Oil tank chassis tool structure of flexible welding robot

A technology for welding robots and fuel tanks, which is applied to manipulators, manufacturing tools, chucks, etc., can solve the problems of high cost, danger to operators, time-consuming and labor-intensive problems, and achieve the effect of convenient operation, scientific and reasonable overall structure, and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

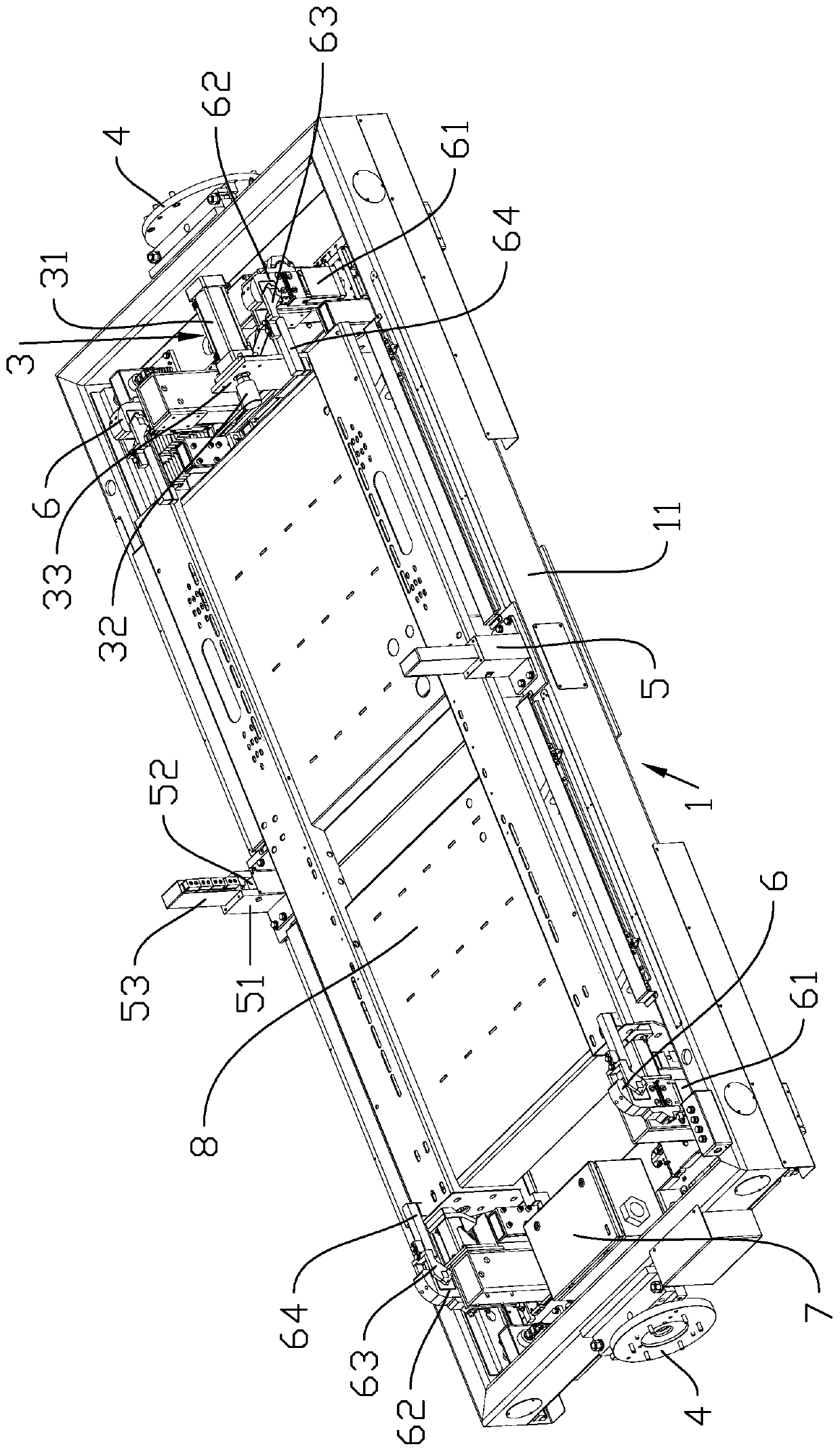

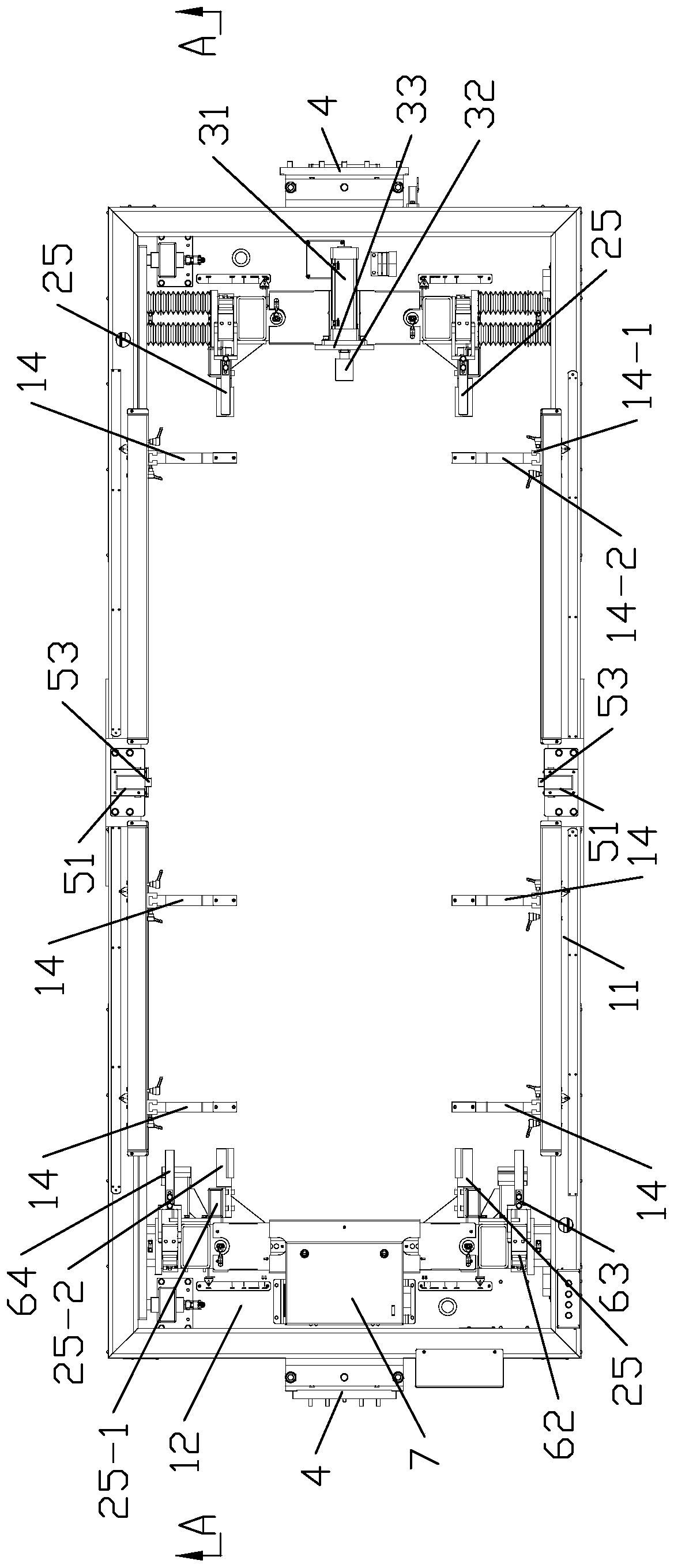

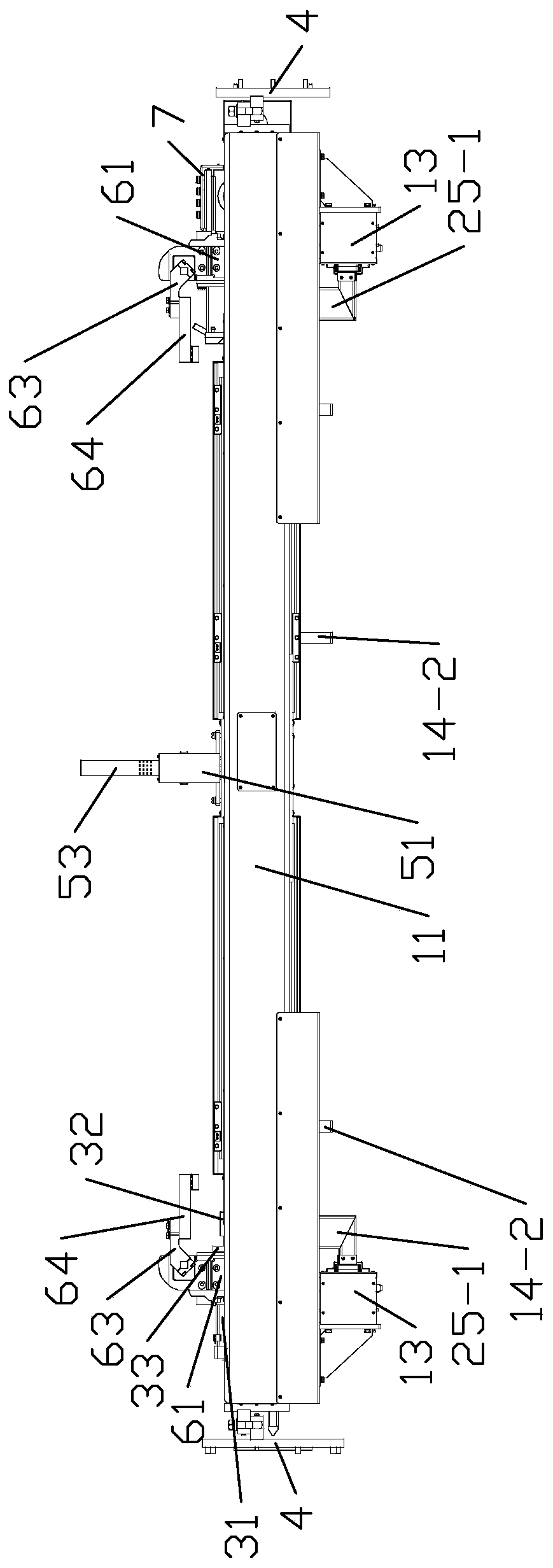

[0034] See Figure 1 to Figure 4 , The flexible welding robot fuel tank chassis tooling structure of this embodiment includes a bottom frame 1, a centering mechanism 2, a top tightening mechanism 3, a rotating fixed plate 4, a central pressing structure 5, both side pressing mechanisms 6 and an electrical control box 7.

[0035] The bottom frame 1 is a steel fuel tank chassis bearing base in the overall shape of a rectangular parallelepiped frame, including a base frame 11 in the shape of a rectangular parallelepiped frame, two first mounting plates 12 connected to the left and right sides below the base frame 11, respectively connected to 2 connecting frames 13 and 6 bearing components 14 below the corresponding first mounting plate 12; The corresponding first mounting plates 12 are connected together, the right end face of the first connecting plate is connected with the left end face of the connecting frame 13 on the left side by fasteners, the upper end face of the first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com