein the clamping assembly includes a first roller 121 and a second roller 122 arranged vertically. The first roller 121 and the second roller 122 cooperate with each other. Moso bamboo can be placed between the first cylinder 121 and the second cylinder 122, and be clamped by both.

[0033] The moving assembly 110 is connected with the first roller 121 and drives the first roller 121 to move vertically close to or away from the second roller 122 . That is, the first roller 121 can move close to or away from the second roller 122 driven by the moving assembly 110 .

[0034] It should be noted that, in this embodiment, the body further includes a motor that drives the second roller 122 to rotate.

[0035] Based on the above, the working p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com