Patents

Literature

32results about How to "Avoid the dangers of manual operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

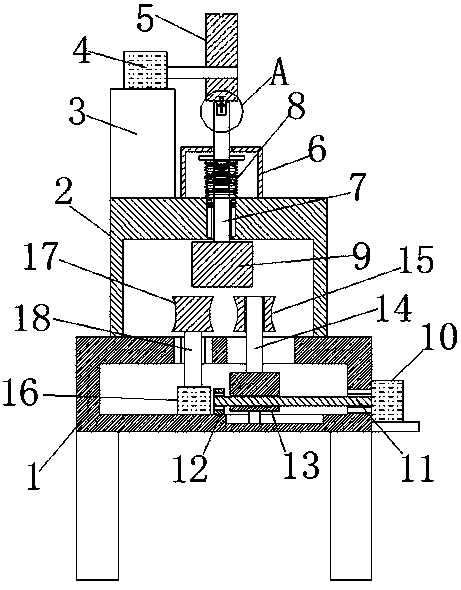

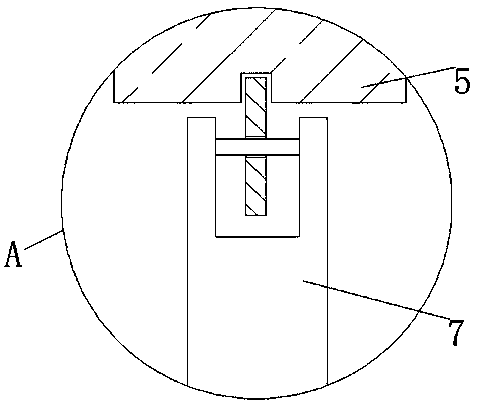

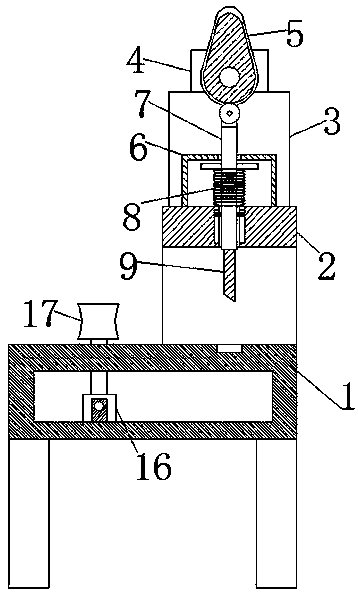

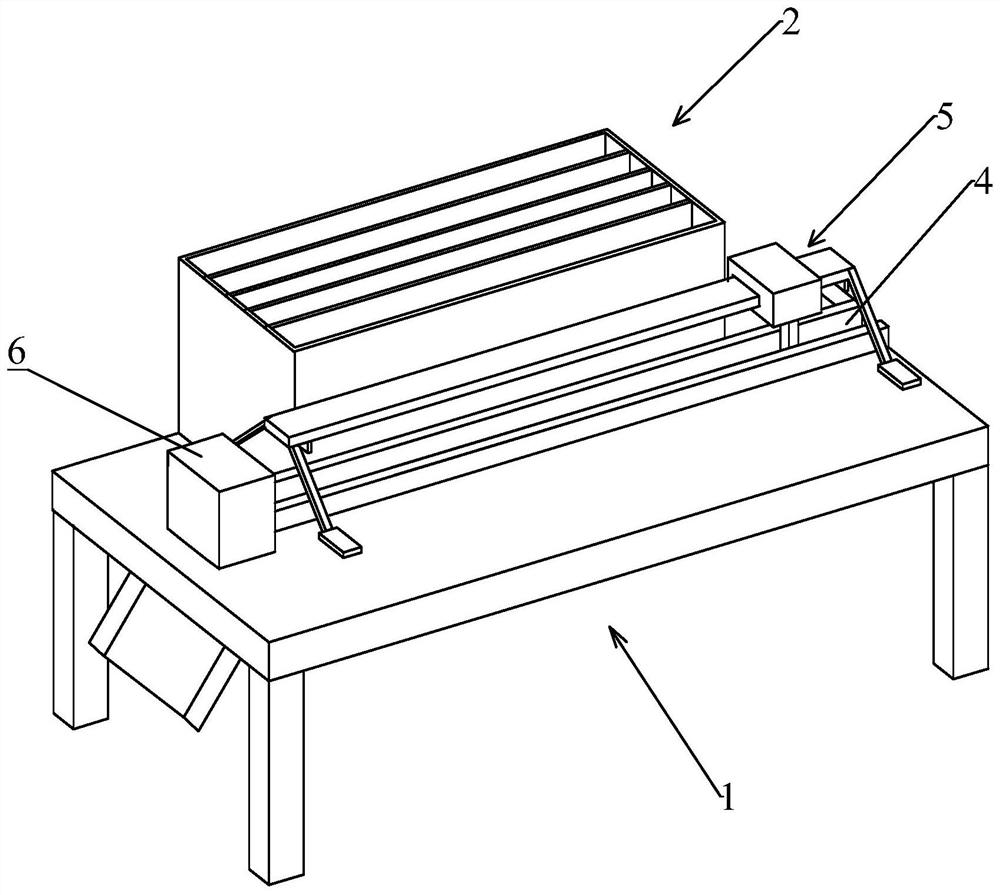

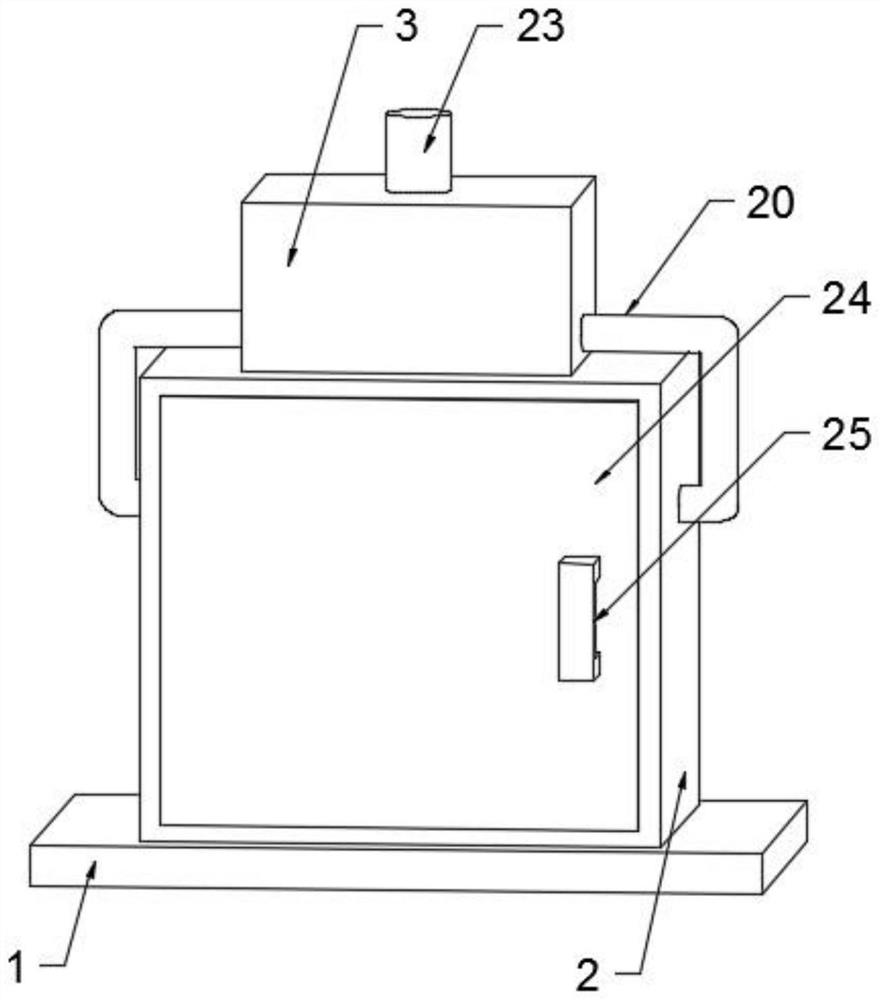

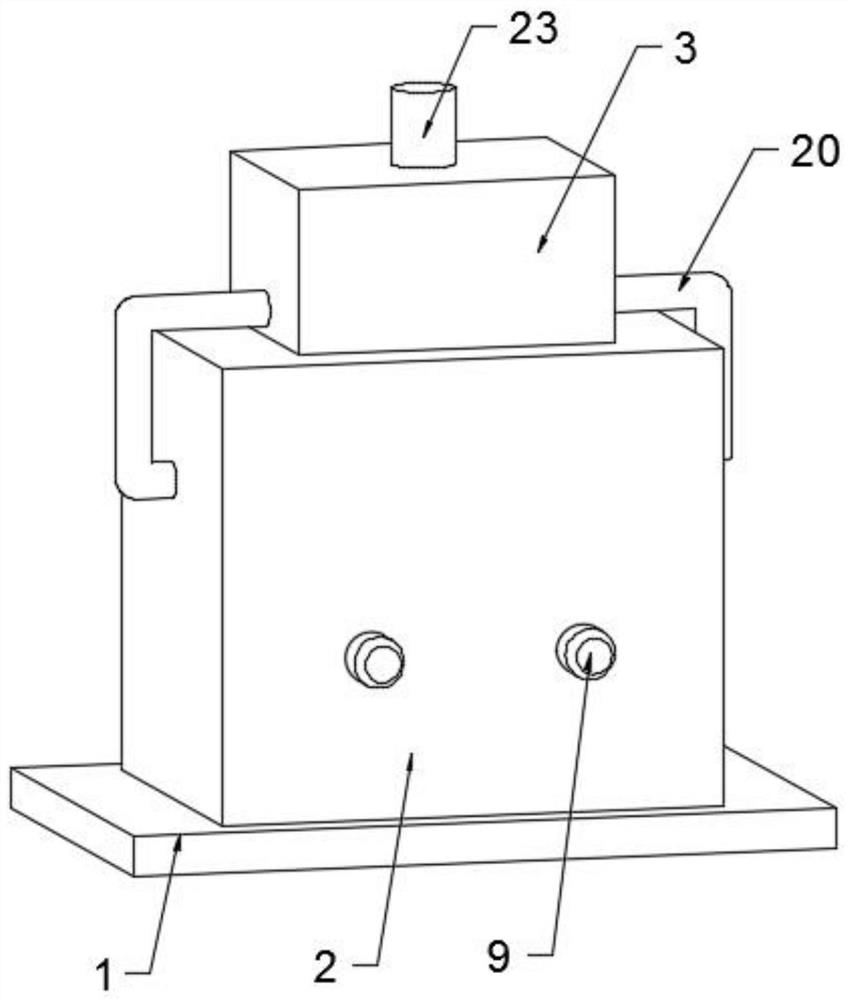

Shearing device for production of rubber and plastic products

InactiveCN108437000AReduce labor intensityRealize repeated cuttingMetal working apparatusEngineeringCam

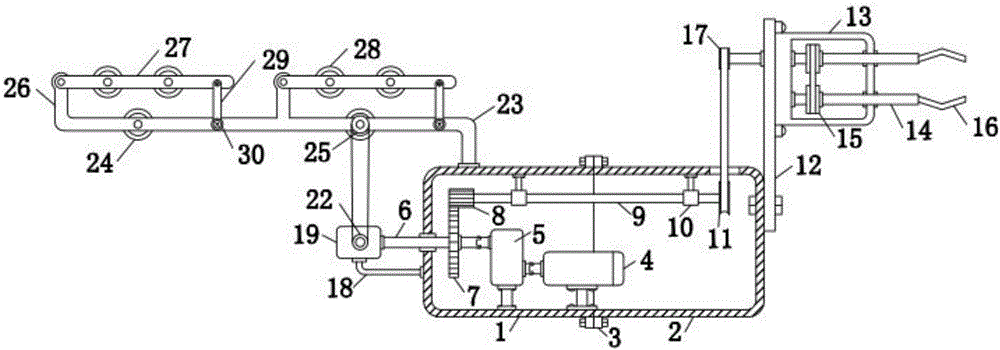

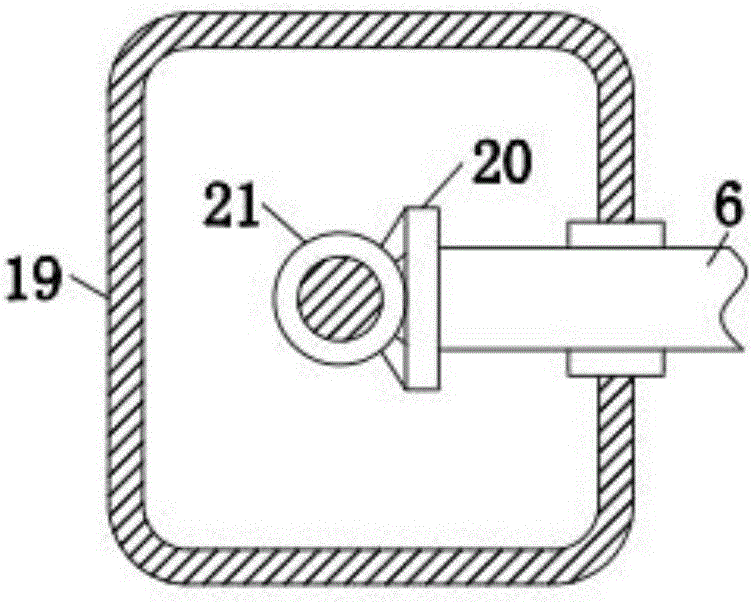

The invention discloses a shearing device for production of rubber and plastic products. The shearing device comprises a shearing table. A portal frame is fixedly connected to the upper surface of theshearing table. A fixed plate is fixedly connected to the upper surface of the portal frame. A first motor is fixedly connected to the upper end of the fixed plate. An output shaft of the first motoris fixedly connected with a cam. A shell is fixedly connected to the upper surface of the portal frame. A movable rod is movably connected into the upper surface of the shell in a sleeved mode through a first through hole. The upper end of the movable rod penetrates through the first through hole to stretch out of the shell and is connected with the cam in a rolling mode. The lower end of the movable rod penetrates through the upper surface of the portal frame through a wall hole and is fixedly connected with a tool. The wall of the movable rod is fixedly sleeved with a stop block. The shearing device is simple in structure and convenient to operate; rubber and plastic tubes can be sheared automatically, so that the labor intensity of workers is relieved, and the risks of manual operationare avoided; and the rubber and plastic tubes can be automatically conveyed at a constant speed so that the rubber and plastic tubes can be accurately sheared at equal intervals, and the labor intensity of the workers is further relieved.

Owner:响水煦隆贸易有限公司

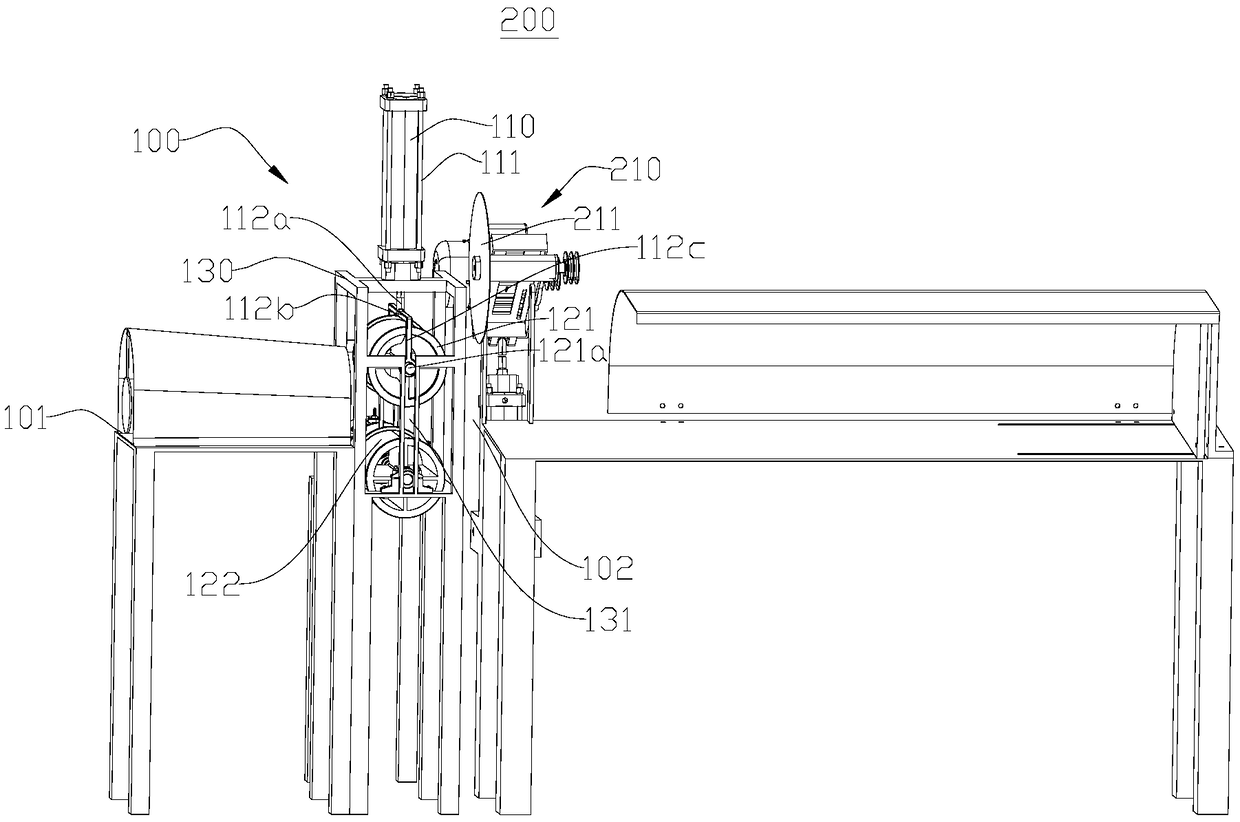

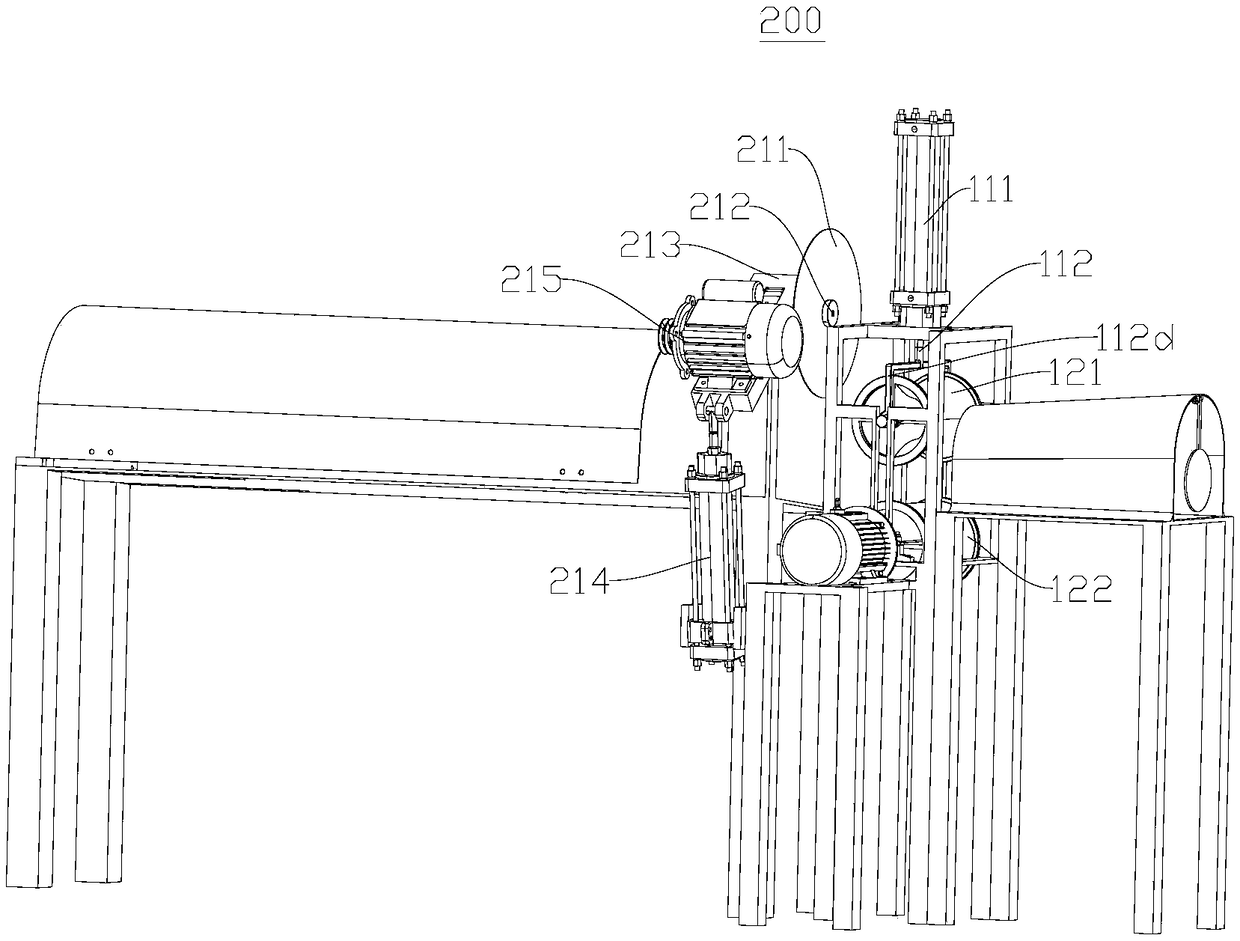

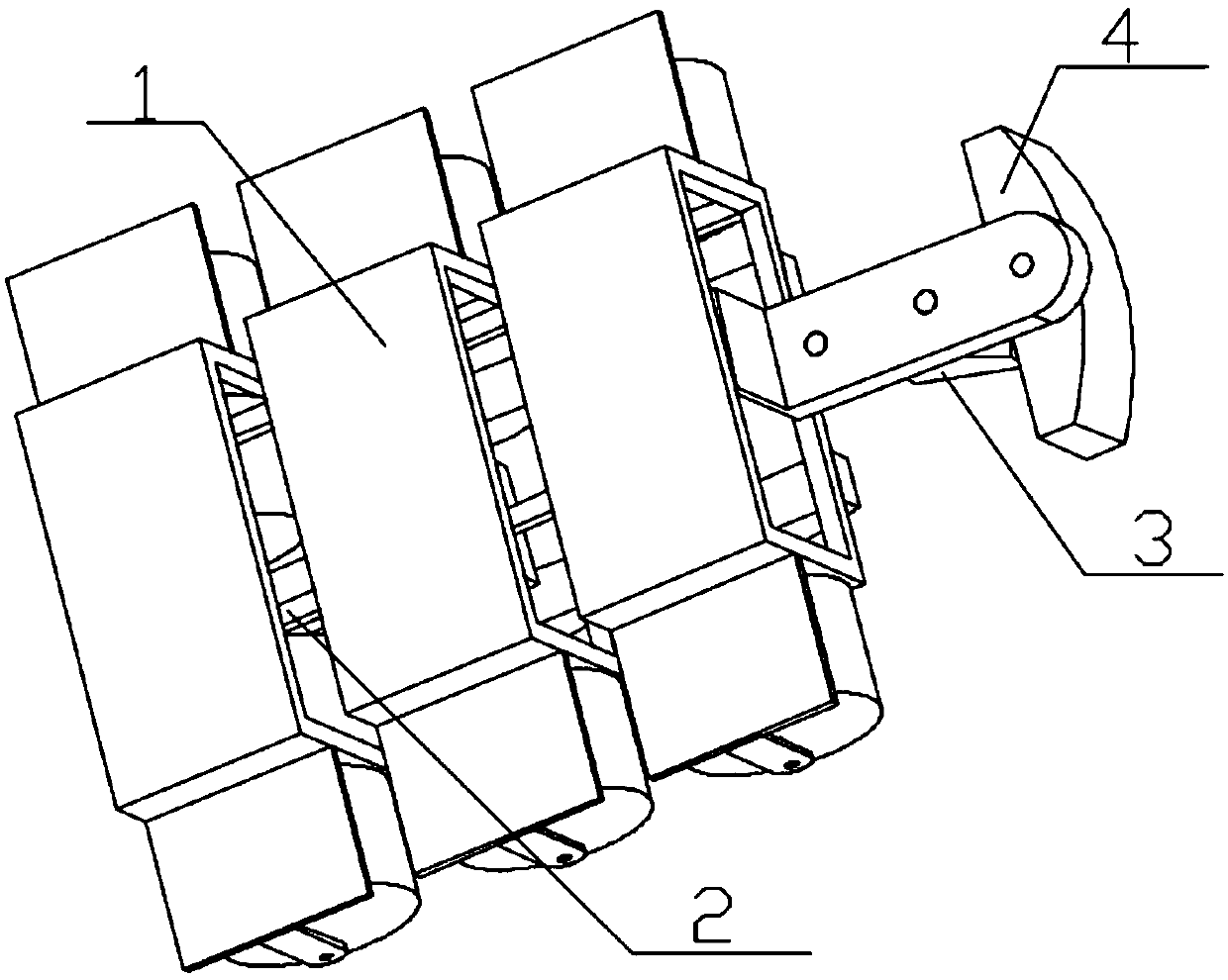

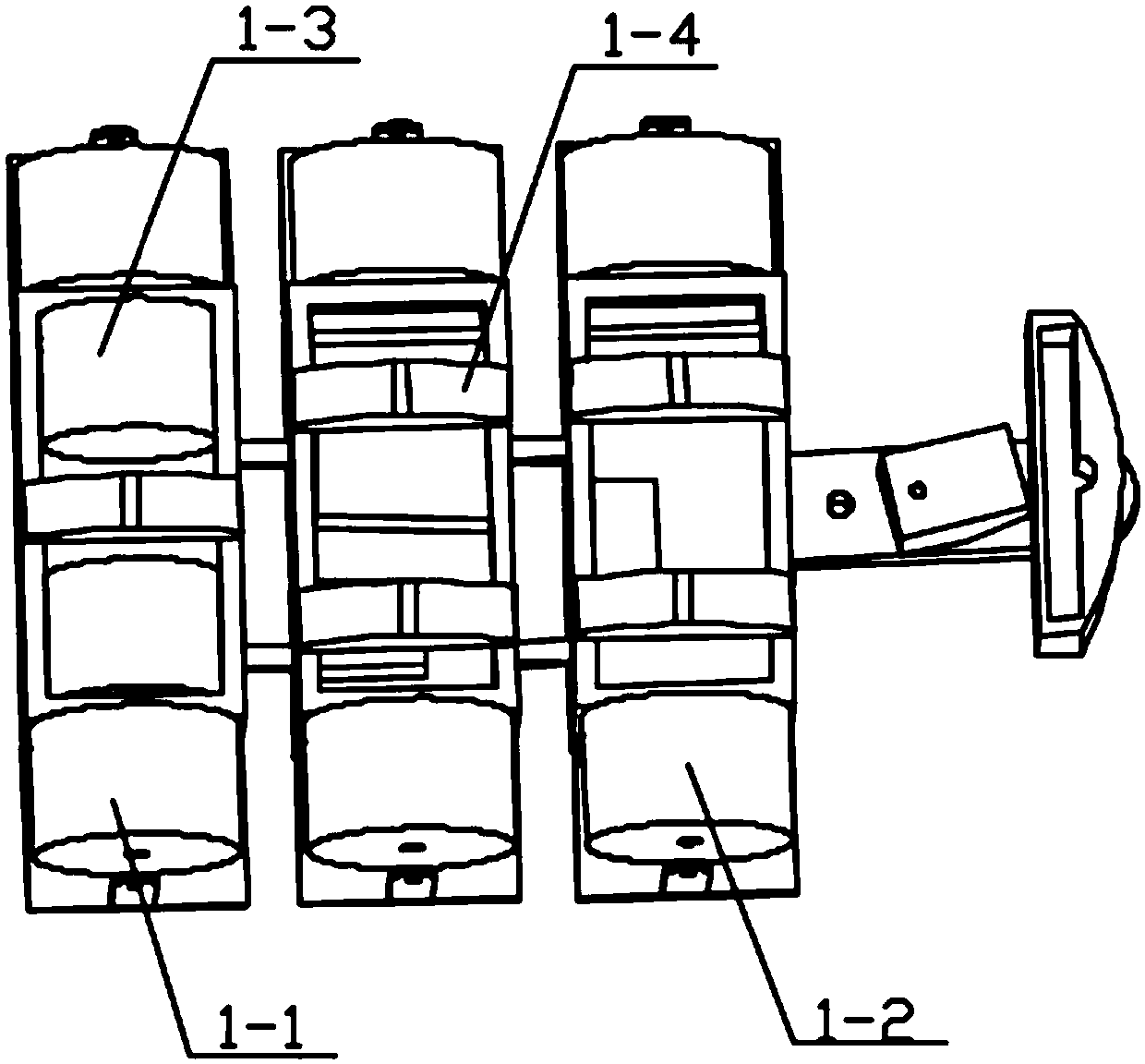

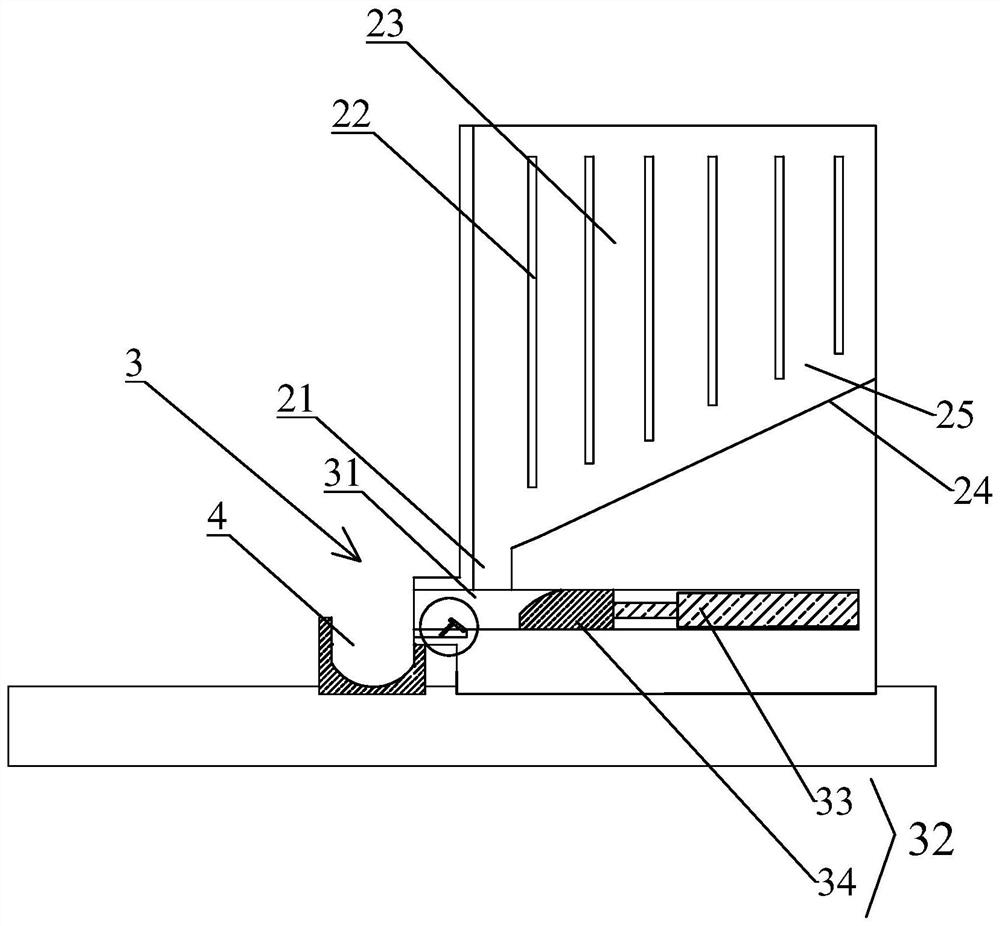

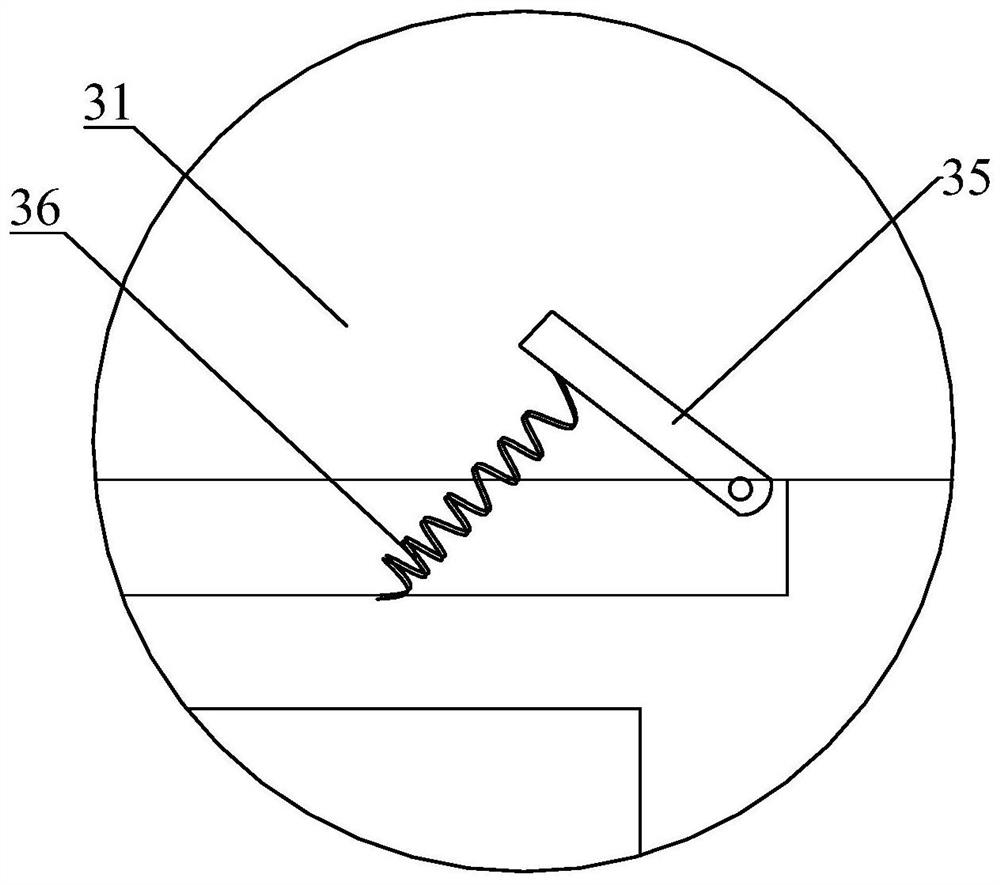

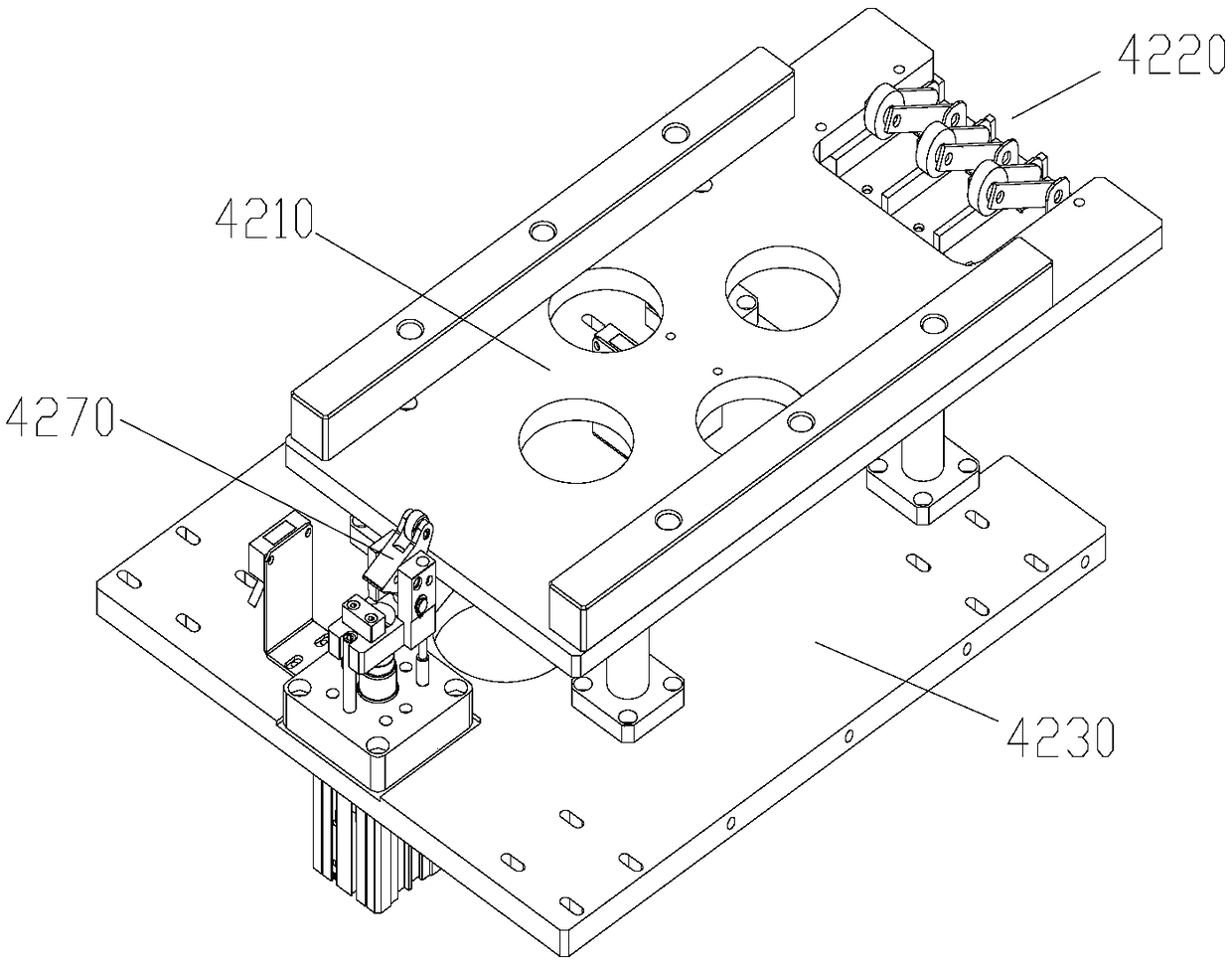

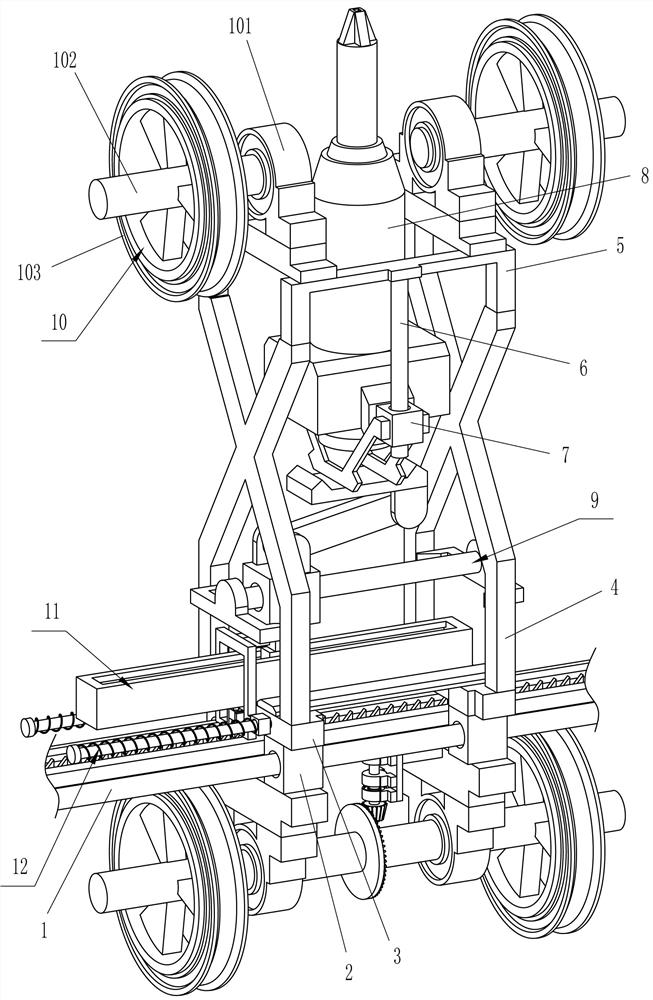

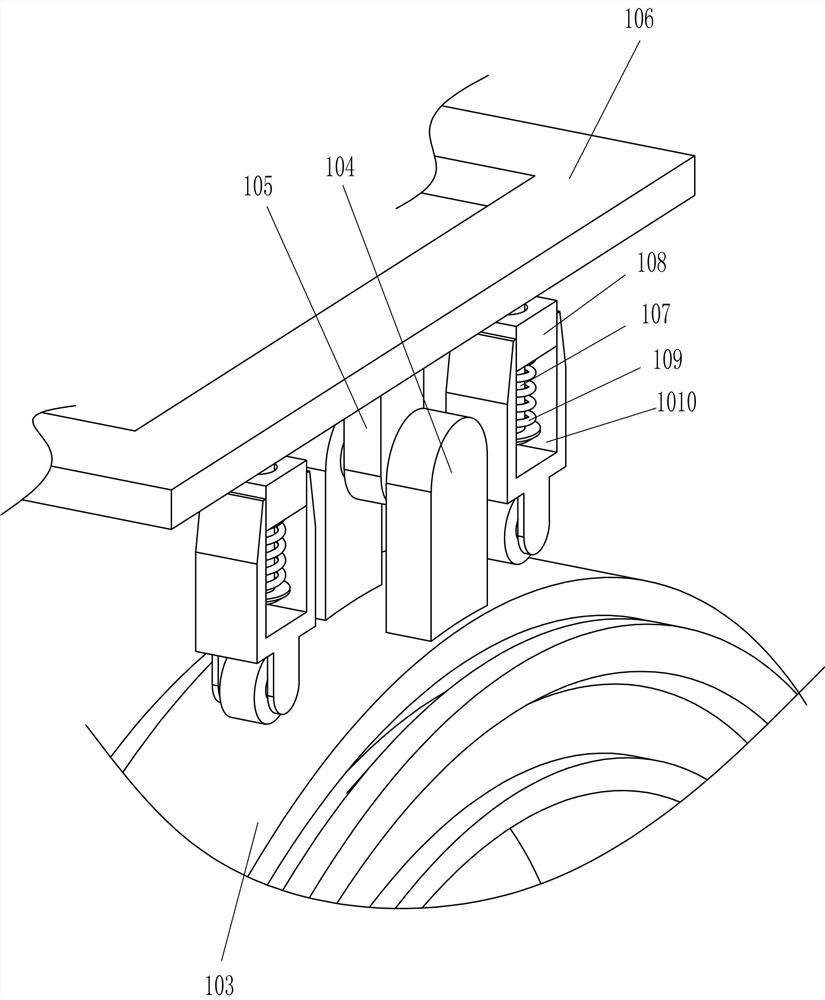

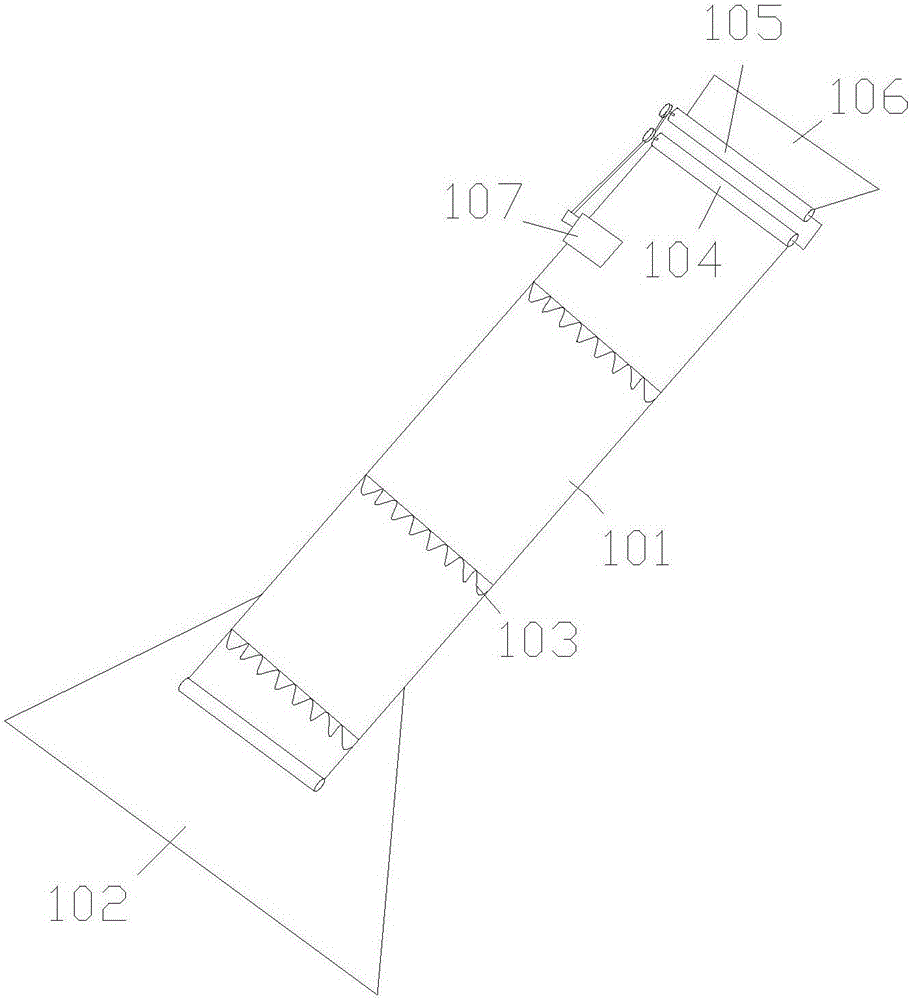

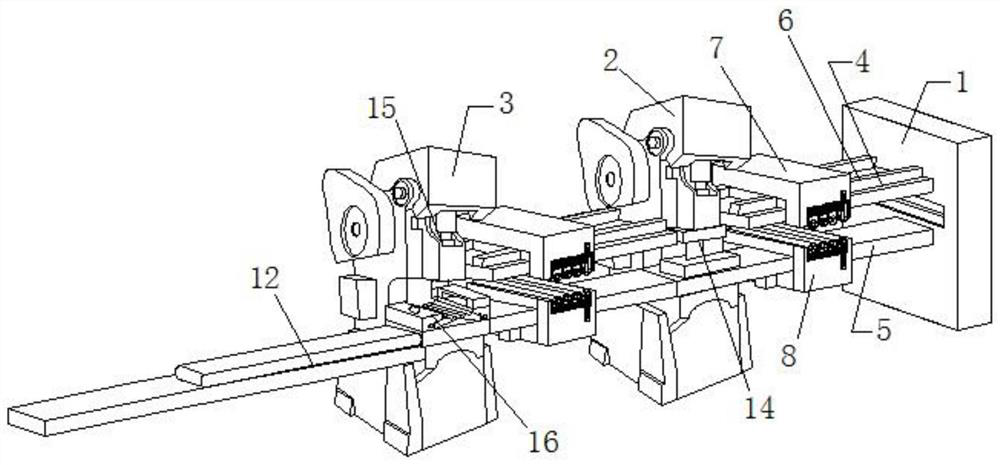

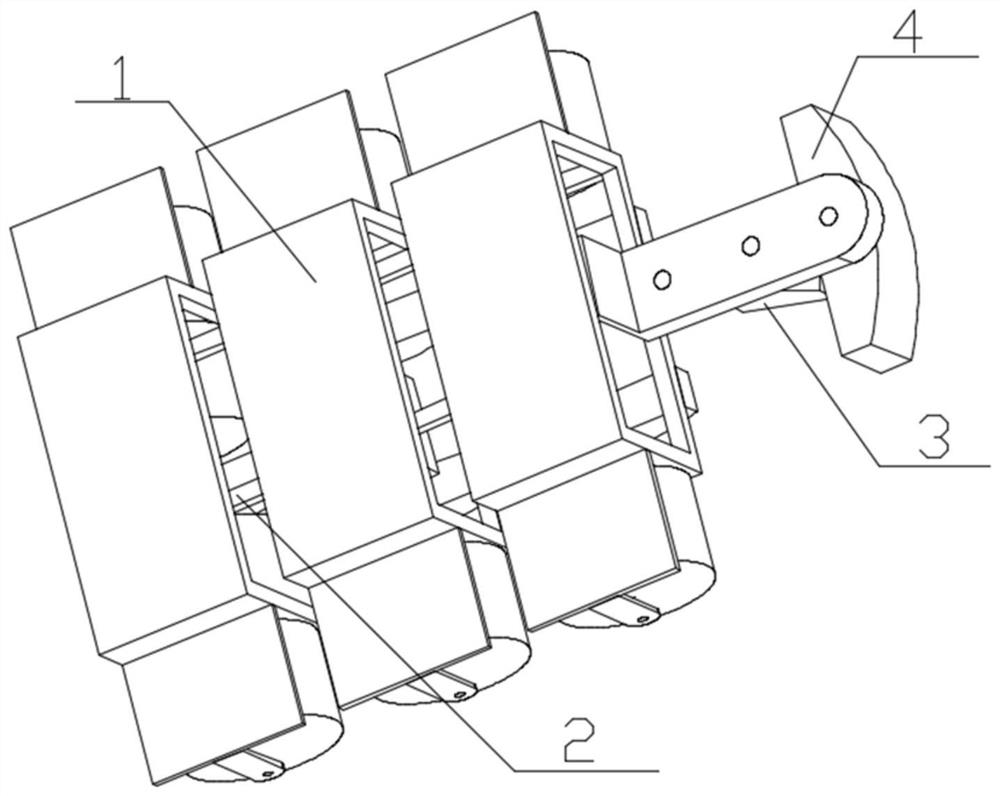

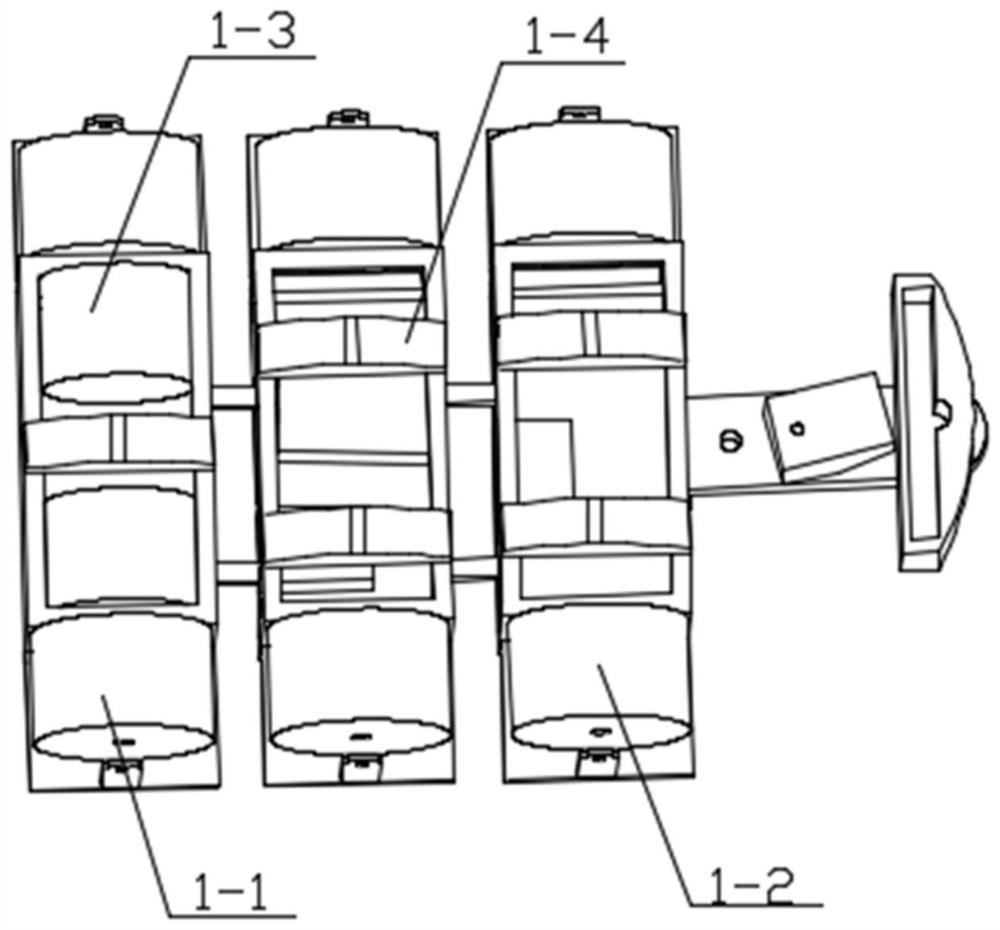

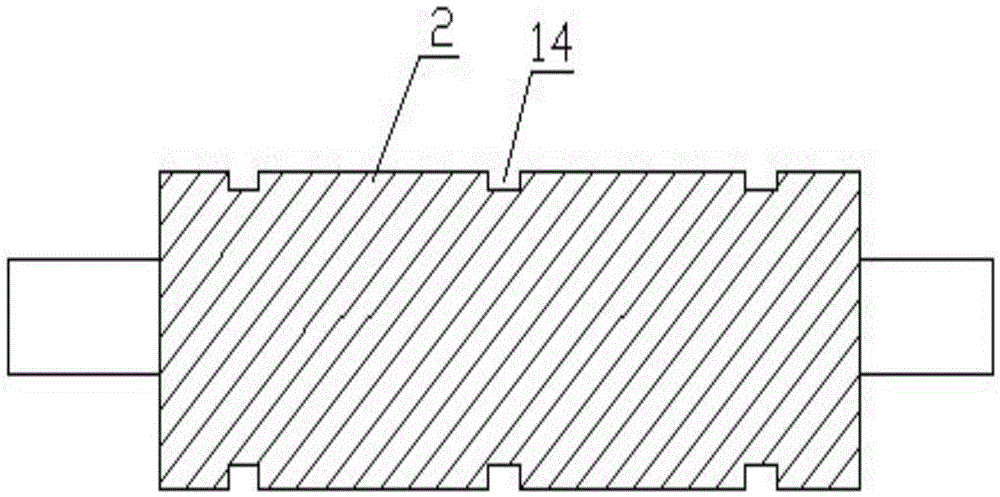

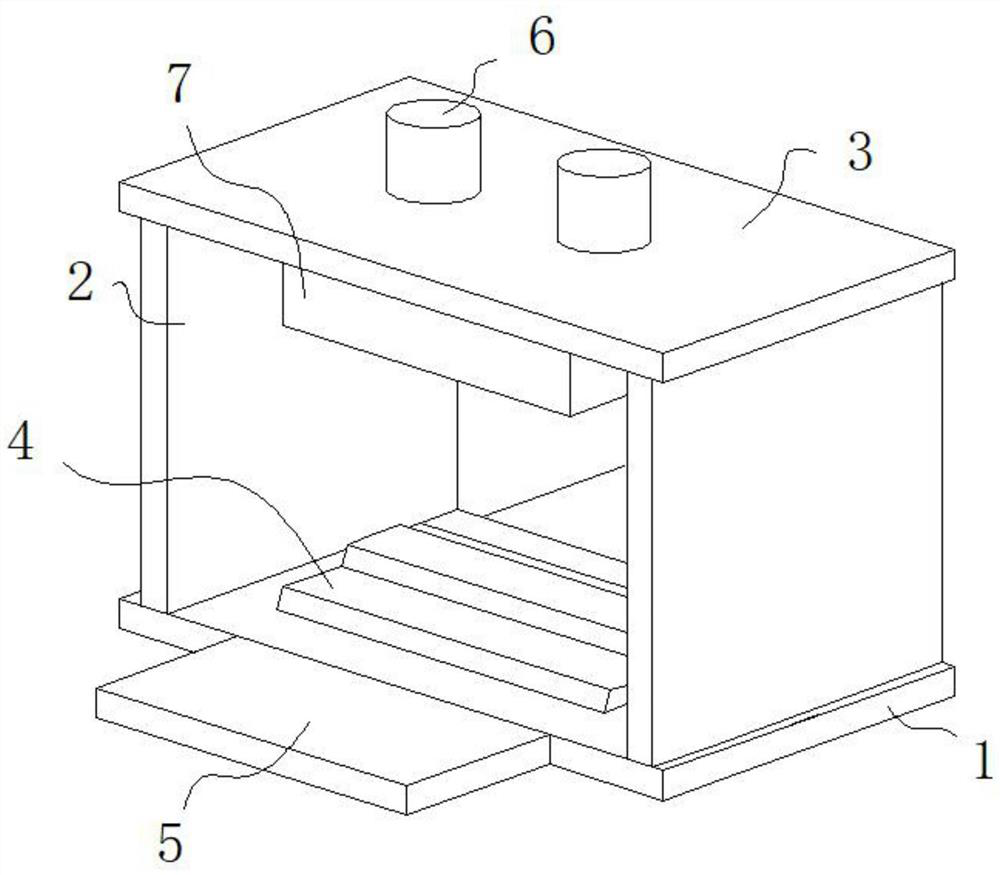

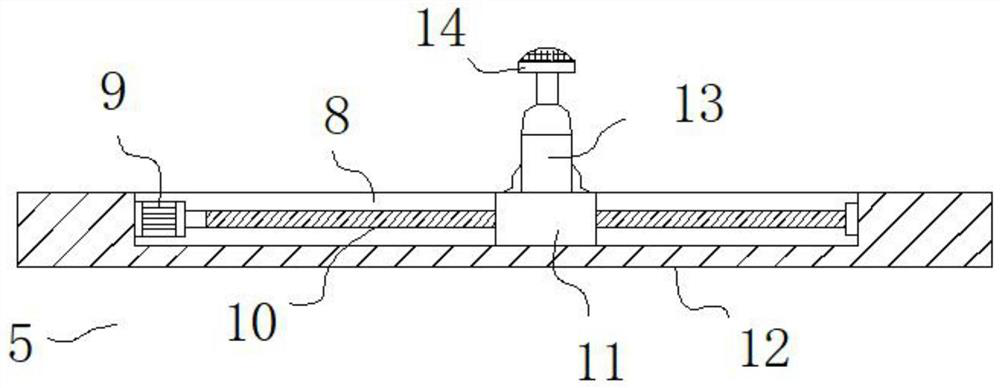

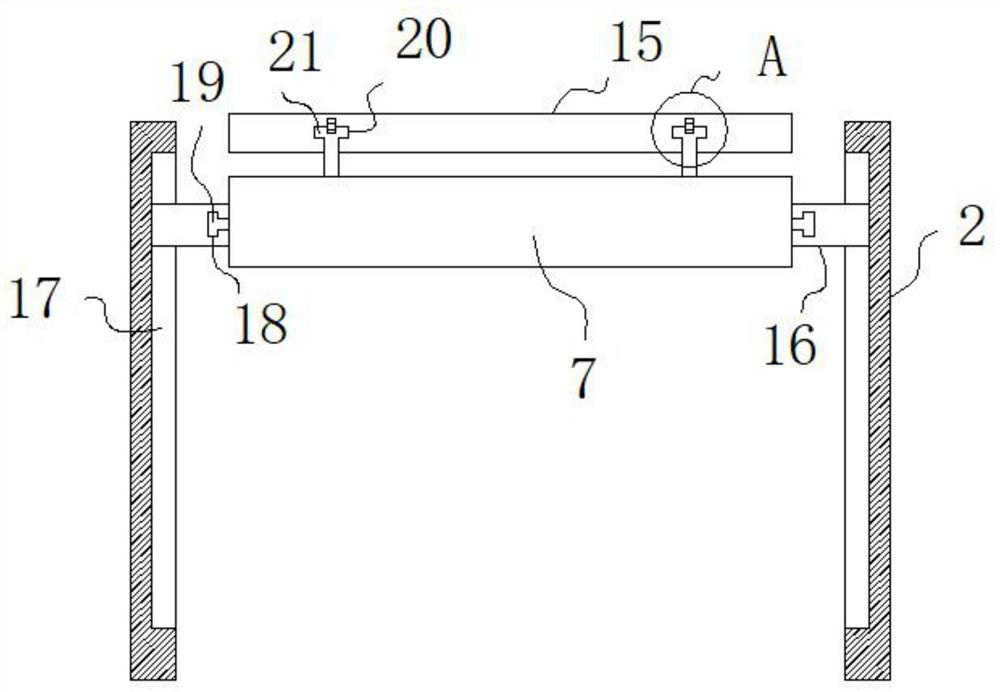

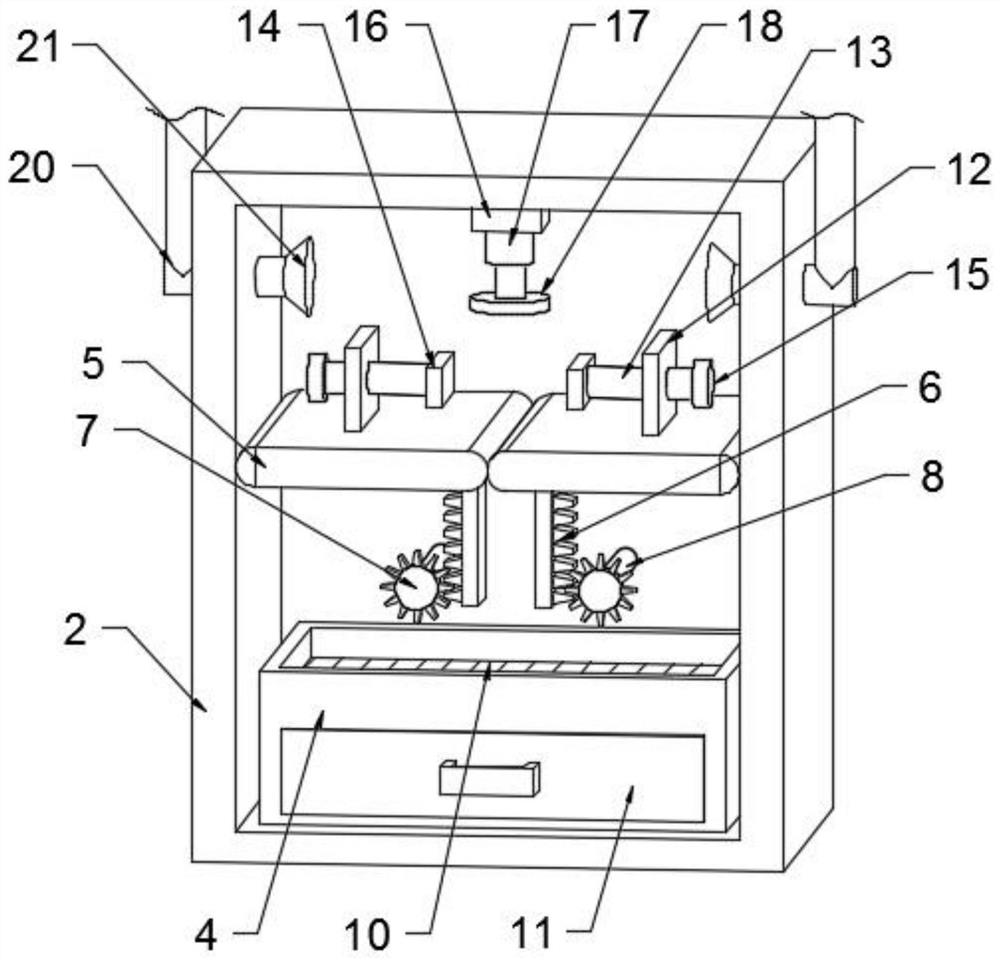

Clamping and feeding device for moso bamboo cutting machine, moso bamboo cutting machine and moso bamboo cutting system

PendingCN109129771AHigh degree of automationSave manpower and material resourcesFeeding devicesCane mechanical workingMaterial resourcesEngineering

The invention provides a clamping and feeding device for a moso bamboo cutting machine, the moso bamboo cutting machine and a moso bamboo cutting system. The clamping and feeding device comprises a moving assembly and a clamping assembly; the clamping assembly comprises a first roller and a second roller which are arranged in the vertical direction, and the first roller and the second roller are mutually matched for use; the moving assembly is connected with the first roller and drives the first roller to get close to or get away from the second roller in the vertical direction; a moso bamboois placed between the first roller and the second roller, thus the moso bamboo is clamped by the first roller and the second roller; and meanwhile, when the first roller and the second roller rotate relatively, the moso bamboo is pushed to move forwards. According to the clamping and feeding device, automatic clamping and feeding of the moso bamboo is achieved, the automatic degree is high, manpower and material resources are greatly saved, and meanwhile, the danger brought by manual operation is also avoided. The moso bamboo cutting machine comprises a cutting device and the clamping and feeding device used for the moso bamboo cutting machine. The moso bamboo cutting system comprises the moso bamboo cutting machine and is convenient to use and high in working efficiency.

Owner:SANMING UNIV

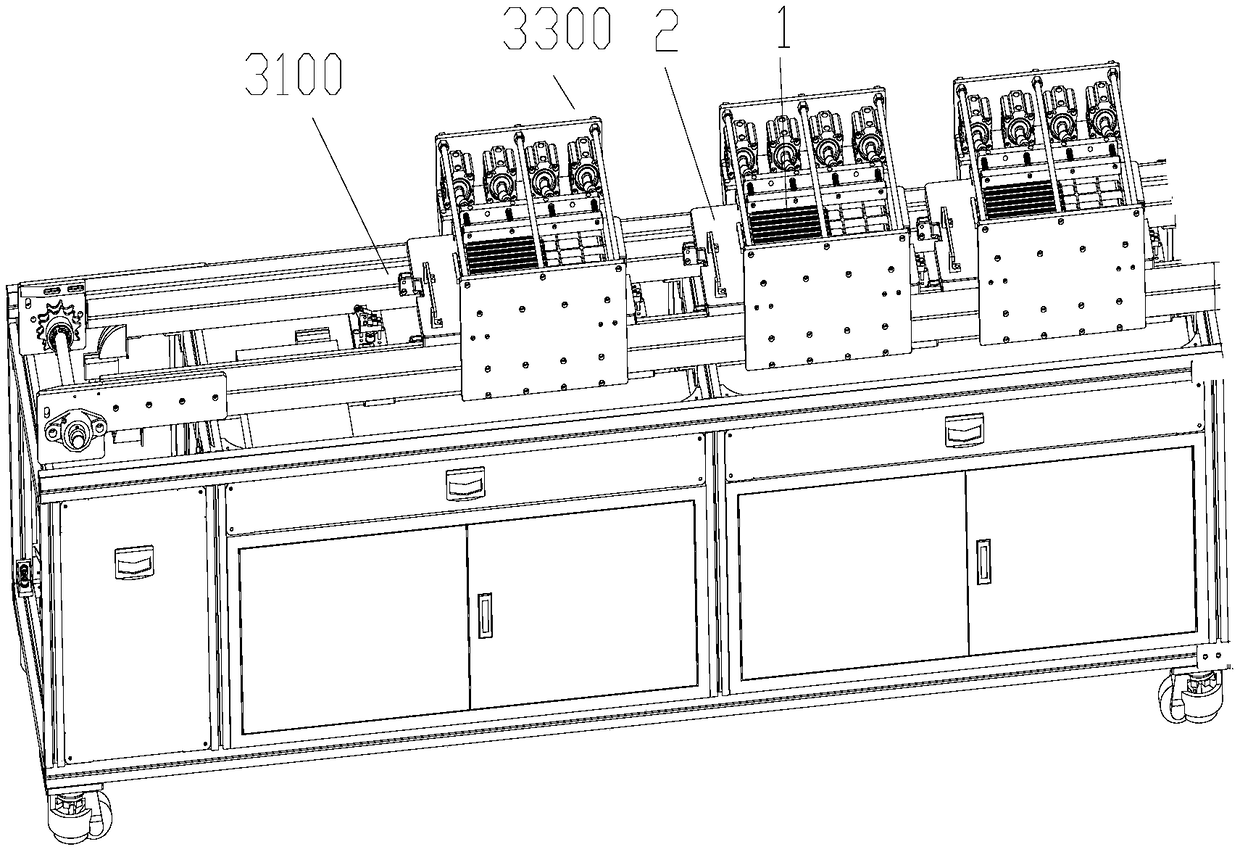

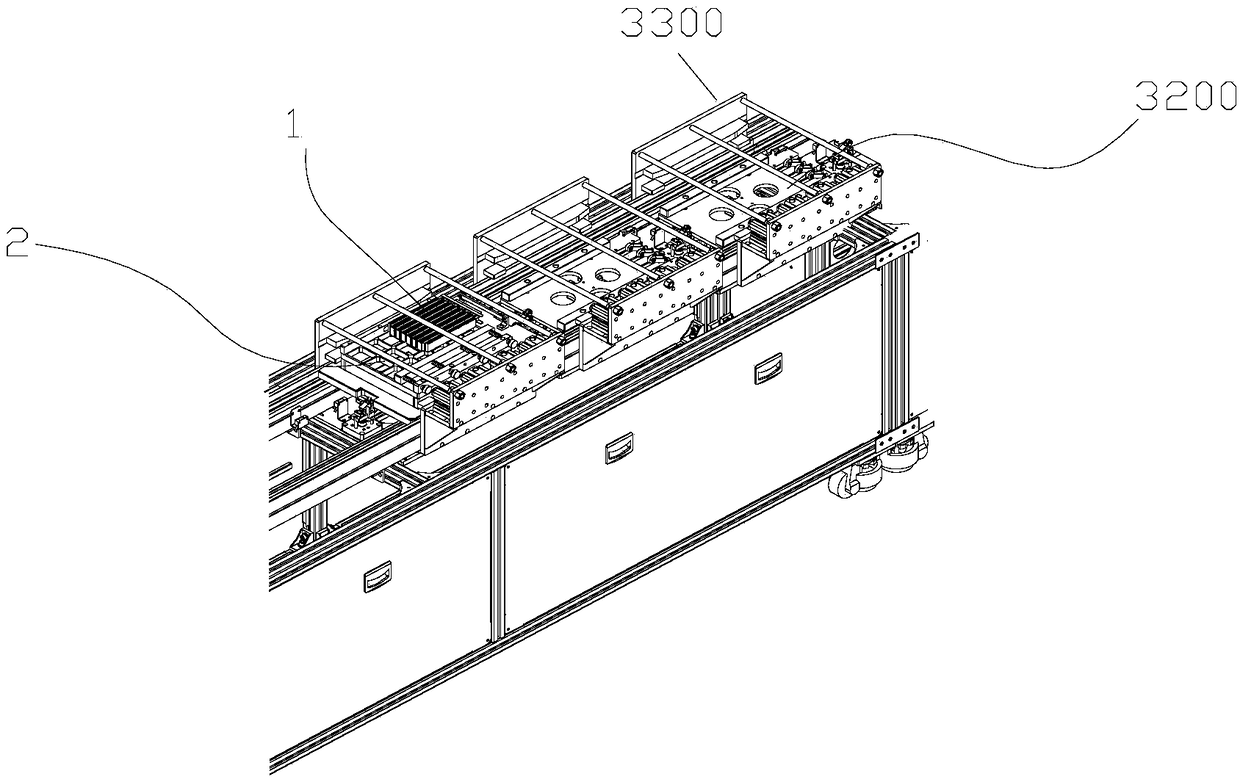

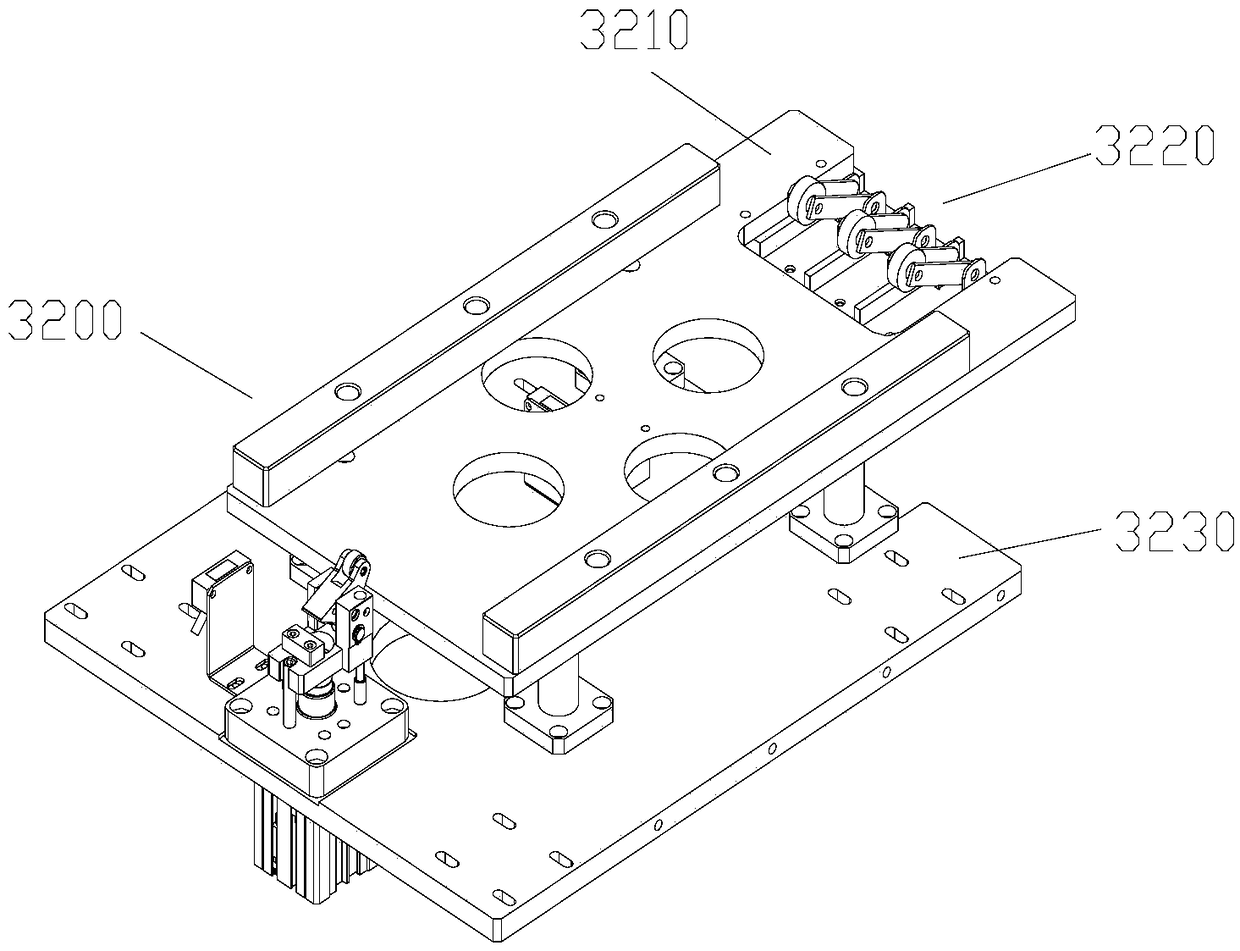

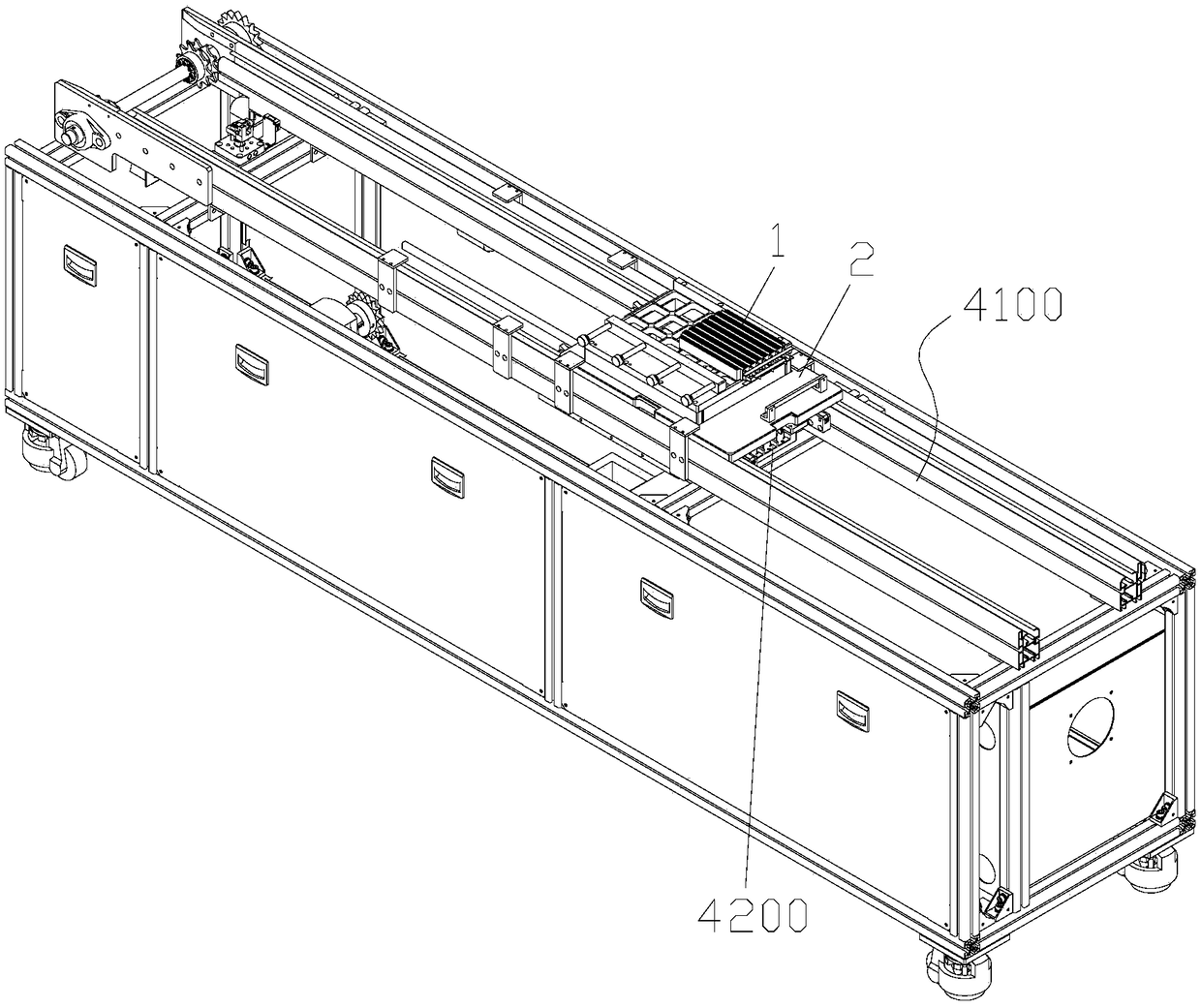

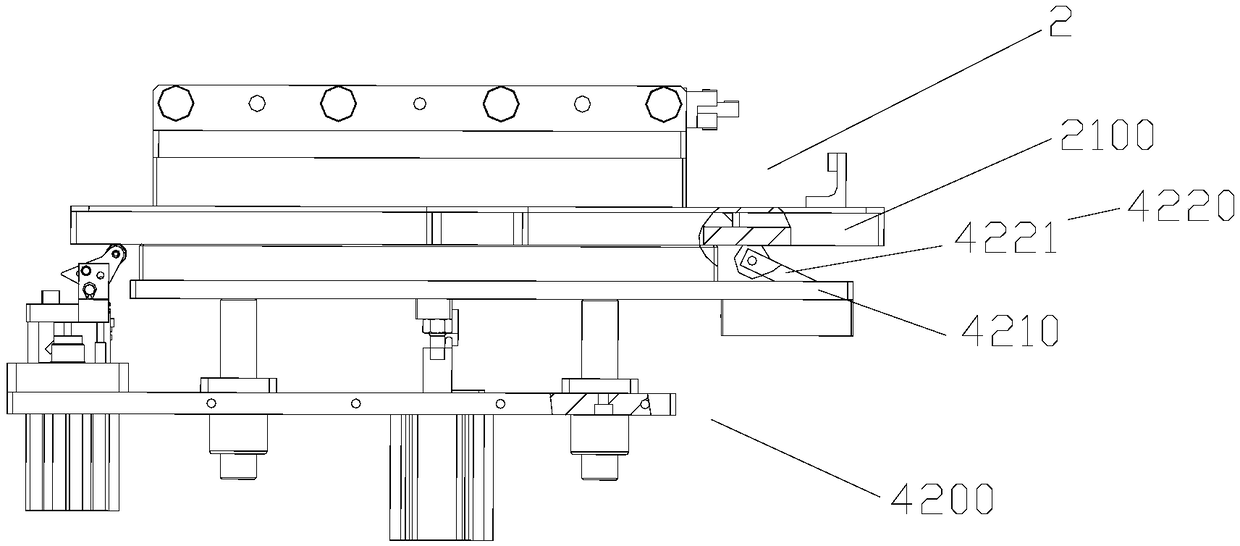

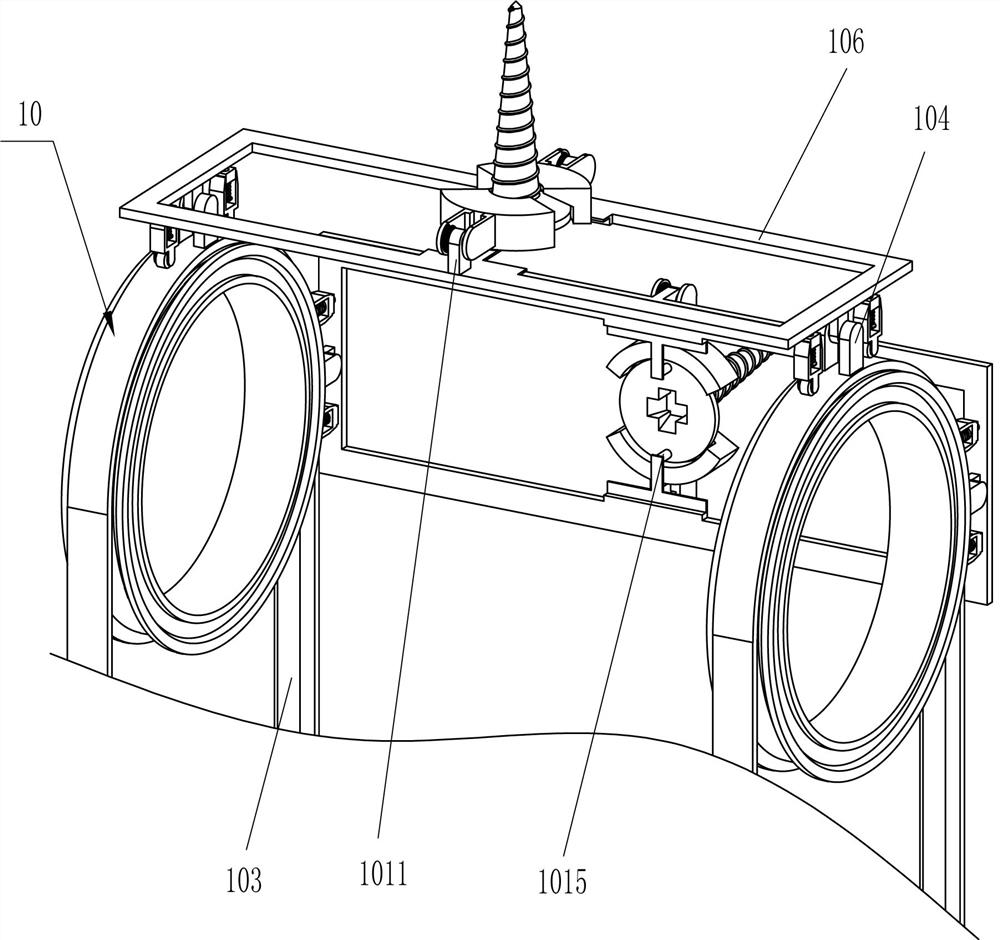

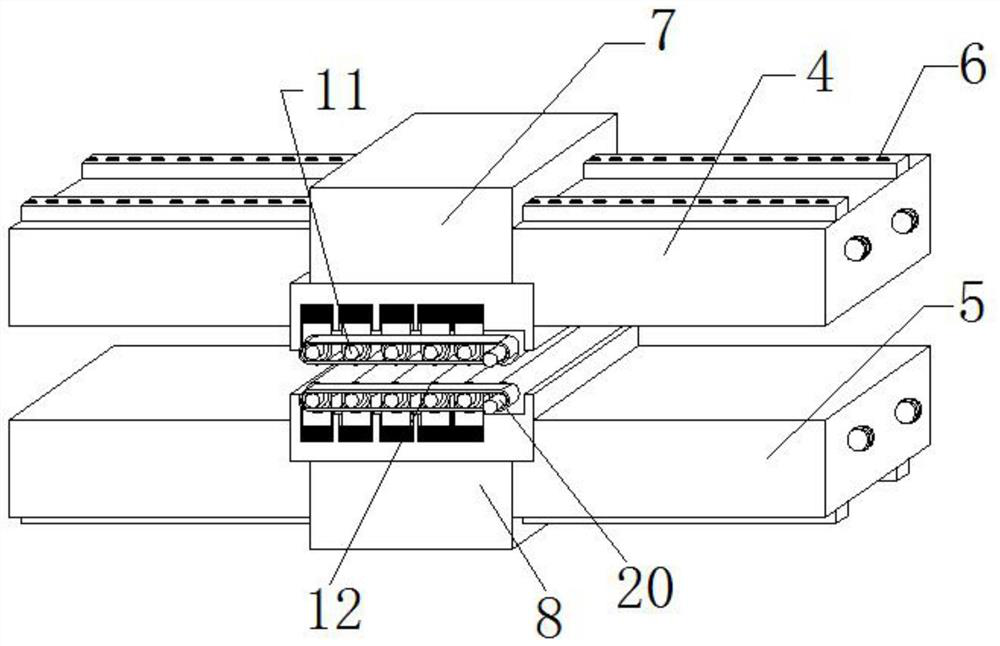

Heating curing device and heater production line

PendingCN109127319AAvoid dangerIncrease productivityPretreated surfacesOhmic-resistance heatingAdhesiveHeating effect

The invention provides a heating curing device and a heater production line. The heating curing device comprises a tool plate, and a heating curing and jacking module, wherein the tool plate comprisesa heater clamping module; the heater clamping module is provided with first clamping space for clamping heaters to clamp or release the heaters; the heaters are in electric conducting connection withthe tool plate; the heating curing and jacking module comprises a heating curing and jacking plate, and a heating curing and electric conducting module arranged on the heating curing and jacking plate; the heating curing and electric conducting module is provided with a first position contacted with the tool plate and in electric conducting connection with the tool plate, and a second position separated from the tool plate; the heating curing and jacking plate is movably arranged for electric conduction heating of the heaters to melt adhesives under a heating effect when driving the heating curing and electric conducting module to move to the first position; and when the heating curing and jacking plate drives the heating curing and electric conducting module to move to the second position, the adhesives are solidified. The heating curing device solves the problem of lower production efficiency of a PTC heater in the prior art.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

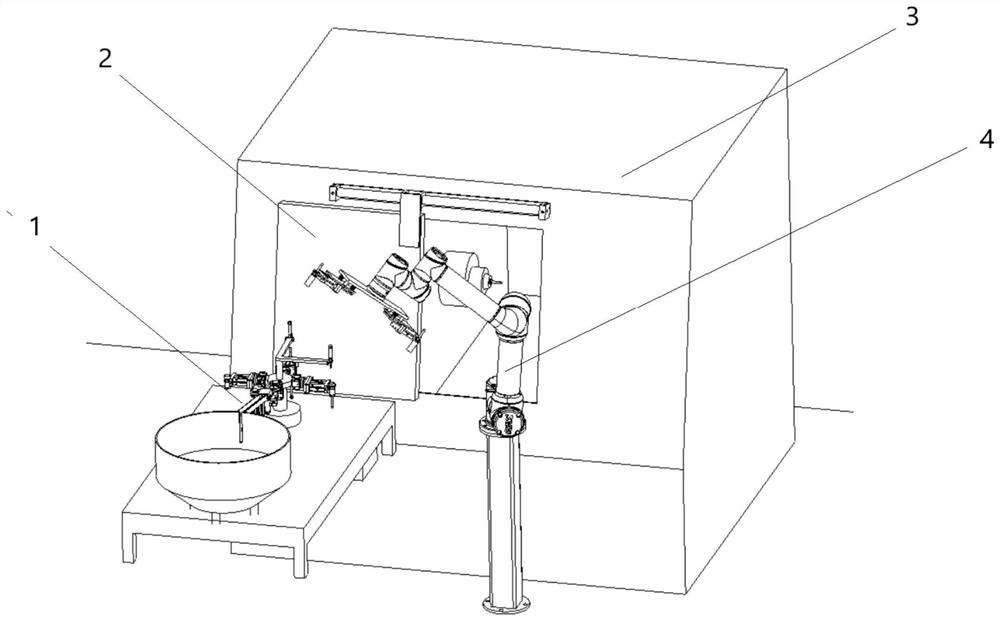

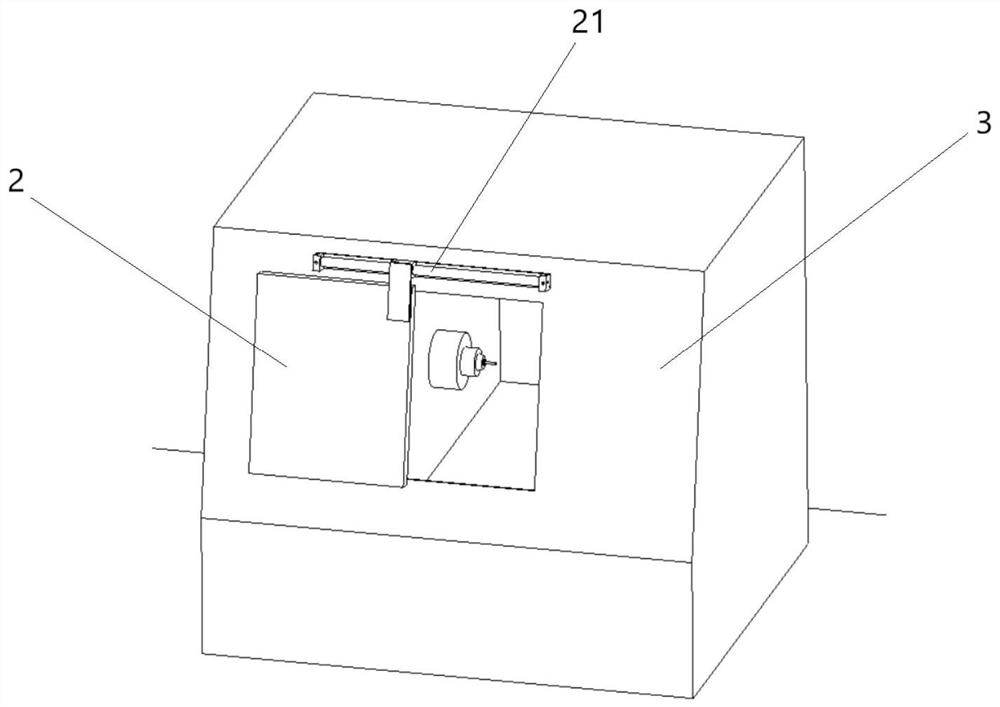

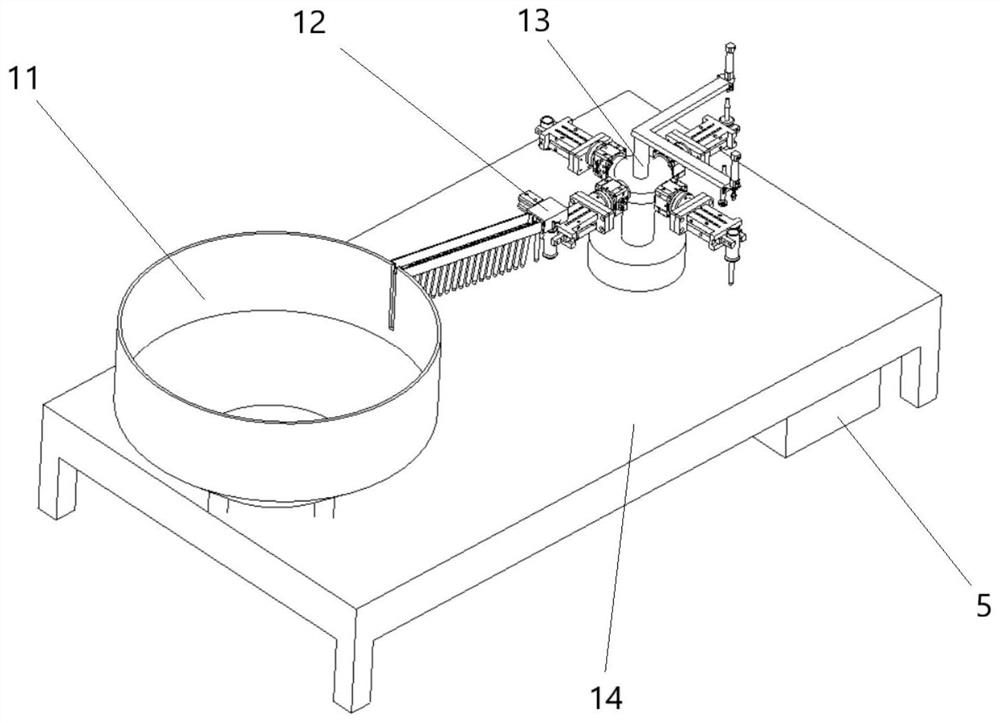

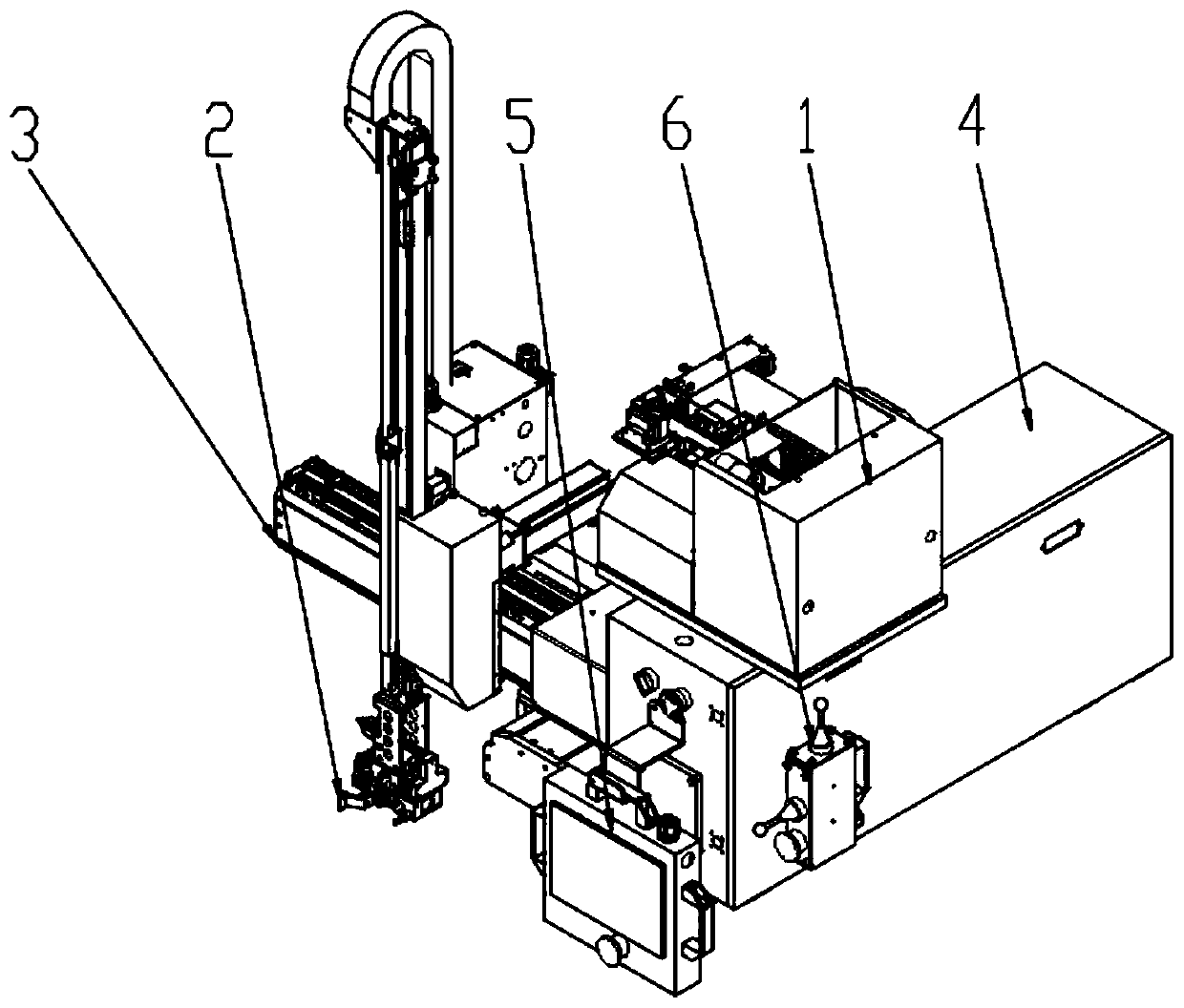

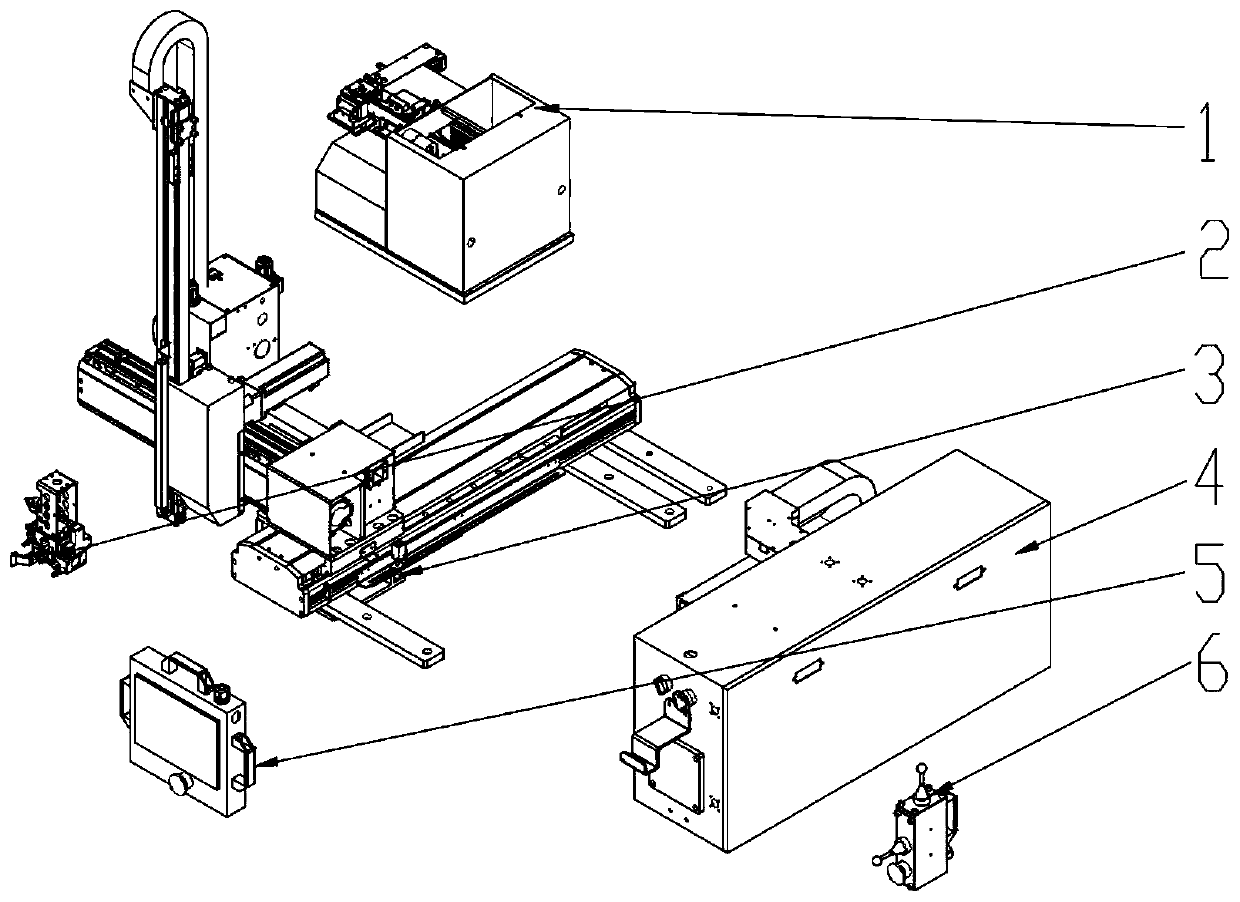

Feeding and discharging device for processing nail products

PendingCN111889711AImprove work efficiencyAvoid the dangers of manual operationAutomatic workpiece supply/removalMetal working apparatusAgricultural engineeringElectrical and Electronics engineering

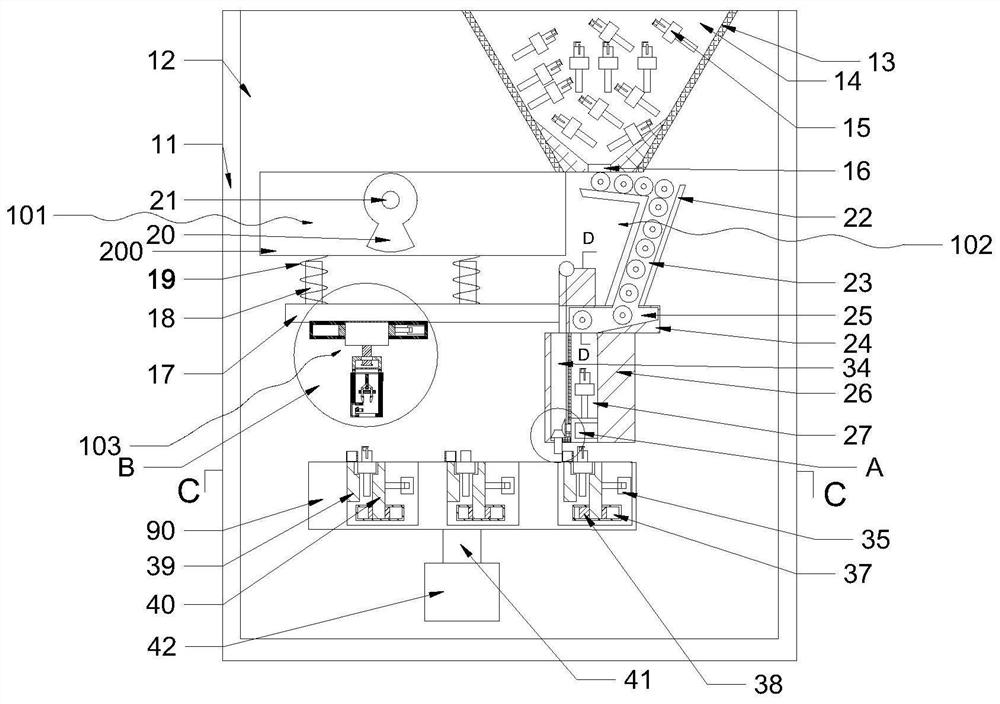

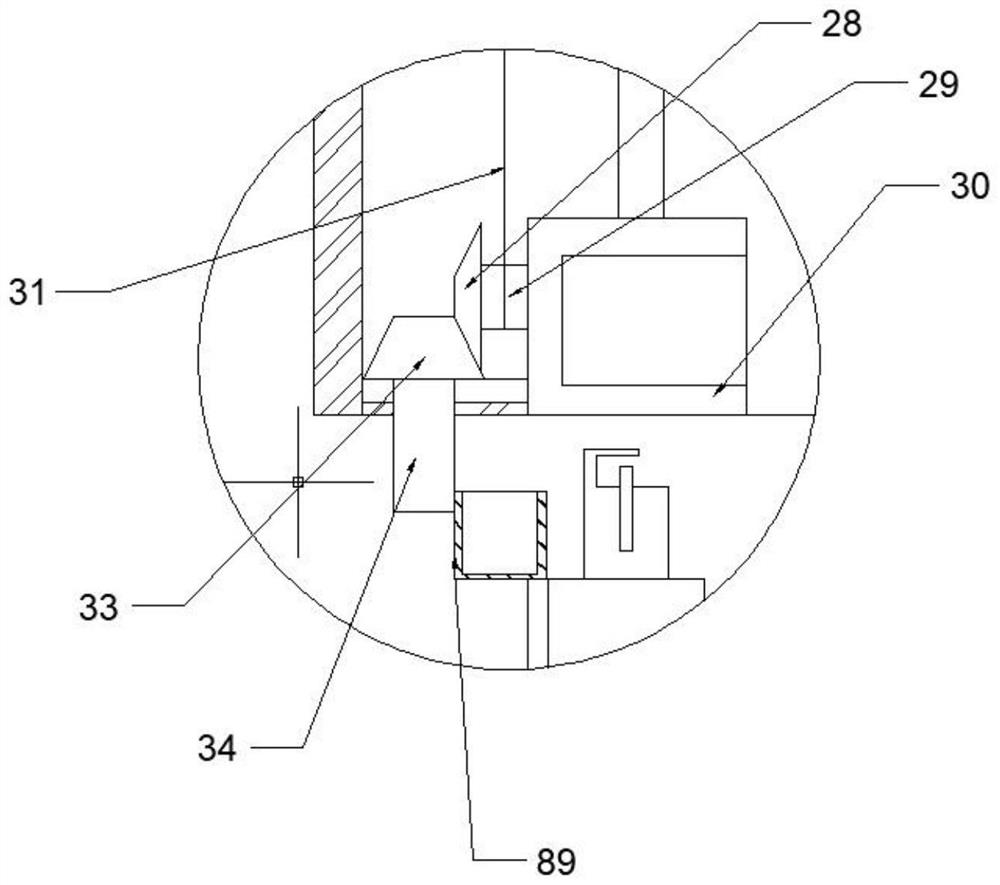

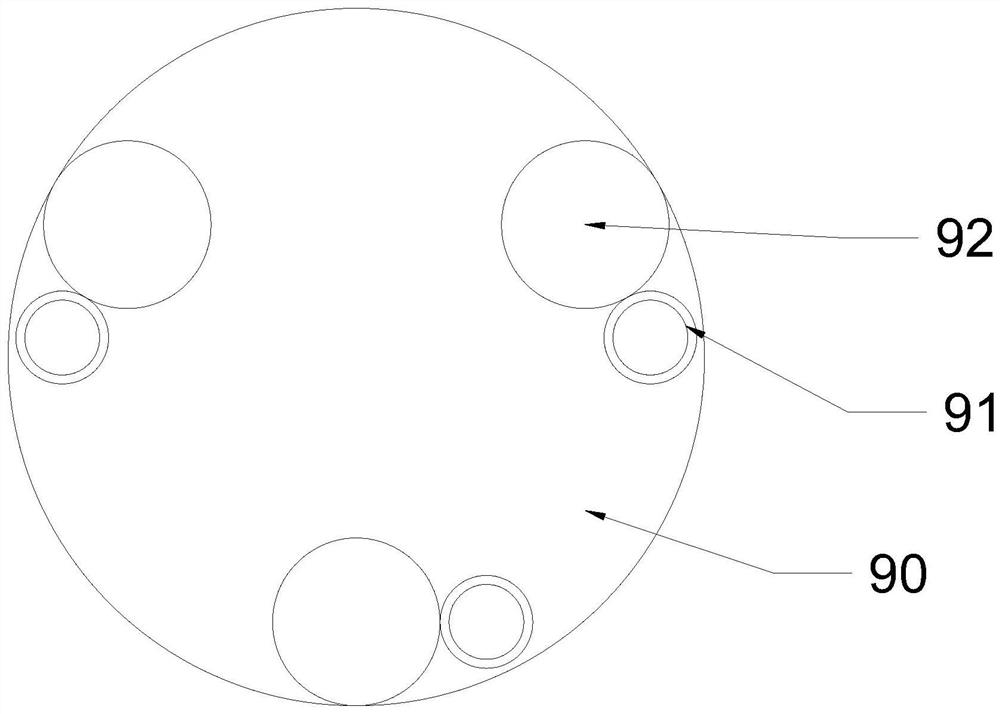

The invention discloses a feeding and discharging device for processing nail products. The feeding and discharging device comprises a feed divider and a mechanical arm, and the feed divider and the mechanical arm are arranged on one side of a processing opening of a processing center; the mechanical arm takes off a finished product from the processing center, grabs a to-be-processed product from the feed divider and sends the product to the processing center; the feed divider comprises a loading vibrating disk, a staggered material distributing mechanism and a lifting material distributing mechanism; the loading vibration disk is used for storing to-be-processed products and guiding the to-be-processed products into the staggered material distributing mechanism; the staggered material distributing mechanism guides the to-be-processed products to a pickup position of the lifting distributing mechanism; and the lifting distributing mechanism conveys the to-be-processed products to the pickup position of the mechanical arm. According to the feeding and discharging device for processing the nail products, to-be-processed nails are placed in the loading vibration disk, the nails are guided into the material distributing device through self-vibration, the mechanical arm takes off finished products from the processing center, takes the to-be-processed nails from the material distributing device and sends the nails to the processing center, the feeding operation and the discharging operation are automatically carried out in the whole process, and the feeding and discharging devicefor processing the nail products is high in working efficiency, safe and reliable.

Owner:深圳市德才科技有限公司

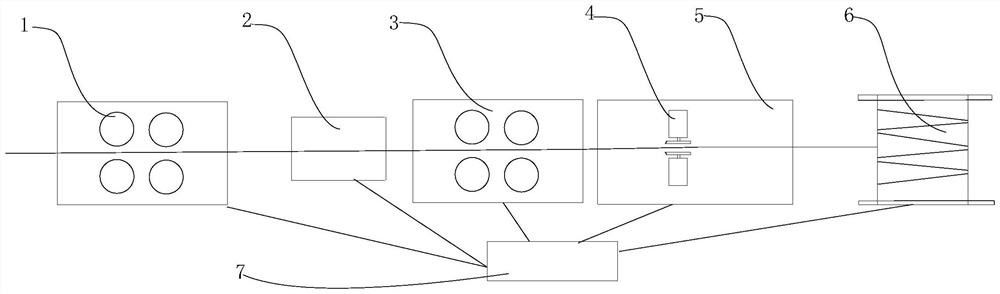

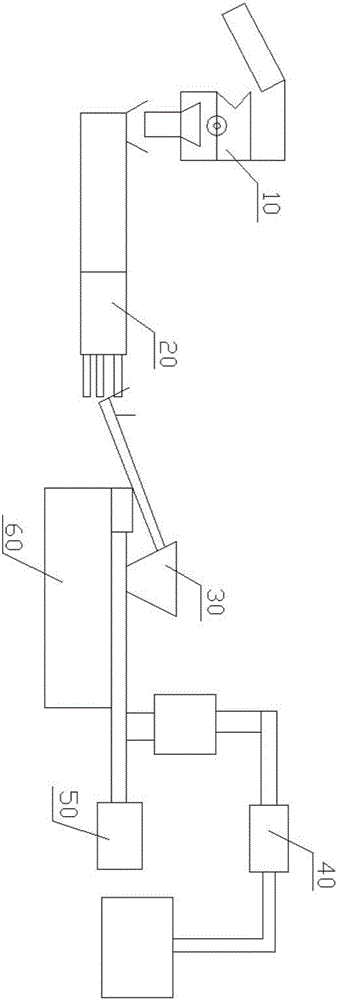

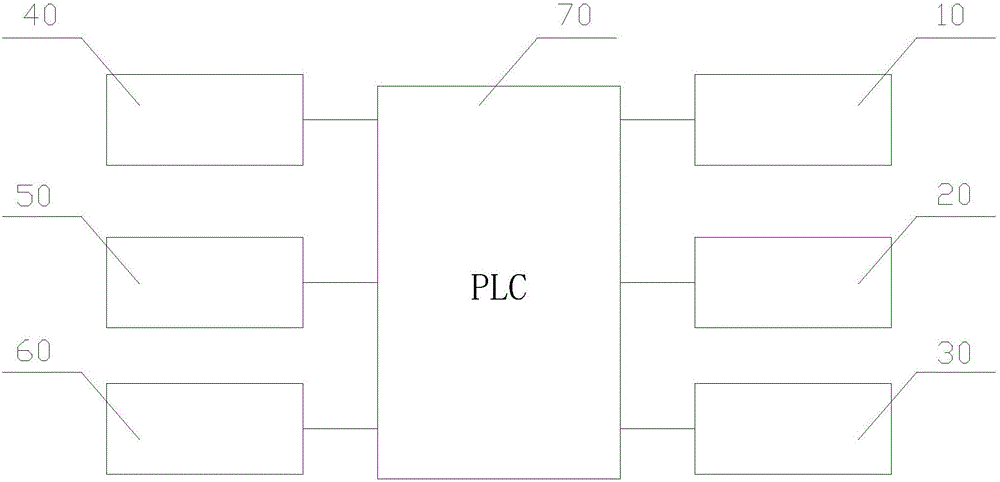

Waste wire arranging and collecting device and method

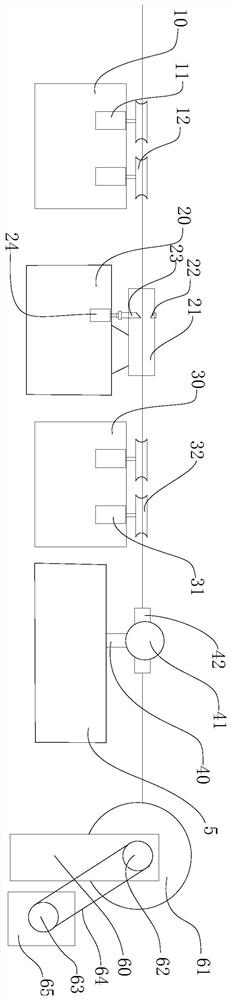

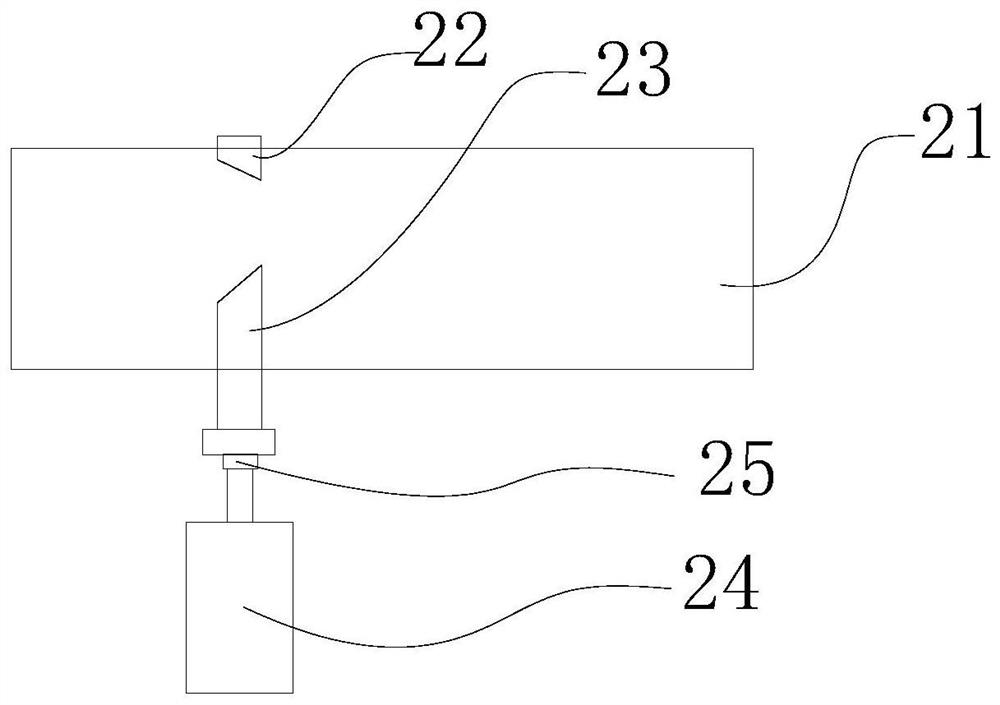

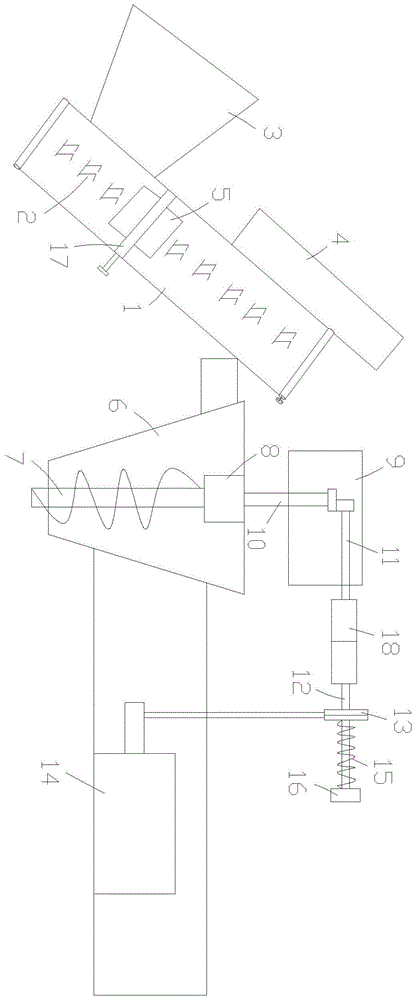

ActiveCN111710483AEasy to operateReduce labor costsBasic electric elementsApparatus for removing/armouring cablesElectrical conductorElectric wire

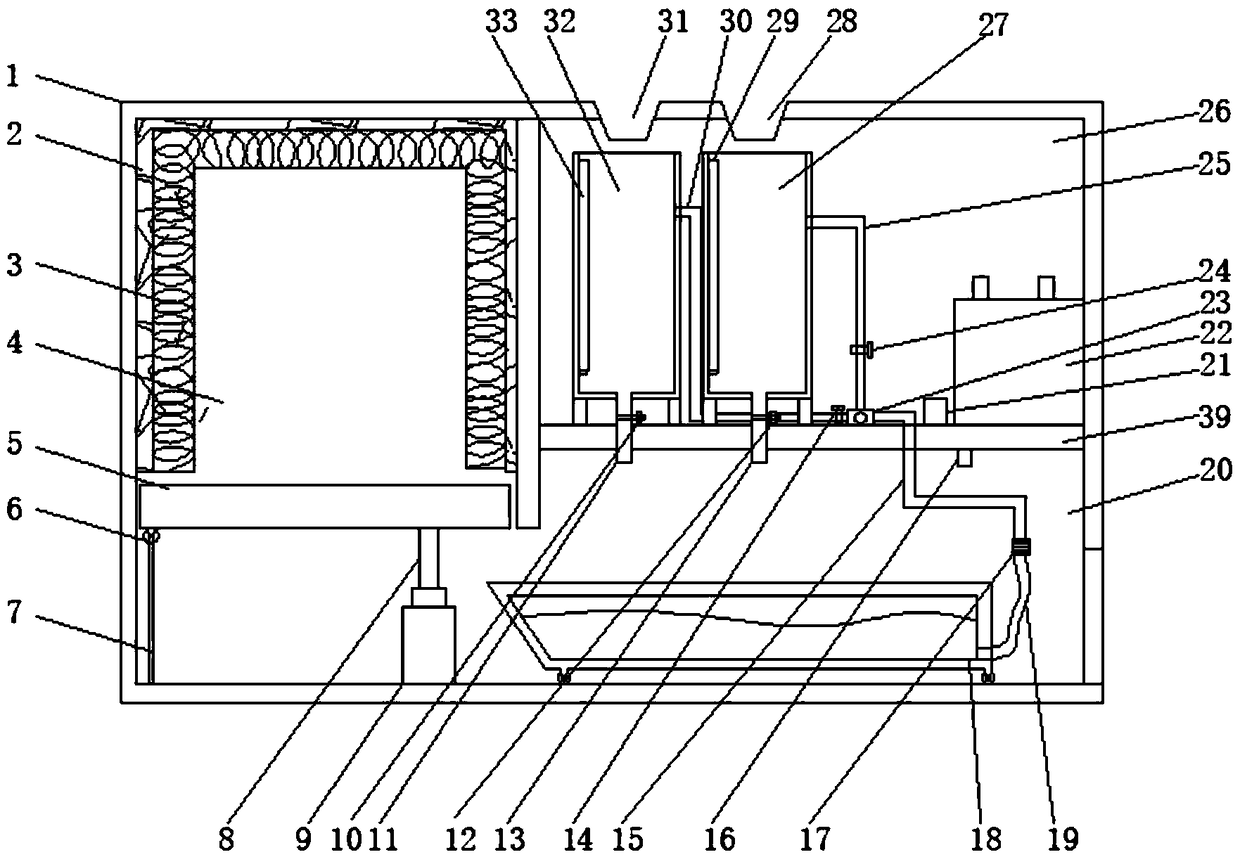

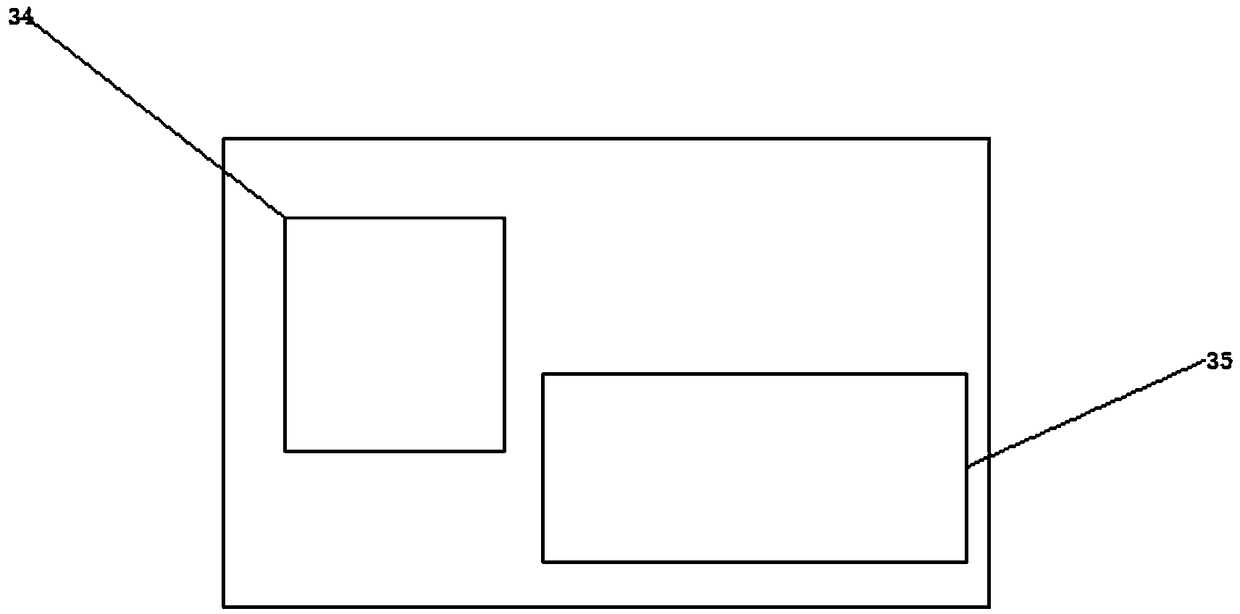

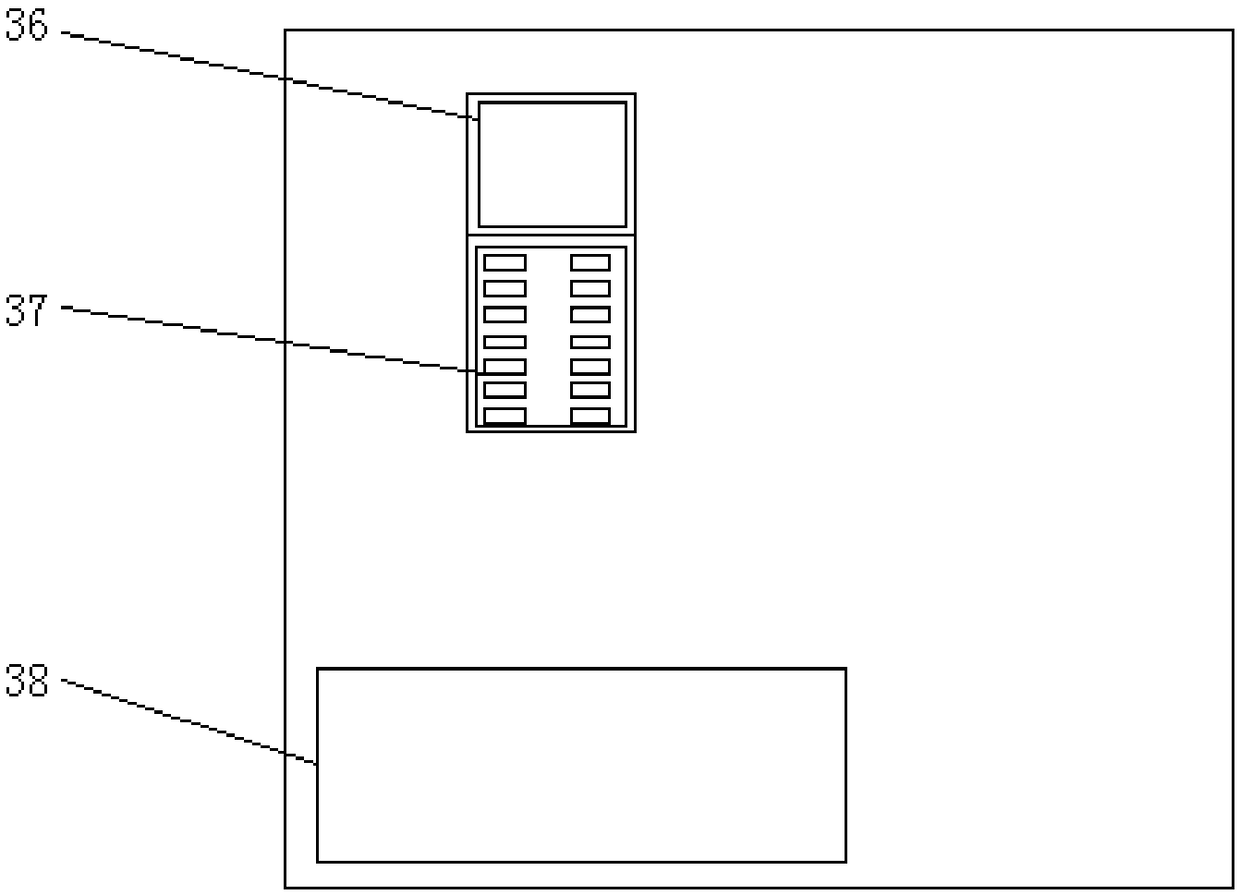

The invention provides a waste wire arranging and collecting device and method. The device comprises an electric wire arranging device, an electric wire breaking device, an electric wire conveying device, an electric wire peeling device, a waste plastic collecting device, an electric wire conductor winding device and a control box. The control box is connected with the electric wire arranging device, the electric wire breaking device, the electric wire conveying device, the electric wire peeling device, the waste plastic collecting device and the electric wire conductor winding device and usedfor supplying power to the devices and controlling the devices. The device is convenient to operate, the whole device can be automatically controlled through the control box. The device is low in labor cost. The wire breaking device and the wire stripping device are adjustable, the corresponding breaking depth and stripping distance can be adjusted according to different types of wires, the wirestripping device is suitable for various types of wire products, the risk of manual operation can be avoided, and the processing capacity of waste wires can be remarkably improved.

Owner:国网湖北省电力有限公司武汉市江夏区供电公司 +2

Ultrasonic flaw detection robot for large spherical tank steel vessel

ActiveCN108680647AAvoid dangerFlexibleAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasoundControl system

The invention discloses an ultrasonic flaw detection robot for a large spherical tank steel vessel. The ultrasonic flaw detection robot comprises a robot body, an image acquisition device, an adsorption device, a flaw detection device and a control system, the robot body comprises a machine body frame and an elastic connection structure, the adsorption device is arranged at the lower part of a machine body, the flaw detection device is arranged at the front part of the machine body, the control system is arranged inside the machine body, the image acquisition device is used for acquiring weldjoint features and transmitting the acquired images to the control system for processing, and the control system receives the images acquired by the image acquisition device and extracts center linesby identifying weld joints on the wall surface of the vessel so as to achieve the function that the robot moves and performs detection according to the center lines. The robot can move to automatically search the weld joints in the wall surface, can perform flaw detection on the weld joints at the same time and can replace manpower to perform high-position operation, and therefore the risk of manual operation is avoided, the robot is flexible in action on the metal wall surface, and the working efficiency is high.

Owner:CHINA JILIANG UNIV

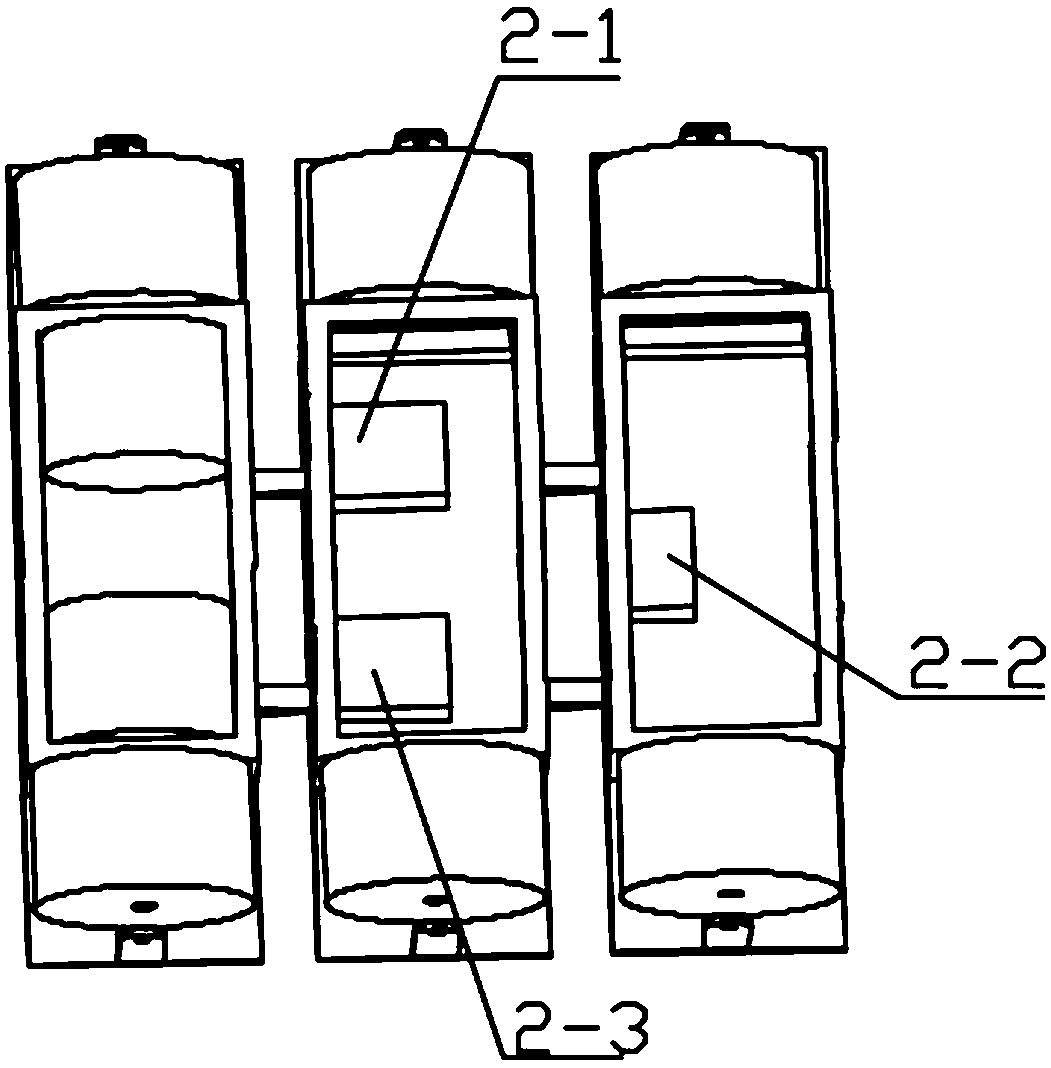

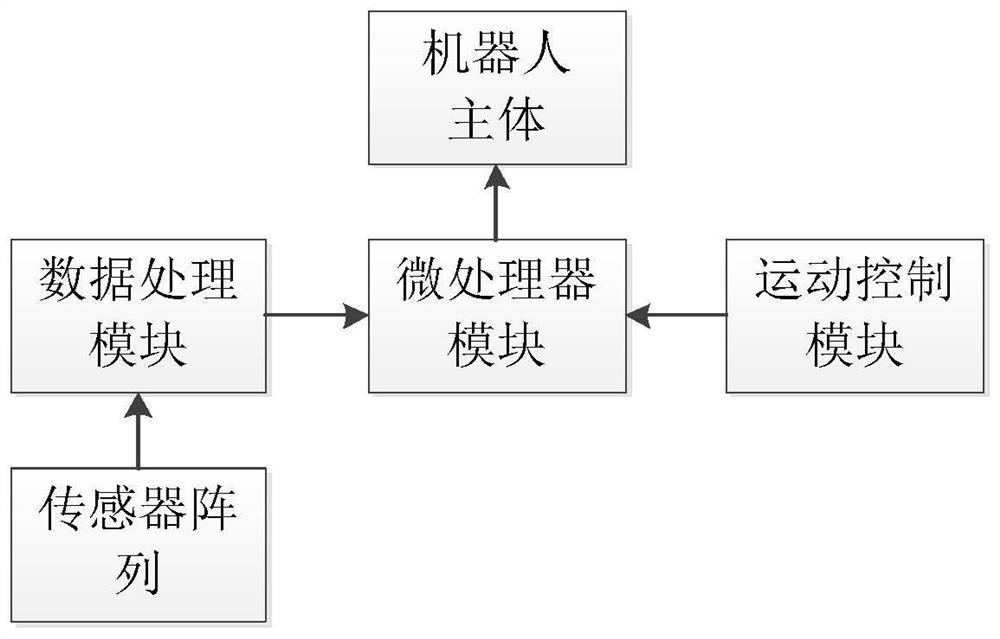

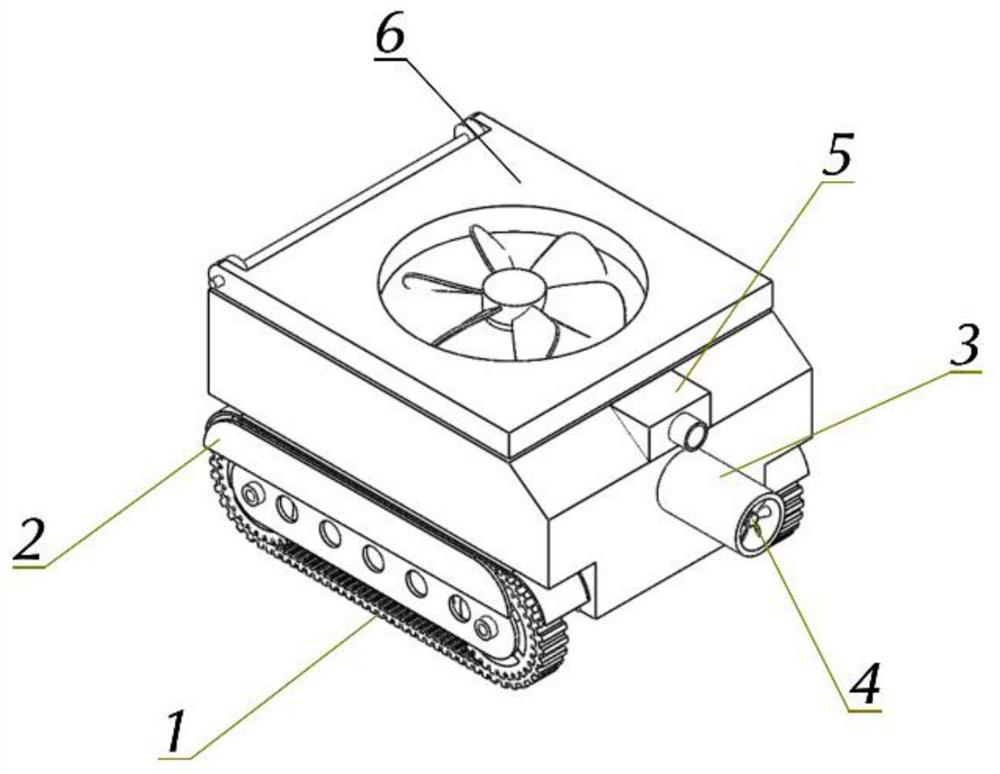

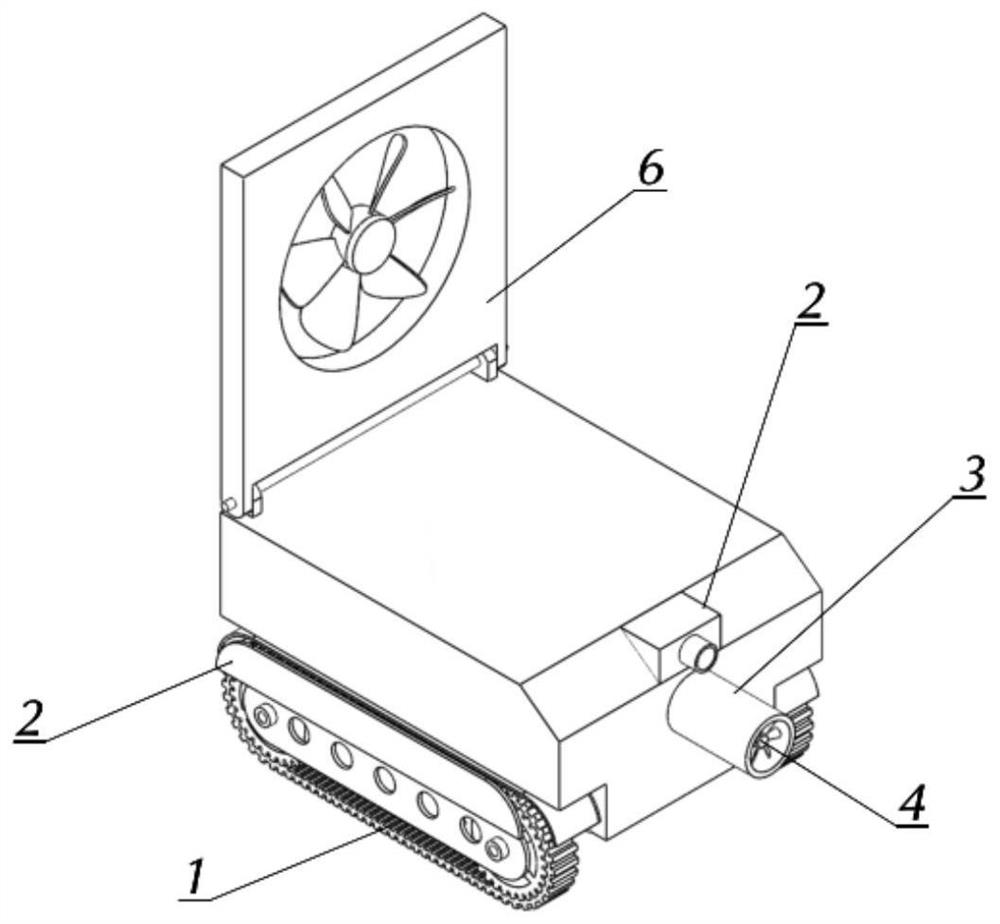

Bionic robot for tracking and diluting underground gas

InactiveCN113371084AHigh precisionAvoid the dangers of manual operationFuel testingTunnel/mines ventillationProcess engineeringMechanical engineering

The invention discloses a bionic robot for tracking and diluting underground gas. The robot comprises a robot body, a crawler-type driving device, a friction protection structure, a supporting structure, a gas collecting and detecting device, a power module, a microprocessor module, a wireless sending module, a camera and a folding fan device. According to the bionic robot for tracking and diluting underground gas, firstly, the robot can analyze concentration information collected by the gas collecting device by using a drosophila learning strategy-based odor source positioning algorithm (CNN-LSTM-FOA) equipped on a microprocessor of the robot, so tracking of the gas is realized, and leaked smell source positioning work can be carried out in time; secondly, the robot is provided with an intelligent folding fan, after the robot is positioned to a gas leakage place, the intelligent fan is switched into a working mode, the fan can increase the flow speed of underground air, the concentration of gas in the gas leakage space is diluted to a certain extent, and more time is won for external rescue work.

Owner:CHINA UNIV OF MINING & TECH

Automatic die-casting die cleaning device

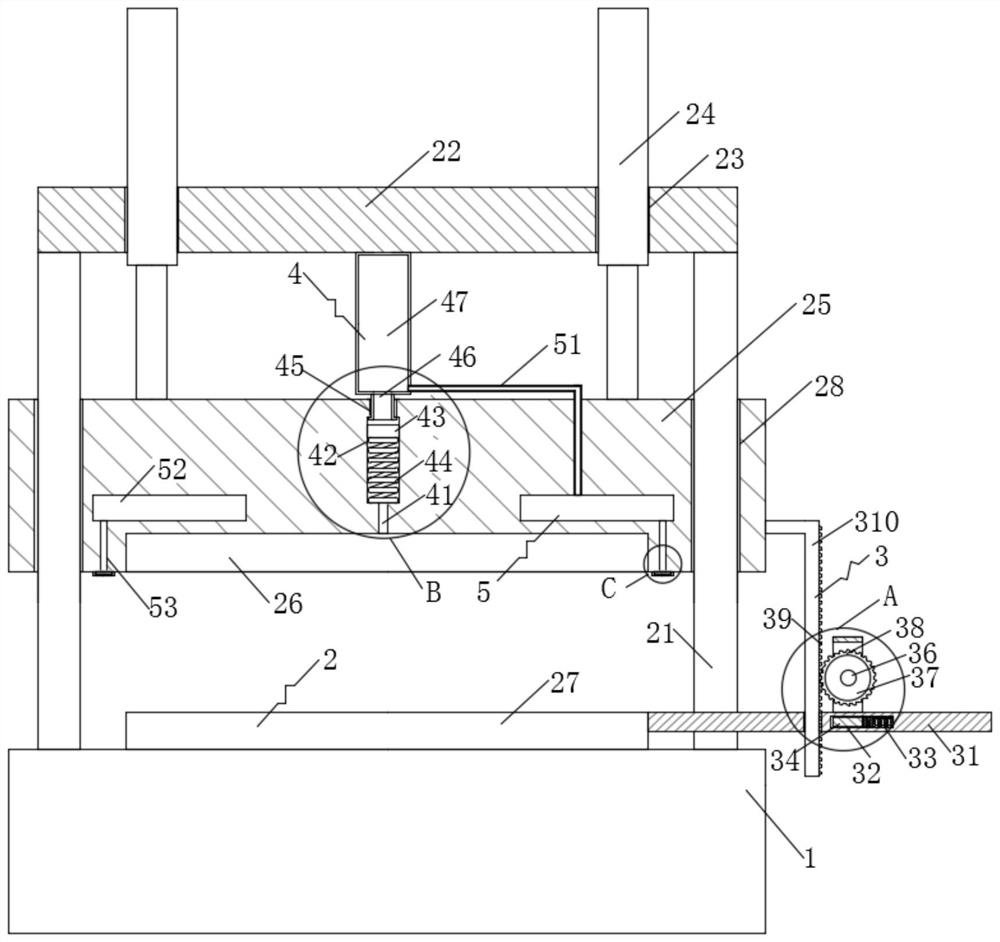

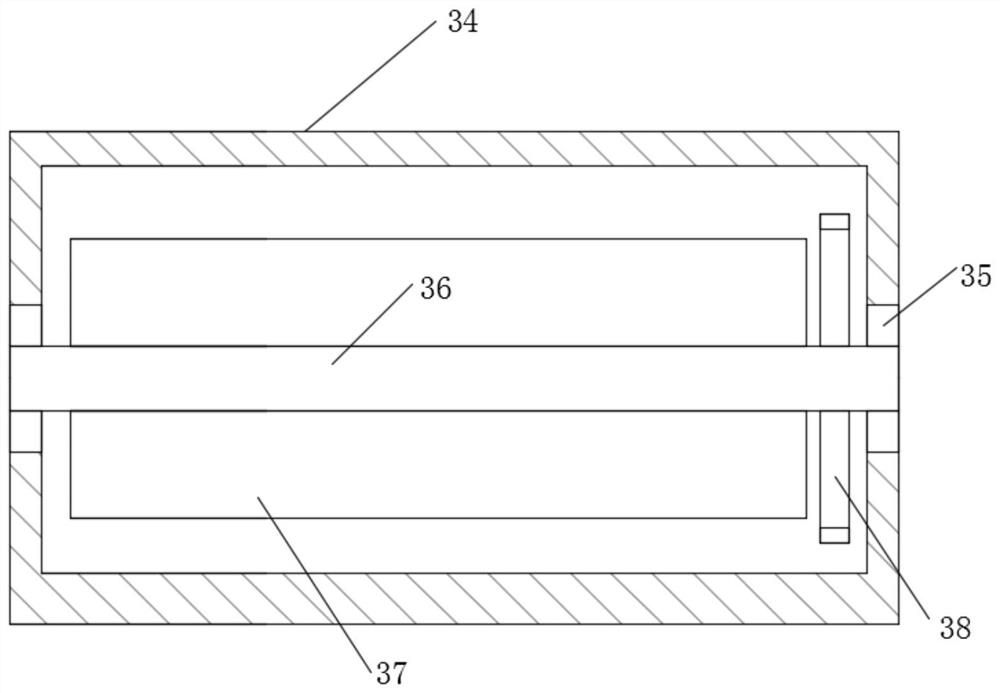

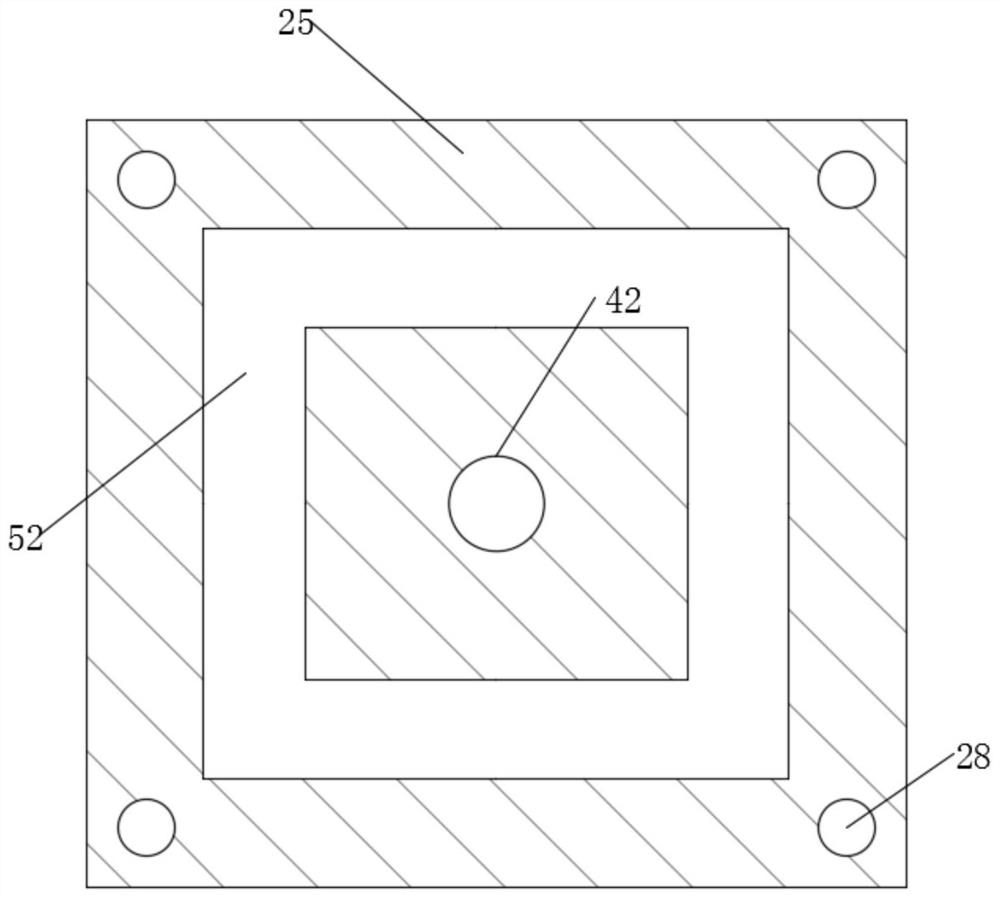

PendingCN114192645AAvoid the dangers of manual operationQuality assuranceCleaning using gasesHydraulic cylinderGear drive

The invention relates to the technical field of die-casting dies, in particular to an automatic die-casting die cleaning device which comprises a base, a die-casting mechanism is arranged at the upper end of the base, a conveying mechanism is arranged on one side of the die-casting mechanism, a discharging mechanism is arranged in the die-casting mechanism, and a cleaning mechanism is arranged in the discharging mechanism. The die-casting mechanism comprises four fixing columns, the four fixing columns are fixedly connected to the four corners of the upper surface of the base correspondingly, the upper ends of the four fixing columns are fixedly connected with the same top plate, through holes are formed in the four corners of the lower surface of the top plate, a hydraulic cylinder pushes a pressing plate to move downwards, the pressing plate drives an L-shaped rod to move downwards when moving downwards, and the L-shaped rod drives a rack to move; when the rack moves, the one-way gear is driven to rotate, the one-way gear drives the rotating shaft to rotate, the rotating shaft drives the rubber barrel to rotate, then the rubber barrel pushes materials on the fixing plate to move between the die plate and the die groove, die casting of the materials is completed, and danger existing in manual operation is avoided.

Owner:JIANGSU COLLEGE OF INFORMATION TECH

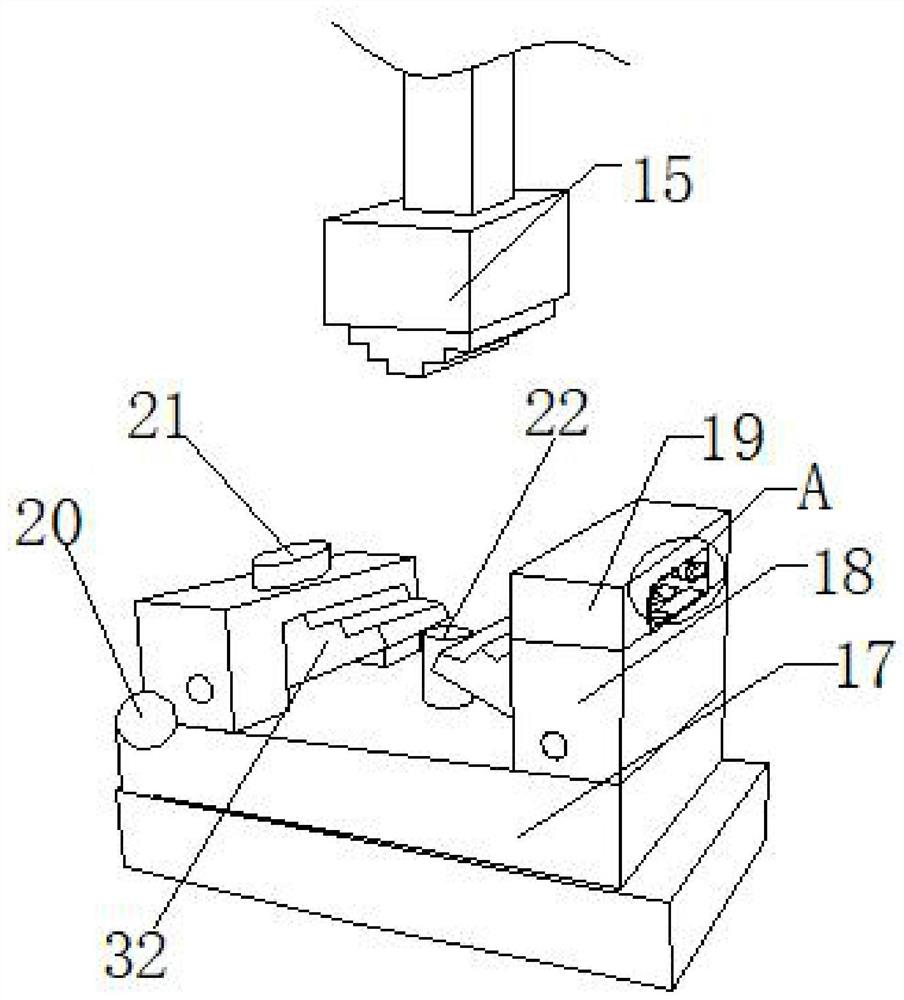

Automatic discharging mechanism for semi-coiled circle bending part

InactiveCN105396975AEasy to manufactureEasy loading and unloadingStripping-off devicesEngineeringCushion

The invention discloses an automatic discharging mechanism for a semi-coiled circle bending part. The automatic discharging mechanism is characterized by comprising a male die holder, a male die, a lower cushion board and a lower die holder, the lower cushion board is arranged above the lower die holder, the male die is fixedly arranged below the male die holder, an ejection piece block is arranged above the lower cushion board, a workpiece is arranged at the upper portion of the ejection piece block, the top end of the workpiece is tightly attached to the bottom of the male die, a cushion block is arranged at the upper portion of the lower cushion board, a swing block is arranged above the cushion block and provided with a pin, a spring lifting pin is arranged on the lower die holder, and the top end of the spring lifting pin makes contact with the bottom of the swing block. The automatic discharging mechanism is easy to move and obtain, and the workpiece is convenient to manufacture, assemble and disassemble; meanwhile the pushing stroke can be controlled, danger caused by manual operation is avoided, and work efficiency is improved; and multiple push rod sets are arranged on a linkage inclined wedge, so that the requirements of workpieces of different sizes are met.

Owner:SUZHOU YUANSHUO PRECISION MOLD

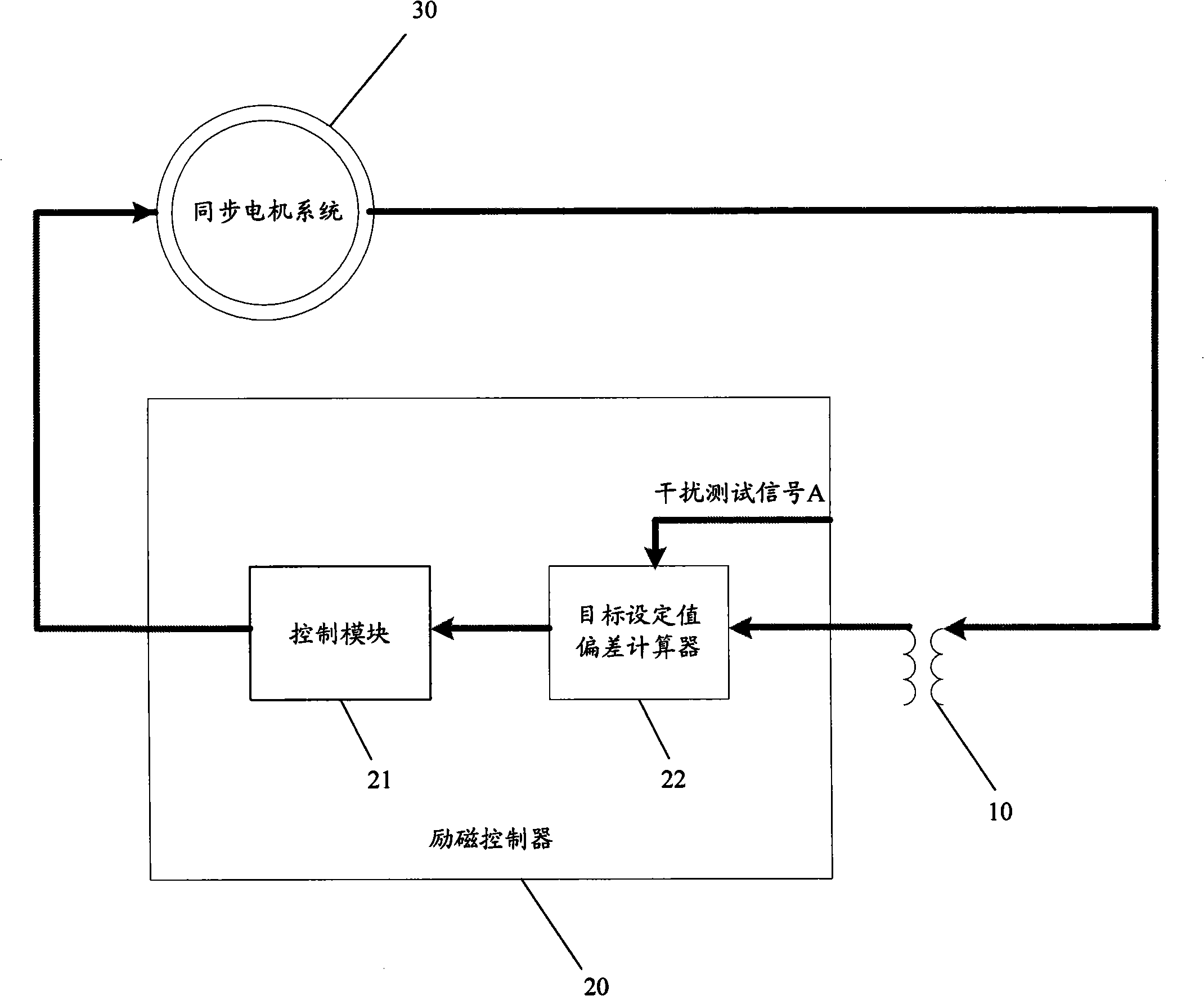

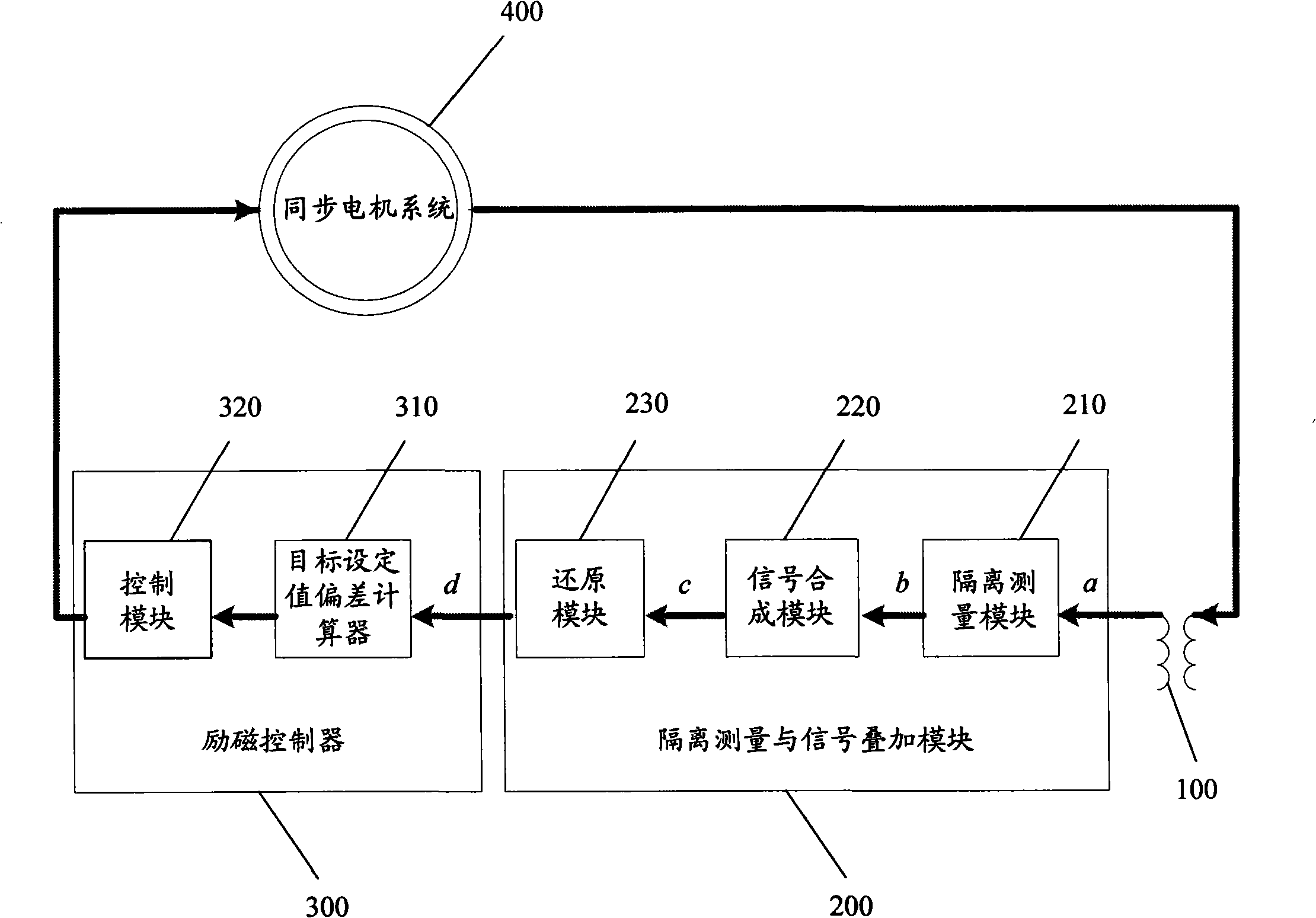

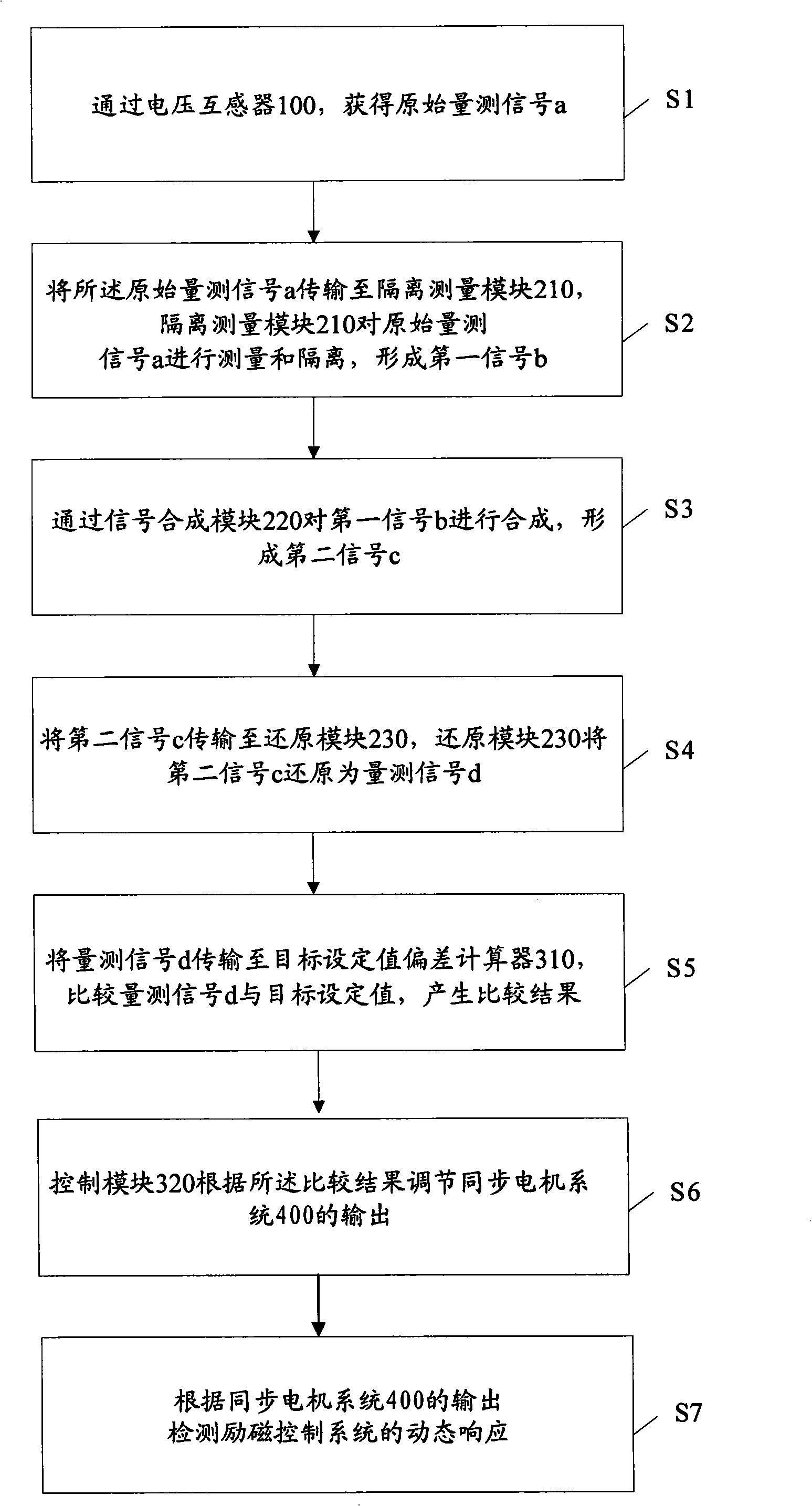

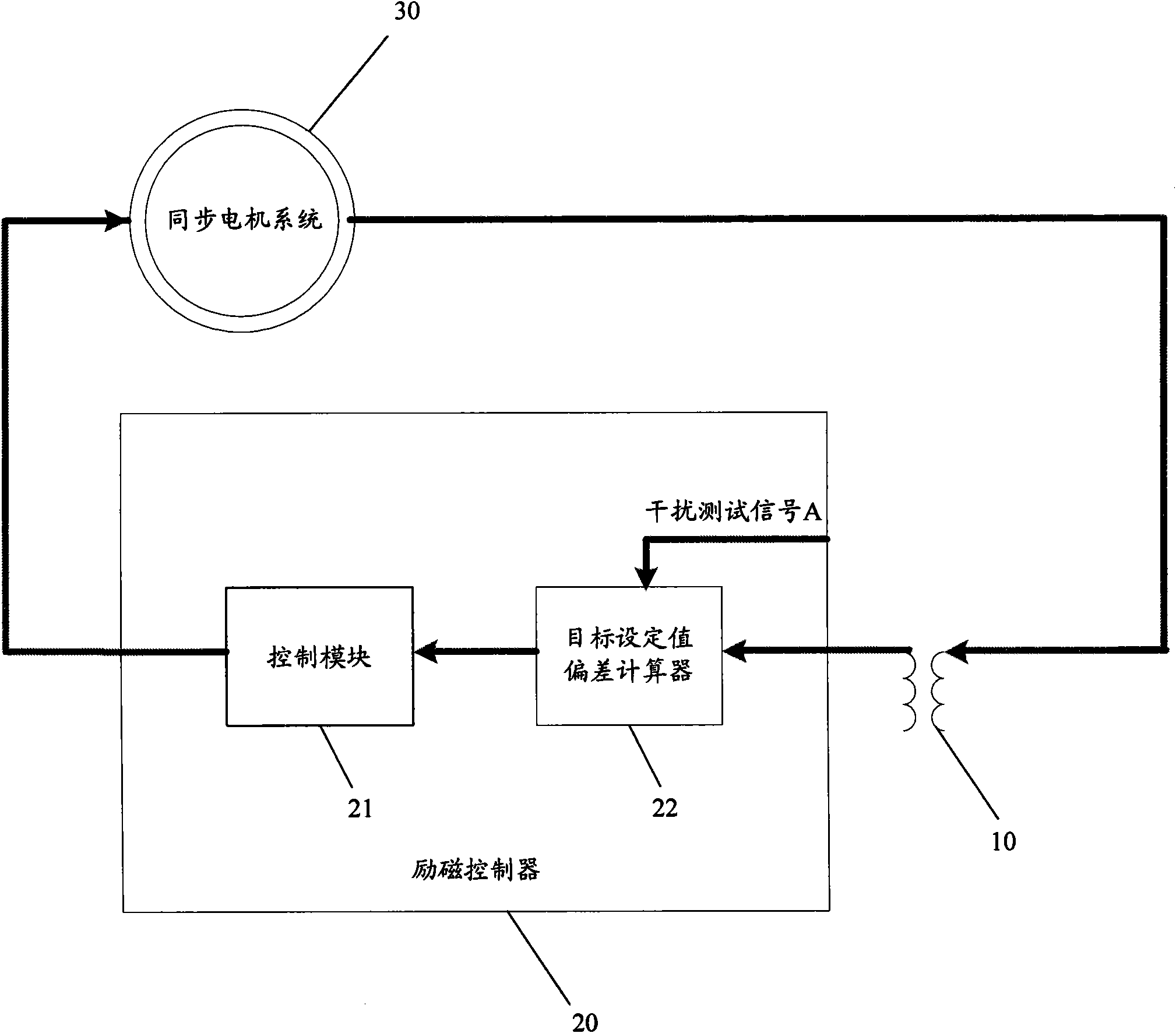

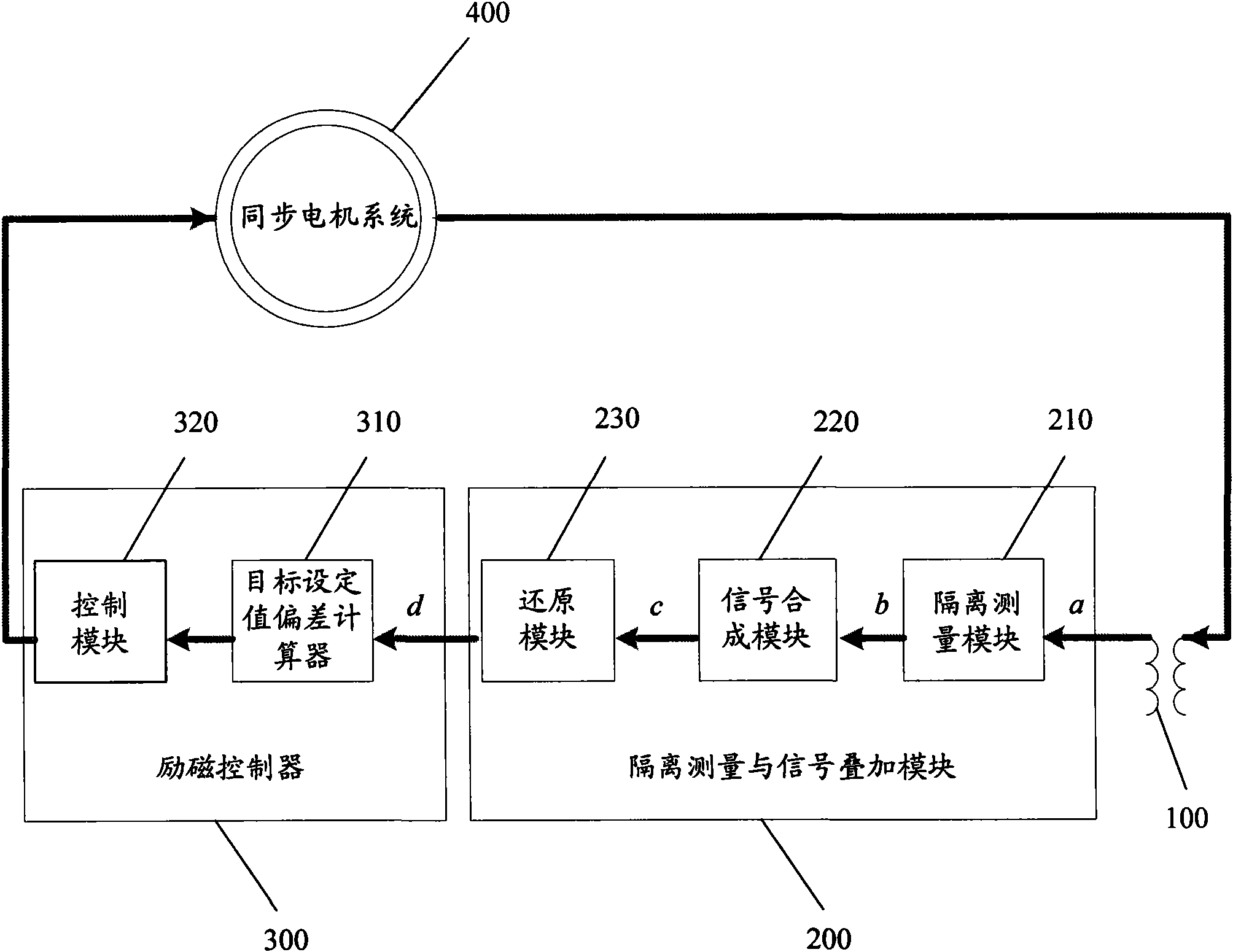

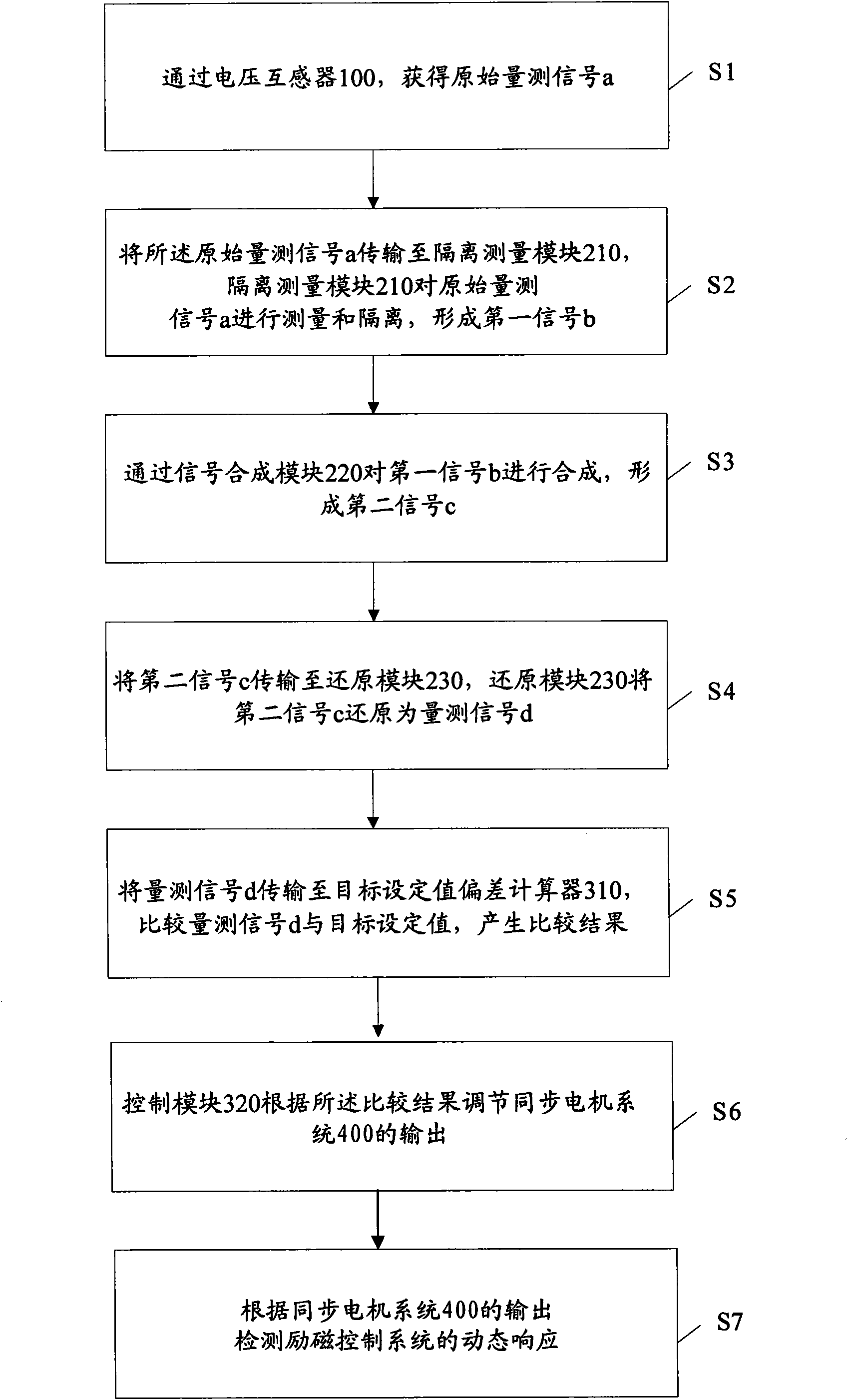

On-line detection method for dynamic response of excitation control system

ActiveCN101833025BDoes not affect running statusReduce dependenceElectronic commutation motor controlCurrent/voltage measurementSynchronous motorTransformer

The invention discloses an on-line detection method for dynamic response of an excitation control system. The method comprises the following steps of: acquiring primary measurement signals by a voltage transformer; transmitting the primary measurement signals to an isolation measurement and signal superposition module, and synthesizing the primary measurement signals by the isolation measurement and signal superposition module to acquire measurement signals; transmitting the measurement signals to an excitation controller, and comparing the measurement signals with a target set value through the excitation controller to produce a comparison result; adjusting the output of a synchronous motor system according to the comparison result through the excitation controller; and detecting the dynamic response of the excitation control system according to the output of the synchronous motor system.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Chinese yam slicing machine and Chinese yam slicing mode

PendingCN112223390AImprove slicing efficiencyAvoid the dangers of manual operationMetal working apparatusProcess engineeringIndustrial engineering

The invention discloses a Chinese yam slicing machine and a slicing method. The slicing machine comprises a rack as well as a storage box, a feeding mechanism, a guide chute, a pushing mechanism and aslicing mechanism which are mounted on the rack, wherein the feeding mechanism is arranged at the outlet of the storage box, and the feeding mechanism communicates with the guide chute and feeds Chinese yams sliding out of the outlet into the guide chute; the Chinese yams on the guide chute are pushed to the slicing mechanism at one end of the guide chute by the pushing mechanism, and are slicedby the slicing mechanism. Under action of the feeding mechanism and the pushing mechanism, the Chinese yams can be automatically pushed to the slicing mechanism one by one, so that risk caused by manual operation is avoided; and the pushing mechanism and the slicing mechanism can effectively control the Chinese yam slicing speed and the slicing thickness in a matched mode, so that the Chinese yamslicing efficiency is greatly improved, and Chinese yam slices of different specifications can be obtained.

Owner:XIAMEN UNIV OF TECH

Voltage-resistant detection device and heater production line

InactiveCN109164366AAvoid misjudgmentAvoid the dangers of manual operationElectrical testingProduction lineEngineering

The invention provides a voltage-resistant detection device and a heater production line. The voltage-resistant detection device comprises a tool plate and a voltage-resistant detection jack-up assembly, wherein the tool plate is used for placing a heater, the heater is electrically connected with the tool plate, the voltage-resistant detection jack-up assembly comprises a voltage-resistant detection jack-up plate and a voltage-resistant detection conductive assembly, the voltage-resistant detection conductive assembly is arranged on the voltage-resistant detection jack-up plate and is provided with a third position and a fourth position, the third position is in contact with the tool plate and is conductively connected with the tool plate, the fourth position is separated from the tool plate, the voltage-resistant detection jack-up plate is movably arranged along a vertical direction, the voltage-resistant detection conductive assembly is driven to move the third position by the voltage-resistant detection jack-up plate during voltage-resistant detection on the heater, a predetermined voltage is applied to the heater, the tool plate also comprises a switch device, and the switch device is used for detecting a current in the heater and is switched on when the current is detected to exceed the predetermined voltage. By the voltage-resistant detection device, the problem of relatively low production efficiency of a PTC heater in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

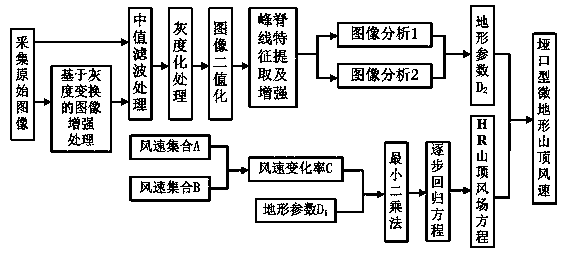

Bealock type microtopography mountain top wind speed intelligent measurement method

PendingCN110765408AAvoid limitationsLess manpower and material resourcesImage enhancementData processing applicationsEngineeringAtmospheric sciences

The invention discloses a bealock type microtopography mountain top wind speed intelligent measurement method comprising the following steps: collecting an original image of a bealock type microtopography with a pre-measured wind speed, and carrying out intelligent image identification processing so as to obtain topographic parameters of the bealock type microtopography; combining the existing wind speed value data of the bealock type microtopography area with topographic parameters of the bealock type microtopography where the power transmission line is located, and fitting an H / R mountain top wind field equation; and combining the topographic parameters obtained through image recognition with a bealock type micro-topography mountain top wind field equation to obtain the bealock type micro-topography mountain top wind speed for establishing the power transmission line. The method is convenient to use and low in cost, necessary data can be provided for safety design when the power transmission line passes through the bealock type microtopography, and safe and stable operation of the power transmission line is effectively guaranteed.

Owner:国网宁夏电力有限公司经济技术研究院 +1

An automatic keel installation equipment for ceiling decoration

The invention relates to decoration equipment, in particular to an automatic keel installation equipment for ceiling decoration. The technical problem to be solved is to provide an automatic keel installation device for ceiling decoration that does not need manual hand-held screwdrivers and screws to free hands, has high speed, high efficiency, and high degree of automation. The technical solution of the present invention is: an automatic keel installation equipment for ceiling decoration, including first guide rails, the number of the first guide rails is at least two groups, and the first guide rails are equipped with first guide sleeves, the first guide sleeves There is a mounting plate between them; a support frame is set on the other side of the mounting plate. The present invention uses the electric slide rail to drive the automatic screwdriver to move upwards, so that the automatic screwdriver does not need to be manually held, and the supply of the screw by the belt transmission component and the clamping frame can make the screw-in process do not need manual participation, liberating It saves manpower and avoids the danger of manual operation.

Owner:安徽新辉达建设工程有限公司

Intelligent control environment-friendly waste plastic energy-saving regeneration preparation system

InactiveCN104875296BReduce manufacturing costSmall transmission powerDispersed particle filtrationPlastic recyclingMetal impuritiesEngineering

Owner:安徽省坤璞塑料机械有限公司

On-line detection method for dynamic response of excitation control system

ActiveCN101833025ADoes not affect running statusReduce dependenceElectronic commutation motor controlCurrent/voltage measurementSynchronous motorControl system

The invention discloses an on-line detection method for dynamic response of an excitation control system. The method comprises the following steps of: acquiring primary measurement signals by a voltage transformer; transmitting the primary measurement signals to an isolation measurement and signal superposition module, and synthesizing the primary measurement signals by the isolation measurement and signal superposition module to acquire measurement signals; transmitting the measurement signals to an excitation controller, and comparing the measurement signals with a target set value through the excitation controller to produce a comparison result; adjusting the output of a synchronous motor system according to the comparison result through the excitation controller; and detecting the dynamic response of the excitation control system according to the output of the synchronous motor system.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Conveying device for plate conveying of punching machine

InactiveCN112475085AImprove practicalityImprove stabilityMetal-working feeding devicesPositioning devicesStructural engineeringStamping press

The invention discloses a conveying device for plate conveying of a punching machine. The conveying device comprises a fixed table, a first guide rail plate and a second guide rail plate are fixedly installed between the fixed table and a first punching machine, a first guide rail plate and a second guide rail plate are fixedly installed between the first punching machine and a second punching machine, the first guide rail plate and the second guide rail plate are each provided with a plurality of servo sliding rails, a first sliding press-fit block is movably installed on the first guide railplate through the servo sliding rails, a second sliding press-fit block is movably installed on the second guide rail plate through the servo sliding rails, a plurality of elastic bases are arrangedat the bottom of the first sliding press-fit block, a plurality of elastic bases are arranged at the top of the second sliding press-fit block, bearing pedestals are fixedly installed on the elastic bases, conveying rollers are movably installed on the bearing pedestals, and a cam is fixedly installed at one end of each of the conveying rollers. According to the conveying device, machines are additionally installed on original equipment, the cost is low, linkage is generated between pieces of equipment, the production efficiency is improved, and the safety is improved.

Owner:陆天祥

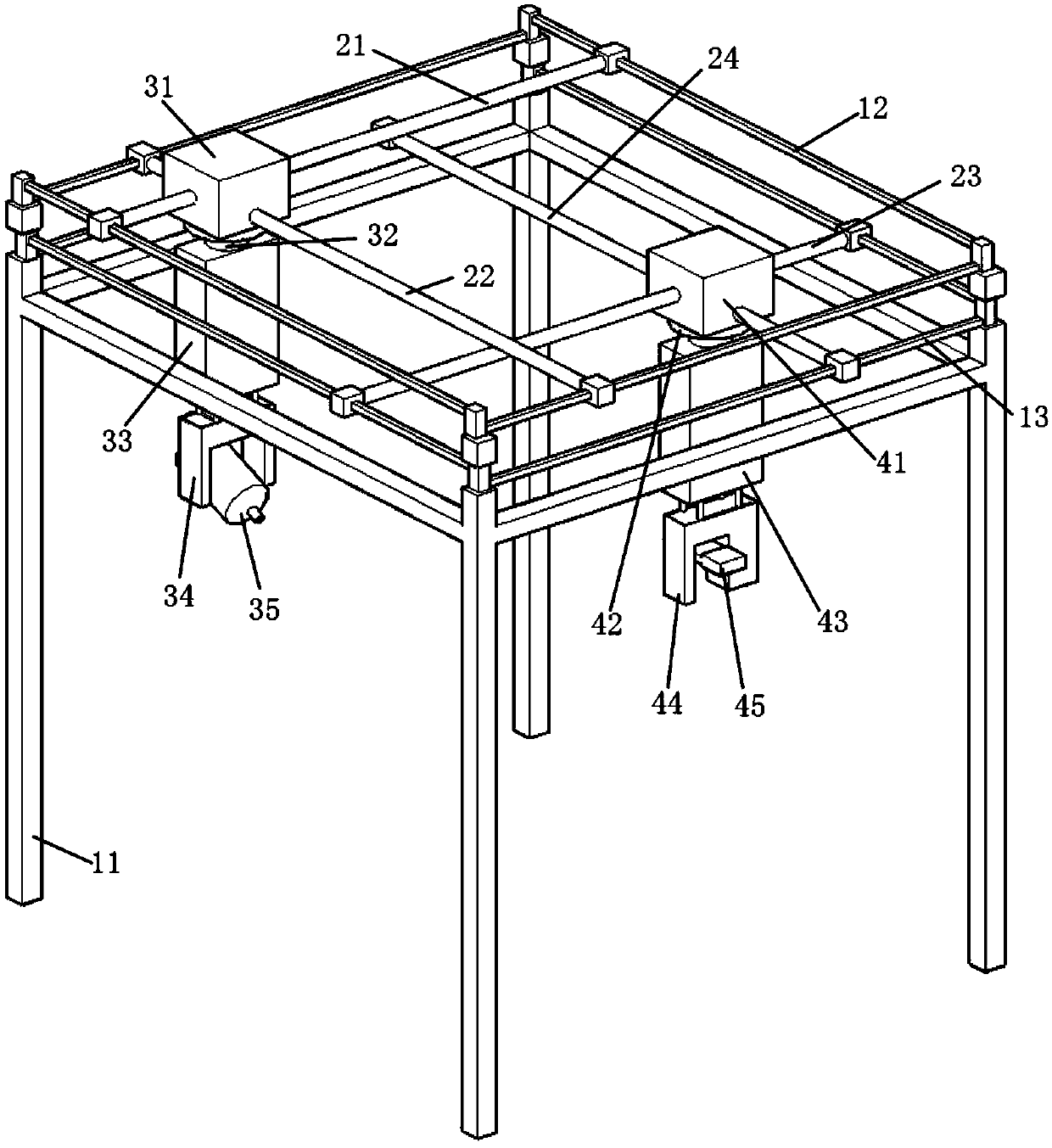

Interior decoration paint spraying and brushing integrated device

InactiveCN107654049AEasy to automateAvoid the dangers of manual operationBuilding constructionsVertical projectionEngineering

The invention provides an interior decoration paint spraying and brushing integrated device. The interior decoration paint spraying and brushing integrated device comprises a mounting rack. A first square frame and a second square frame are fixed to the top of the mounting rack in a stacked mode, the two ends of each of a first transverse translation rod and a first longitudinal translation rod are movably fixed to the first square frame, the first transverse translation rod and the first longitudinal translation rod are located on non-same planes, the two ends of each of a second transverse translation rod and a second longitudinal translation rod are movably fixed to the second square frame, and the second transverse translation rod and the second longitudinal translation rod are locatedon non-same planes; and the first transverse translation rod and the first longitudinal translation rod penetrate through a first translation block in a cross staggered mode on a vertical projection,and the second transverse translation rod and the second longitudinal translation rod penetrate through a second translation block in a cross staggered mode on a vertical projection. According to theinterior decoration paint spraying and brushing integrated device, through the installation structural arrangement of an injector and a hairbrush, the injector and the hairbrush are erected and installed in a room when decoration is conducted, paint spraying and paint brushing operation of the high position is convenient to achieve so that paint spraying and paint brushing operation can be easilycompleted, dangers brought by manual operation are avoided, and automated operation is convenient.

Owner:夏德银

An ultrasonic flaw detection robot for steel containers of large spherical tanks

ActiveCN108680647BAvoid the dangers of manual operationFlexibleAnalysing solids using sonic/ultrasonic/infrasonic wavesControl systemStructural engineering

Owner:CHINA JILIANG UNIV

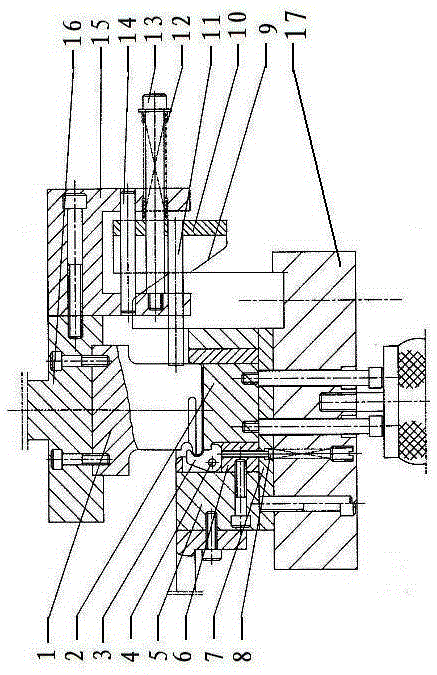

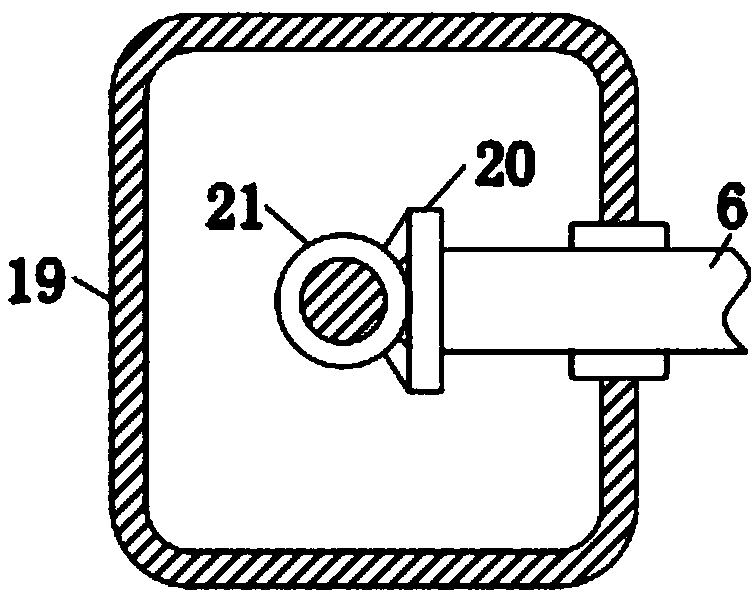

Threaded self-locking quick release device

A threaded self-locking quick release device capable of simulating falling from a broken rope, not affected by external power outages, capable of remote electric control operation, simple in structure, low in cost, convenient in operation, safe and reliable, with a vertical cavity at the bottom of the lock body , the lock head is inserted into the vertical cavity, and the middle part of the lock body is provided with a lower radial through hole. The positioning pin is positioned, and the inner end of the locking block is provided with a protrusion; the upper part of the lock body is provided with an upper radial through hole, and a screw drive shaft is inserted in the upper radial through hole, and a sliding bearing is installed on the screw drive shaft. The two ends of the shaft are provided with positive and negative trapezoidal threads and nuts, and the right end of the screw drive shaft is equipped with a driving wheel and a baffle II; both sides of the lock body are equipped with a fork locking arm, and the fork locking arm The bottom is hinged on the lock body, the forks of the two locking arms of the shift fork are respectively inserted into the protruding cylinders on the front and rear sides of the two nuts, and the inner side of the middle part of the locking arms of the shift fork is provided with a protruding top platform.

Owner:锦州市特种设备监督检验所

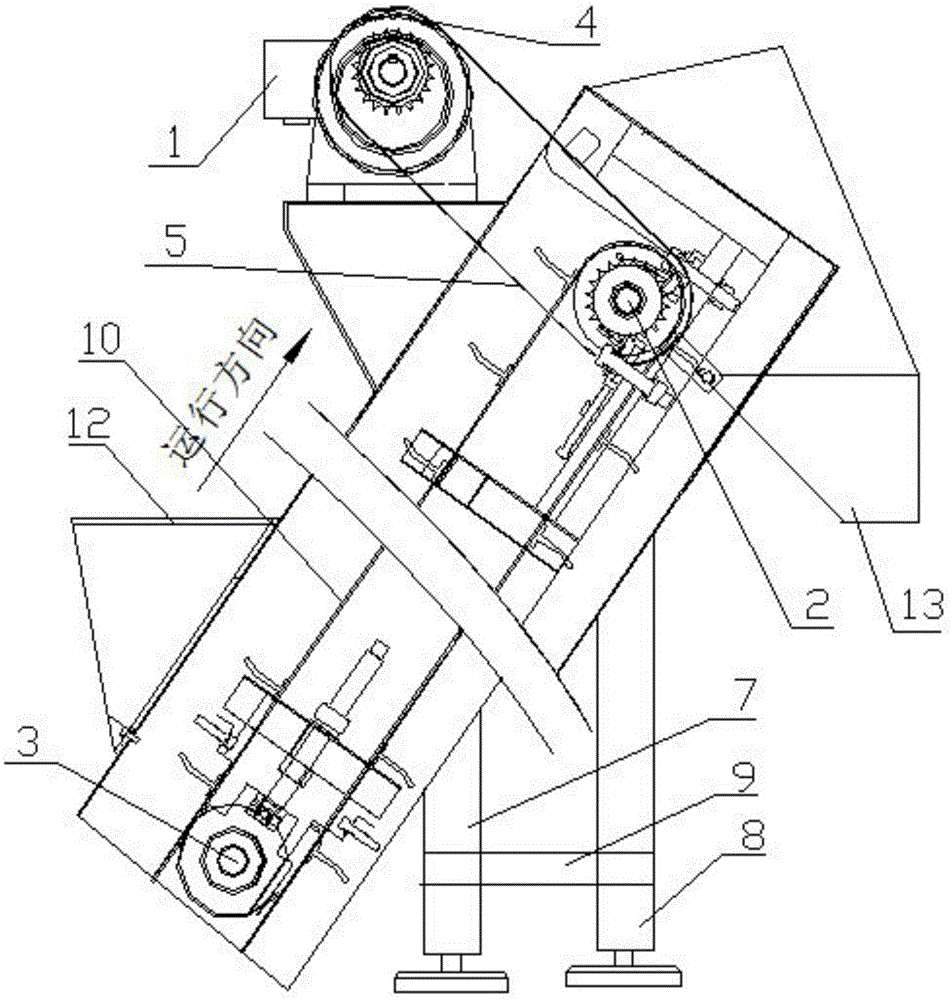

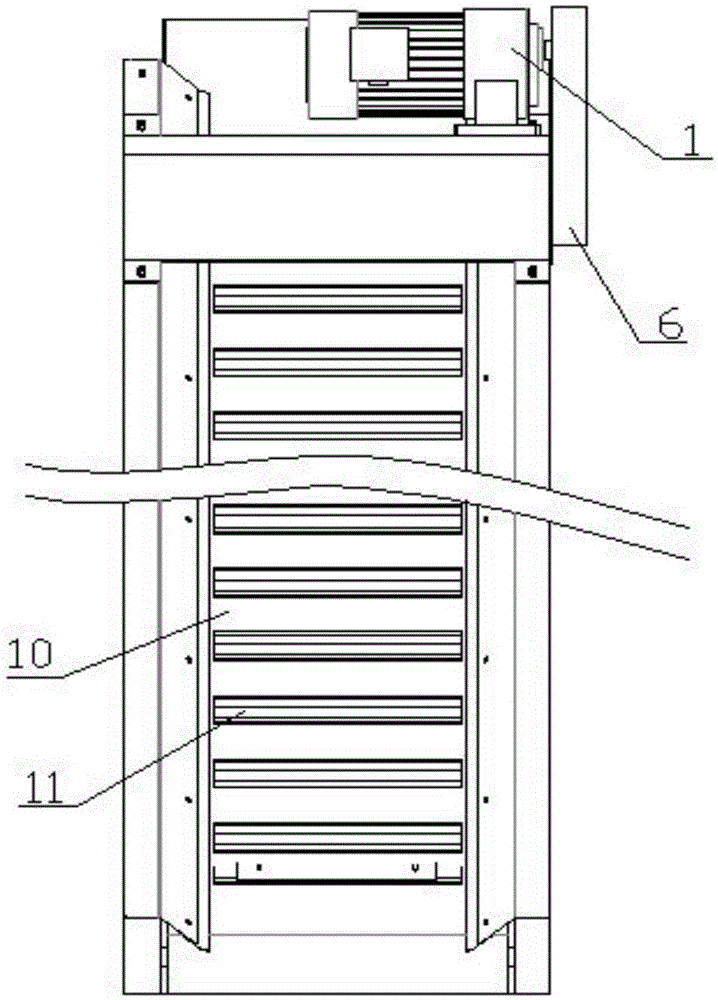

Climbing machine

InactiveCN105564905APrevent slippingShorten the transportation distanceConveyorsLoading/unloadingDrive shaftSprocket

The invention discloses a climbing machine, which comprises a drive motor, a drive shaft and a driven shaft; the output end of the drive motor is provided with a drive sprocket; the drive sprocket is connected with the drive shaft through a transmission chain; the drive shaft and the driven shaft are respectively arranged at two ends of a rack; the rack is obliquely arranged, and two ends of the rack are respectively supported on ground through a first pillar and a second pillar; a conveying belt is twined between the drive shaft and the driven shaft; baffle plates for preventing a material from slipping are arranged on the conveying belt at an equal interval; the drive shaft and the driven shaft are respectively provided with knurls used for increasing a friction force between the drive shaft and the conveying belt and a friction force between the driven shaft and the conveying belt; more than one skid-proof groove is formed in the drive shaft. The climbing machine disclosed by the invention is capable of rapidly and effectively conveying a granular material to a high place from a low place; as the conveying belt can be placed at a relatively high angle relative to a horizontal plane, a conveying distance of the material is greatly shortened, thus being conductive to increasing conveying efficiency of the climbing machine and reducing manufacturing cost.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Building machinery corrugated web steel box steel plate leveling device

PendingCN113843307ANo manual copying requiredAvoid the dangers of manual operationShaping toolsHydraulic cylinderArchitectural engineering

The invention belongs to the field of web steel box leveling, and particularly relates to a building machinery corrugated web steel box steel plate leveling device which comprises a base and a top plate, wherein supporting plates are fixed to the two sides of the top of the base, the tops of the two groups of supporting plates are fixedly connected with the two sides of the bottom of the top plate correspondingly, and a transverse plate is mounted at the bottom of the top plate; and hydraulic cylinders are fixedly mounted on the two sides of the top of the top plate. After an upper leveling block is driven by a hydraulic cylinder to descend for single-time leveling, a first electric push rod can drive a lifting plate to lift a web plate, then a lead screw motor drives a lead screw sliding block to move, so that the lifting plate is driven to communicate with the web plate to move, transposition is carried out, continuous leveling can be achieved, manual copying is not needed, the danger of manual operation is avoided, and meanwhile, the efficiency is effectively improved.

Owner:徐州清歌机械制造有限公司

Ice breaking device of high voltage transmission line

InactiveCN106786309AEasy to useAvoid the dangers of manual operationOverhead installationReduction driveHigh tension line

The invention discloses an ice breaking device of a high voltage transmission line, comprising a left shell and a right shell; the joint of the left shell and the right shell is provided with connecting plates, and two groups of connecting plates are connected through a bolt; an inner cavity formed by the left shell and the right shell is equipped with a leaf pushing type engine through a bracket, and the left end of the output shaft of the leaf pushing type engine is connected with a reducer; the left end of the output shaft of a reducer is connected with a first rotary shaft, and the outer wall of the first rotary shaft is sleeved with an active gear; the top part of the active gear is meshed with a driven gear, and the right end of the driven gear is connected with a second rotary shaft; the outer wall of the second rotary shaft is sleeved with two groups of shaft bases. Through the mechanical transmission method, the ice breaking device of the high voltage transmission line removes the frozen ice on the high voltage line, thus the high voltage line can be normally used, and the device also avoids the manual operation risk.

Owner:JILIN TEACHERS INST OF ENG & TECH

A spark plug recovery device

ActiveCN111618788BAvoid problems such as folding endsAvoid pollutionMetal-working hand toolsHydraulic cylinderWasted spark

The invention discloses spark plug recovery equipment. The spark plug recovery equipment comprises a shell, a support plate arranged in the shell and fixedly arranged on the back end wall of the shell, an unloading device arranged on the upper surface of the support plate, an arrangement device arranged on the right end surface of the support plate, and an extraction device arranged on the lower surface of the support plate; and the extraction device comprises a first chute fixedly formed in the lower surface of the support plate, a first slide block slidingly arranged in the first chute in areciprocating manner, a first hydraulic cylinder fixedly arranged in the first chute, and a hydraulic control rod slidingly arranged on the left end surface of the first hydraulic cylinder in a reciprocating manner. The spark plug recovery equipment can automatically take out platinum-plated center electrodes in waste spark plugs, is automatic in the whole process, only needs to manually put the collected spark plugs in bins, can feed the spark plugs into a worktable through a series of bins to prevent the manual clamping danger, meanwhile, can reuse wastes to save non-renewable resources forthe world, and prevents pollution of heavy metals to soil.

Owner:山东临港汽车制造有限公司

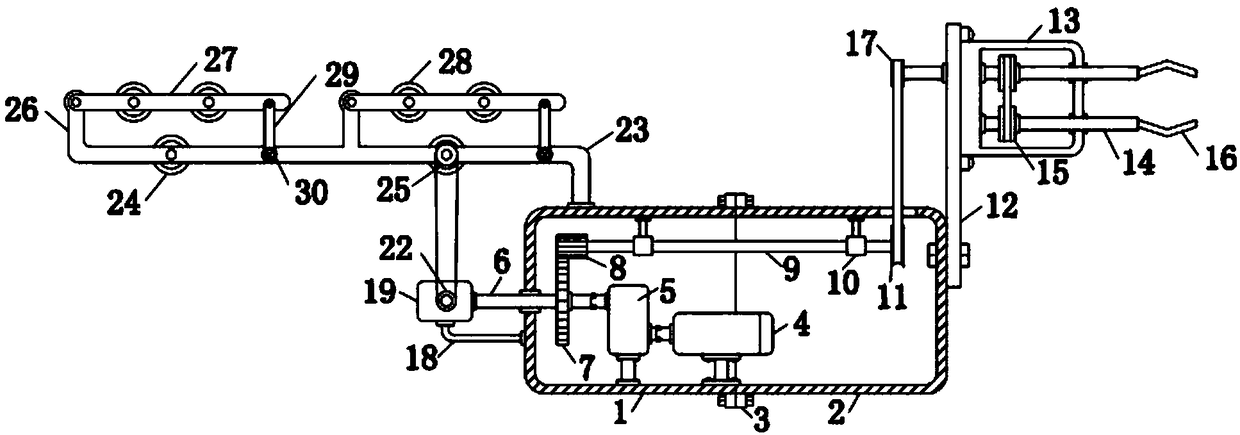

Novel high-efficiency workpiece quenching furnace

InactiveCN109161663AWon't happenReduce pollutionIncreasing energy efficiencyFurnace typesHydraulic cylinderInsulation layer

The invention discloses a novel high-efficiency workpiece quenching furnace which comprises a main body and a heating cabin, wherein a refractory brick insulation layer is arranged in the heating cabin; an electromagnetic heating coil is arranged on the inner side of the refractory brick insulation layer; a bottom plate is arranged below the heating cabin; rollers are arranged at one end of the bottom plate; supporting rods are arranged below the rollers; the other ends of the supporting rods are arranged on the lower surface inside the main body; a hydraulic cylinder is arranged on one sidesof the supporting rods; one end of the hydraulic cylinder is arranged on the lower surface inside the main body, and the other end of the hydraulic cylinder is connected with the lower surface of thebottom plate by virtue of a telescopic rod; a cooling cabin is formed in one side of the hydraulic cylinder; a cooling tank is arranged at the bottom end inside the cooling cabin; a PVC (Polyvinyl Chloride) hose is arranged at one end of the cooling tank and connected with an output pipe by virtue of a pipe connector; and an equipment cabin is formed in the upper side of the cooling cabin and partitioned from the cooling cabin by a partition plate. The novel high-efficiency workpiece quenching furnace disclosed by the invention has the characteristics of being small in environmental pollution,long in service life, maintenance-free, safe in operation and the like.

Owner:天津市宝盈金属制品有限公司

Intelligent dust-free feeding and feeding all-in-one machine

ActiveCN104786384BAvoid the dangers of manual operationReduce production laborPlastic recyclingFrequency changerProduction line

The invention relates to an intelligent dust-free material adding and material feeding integrated machine, which comprises a conveying belt arranged on a conveyor, wherein material pushing hooks are arranged on the conveying belt and are fixed on the conveying belt in a row manner, the upper portion on one end of the conveying belt is connected with a material collection hopper, the upper portion on the other end is provided with a diversion shield, material pushing plates are arranged on the conveying belt at intervals, the outlet end of the diversion shield is connected with a material feeding hopper, a conical spiral rod is arranged in the material feeding hopper, the upper end of the conical spiral rod is connected to the output shaft of an umbrella-shaped gear transmission chamber through a transmission bearing chamber, the input shaft of the umbrella-shaped gear transmission chamber is connected to a clutch plate transmission gear disk through a transmission gear chamber and a transmission shaft, the clutch plate transmission gear disk is connected with a material feeding motor through a transmission chain, the other end of the conical spiral rod extends out of the material outlet of the material feeding hopper, the material feeding motor is connected with an electrical control box, and a frequency converter is arranged in the electronic control box and is used for controlling the material feeding motor and the conveyor. According to the present invention, the artificial manner is changed into the intelligent manner, such that the waste plastic recycling production line can be well combined so as to provide advantages of integration and intelligence.

Owner:山东济南巧媳妇食品有限公司

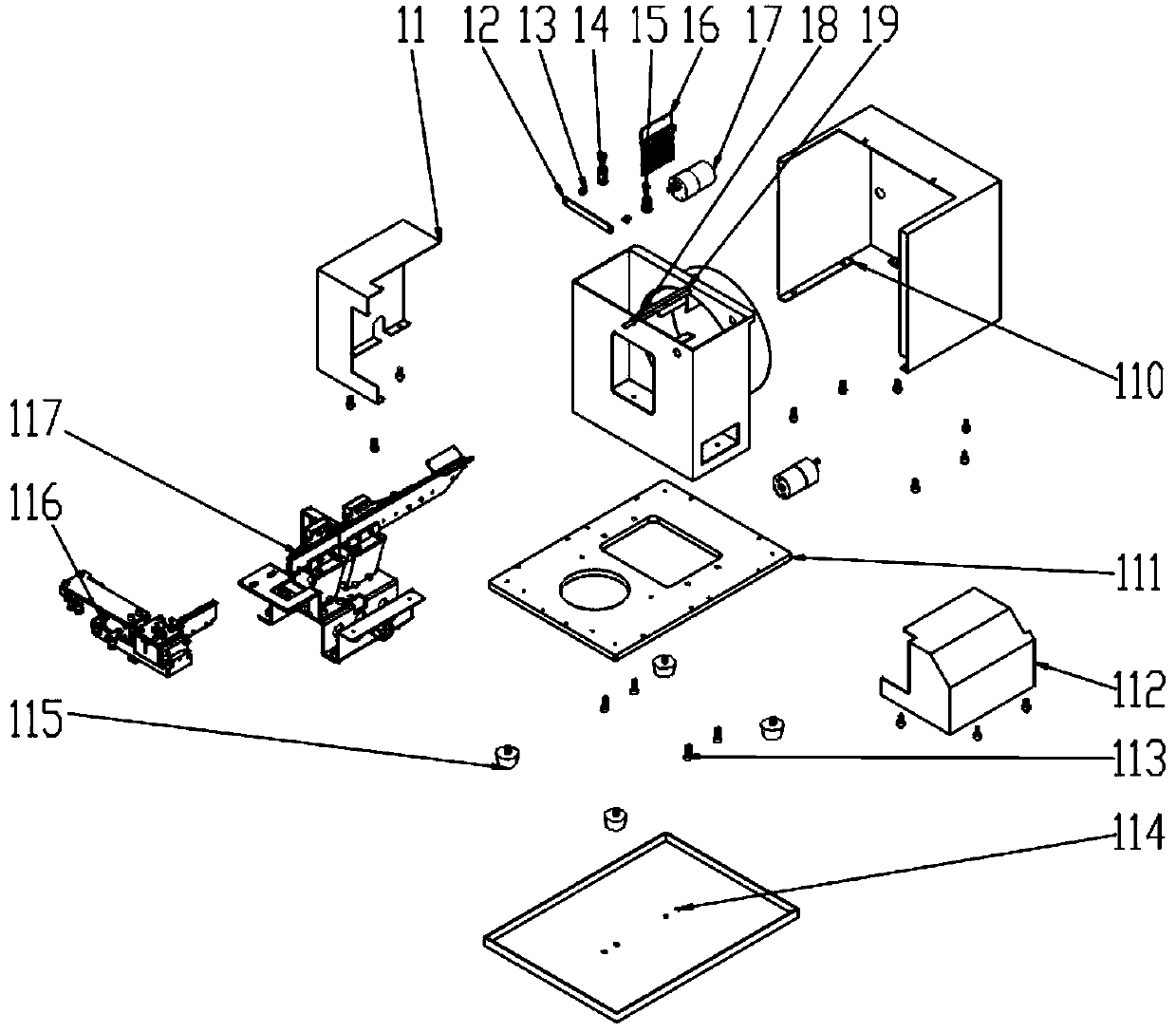

Automatic nail insertion device

InactiveCN110811076AReduce labor intensityIncrease productivityNailingRobot handInjection molding machine

The invention discloses an automatic nail insertion device. The automatic nail insertion device comprises a nail arrangement and distribution part, a nail head insertion part, an XYZ three-axis servomain body, an electric box part, a touch screen box and a cross rocker box; the electric box part is fixedly mounted on the side wall of the rear end of the XYZ three-axis servo main body; the nail head insertion part is fixedly mounted on the side wall of the XYZ three-axis servo main body; the nail arrangement and distribution part is fixedly mounted at the upper end of the electric box part; and the touch screen box is fixedly mounted on the side wall of the electric box part. According to the automatic nail insertion device, by arranging the nail arrangement and distribution part, the nailhead insertion part, the XYZ three-axis servo main body and the electric box part, a process of manually holding a nail with a hand to insert into an injection molding machine die can be changed intoa process of completing nail insertion by a manipulator; the manipulator has the characteristics of high speed, high efficiency, labor saving, reduction of labor intensity, safety and the like; and the automatic nail insertion device also has a function of automatically taking a product.

Owner:佛山市际巧自动化机械有限公司

Nut machining device with waste recycling function

PendingCN113927412AEasy to reuseImprove work efficiencyDispersed particle filtrationGrinding drivesElectric machineryDrive motor

The invention discloses a nut machining device with a waste recycling function. The nut machining device comprises a base, a box body fixedly connected to the upper end of the base and a filter box fixedly connected to the upper end of the box body. The nut machining device is provided with a waste recycling assembly, and the waste recycling assembly comprises a recycling box fixedly connected to the inner wall of the bottom end of the box body; and the inner walls of the left side and the right side of the box body are each provided with a machining plate in a hinged mode, the lower ends of the two machining plates are each fixedly connected with a rack, one side of each rack is provided with a gear, the racks are meshed with the gears, the back faces of the gears are fixedly connected with rotating shafts, the ends, away from the gears, of the rotating shafts are fixedly connected with the output ends of driving motors, and the driving motors are fixedly installed on the back face of the box body. After nuts are machined, the nuts and waste materials generated in the machining process can be collected and filtered, workers can conveniently conduct secondary utilization on the waste materials, and economy is achieved.

Owner:惠州市友仁五金制品有限公司

A high-voltage transmission line ice breaking device

InactiveCN106786309BEasy to useAvoid the dangers of manual operationOverhead installationReduction driveHigh tension line

The invention discloses an ice breaking device of a high voltage transmission line, comprising a left shell and a right shell; the joint of the left shell and the right shell is provided with connecting plates, and two groups of connecting plates are connected through a bolt; an inner cavity formed by the left shell and the right shell is equipped with a leaf pushing type engine through a bracket, and the left end of the output shaft of the leaf pushing type engine is connected with a reducer; the left end of the output shaft of a reducer is connected with a first rotary shaft, and the outer wall of the first rotary shaft is sleeved with an active gear; the top part of the active gear is meshed with a driven gear, and the right end of the driven gear is connected with a second rotary shaft; the outer wall of the second rotary shaft is sleeved with two groups of shaft bases. Through the mechanical transmission method, the ice breaking device of the high voltage transmission line removes the frozen ice on the high voltage line, thus the high voltage line can be normally used, and the device also avoids the manual operation risk.

Owner:JILIN TEACHERS INST OF ENG & TECH

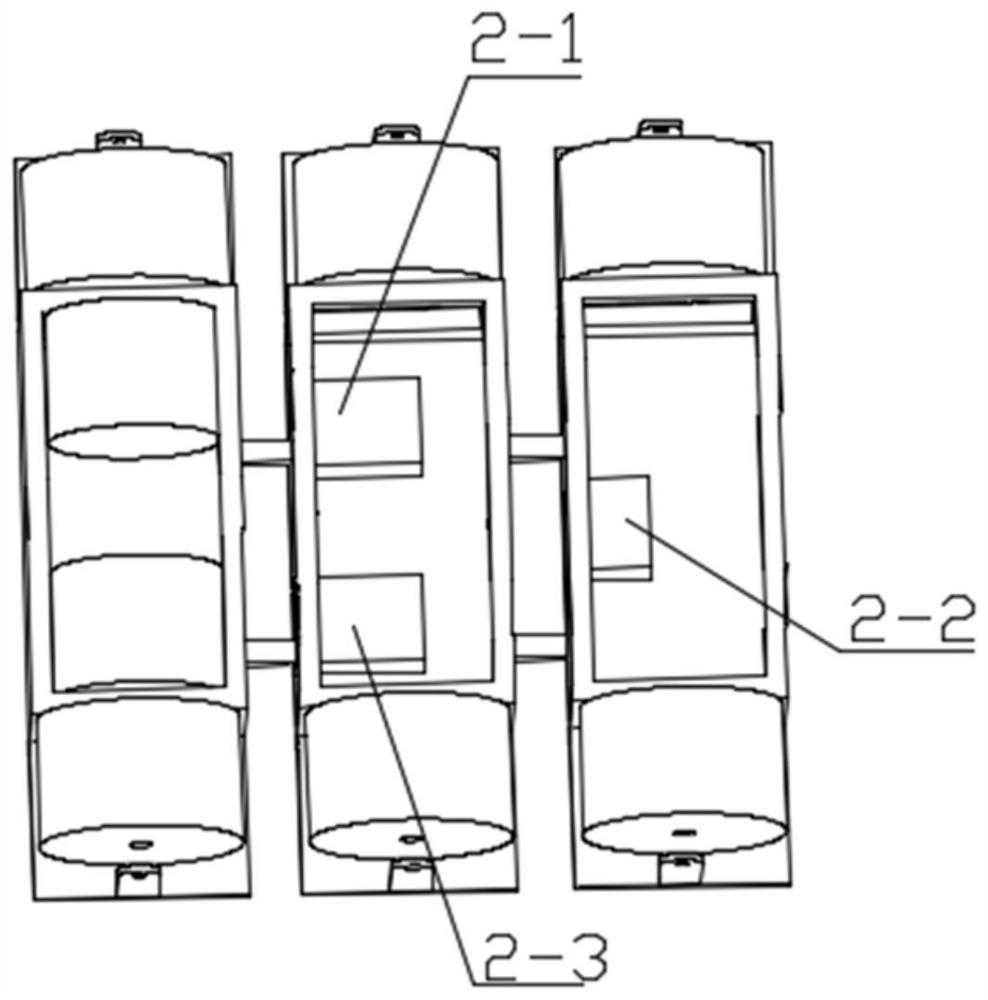

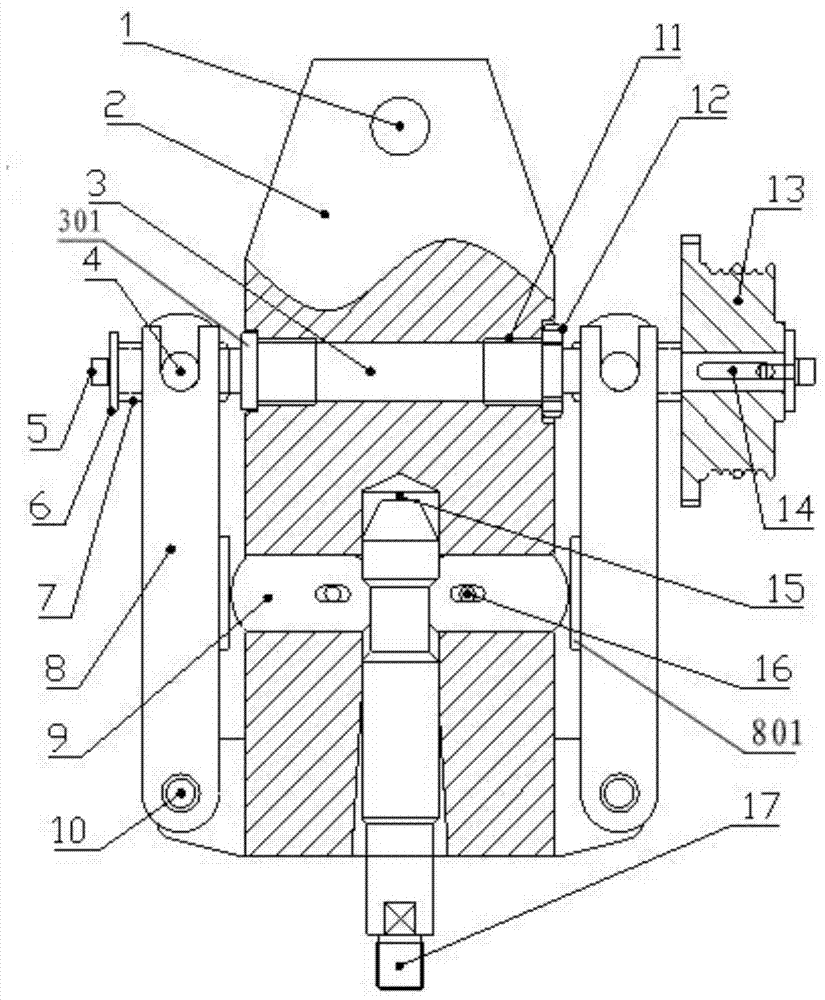

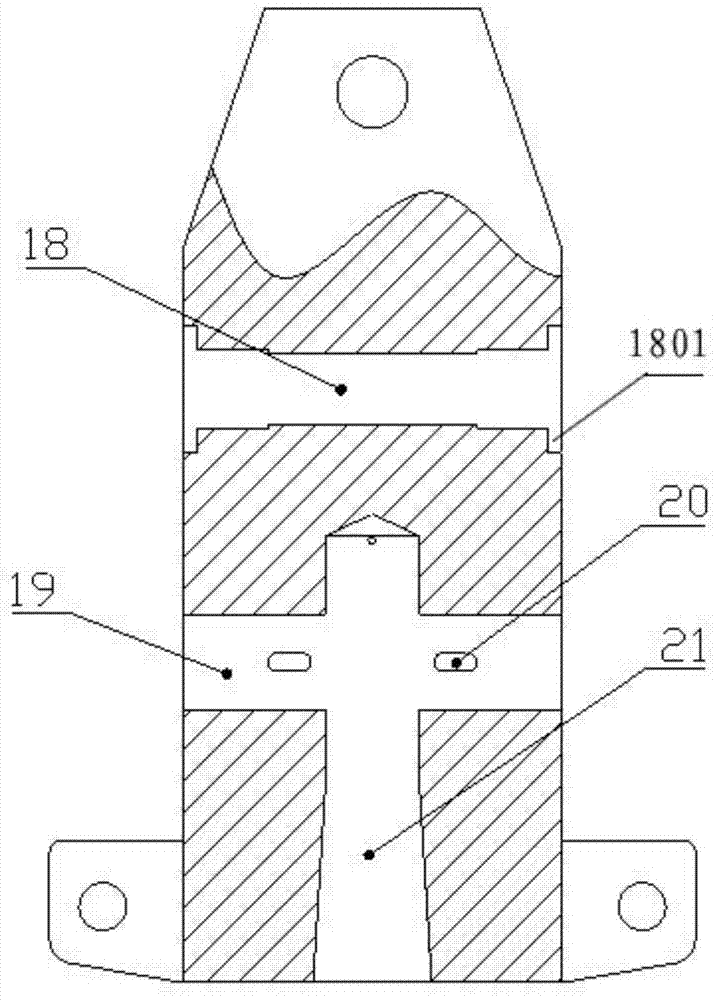

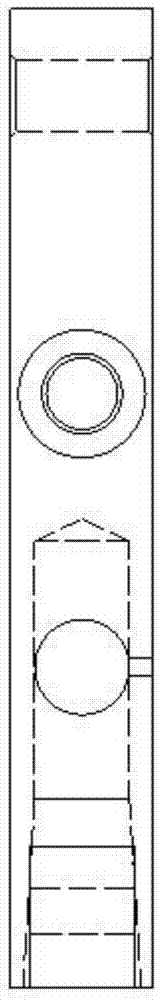

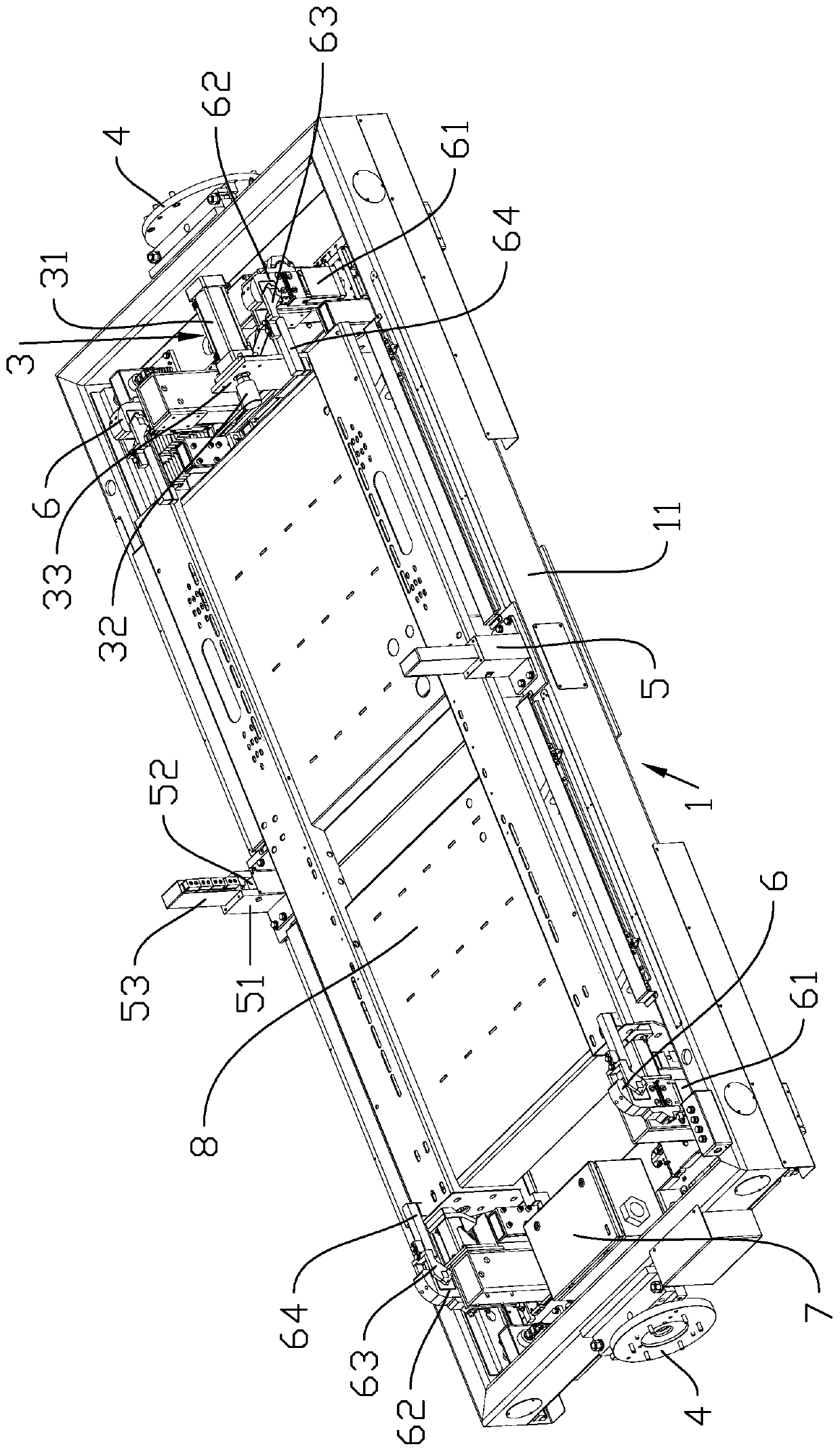

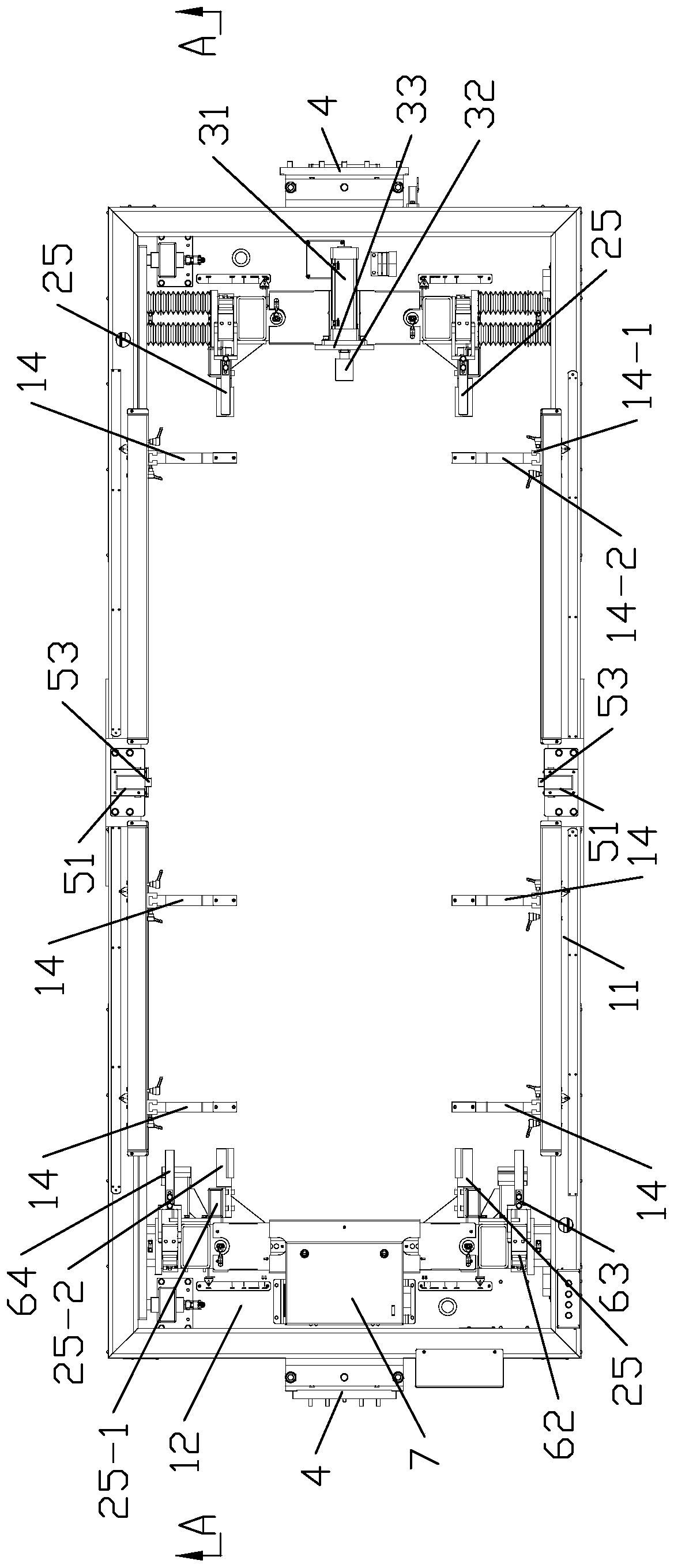

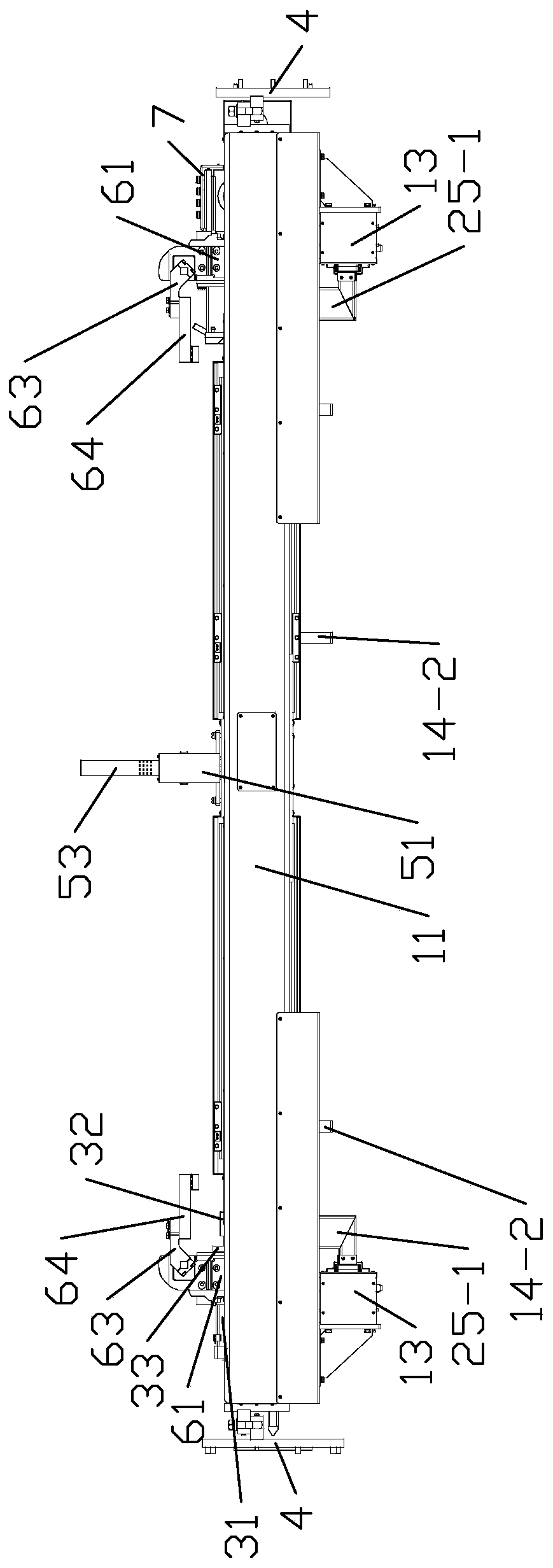

Oil tank chassis tool structure of flexible welding robot

The invention relates to an oil tank chassis tool structure of a flexible welding robot. The oil tank chassis tool structure comprises a bottom frame, centering mechanisms, a jacking mechanism, central pressing structures and two-side pressing mechanisms; two centering mechanisms are provided, the centering mechanisms are arranged on connecting frames on the two sides of the bottom frame correspondingly, and centering supporting claws face the center of the bottom frame; the jacking mechanism is arranged on the bottom frame and is located on the right side of the inner part of the bottom frame; four two-side pressing mechanisms are provided, the four two-side pressing mechanisms are divided into two sets, each set of the two-side pressing mechanisms are installed on the two sides of the upper portion of each corresponding first mounting plate of the bottom frame, so that the two sets of two-side pressing mechanisms are arranged on the bottom frame and are located on the left side and the right side of the inner part of the bottom frame correspondingly; and the two-side pressing mechanisms of each set are symmetrically arranged in a front-back mode. Two central pressing structures are provided, and the central pressing structures are arranged at the center of the front side portion and the center of the rear side portion of a base frame of the bottom frame correspondingly. The tool structure is convenient to use, good in adaptability, high in efficiency, and can be connected to the flexible welding robot to carry out oil tank chassis welding work.

Owner:雅柯斯电力科技(中国)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com