Patents

Literature

118results about How to "Increase radial size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kit to be implanted in a blood circulation conduit

Owner:WL GORE & ASSOC INC

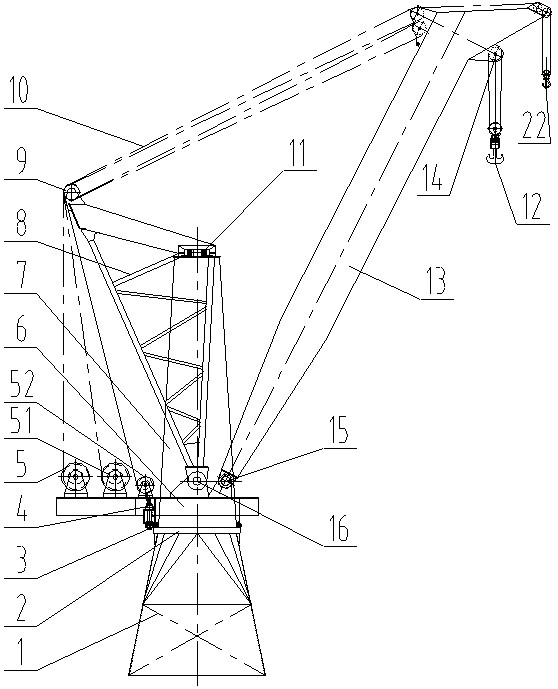

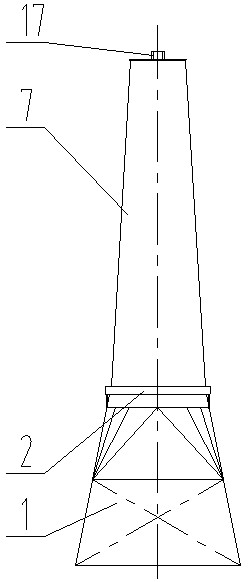

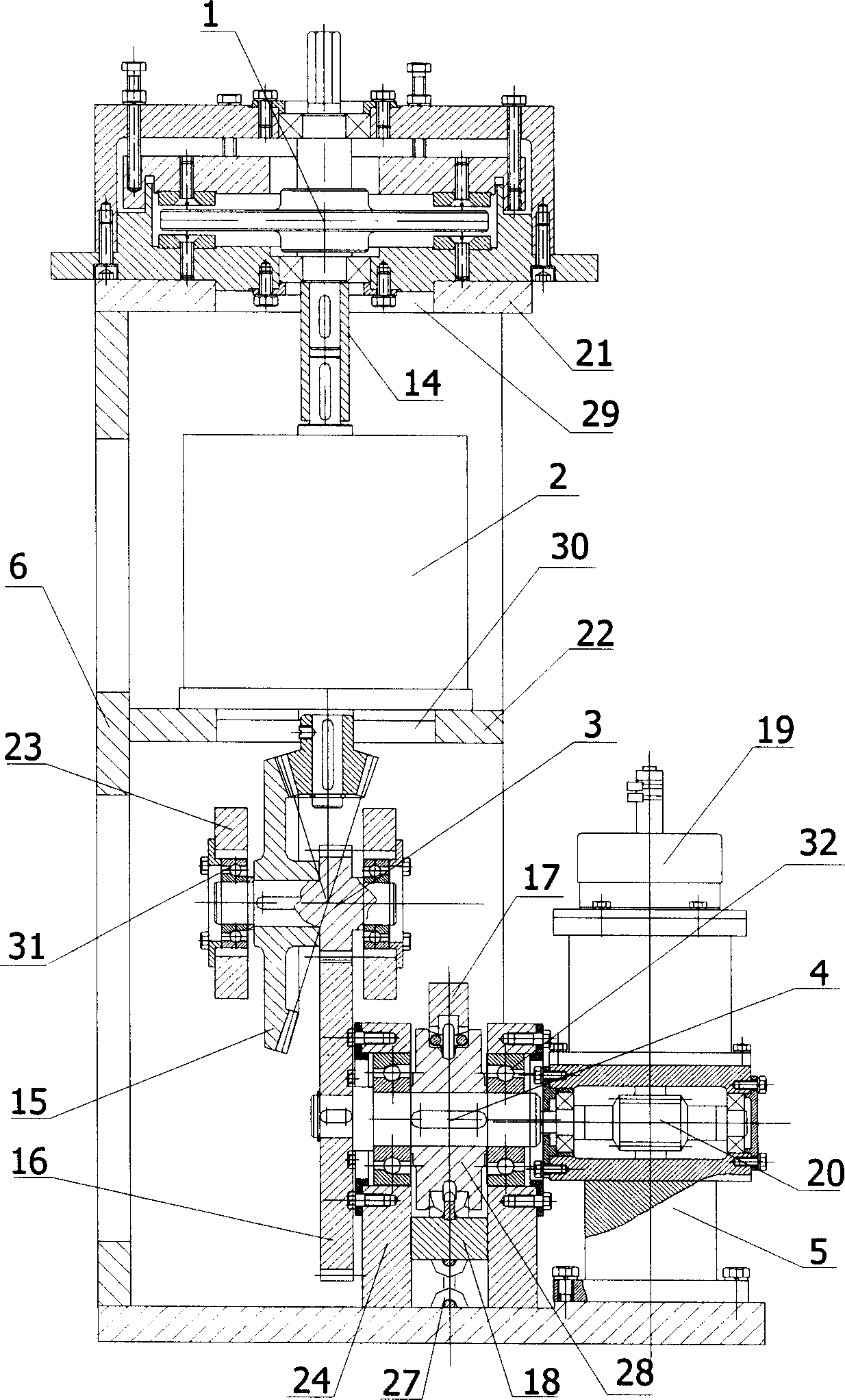

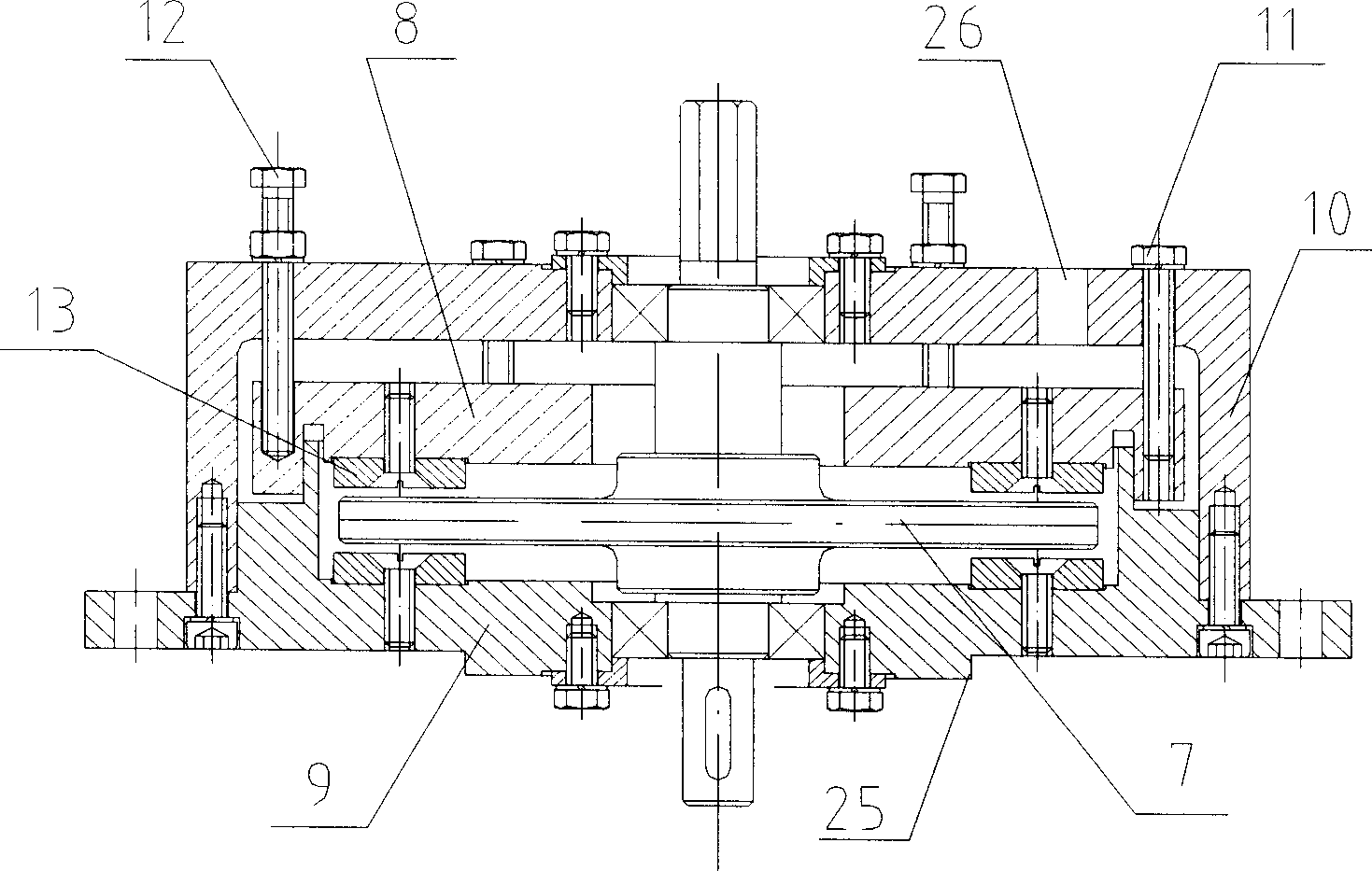

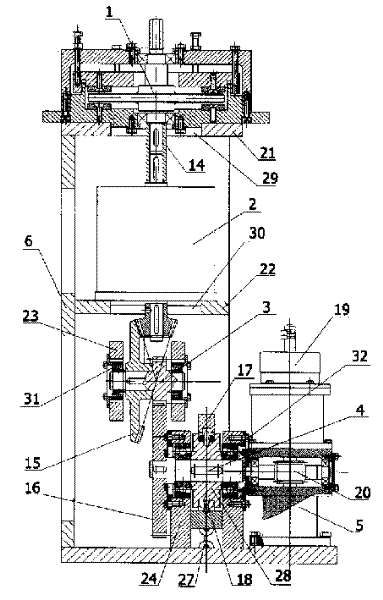

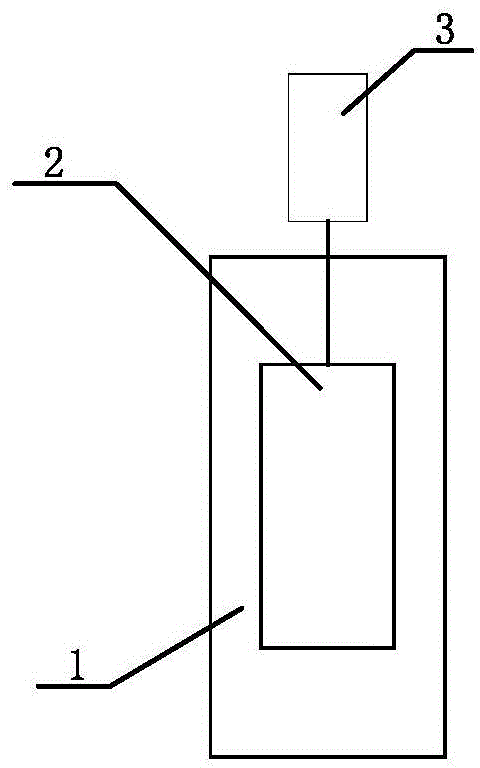

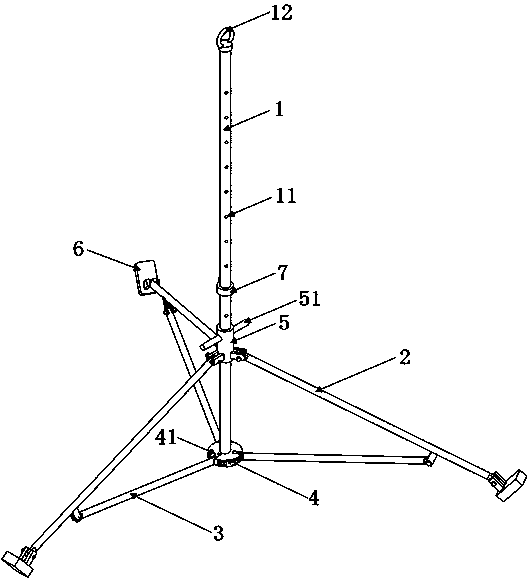

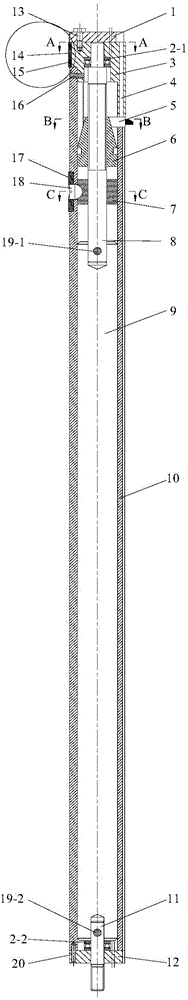

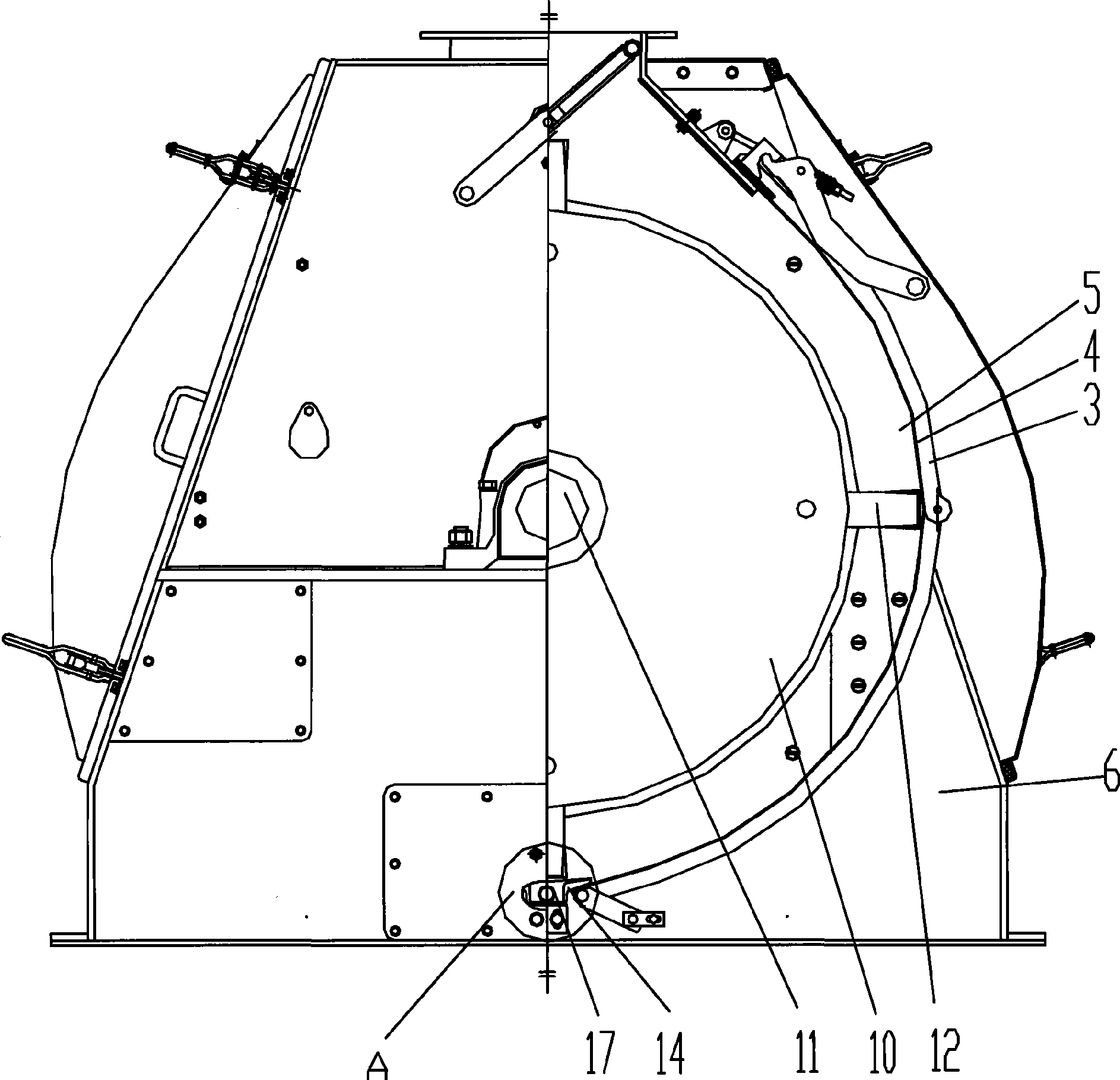

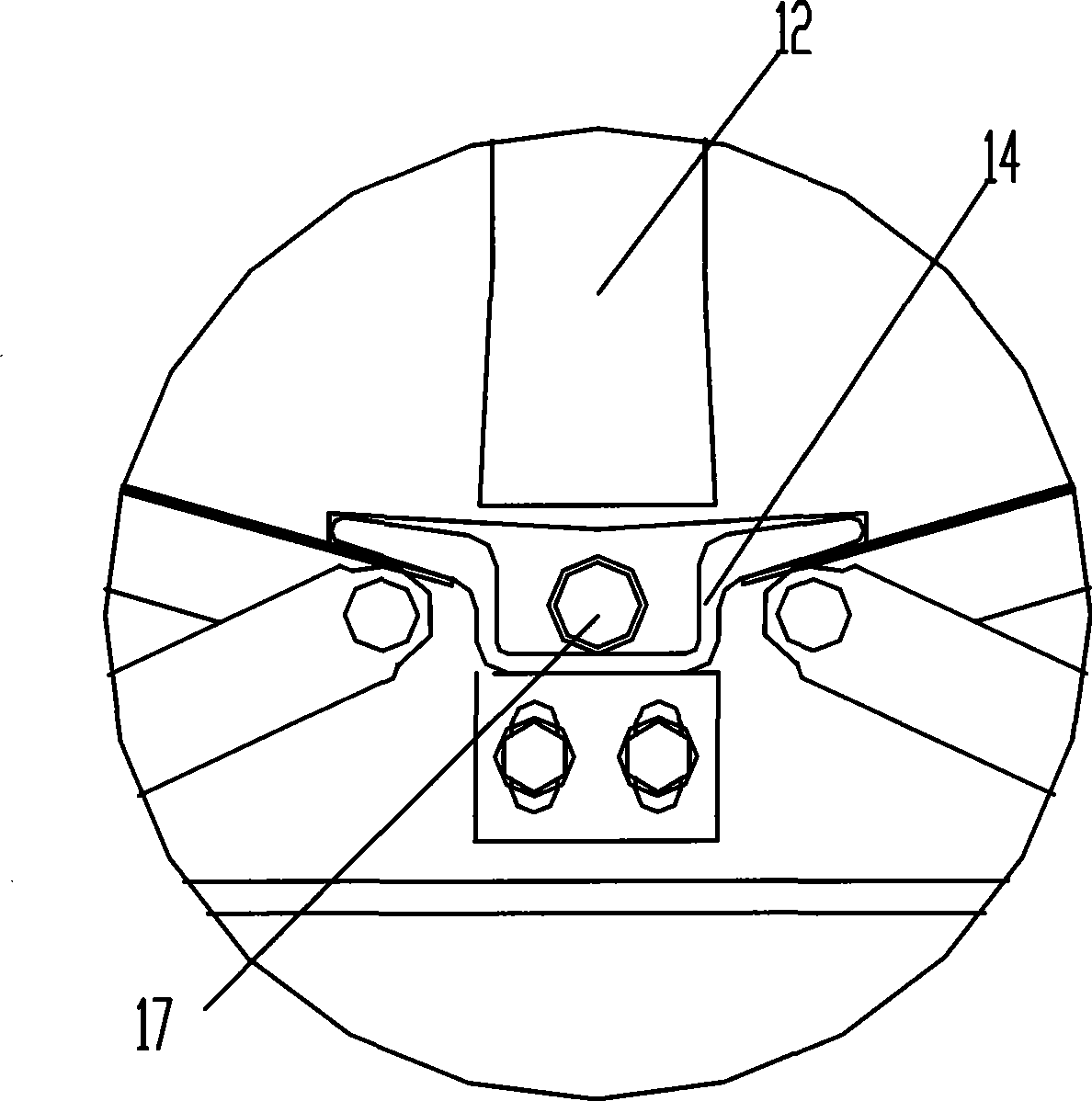

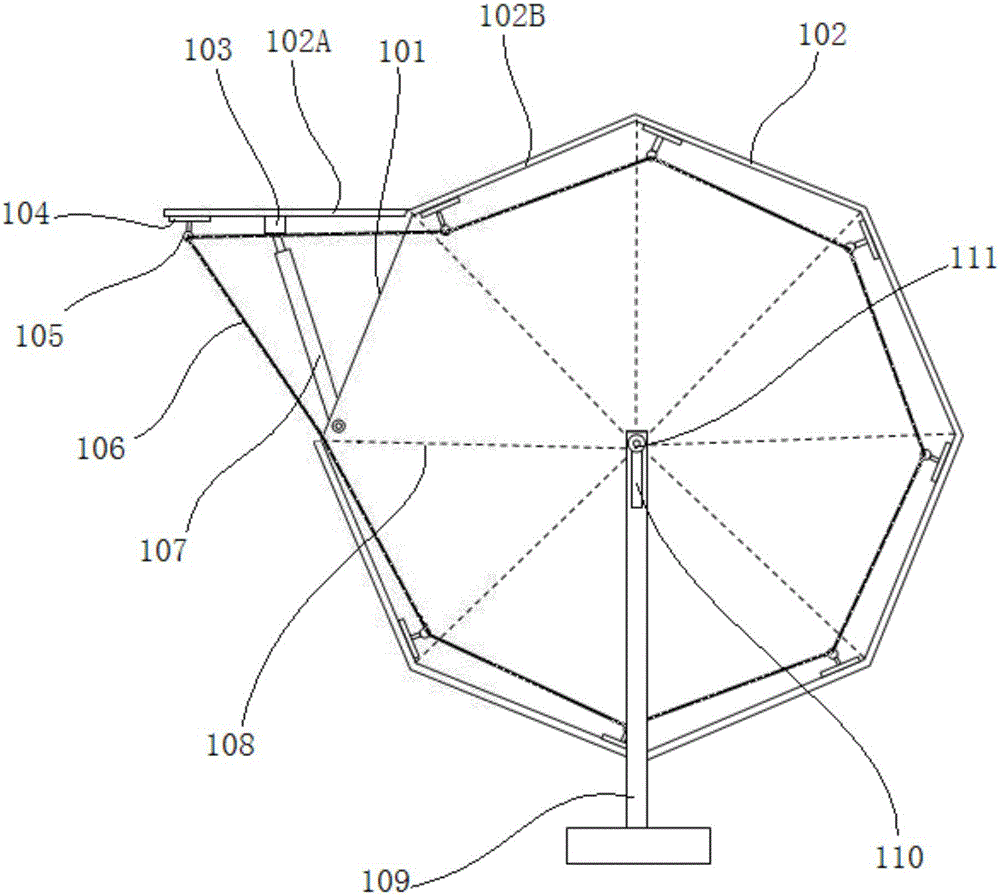

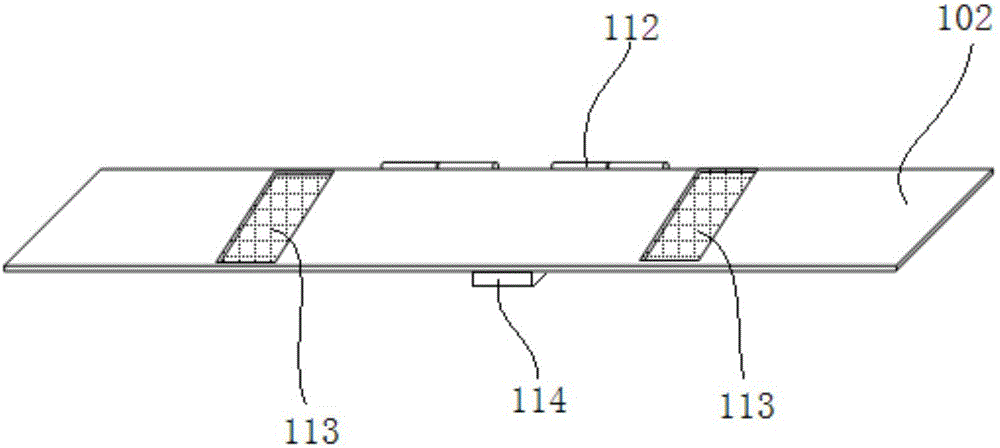

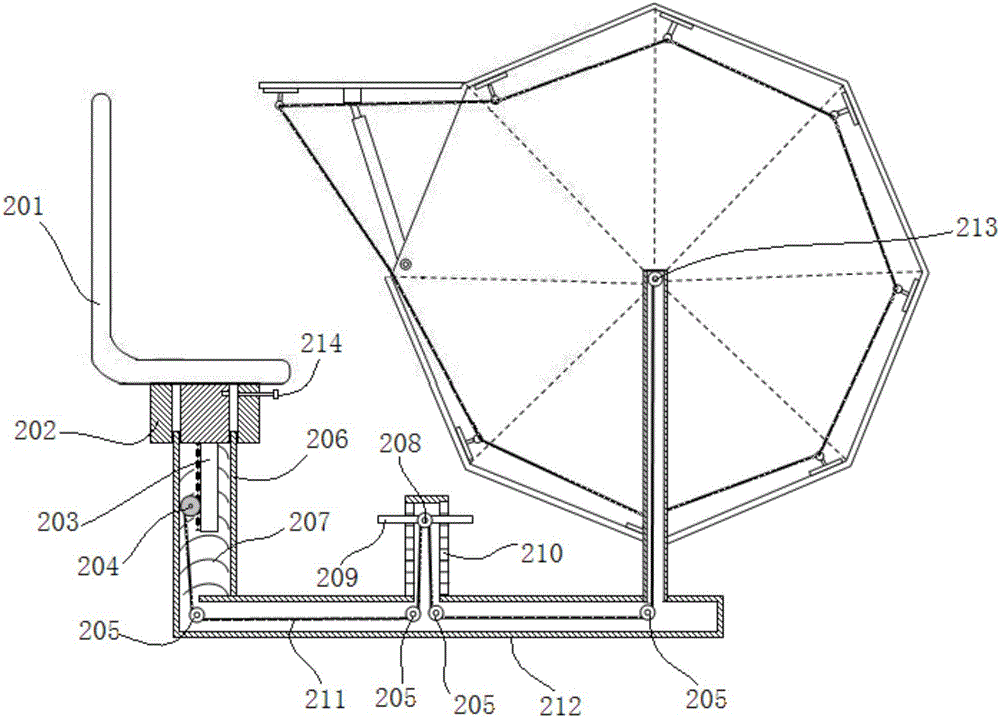

Fixed post type fully rotary crane

ActiveCN102431908ASimplify the load-bearing structureImprove the state of stressCranesEngineeringMarine navigation

The invention relates to a fixed post type fully rotary crane, which belongs to crane transportation machinery for a boat. A flange (2) is arranged on the outer surface of the middle lower section of a fixed post, a fixed post top shaft (17) is arranged in the end surface center of the top of an upper fixed post (7), a rotary supporter (3) is connected above the flange (2), the upper part of the rotary supporter (3) is fixedly connected with a rotary table (6), a hanging arm (13) and a top pulley frame (8) are respectively hinged on the rotary table (6), a top bearing (11) and a top pulley group (9) are respectively and fixedly arranged on the top pulley frame (8), the top bearing (11) is sheathed onto the fixed post top shaft (17), a rotary mechanism (4) is arranged on the rotary table (6) or a lower fixed post (1), the integral height of the crane is reduced, in addition, the full rotation is realized, the operation of the whole machine is stable, the load bearing and the bending resistance capability of the crane are greatly improved, the service life is greatly prolonged, and the fixed post type fully rotary crane is particularly suitable for being used on large-scale floatingcrane boats and ocean engineering boats with crane weight limitation and navigation height limitation.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

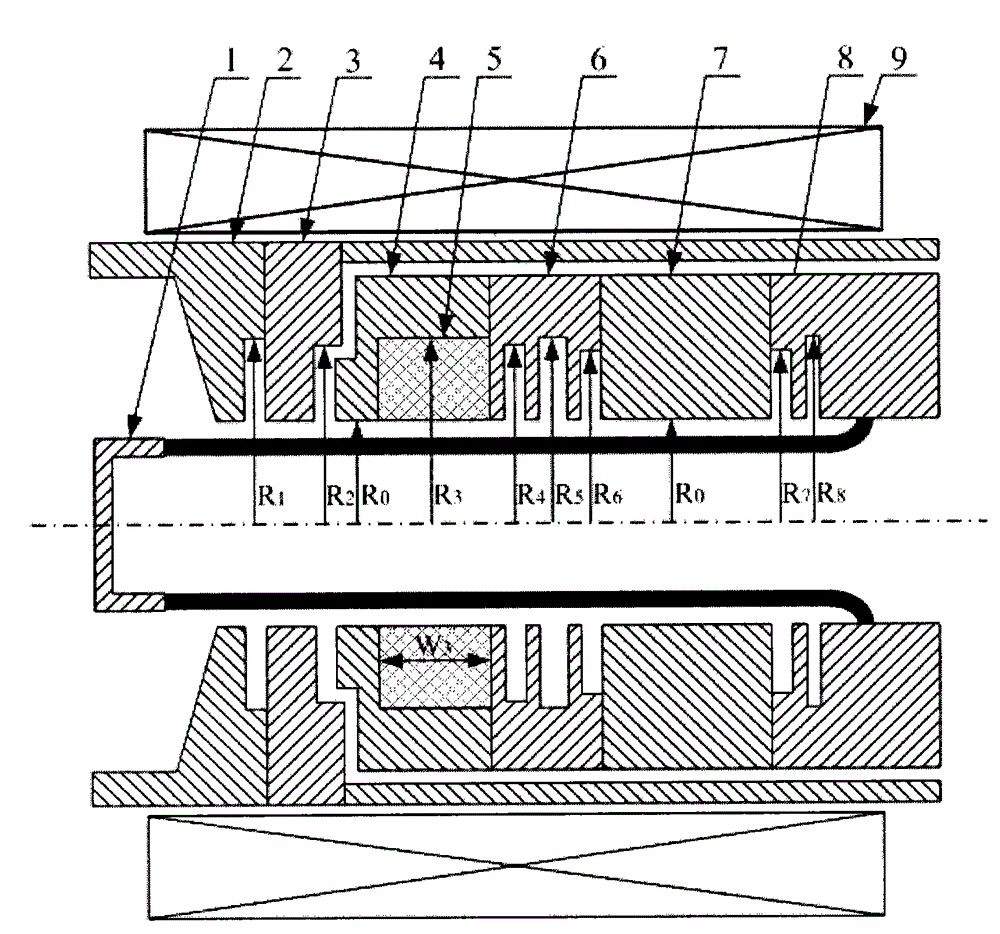

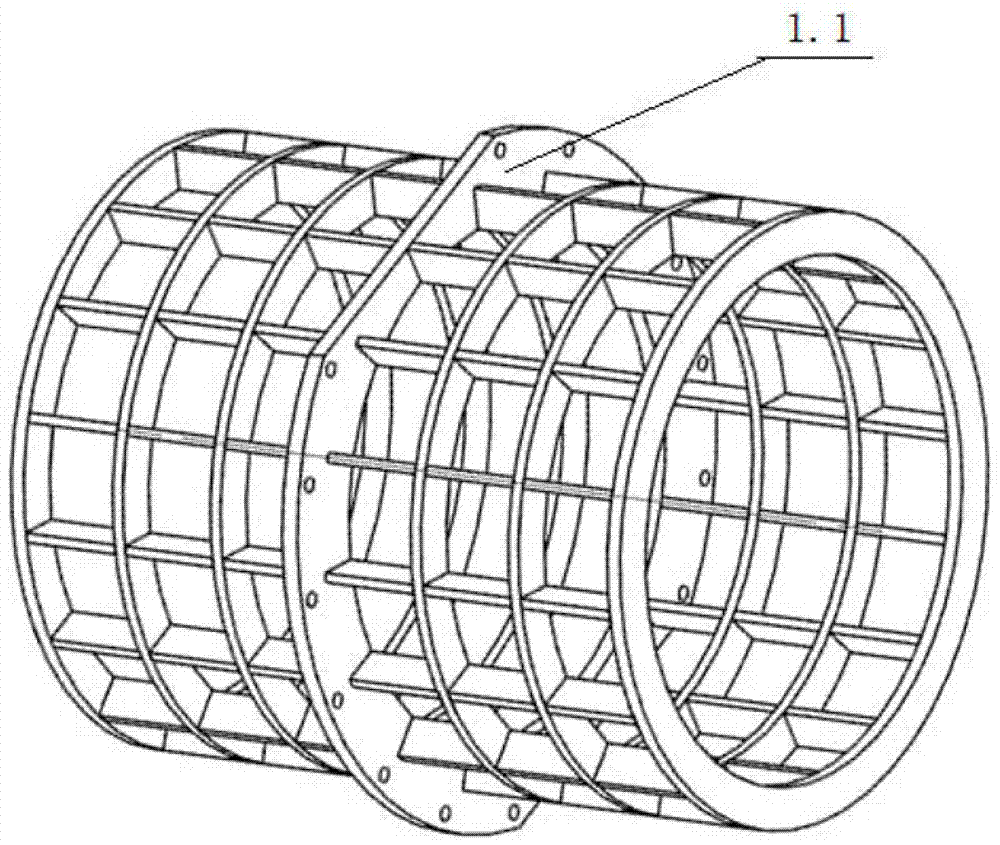

X wave band over-mode relativistic klystron amplifier

The invention discloses an X wave band over-mode relativistic klystron amplifier, which comprises an annular cathode, a resonant reflector, an input cavity, a first section of drift tube, a wave absorbing material, a buncher cavity, a second section of drift tube, an output cavity and a magnetic field coil, wherein the annular cathode is arranged at the most significant end of the structure and emits annular relativistic electron beams outwards under the action of high voltage pulse, the resonant reflector, the input cavity, the first section of drift tube, the wave absorbing material, the buncher cavity, the second section of drift tube and the output cavity are sequentially arranged at rear of the annular cathode, the magnetic field coil is installed at the periphery of the whole structure, the working mode of the resonant reflector, the input cavity, the buncher cavity and the output cavity is a TM02 mode, and the first section of drift tube and the second section of drift tube can transmit a TM01 mode. The X wave band over-mode relativistic klystron amplifier can produce high power X wave band microwave.

Owner:NORTHWEST INST OF NUCLEAR TECH

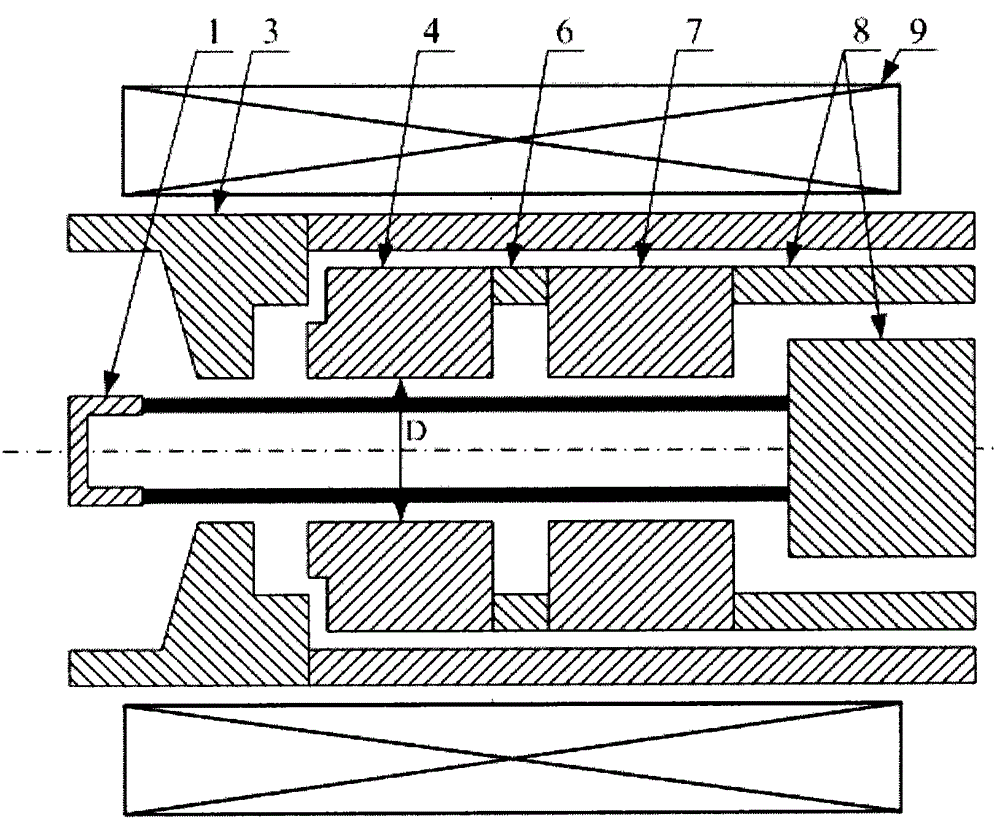

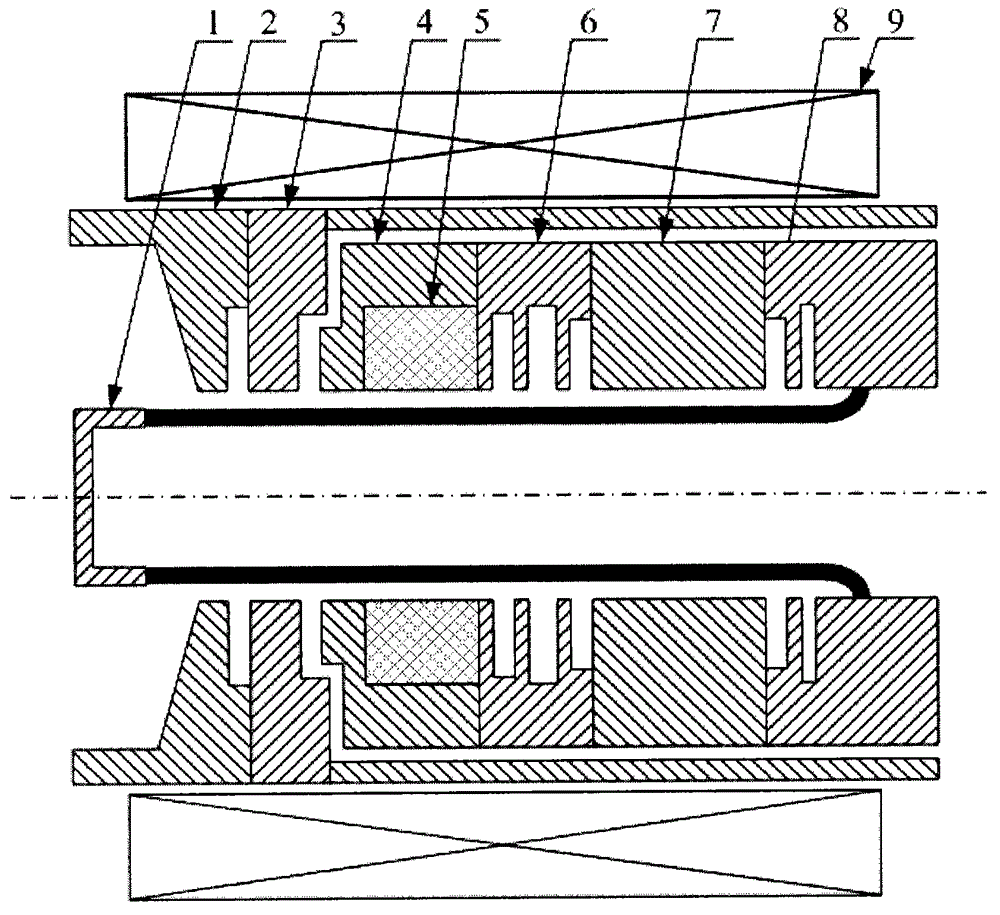

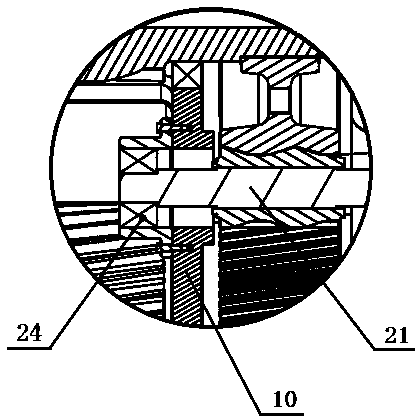

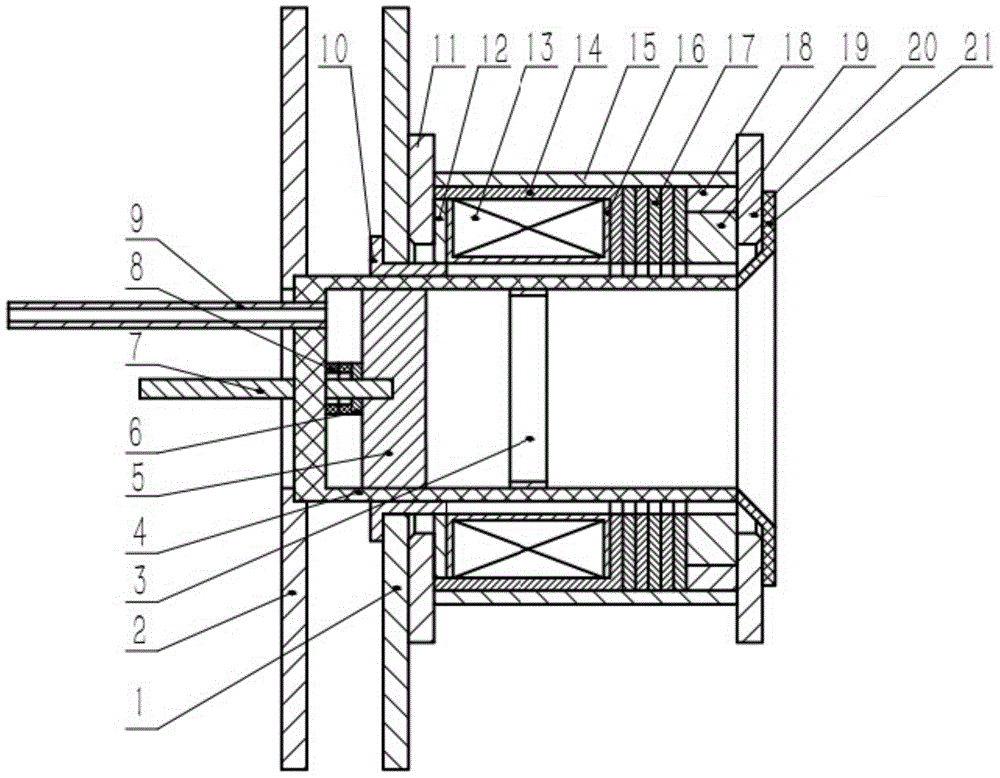

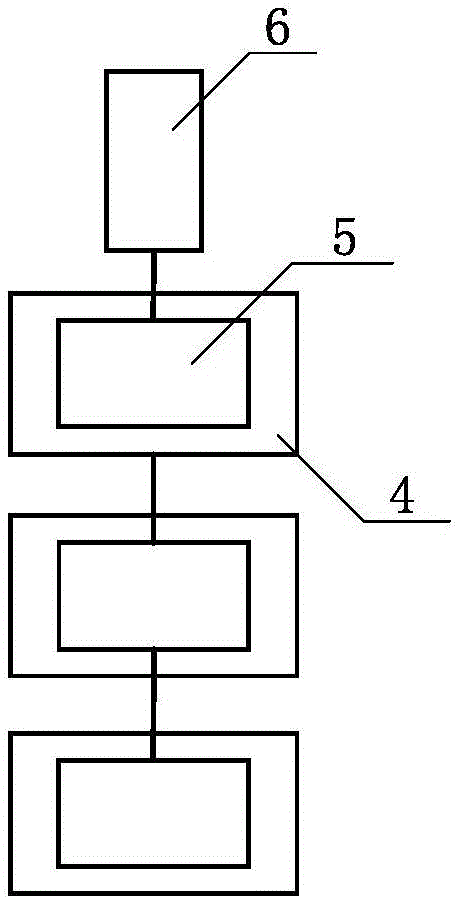

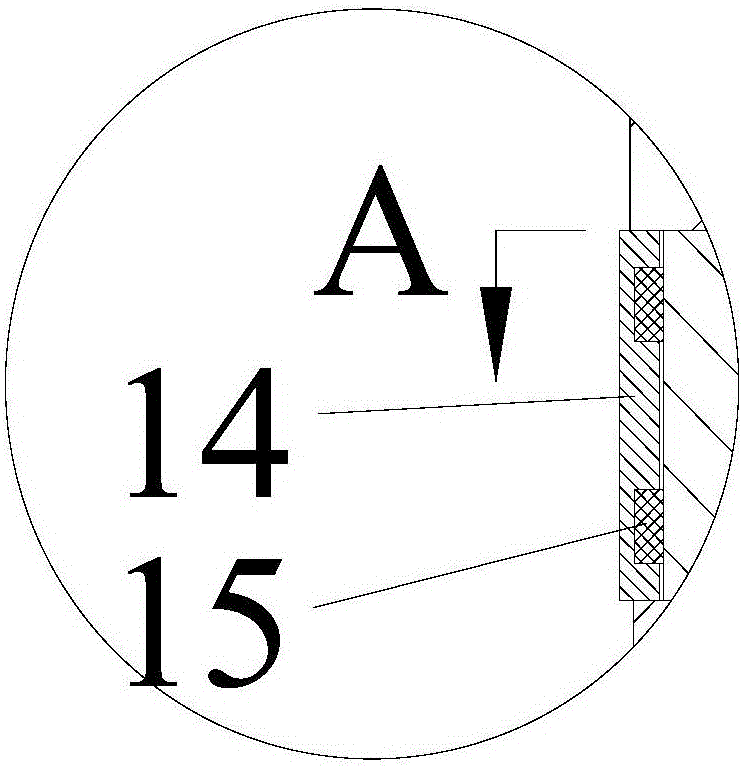

Reactor control-rod driving mechanism with adjustable magnetic damper

InactiveCN1405788ADrive chain shortIncrease radial sizeNuclear energy generationNuclear reaction controlDamping functionElectric machine

The drive mechanism comprises the drive mechanism bracket, the driving chain, the system for measuring the position of the rod and the magnetic damper. The driving chain consists of the motor, the gear reduction mechanism and the chain wheel. The magnetic champer comprises the moving disc, the upper and lower magnetic discs and the bearing seat. Since playing the damping function only without the driving function as well as the adjustable structure, the magnetic damper provides the features of shorter driving chain, smooth reliable driving and large enough brake moment. Said mechanism reduces the influence of the precision of manufacturing and assembling the control rod driving mechanism on the rod drop as well as eliminates the 'scraping' between the moving disc and the magnetic disc.

Owner:TSINGHUA UNIV

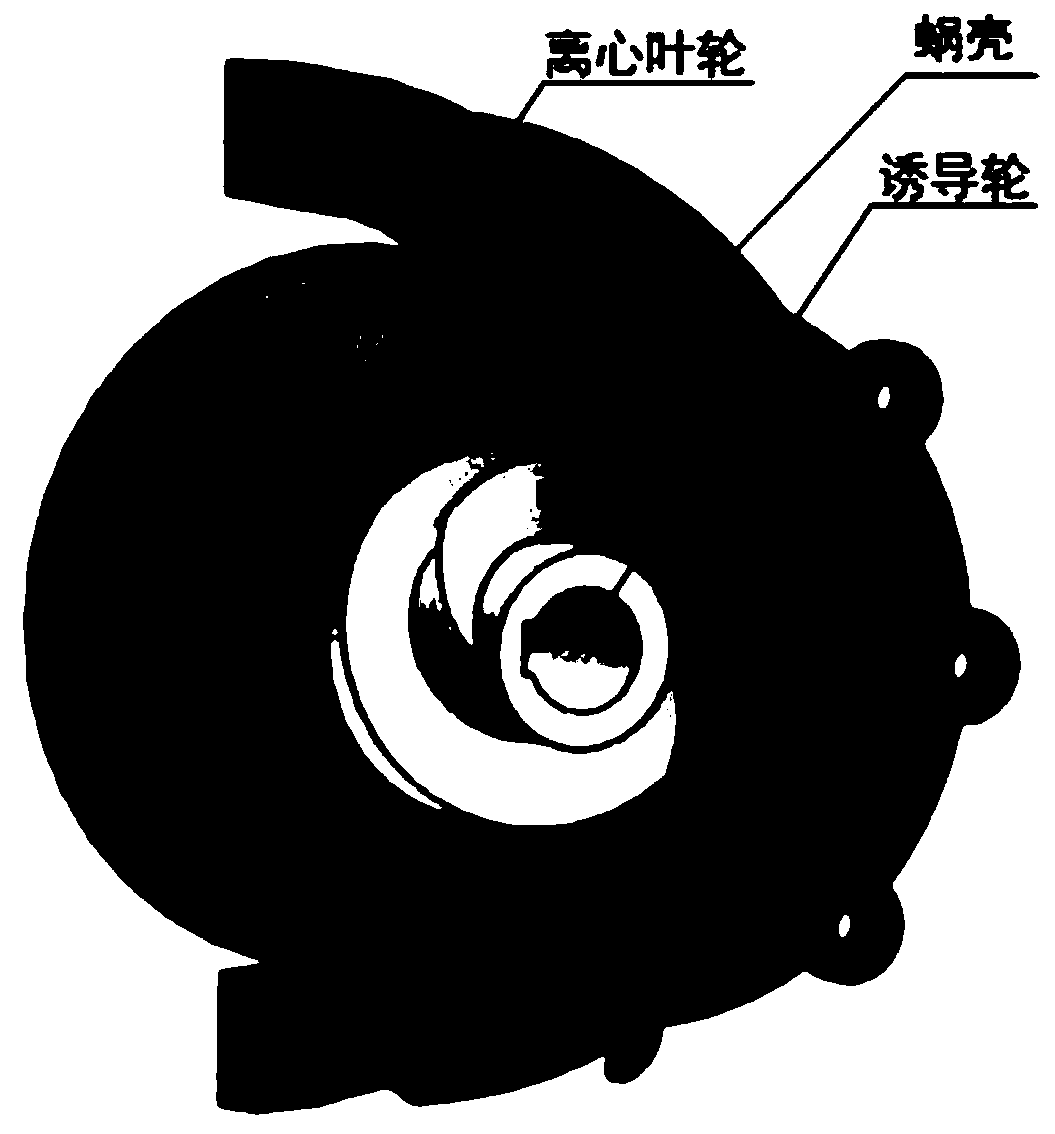

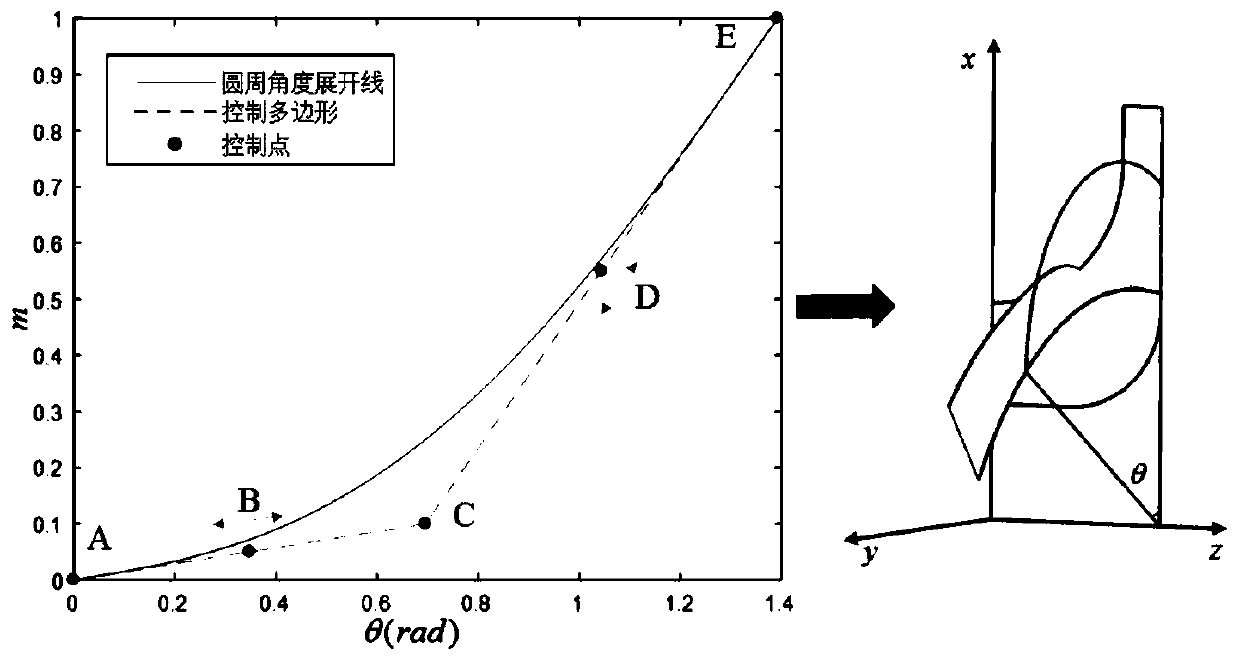

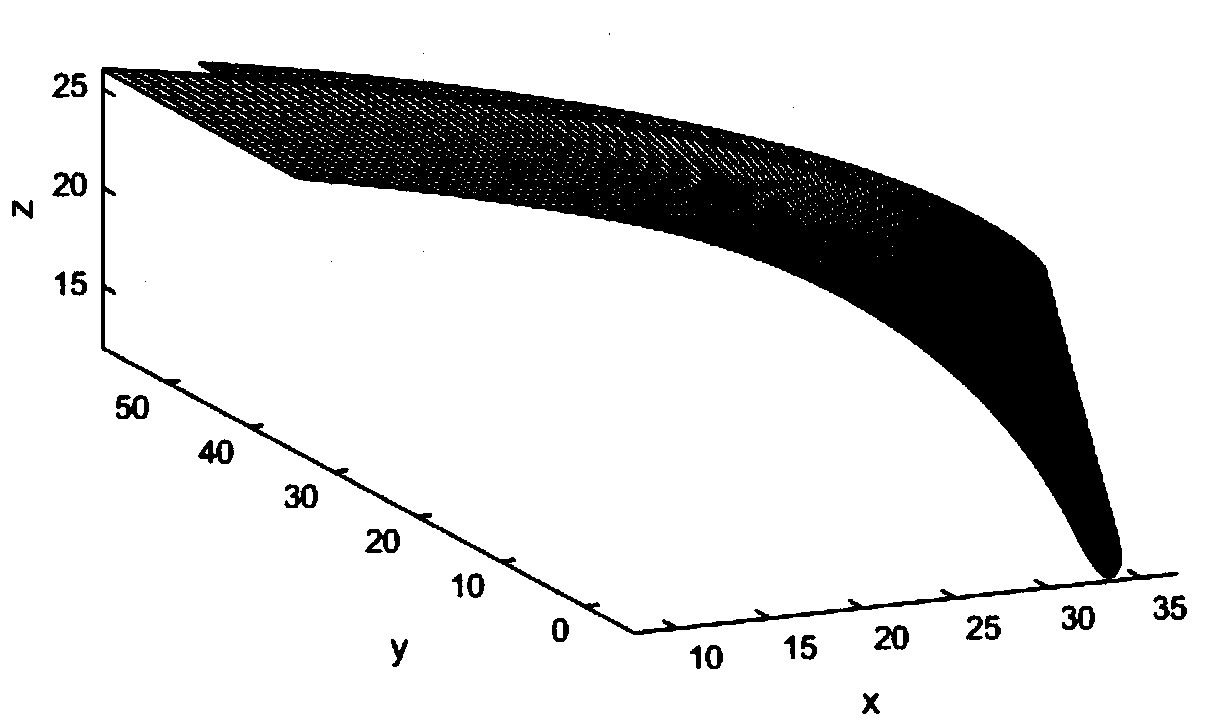

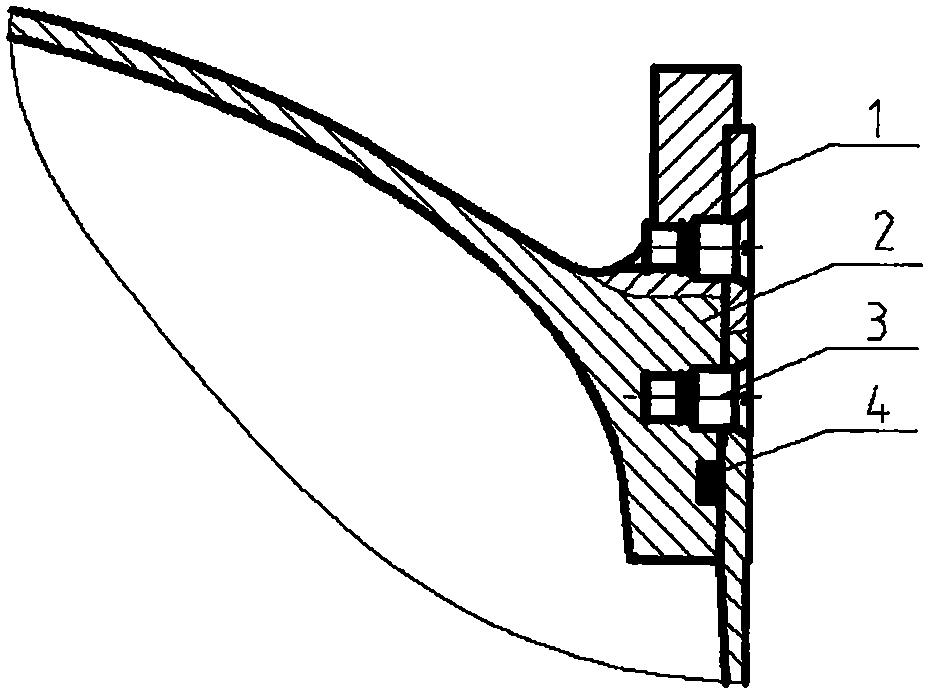

Aviation centrifugal pump blade profile optimization design method

ActiveCN110008653APerfect agreement predictive valueCompletely consistent test valueGeometric CADSustainable transportationAviationBatch processing

The invention discloses an aviation centrifugal pump blade profile optimization design method. Under a Matlab platform, a five-point four-time bezier curve and a linear function are adopted to controlthe blade profile circumference angle distribution and the product superposition change rule, and internal flow field numerical simulation is carried out on 15 sets of design results through a software UG and Fluent combined batch processing method. On the basis of obtaining a calculation space boundary condition through curved surface interpolation, numerical solution is carried out on the dual-harmonic partial differential equation by adopting a central difference format, and a hypercurved surface performance agent model is sestaboished. Global optimization is carried out on the design variable based on an artificial fish swarm algorithm by taking the highest efficiency as an objective function. The result shows that the hypersurface agent model based on the double harmonic equation canensure that the test value and the predicted value are completely consistent, the wake effect in the optimized centrifugal impeller flow is obviously weakened, and the hydraulic efficiency is improved by 5.4% compared with that of a prototype pump.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

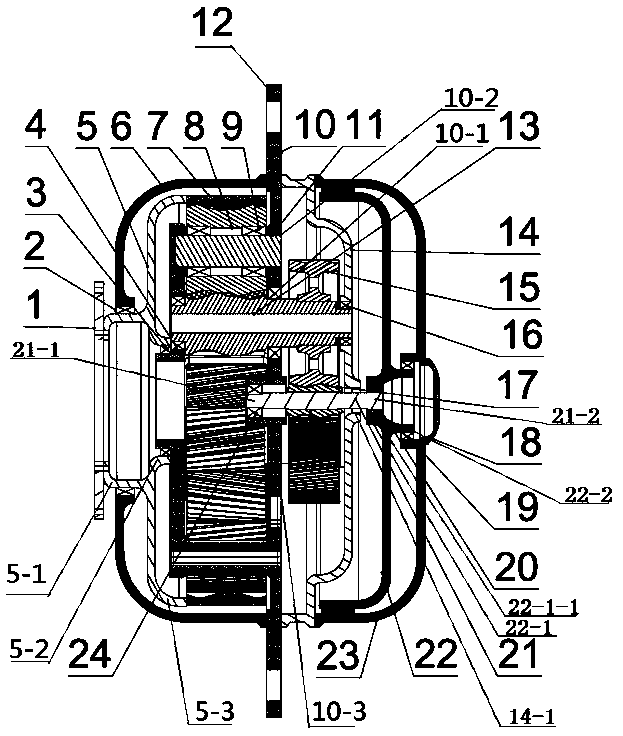

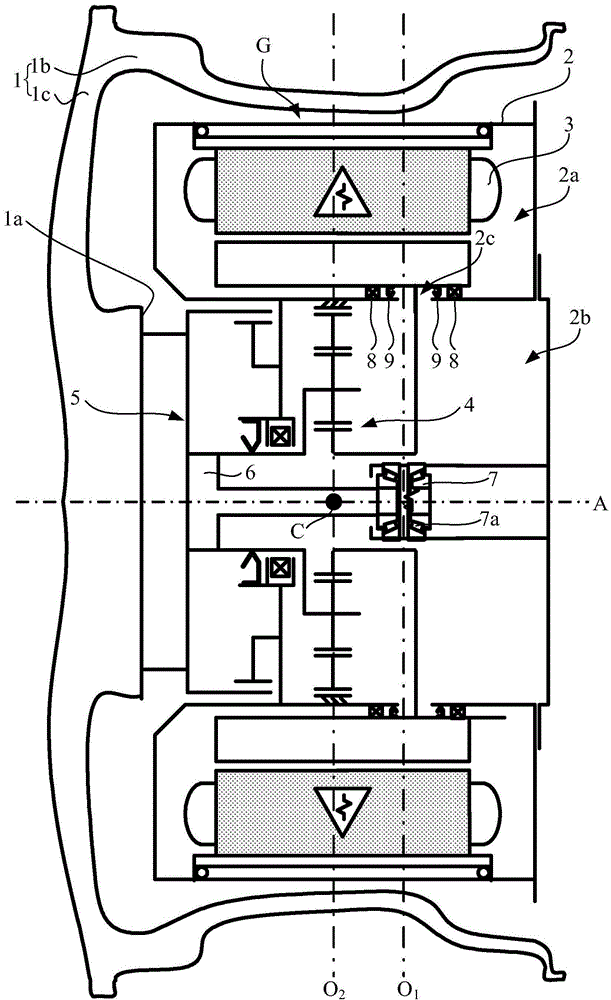

Integrated semi-direct drive wind generator transmission chain and gearbox for same

The invention provides an integrated semi-direct drive wind generator transmission chain and a gearbox for the same. The gearbox comprises a front box body (6), a rear box body (14), a spindle (5) and a planetary carrier (10), a large-diameter portion (5-3) of a downwind end of the spindle is fixedly connected with an inner gear ring (7), the inner gear ring (7) is engaged with at least three idle gears (8) mounted on the planetary carrier (10), the inner gear ring (7), the idle gears (8) and a first planetary gear form a primary fixed shaft transmission pair, a portion of each planetary gear shaft (13) extending out of the planetary carrier (10) is connected with a secondary planetary gear (15), the secondary planetary gear (15) is positioned in a cavity formed by the planetary carrier (10) and the rear box body (14) and engaged with the same sun gear (17), and the secondary planetary gear (15) and the sun gear (17) form a secondary fixed shaft transmission pair. The gearbox has the advantages of integration, light weight, short axial length, convenience in disassembly and assembly and the like.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Cylindrical cuspend magnetic field thruster

InactiveCN104595139ALight in massChanging the magnetic field configurationMachines/enginesUsing plasmaEngineeringDistributor

The invention relates to a cylindrical cuspend magnetic field thruster, and relates to a cuspend magnetic field thruster, which aims at solving the problem of overlong thruster ceramic passage caused by the smaller radial size of the existing ionizing area. An air guide device is arranged on a working medium spraying hole, a conducting bolt is arranged in the other working medium spraying hole in a penetrating way, two ceramic gaskets sleeve the conductive bolt and are fixed by a nut, an annular anode is fixedly arranged in the middle part of the inside wall of a cylindrical ceramic channel body, an air distributor is arranged in the cylindrical ceramic channel body, a second aluminum alloy end cover, a magnet, a plurality of second magnetic pieces, a first magnetic piece, a coil, a magnetic piece base, a first aluminum alloy bracket and a bracket plate sequentially sleeve the outside wall of the cylindrical ceramic channel body from right to left, the magnet bracket sleeves the magnet, the coil bracket sleeves the coil, the outer aluminum alloy sleeve sleeves the first magnetic piece, the second magnetic pieces and the magnet bracket, and the aluminum alloy bracket sleeves the outer wall of the cylindrical ceramic channel body. The cylindrical cuspend magnetic field thruster is applied to the field of aerospace.

Owner:HARBIN INST OF TECH

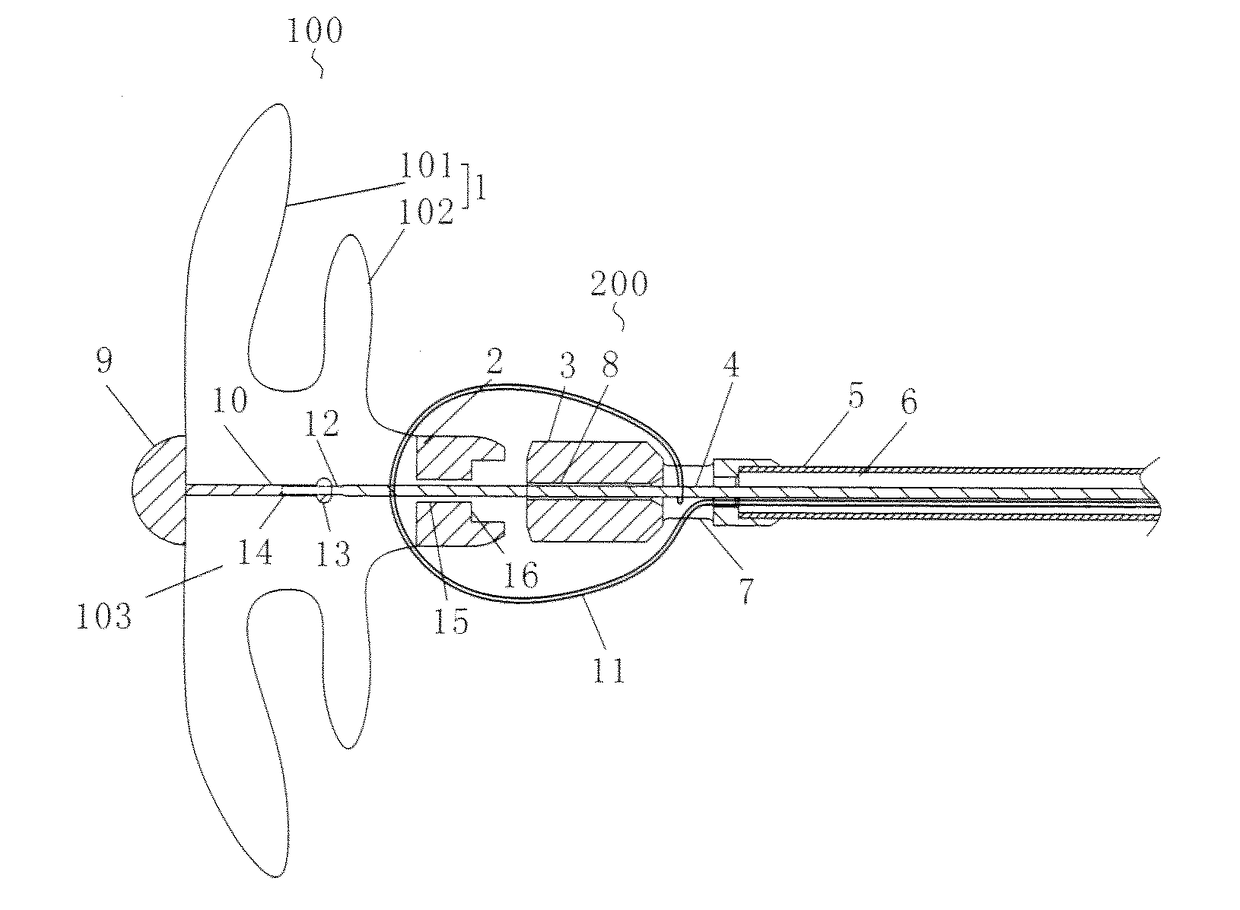

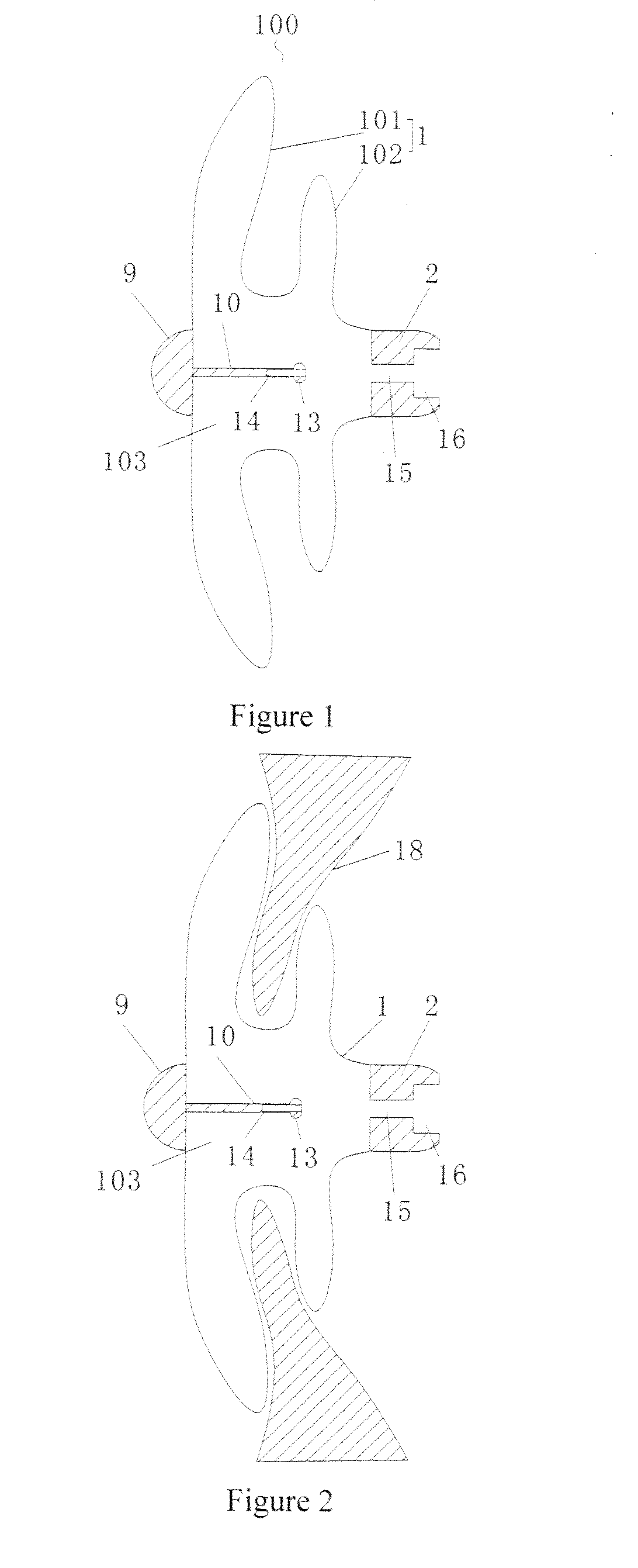

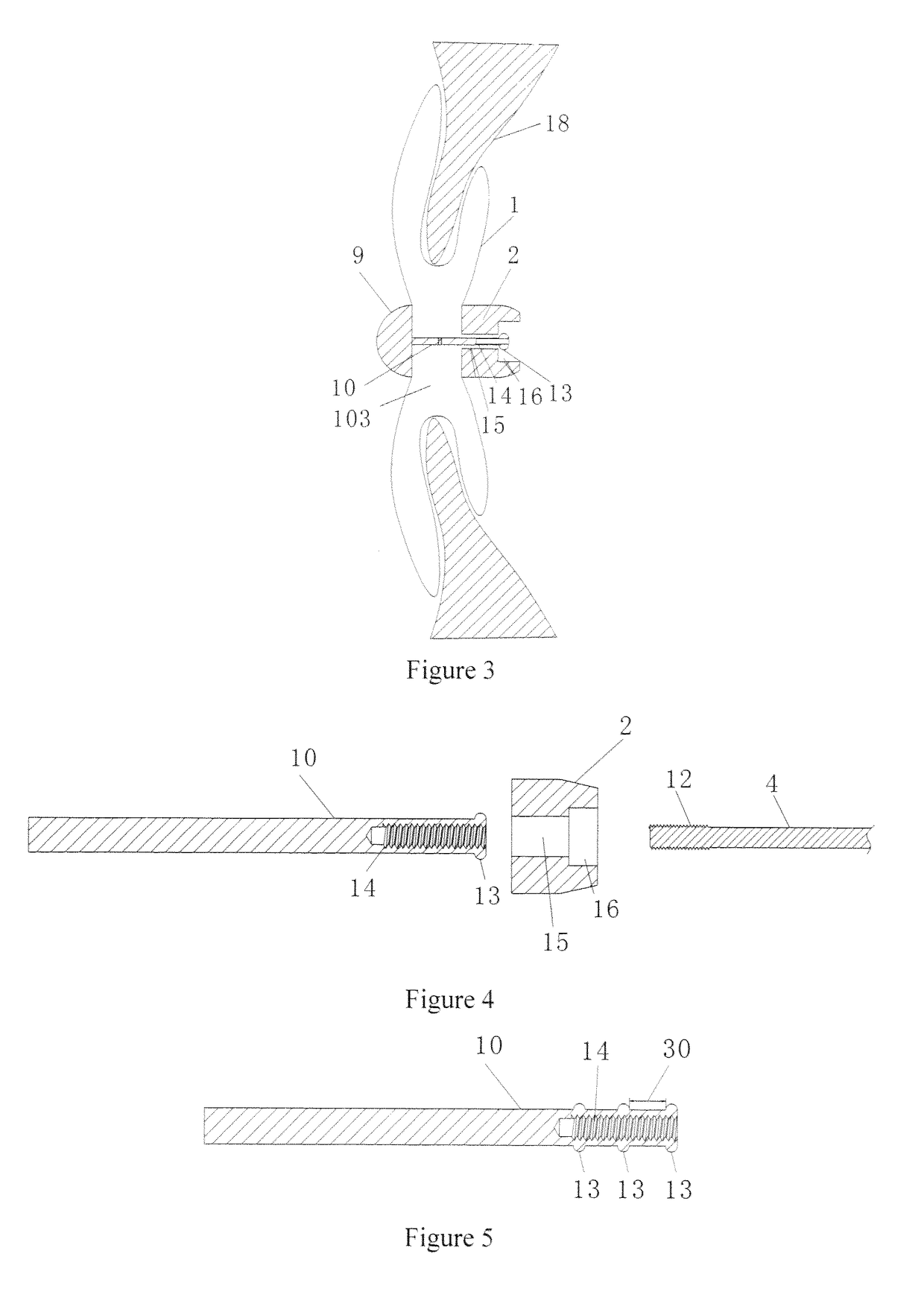

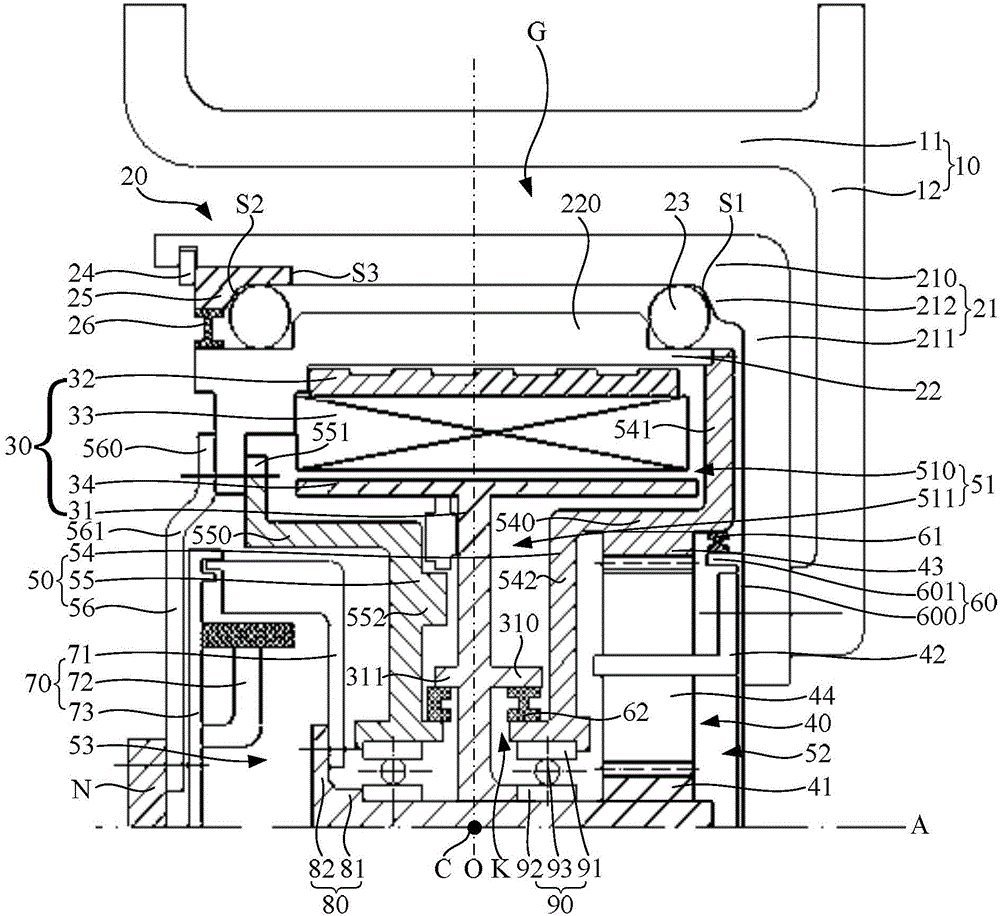

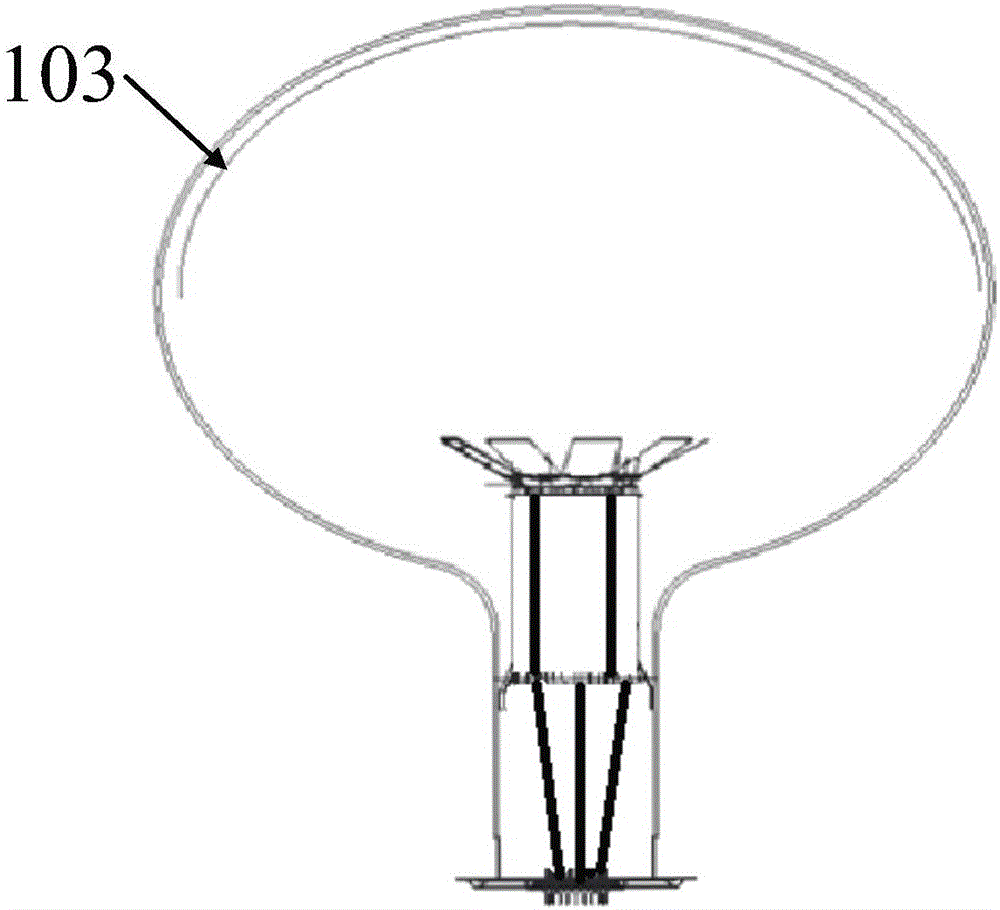

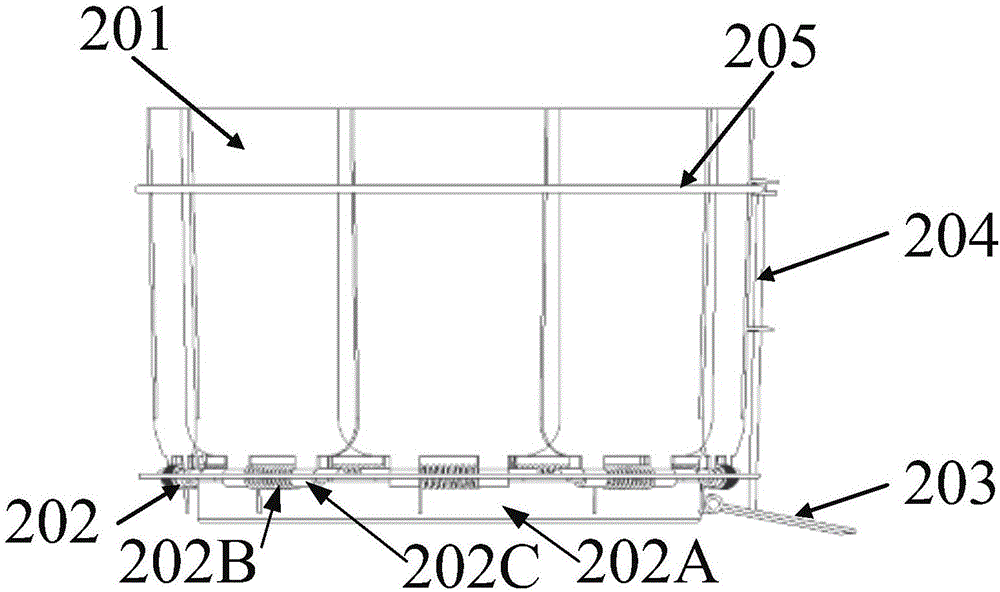

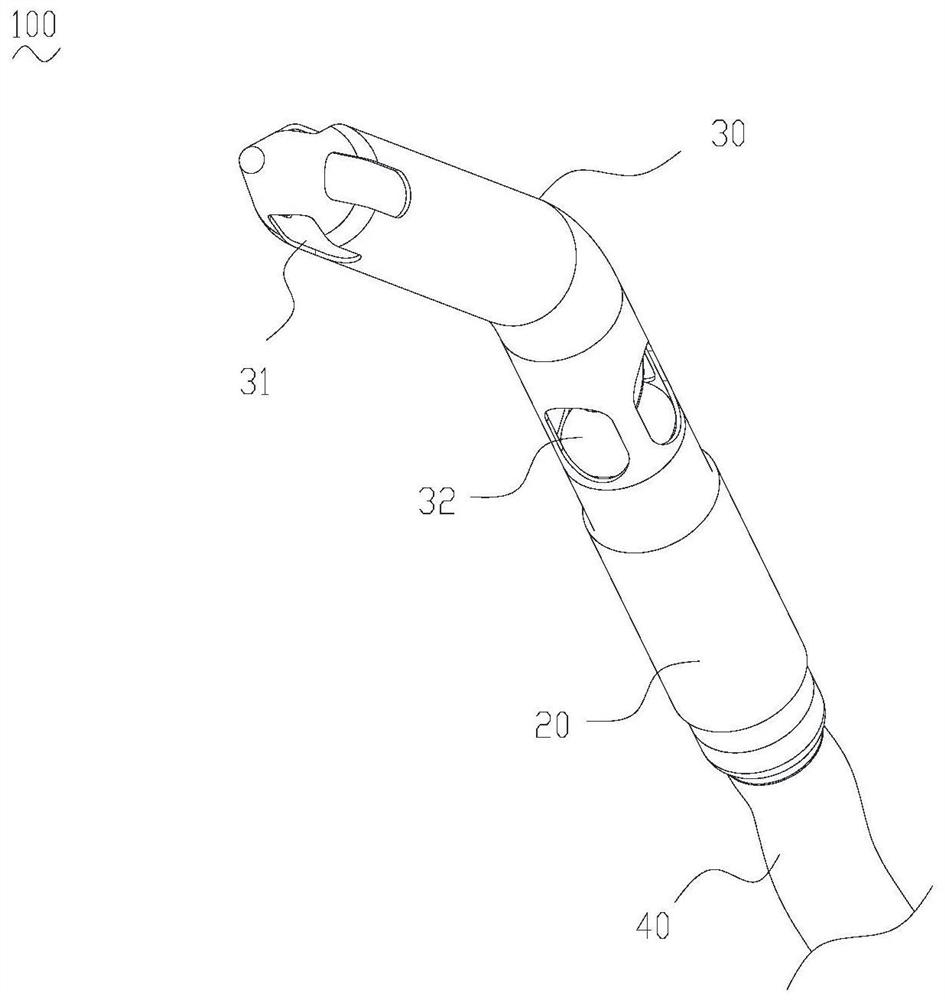

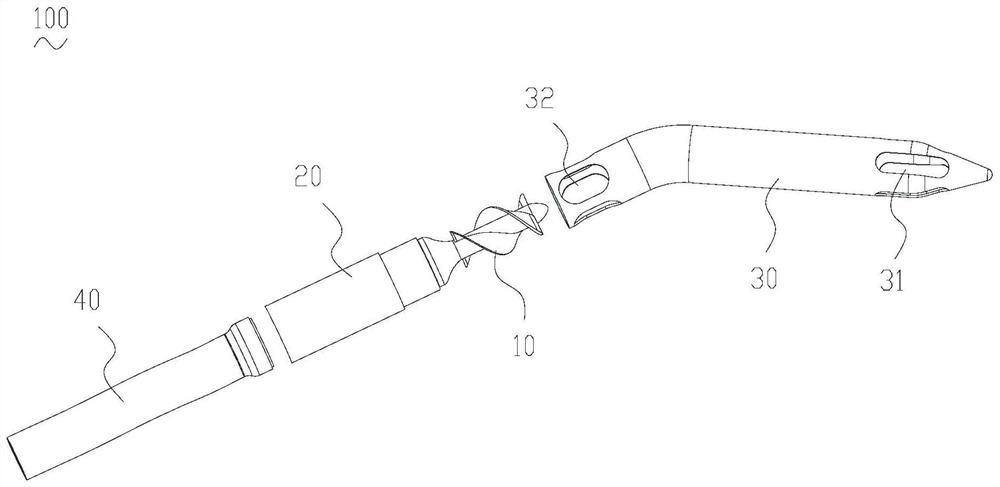

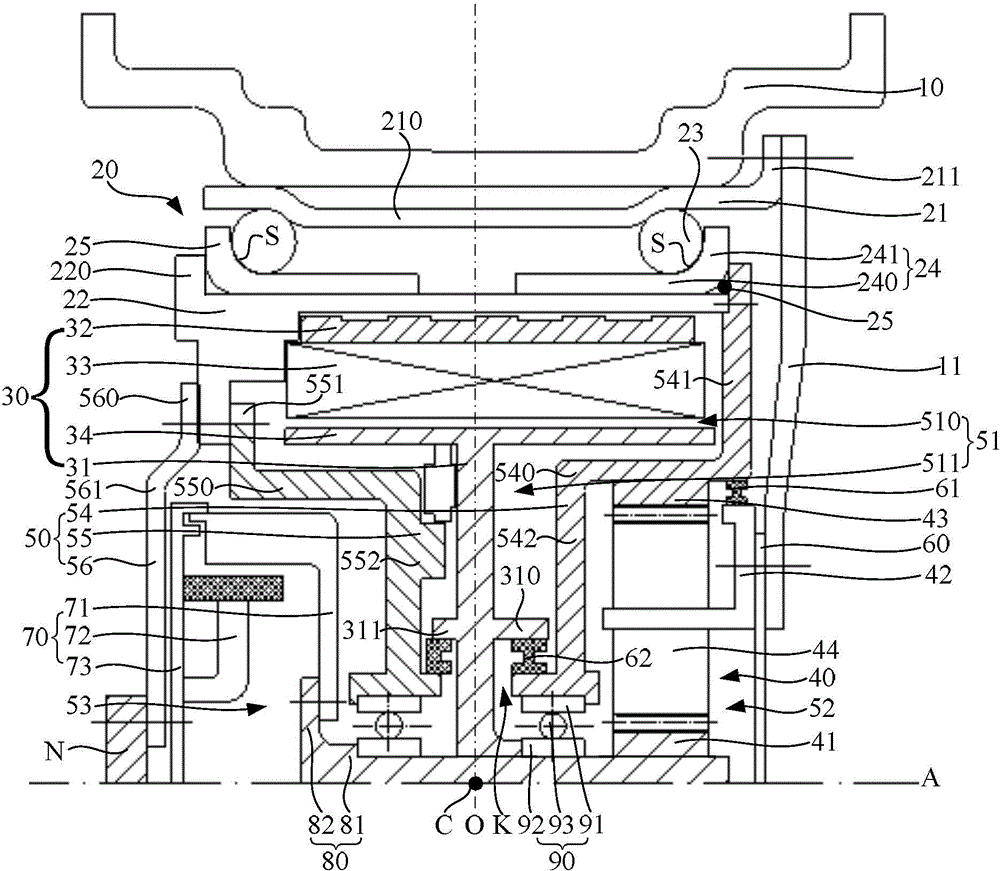

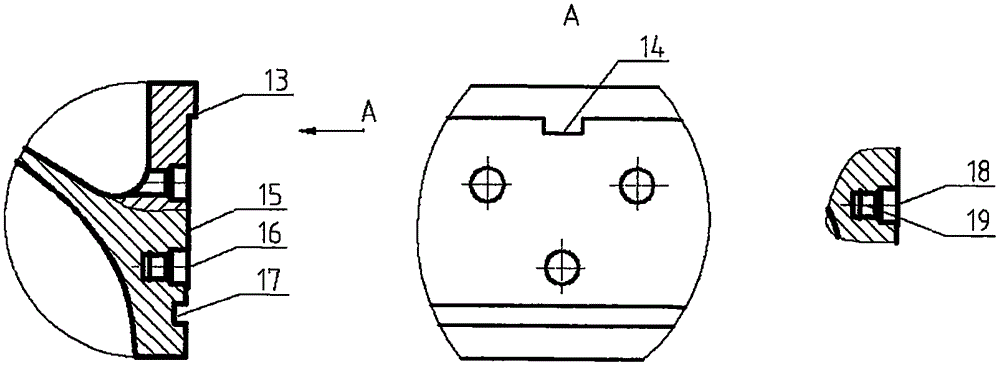

Occluder and Occlusion Device

The present invention relates to an occluder (100), comprising a meshed occlusion body (I) provided with a cavity (103), and a proximal hub (2), as well as a locking member (10) and a stopping member (13) both of which are located in the cavity (103). The distal end of the locking member (10) is connected to the distal end of the occlusion body (1). The stopping member (13) is disposed at the proximal end of the locking member (10). The proximal occluder head (2) is provided with a locking hole (15) in communication with the cavity (103). The radial size of the stopping member (13) is slightly larger than the diameter of the locking hole (15). The radial size of the locking member (10) is smaller than the diameter of the locking hole (15), and at least one of the proximal occluder head (2) and the stopping member (13) is an elastic member. An occlusion device comprises the occluder (100), a hollow delivery mechanism (200) and a traction member (4). The distal end of the traction member (4) is detachably connected to the proximal end of the locking member (10) of the occluder (100) after extending through the distal end of the delivery mechanism (200). The occlusion device has a simple locking structure, and simplifies the manufacturing process and the locking operation.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

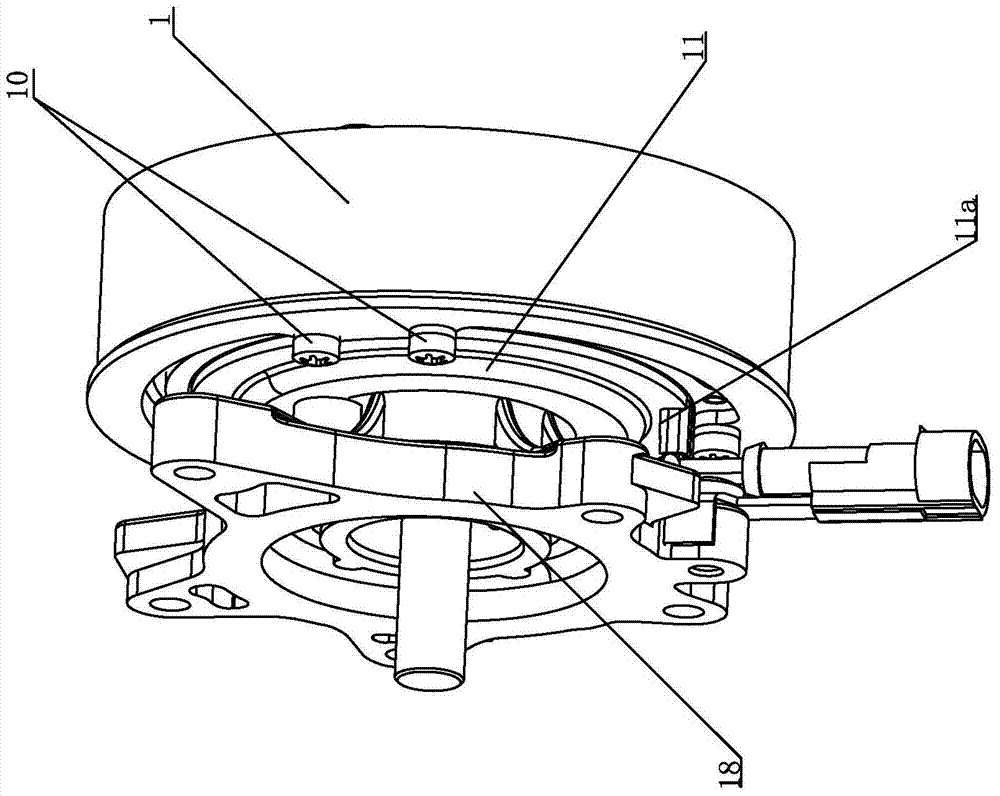

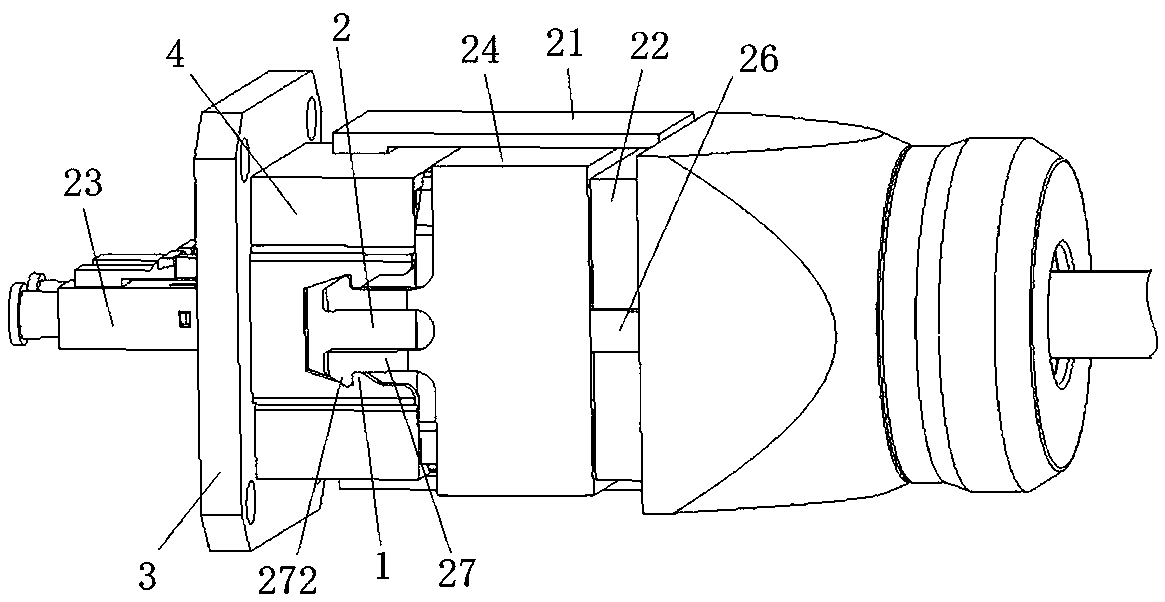

Hub driving assembly

InactiveCN105691103AIncrease radial sizeIncrease stiffnessHubsMotor depositionReduction driveRoad surface

A hub driving assembly comprises a hub, a hub bearing, a motor, a speed reducer and a housing, wherein the hub bearing is positioned in the hub. The hub bearing comprises an outer ring, an inner ring and a rolling body, wherein the rolling body is positioned in a radial gap between the outer ring and the inner ring; the housing defines a motor chamber, in which the motor is accommodated, and a speed reducer chamber, in which the speed reducer is accommodated; an output end of the motor extends out of an opening of the motor chamber and is connected with an input end of the speed reducer; an output end of the speed reducer is connected with the hub; the motor, the speed reducer and the housing are all positioned on the internal side of the hub bearing in a radial direction; the outer ring is fixedly connected with the hub, or the hub is also used as the outer ring; and the inner ring is fixedly connected with the housing. According to the technical scheme of the invention, problems that the rigidity of the hub bearing in the traditional hub driving assembly is not enough, hard matters may stop the rotation of the hub and wear and tear the hub when the hard matters on a pavement are clamped into the internal circumferential surface of the hub in the vehicle running process, and the speed reducer cannot obtain a large speed reduction ratio are solved.

Owner:SCHAEFFLER TECH AG & CO KG

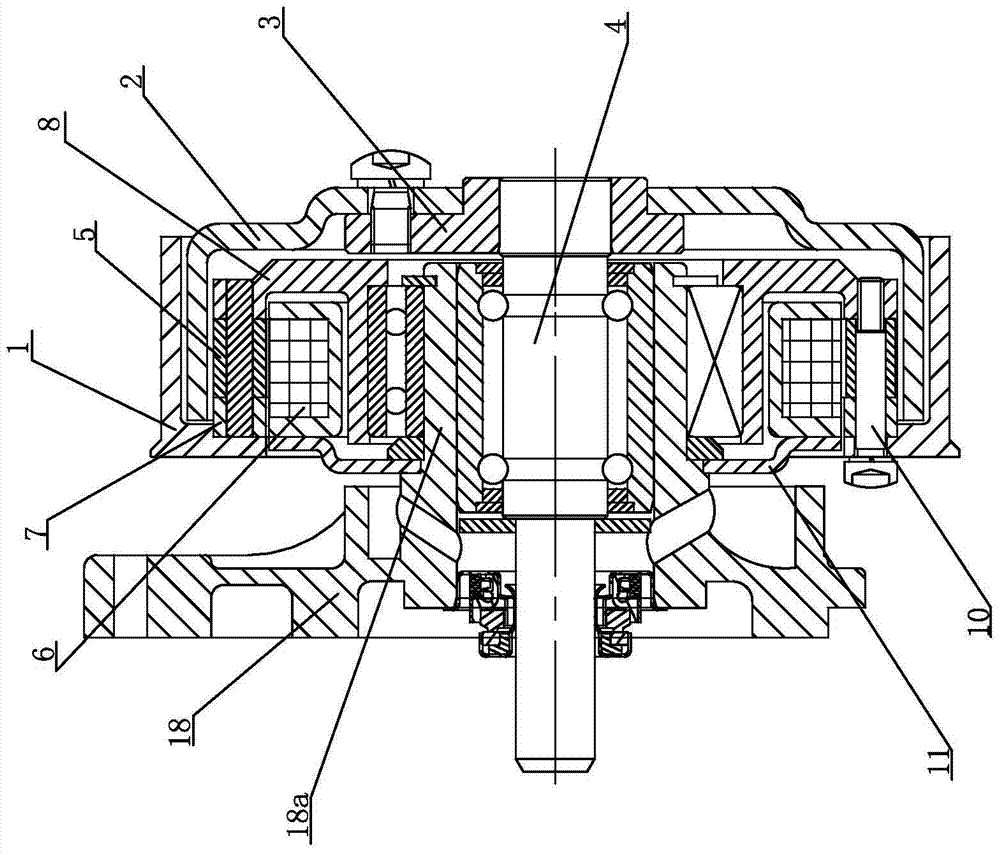

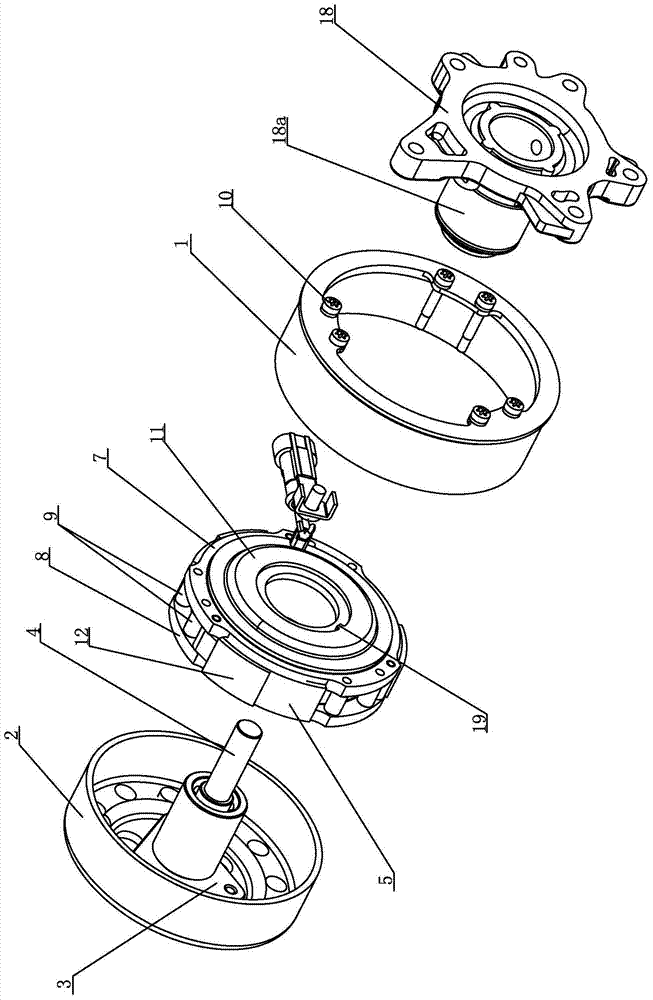

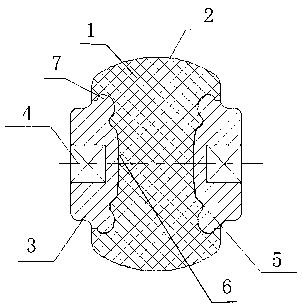

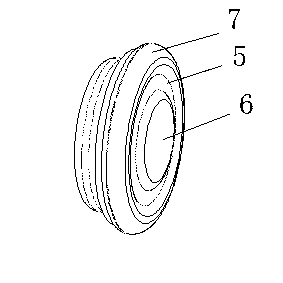

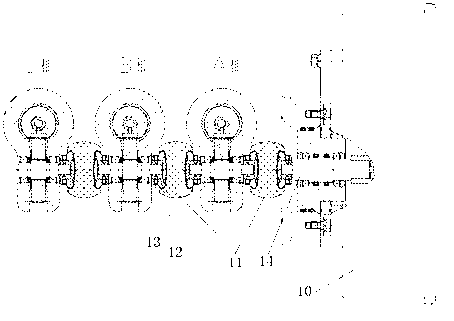

Centrifugal electromagnetic clutch and water pump with centrifugal electromagnetic clutch

ActiveCN103615477AAxial dimensions are compactReduce volumeMagnetically actuated clutchesPump controlElectromagnetic clutchDrive shaft

Provided is a centrifugal electromagnetic clutch. The centrifugal electromagnetic clutch comprises a first rotating body, a second rotating body and a transmission shaft, wherein the second rotating body can rotate along with the first rotating body, power of the second rotating body is transmitted out through the transmission shaft, the second rotating body is arranged inside the first rotating body in a radial mode, and a centrifugal clutch device is axially arranged between the first rotation body and the second rotating body, and is arranged inside the second rotating body in a radial mode. The centrifugal clutch device comprises a plurality of magnetism-conductive centrifugal pieces, an electromagnetic coil, a magnetism-conductive connecting body and a magnetism-conductive supporting body, wherein the magnetism-conductive connecting body is fixed to the inner side of the first rotating body, and is arranged outside the electromagnetic coil in a radial mode, the magnetism-conductive supporting body is installed on the transmission shaft, the first rotating body is fixed to the magnetism-conductive supporting body, the magnetism-conductive centrifugal pieces are distributed along the outer circumference of the electromagnetic coil, one end of each magnetism-conductive centrifugal piece is hinged to the position between the magnetism-conductive connecting body and the magnetism-conductive supporting body, friction plates are arranged on the outer surfaces of the magnetism-conductive centrifugal pieces, wear-resistant layers are arranged on the inner wall face, opposite to the friction plates, of the second rotating body, when the electromagnetic coil is deenergized, the friction plates are attached to the wear-resistant layers of the second rotating body, and when the electromagnetic coil is energized, the friction plates are separated from the wear-resistant layers of the second rotating body.

Owner:LONGKOU ZHONGYU MACHINERY

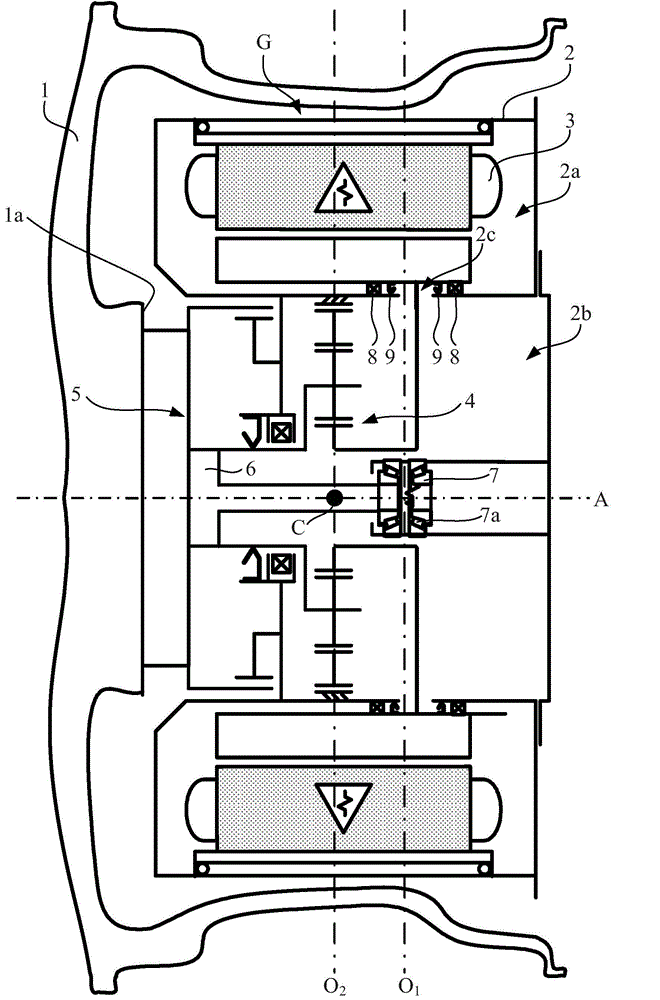

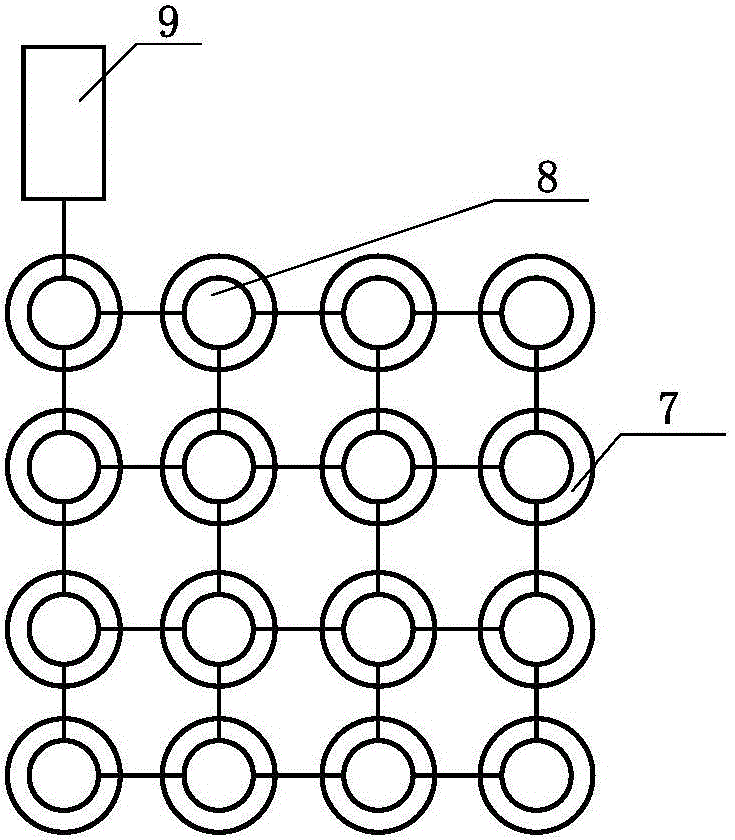

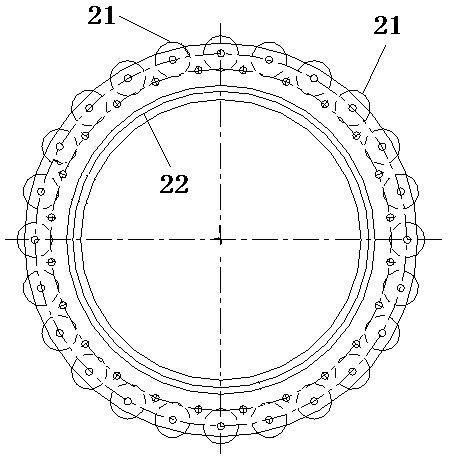

Capacitance type micro-ultrasonic sensor ring array with oval diaphragm unit structure and circuit system thereof

InactiveCN104622512AIncrease radial sizeImprove receiver sensitivityOrgan movement/changes detectionInfrasonic diagnosticsCapacitanceWork unit

The invention discloses a capacitance type micro-ultrasonic sensor ring array with an oval diaphragm unit structure and a circuit system thereof. The work unit of the ring array is an oval diaphragm secondary array. The oval diaphragm secondary array comprises an oval vibrating diaphragm, oval diaphragm secondary array top electrodes and oval diaphragm secondary array top electrode outlet PADs, wherein the oval diaphragm secondary array top electrodes are distributed above the oval vibrating diaphragm, and each oval diaphragm secondary array top electrode is connected with the corresponding oval diaphragm secondary array top electrode outlet PAD. An FPGA controls a transmitting end to scan each device unit and send phase-controlled pulse signals, and focusing and translation of transmitted acoustic waves of the capacitance type micro-ultrasonic sensor ring array with the oval diaphragm unit structure are achieved through a phased array. A receiving device receives ultrasonic echo signals which are then read into an FPGA memory through a pre-amplifier and an analog to digital conversion module (AD), and imaging is conducted according to the phase and amplitude of each received signal. According to the capacitance type micro-ultrasonic sensor ring array with the oval diaphragm unit structure, the sweep area of the imaging ring array is increased and the receiving sensitivity of an oval vibrating diaphragm is improved.

Owner:TIANJIN UNIV

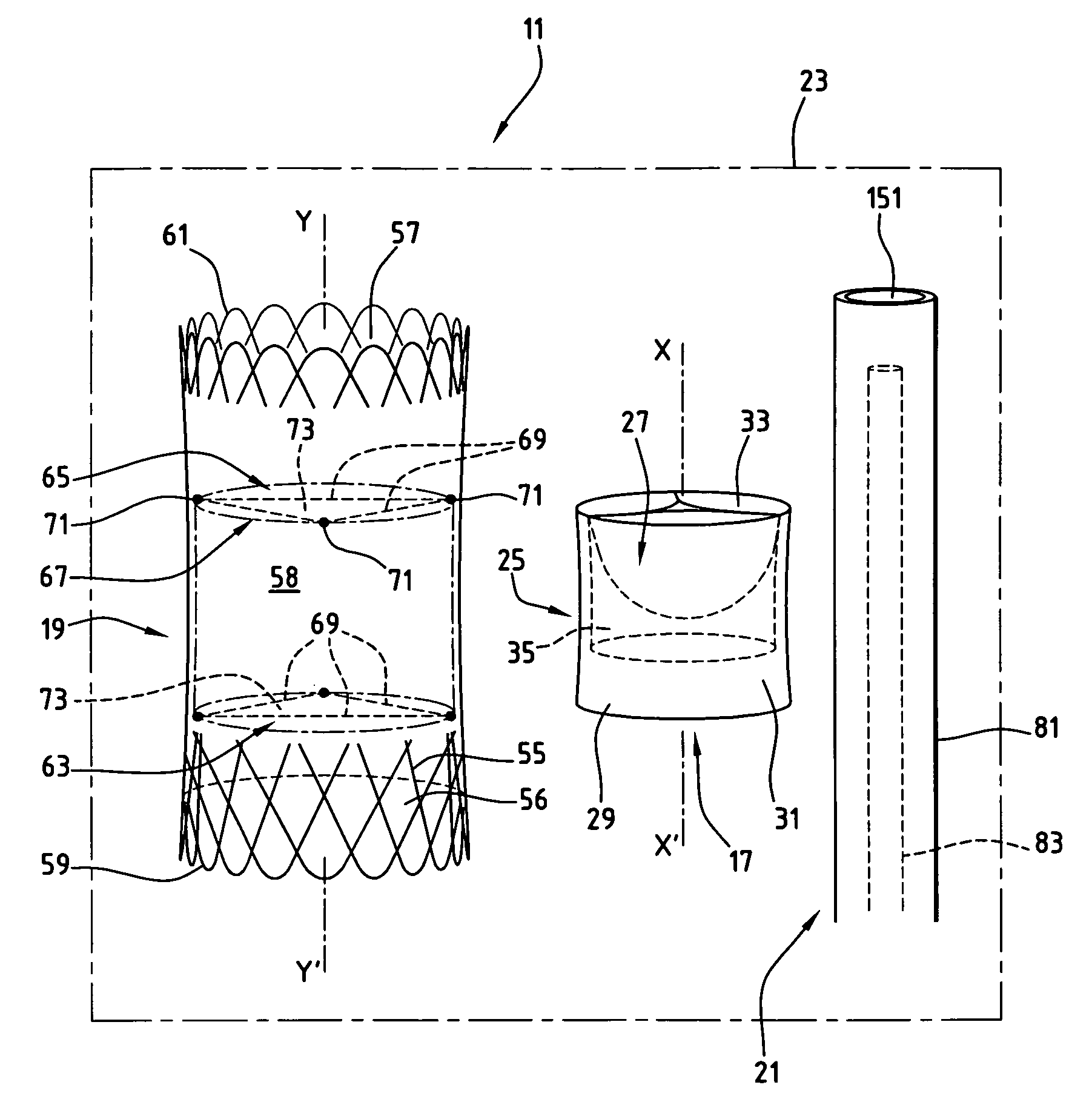

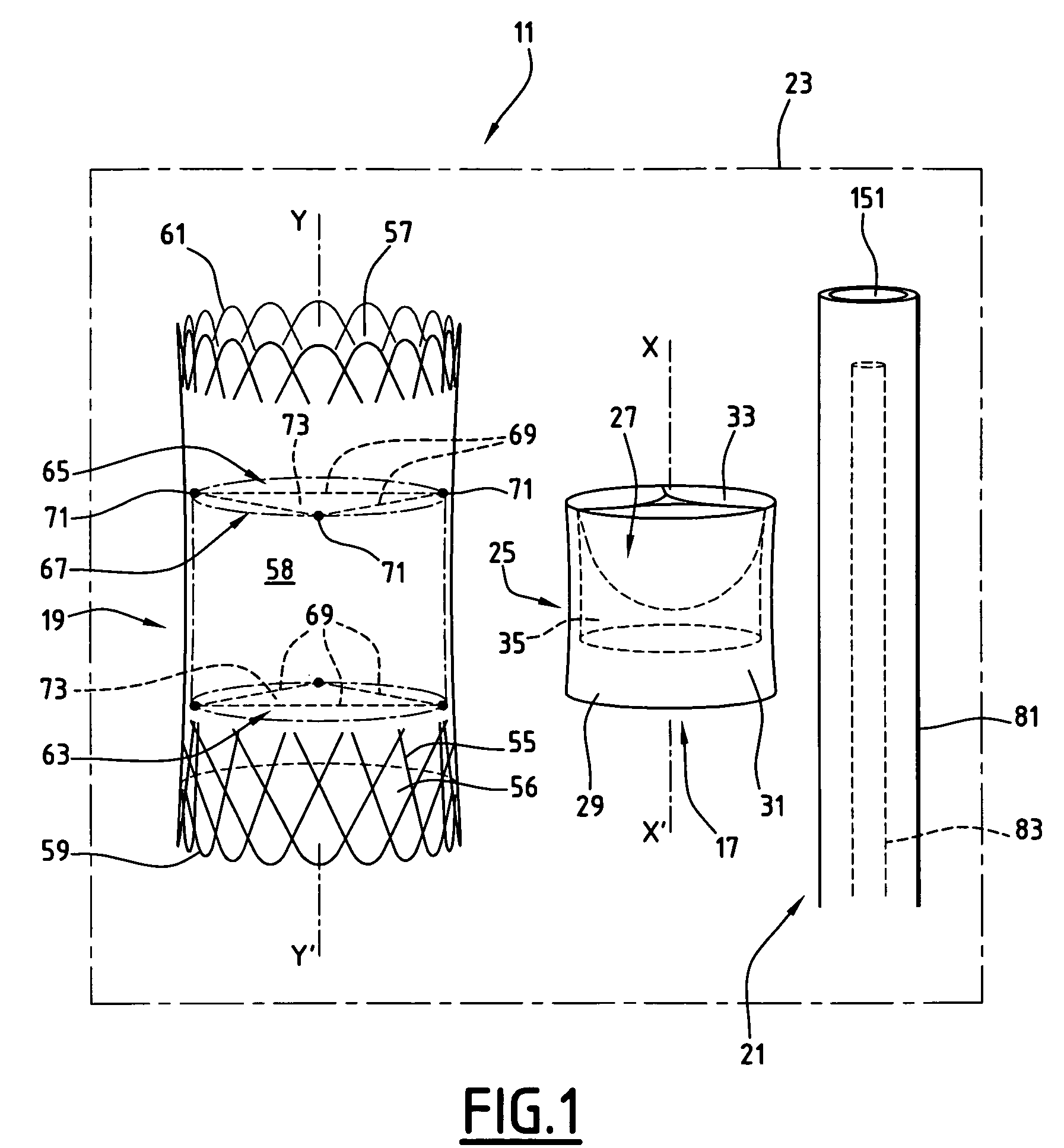

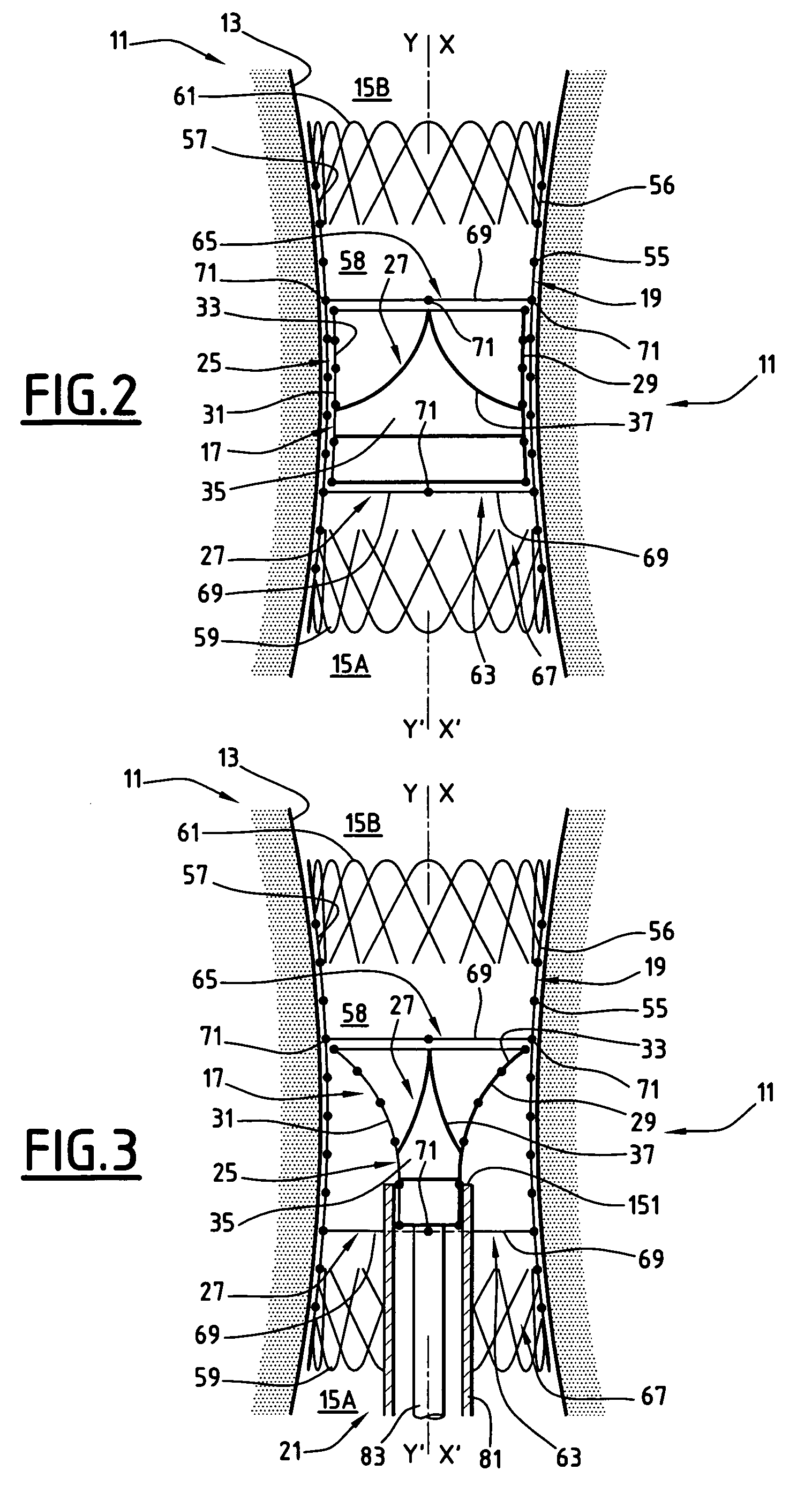

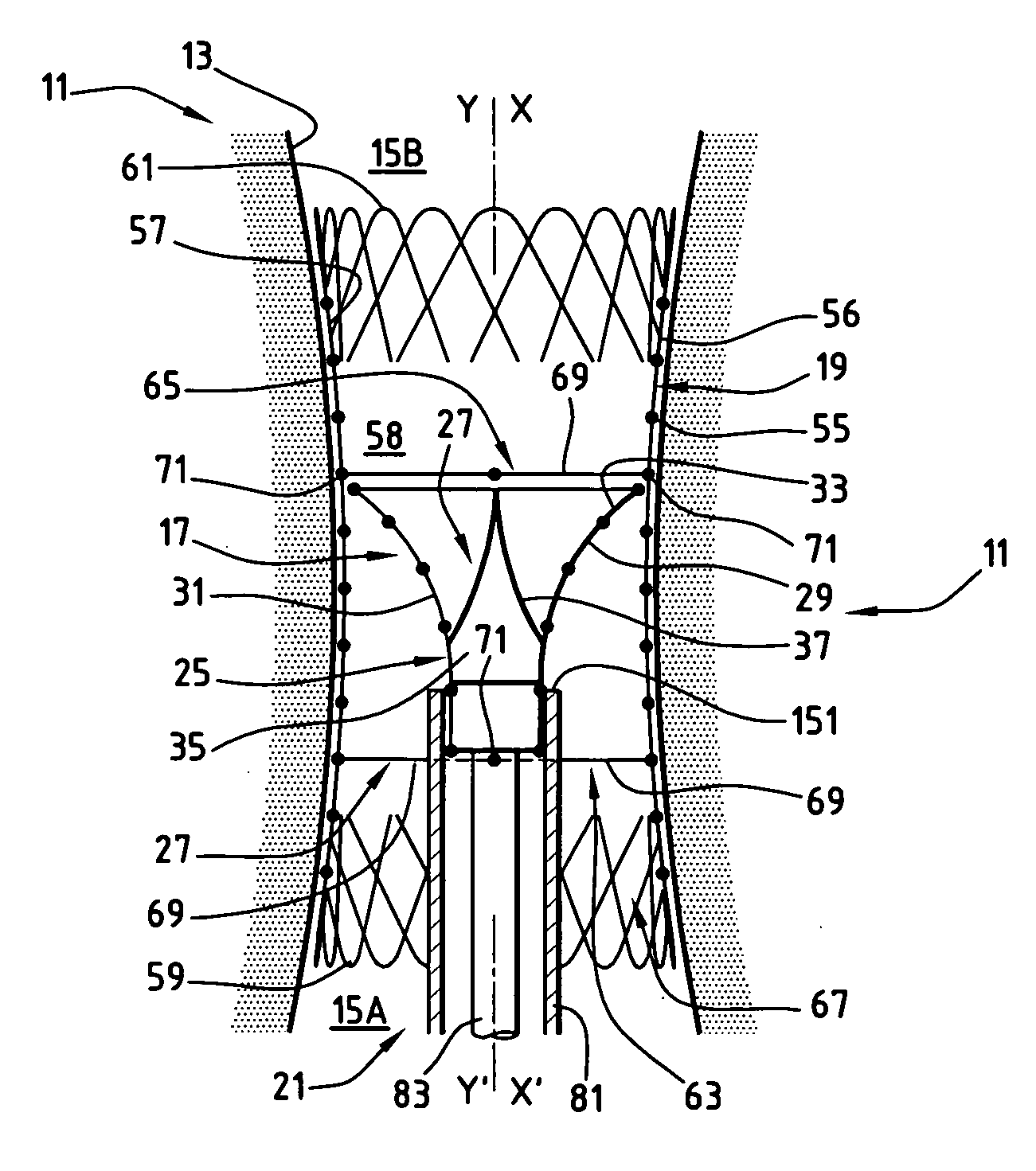

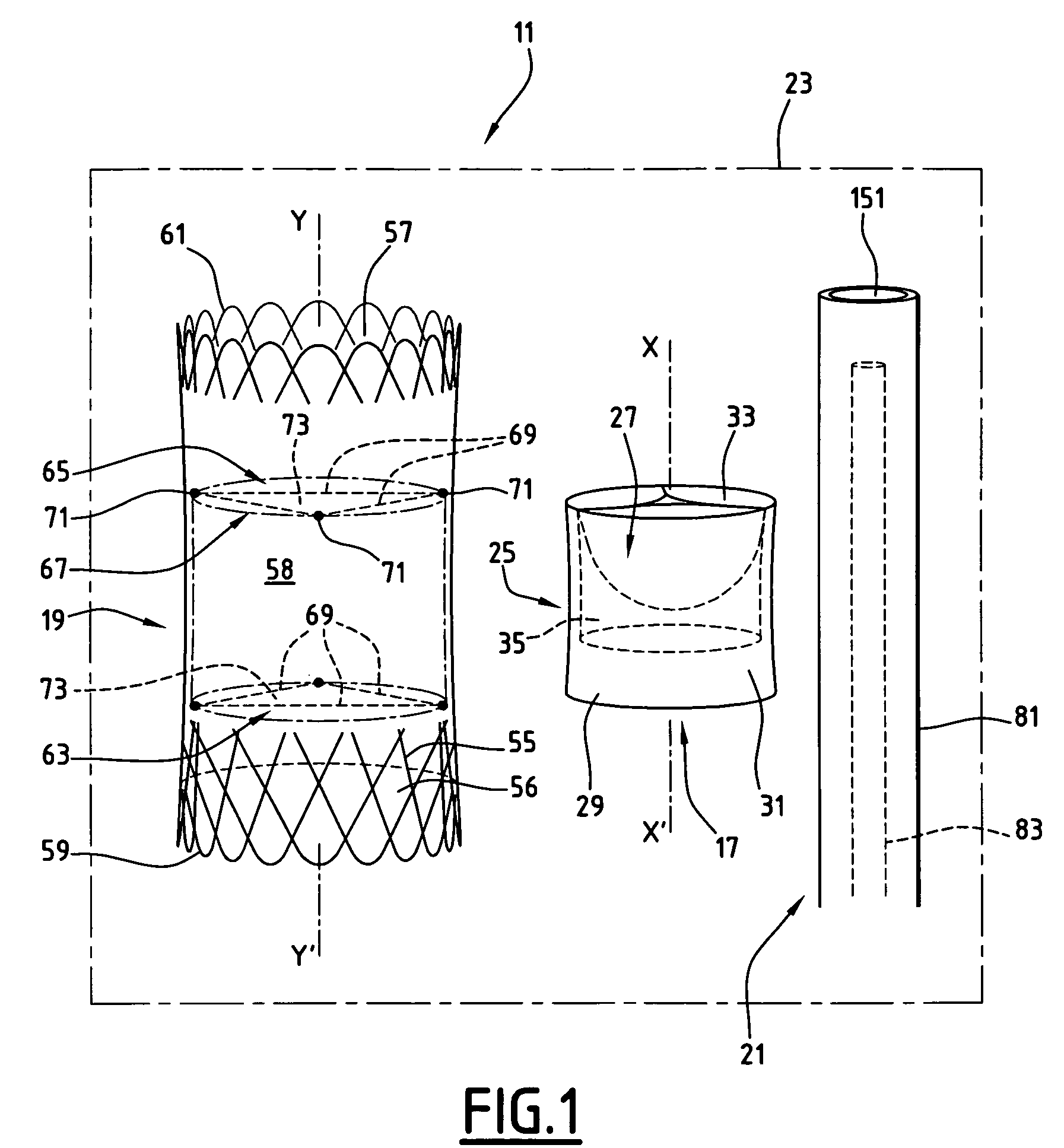

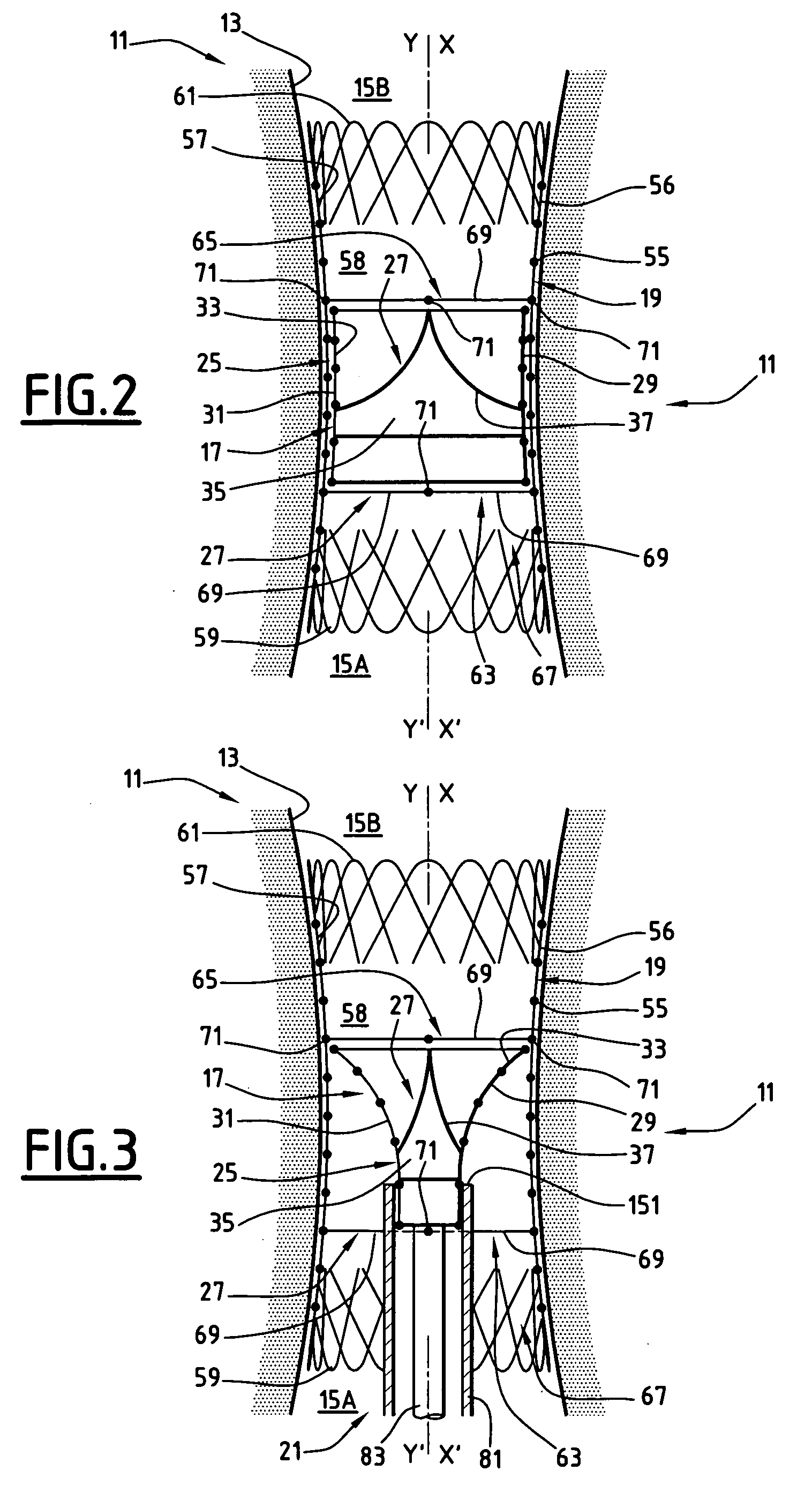

Kit to be implanted in a blood circulation conduit

This kit (11) comprises a tubular endoprosthesis (19) having an inner surface (57) which delimits a channel (58) with a longitudinal axis (Y-Y′). It comprises a prosthetic valve (17) to be implanted in the channel (58). The valve (17) comprises a supporting framework (25) having an outer surface (31) to be applied against the inner surface (57), and a flexible obturator (27) which is connected to the framework (25).The endoprosthesis (19) comprises a stop (63, 65) for locking the supporting framework (25) in order to block the axial displacement of the outer surface (31) along the inner surface (57) in at least a first direction. The stop (63, 65) comprises at least one flexible connection (69) extending transversely in the channel (58) between two connection points (71), which are located on the inner surface (57) and are angularly spaced about the axis (Y-Y′).

Owner:WL GORE & ASSOC INC

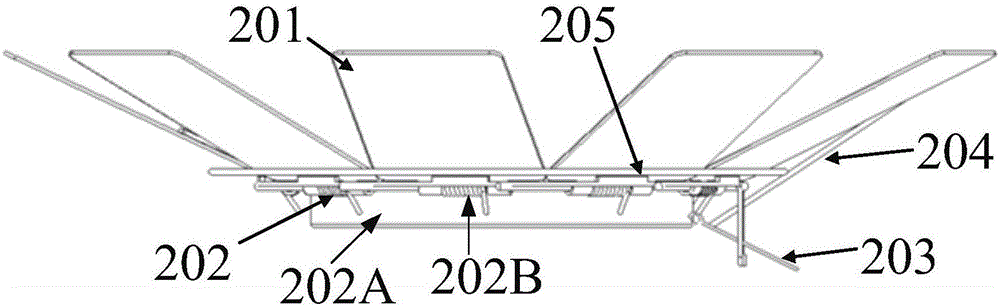

Automatic expansion focusing electrode for photomultiplier and photomultiplier

ActiveCN106449346AObvious beneficial effectImprove time characteristicsMultiplier dynodesQuantum efficiencyPhotocathode

The invention discloses an automatic expansion focusing electrode and an automatic expansion focusing electrode-based photomultiplier. The photomultiplier comprises a high-vacuum seal shell, the automatic expansion focusing electrode, a high-quantum efficiency photocathode, an electronic multiplier system and a connection and lead system, wherein the high-vacuum seal shell has main functions of sealing and being used as a substrate for other films as a photomultiplier housing part; and the automatic expansion focusing electrode comprises a bottom plate, expansion blades and an automatic trigger mechanism as an electronic collector of the photomultiplier. The high-quantum efficiency photocathode is located in an upper area of the high-vacuum seal shell and converts incident photons into electrons. The electronic multiplier system is located at the lower part of the automatic expansion focusing electrode, amplifies the electrons collected by the focusing electrode and then leads out the electrons through the lead system. The automatic expansion focusing electrode touches the trigger mechanism in a photomultiplier packaging process, so that an expansion action of the automatic expansion focusing electrode is achieved and expansion of the radial size of the focusing electrode is achieved.

Owner:NORTH NIGHT VISION TECH

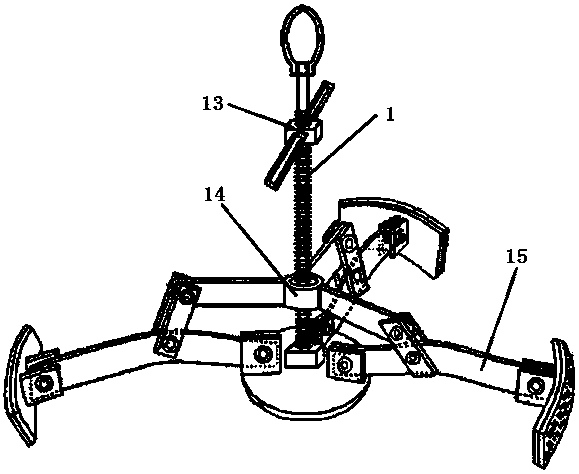

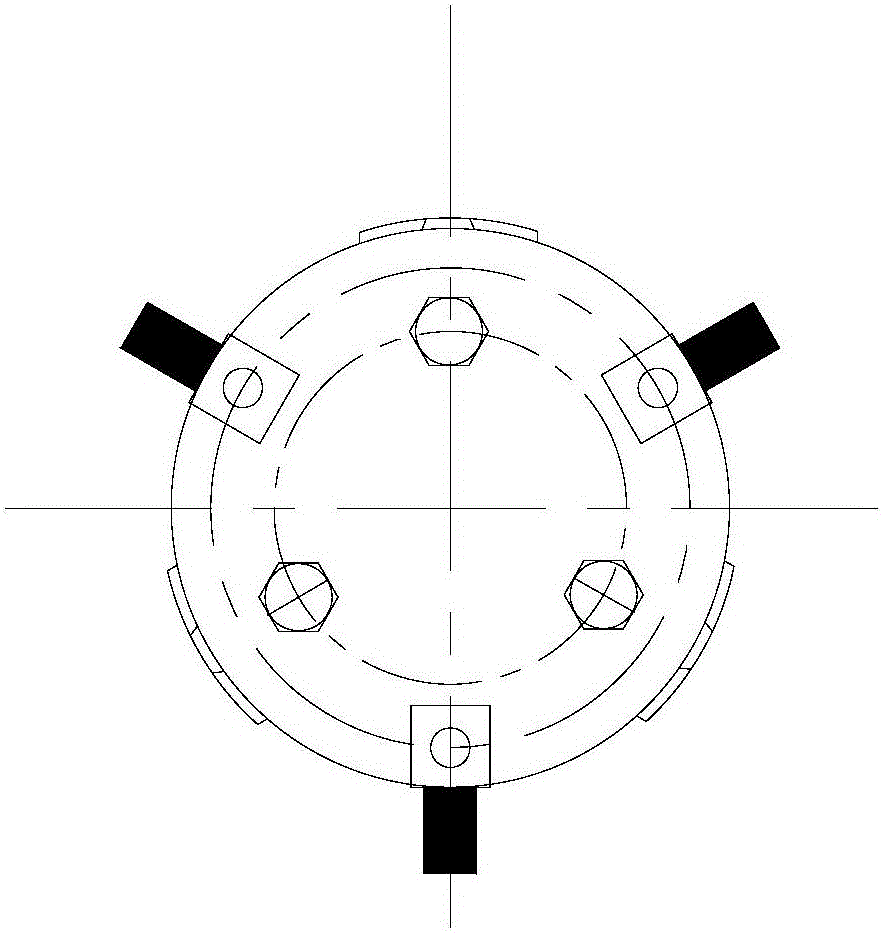

Lifting and transporting tool for crucible

PendingCN108394809AImprove support strengthGuaranteed stabilityLoad-engaging elementsCrucibleArchitectural engineering

The invention relates to the technical field of transport lifting slings, and particularly provides a lifting and transporting tool for a crucible. The lifting and transporting tool for the crucible comprises a suspender which is vertically arranged. The suspender is sleeved with a connecting sleeve capable of moving up and down, and the connecting sleeve is hinged to external support rods for supporting the inner wall of the crucible. The external support rods are provided with supporting members for supporting the inner wall of the crucible, and the three or more external support rods are arranged. A hinge seat is fixedly arranged at the bottom of the suspender, and inner support rods which are hinged to the external support rods and are used for supporting the external support rods arearranged between the hinge seat and the external support rods. In the process of the movement of the external support rods and the inner support rods, the lifting and transporting tool for the crucible has the movement state of the external support rods facing down and the inner support rods facing up. Technicians can only move the connecting sleeve on the suspender to drive the movement of the external support rods and the inner support rods, and the extension or contraction of the external support rods are achieved, and the operation is simple.

Owner:洛阳乾中新材料科技有限公司

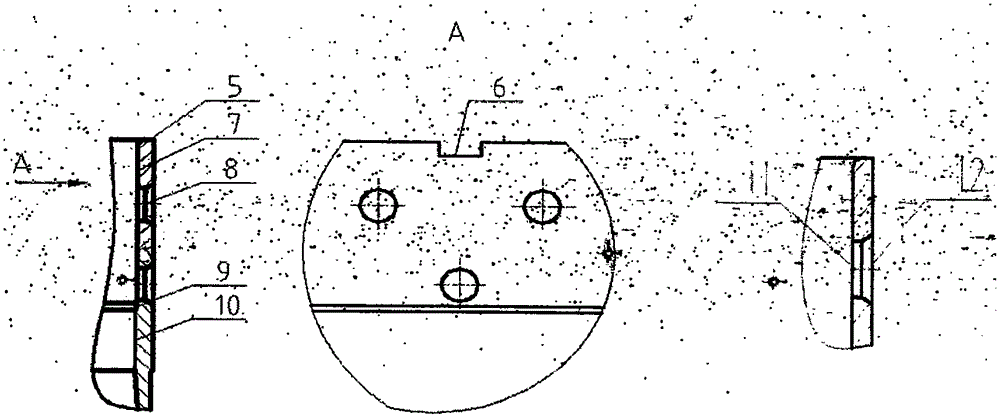

Special cutter bar for boring inner annular grooves of deep-long holes

InactiveCN105710401AImprove the rigidity of the tool holderReduce cylindricity errorBoring barsDiameter ratioTangential force

The invention discloses a special segmented boring bar with double guide support and used for boring machining for inner annular grooves of deep holes. The boring bar comprises a guide part, a cutter bit part, a cutter advancing-retreating control part, an axial location part, an auxiliary support part and a bar body part, wherein a guide head is connected with the front end of a sleeve by virtue of dowels, the auxiliary support part is connected with the sleeve by virtue of spherical screws, and due to the combination of the guide head and auxiliary support blocks, the partial static rigidity of the cutter bit can be greatly improved; a front baffle is connected with the front end of the guide head by virtue of a screw, and a rear baffle is connected with the rear end of the sleeve by virtue of a screw; and three uniformly-arranged blades are arranged in the peripheral direction of the cutter bit part, and capable of counteracting a radial force and a tangential force during cutting, and further improving the rigidity of the cutter bar. The special segmented boring bar with double guide support, which is disclosed by the invention, is applicable to boring machining for inner annular grooves of deep holes with large length-diameter ratios and multilayer deep holes; and compared with a boring bar in the prior art, the machining range is wider, and the machining surface quality and machining accuracy are remarkably improved.

Owner:NANJING UNIV OF SCI & TECH

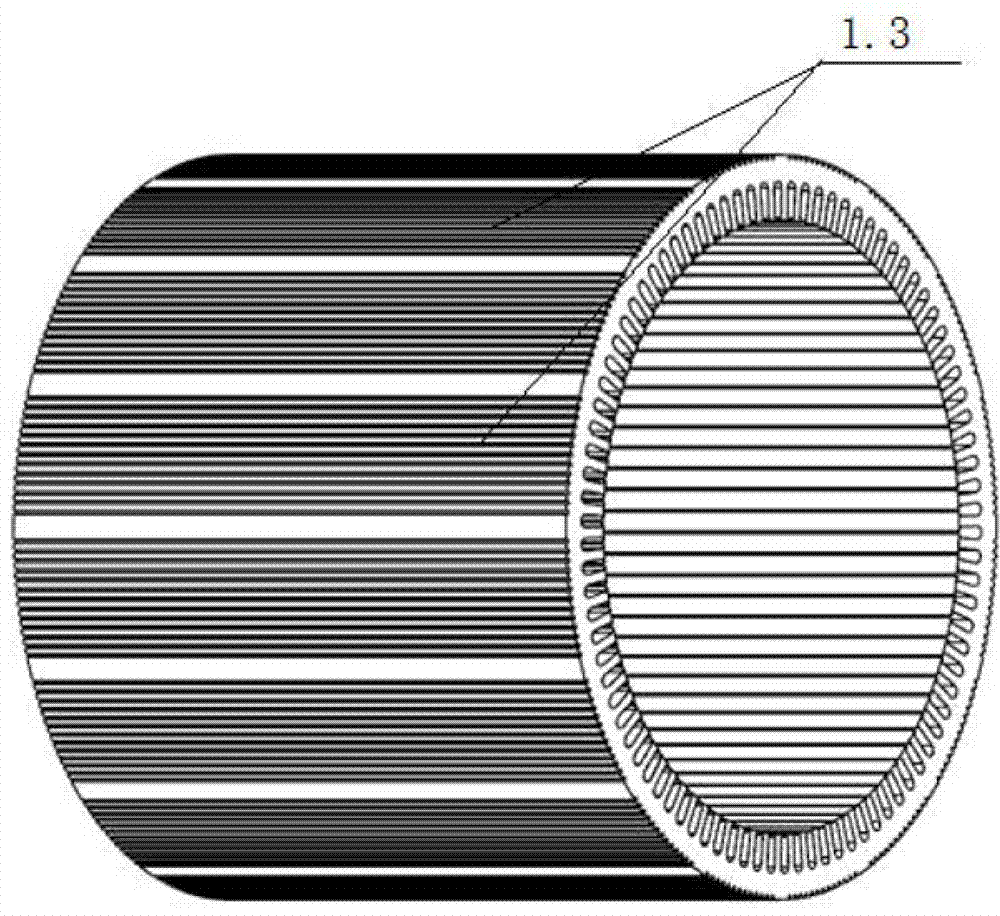

Natural cooling permanent magnet motor

ActiveCN107994736AIncrease radial sizeReduce weightMagnetic circuit rotating partsMagnetic circuit stationary partsPunchingPermanent magnet motor

The invention discloses a natural cooling permanent magnet motor comprising a stator and a rotor. The stator comprises a hollow machine base and a stator core. A plurality of grooves are formed in theouter circumference of a stator punching sheet, and cooling fins are disposed in the grooves. The stator core is internally provided with a plurality of stator slots. Stator windings are disposed inthe slots. The rotor includes a rotor body and a rotor fan. The rotor body includes a rotor hollow shaft and a rotor support. One end of the rotor hollow shaft is provided with an air inlet, the otherend of the rotor hollow shaft is provided with an air outlet, and the air inlet and the air outlet are communicated with a cavity of the rotor support. The rotor support is in a tubular body. The rotor hollow shaft is in series connection with the cavity of the rotor support to form a cooling air flowing channel. Wind pressure is generated by rotation of blades of the rotor fan in the rotor support, so that external environment cooling air is sucked in through the air inlet in the axial direction of a rotating shaft, the air flows through the rotor hollow shaft and the inner surface of the rotor support, and flows out from the air outlet of the rotating shaft to cool the magnetic steel.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

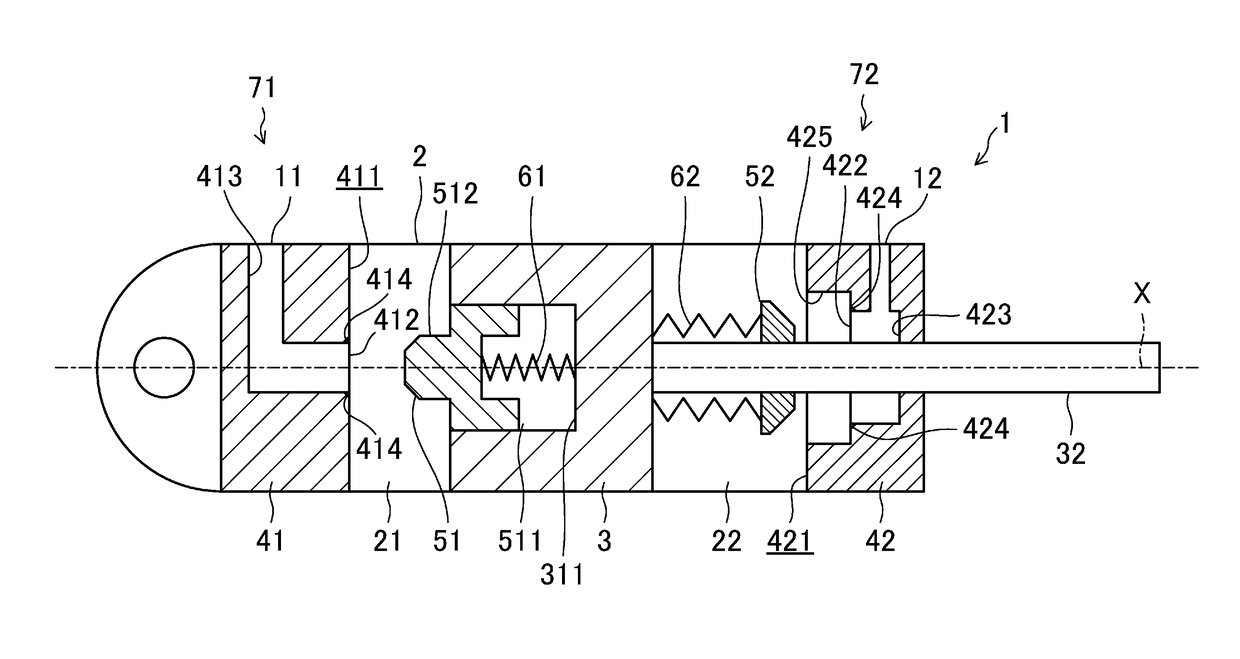

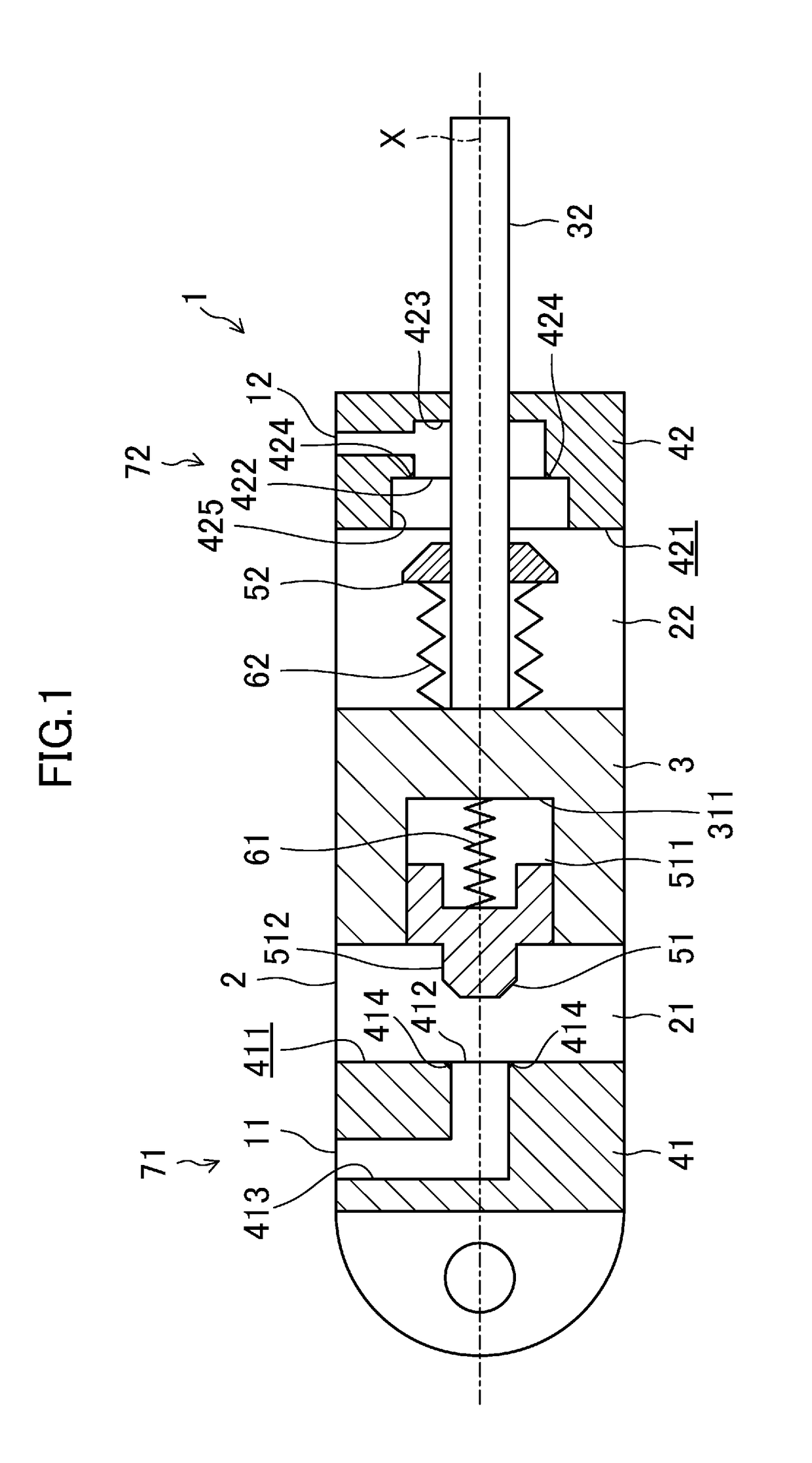

Hydraulic cylinder for aircraft landing gear

ActiveUS20170088256A1Reduce movement speedIncrease radial sizeFluid-pressure actuatorsUndercarriagesAirplaneMoving speed

A hydraulic cylinder includes: a cylinder tube; a piston; a piston rod; a pair of end covers; and a snubbing mechanism configured to reduce the moving speed of the piston after the piston reaches the vicinity of the end of its stroke. The snubbing mechanism includes: a supply / discharge port formed in an associated one of the end covers; a valve configured to open and close the supply / discharge port; a connector configured to connect the valve and the piston together; and at least one recess extending from the edge of the supply / discharge port. When the piston approaches the end of its stroke, the valve closes the supply / discharge port to form a throttle oil passage, and hydraulic oil is discharged through the throttle oil passage to reduce the moving speed of the piston.

Owner:SUMITOMO PRECISION PROD CO LTD

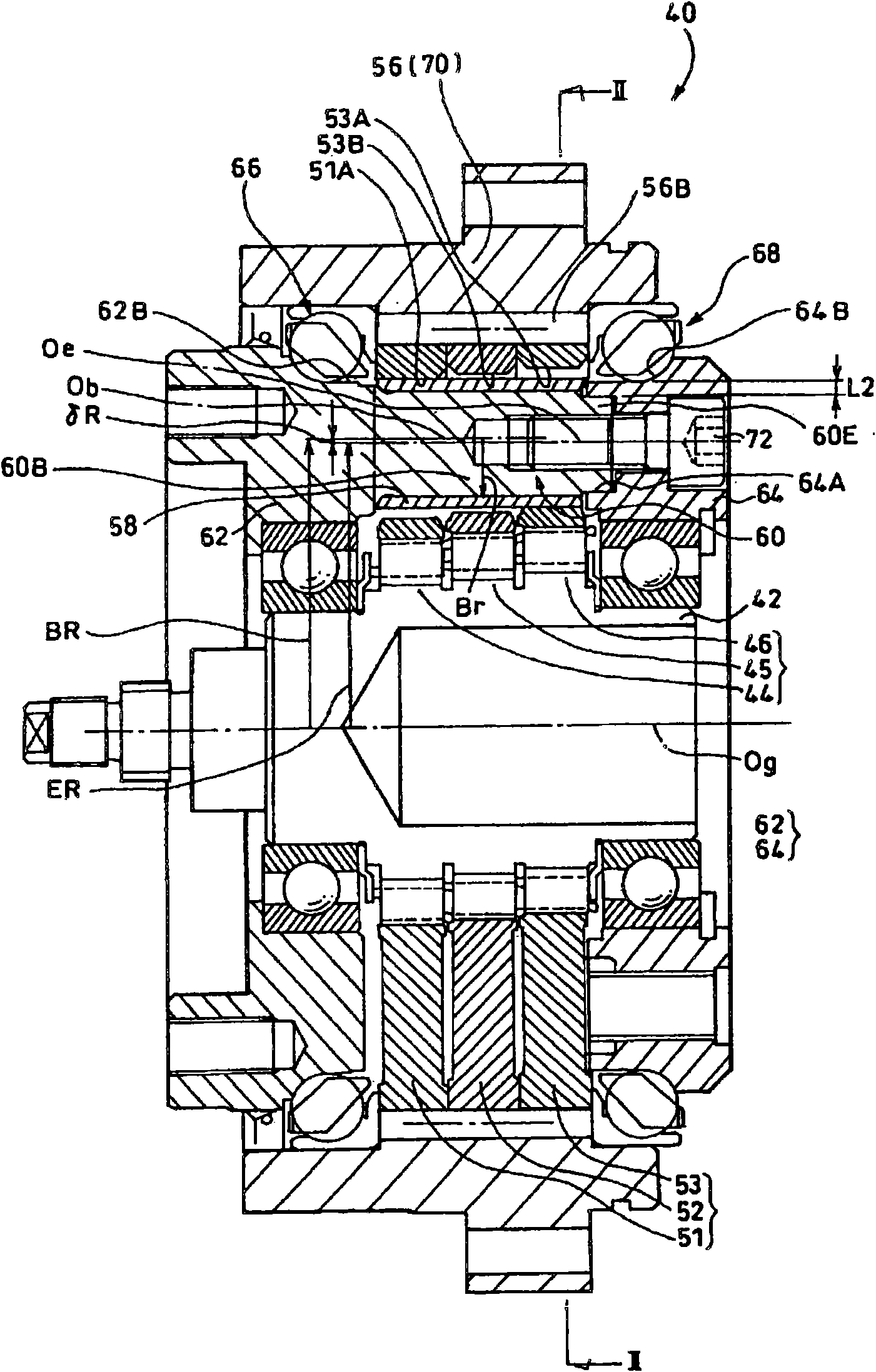

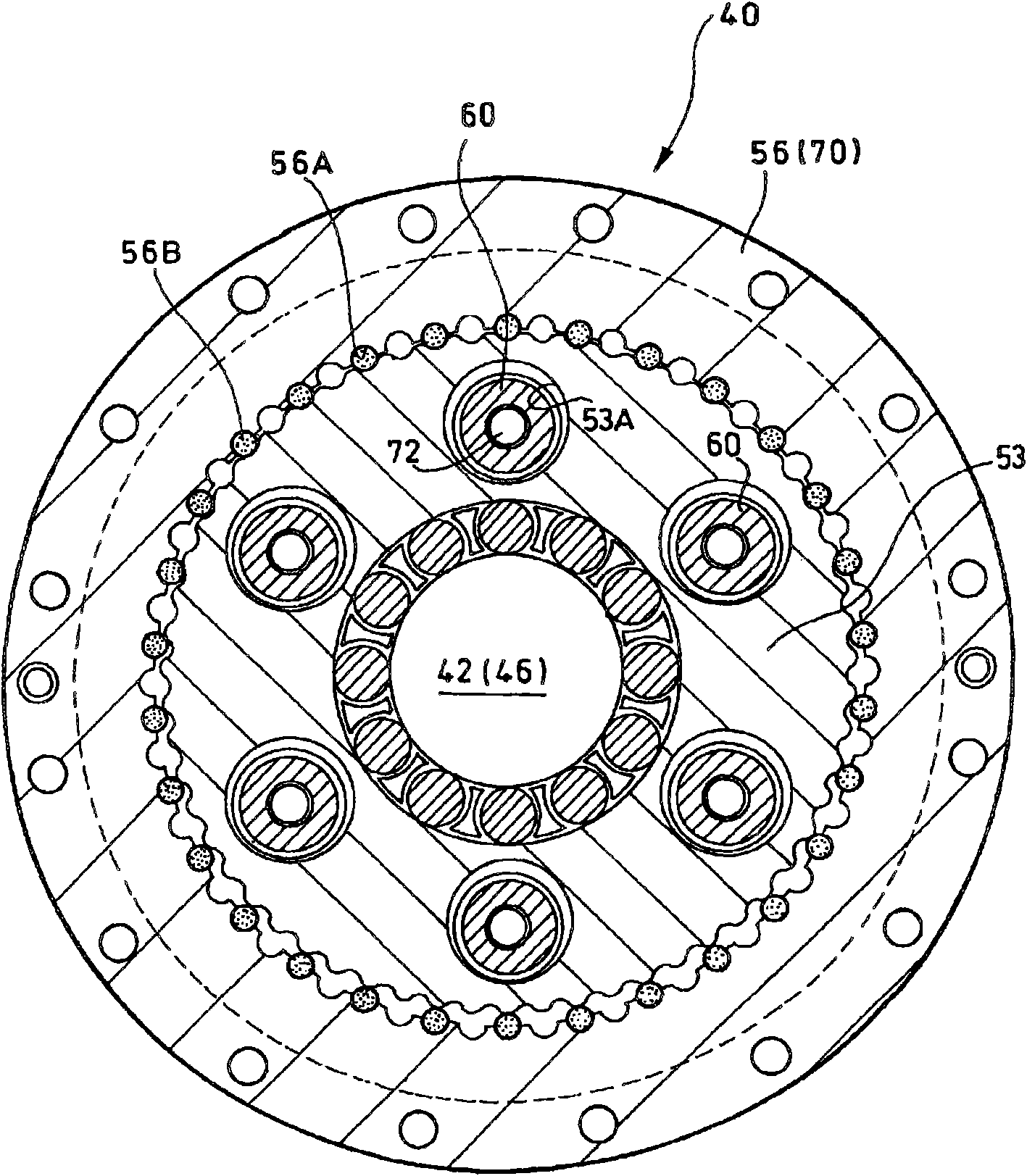

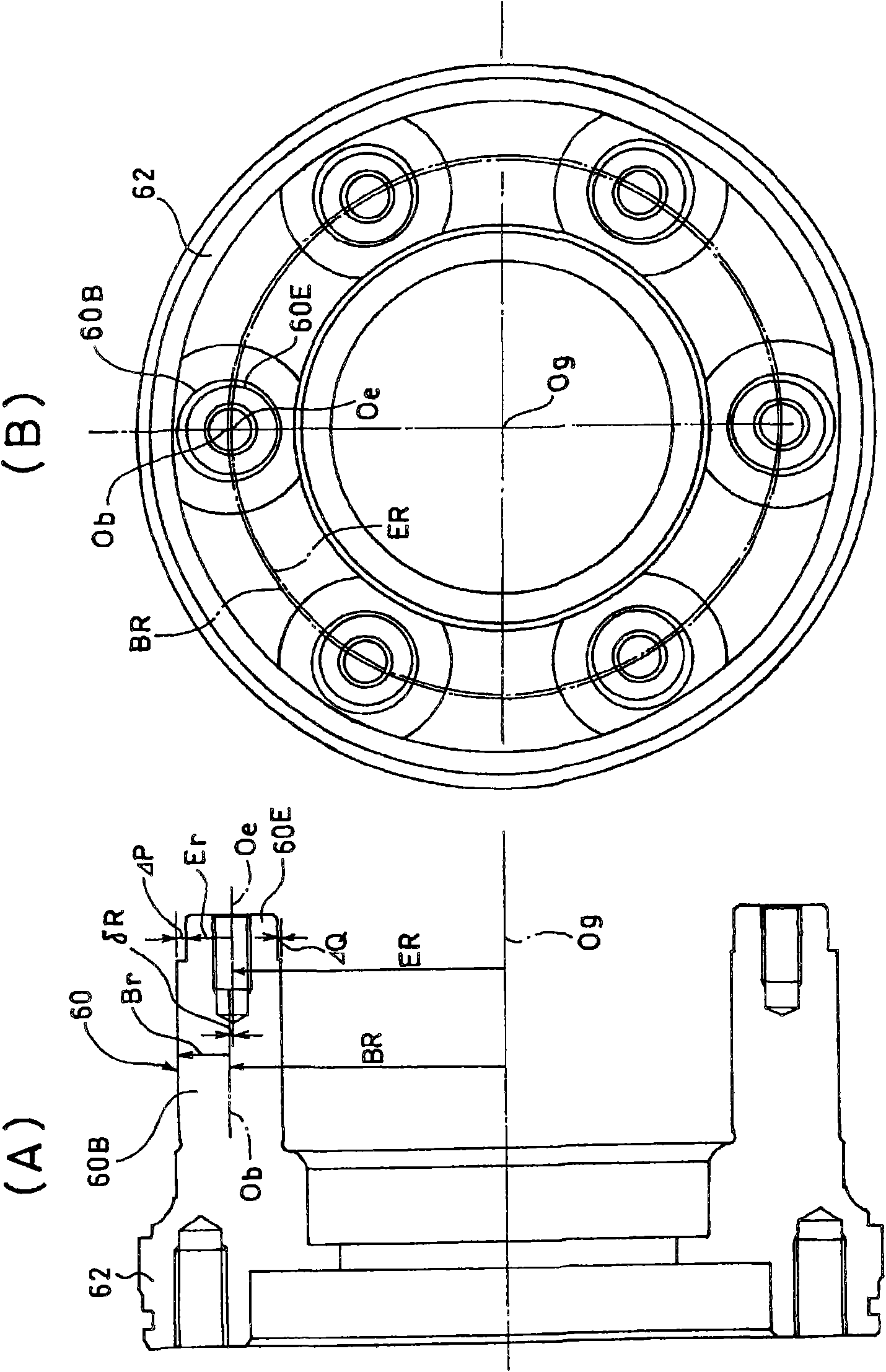

Epicycle reduction gear

The invention provides an epicycle reduction gear which improves degree of design freedom around a main bearing of a wheel carrier, meanwhile, needs not to reduce the intensity around the main bearing and further shorten the size of radius of the epicycle reduction gear. The provided epicycle reduction gear which takes relative rotation component of external gears (51-53) and a internal gear (56) as output is provided with a pair of first and second wheel carriers (62, 64) which are arranged on both sides on axial direction of the external gears (51-53); an inner pin (pillar part) (60) which penetrates through the external gears (51-53) and connects the first and second wheel carriers (62, 64). The inner pin (60) is provided with a main body part (60B) comprising an embedded end part (60E) which is embedded in and fixed on the second wheel carrier (64) and penetrates the external gears (51-53). The axis circle diameter (ER1) of an axis (O e) of the embedded end part (60E) of the inner pin (60) is smaller than the axis circle diameter (BR2) of an axis (O b) of the main body part.

Owner:SUMITOMO HEAVY IND LTD

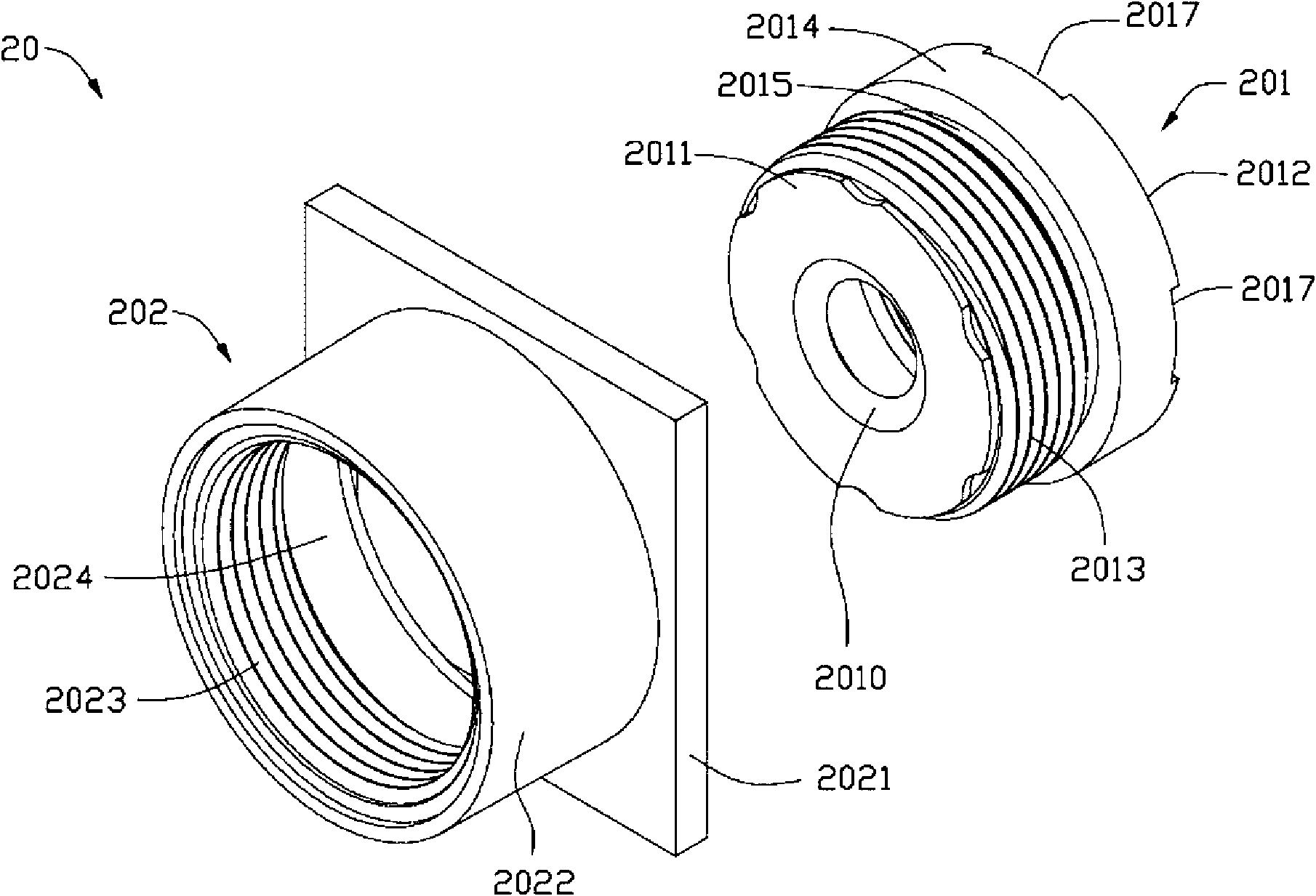

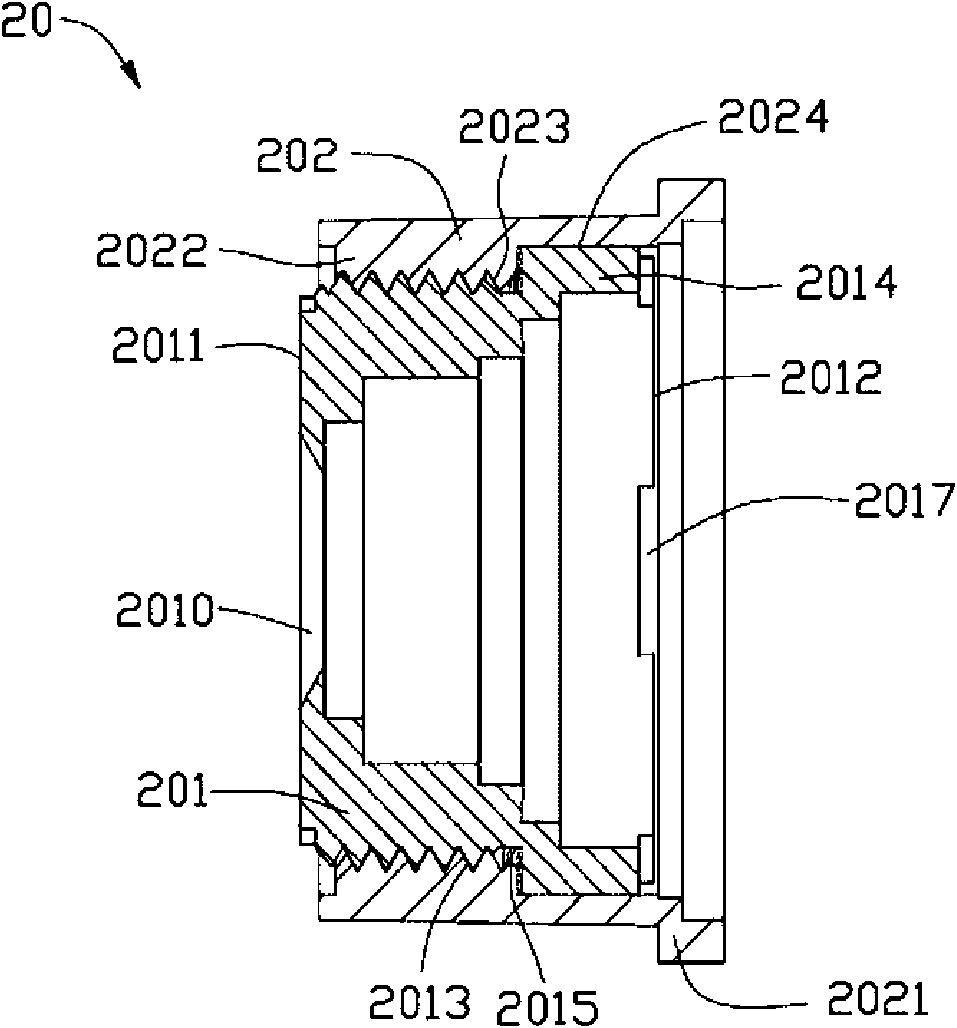

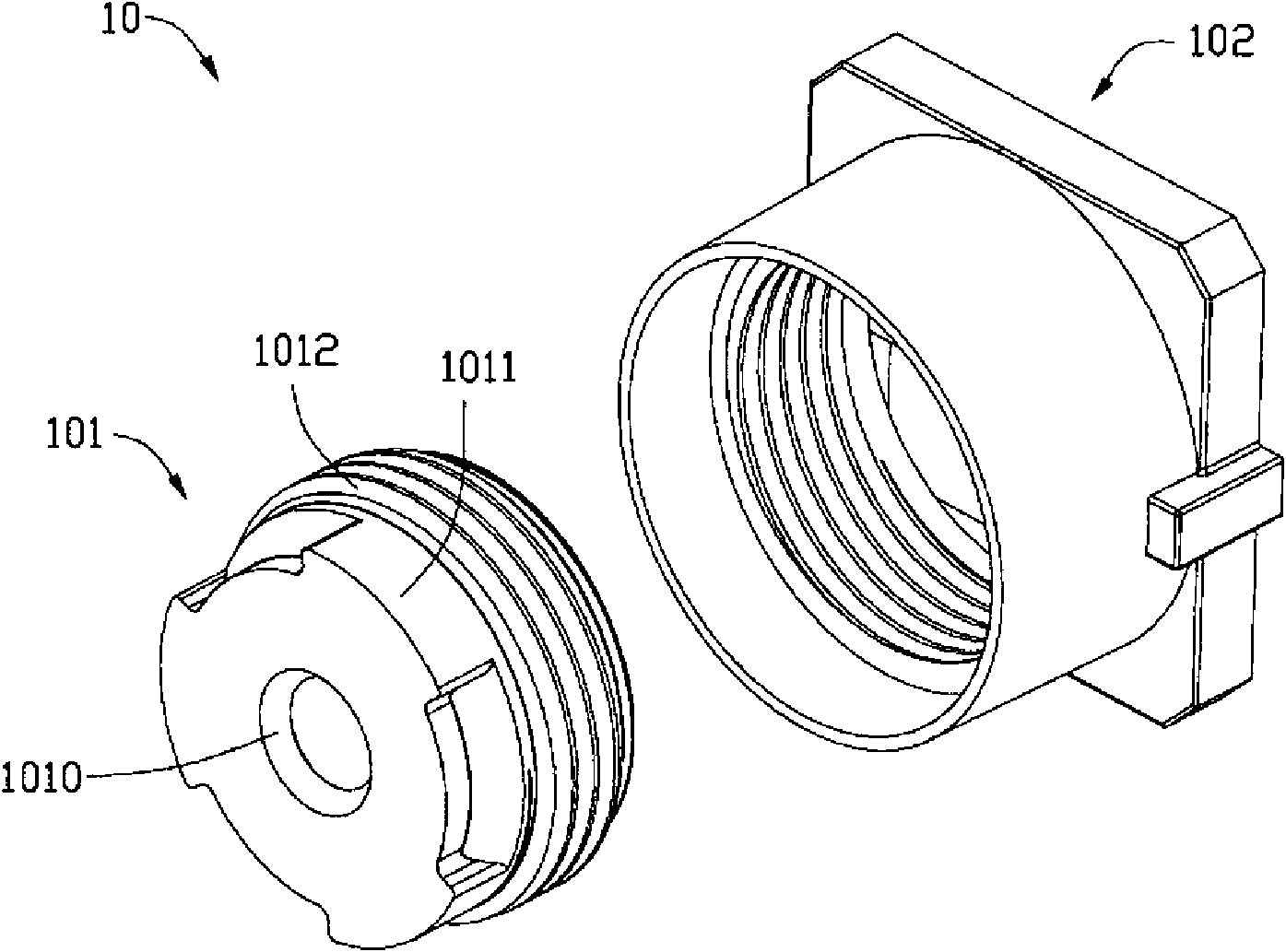

Lens module

InactiveCN102033285AAffect the imaging effectIncrease production capacityTelevision system detailsColor television detailsCamera lensEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

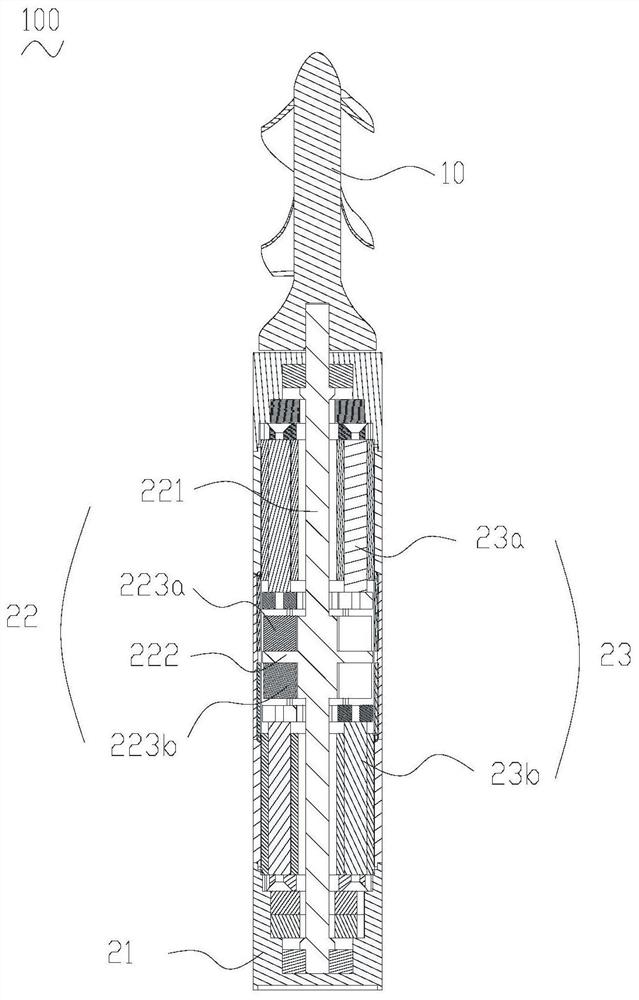

Blood pump

PendingCN112587792AIncrease load torque and powerImprove pumping efficiencyIntravenous devicesBlood pumpPhysicsBlood stream

The invention provides a blood pump. The blood pump comprises a cannula having a blood flow inlet and a blood flow outlet, an impeller disposed within the cannula, and a driving unit for rotating theimpeller; the driving unit comprises a shell, a rotor and a stator, wherein the rotor and the stator are arranged in the shell; the rotor comprises a rotating shaft; and the driving unit is characterized in that the rotor also comprises at least two magnets arranged on the rotating shaft; the stator comprises a first stator body and a second stator body which are arranged around the rotating shaft; the first stator body and the second stator body are arranged in the axial direction in a spaced mode; a rotating magnetic field generated by the first stator body interacts with one of the two magnets so that the rotating shaft can rotate; and a rotating magnetic field generated by the second stator interacts with the other one of the two magnets so as to enable the rotating shaft to rotate. According to the blood pump, on the basis that the overall radial size of the blood pump is reduced, the output power and the load torque of the driving unit of the blood pump can be increased.

Owner:SHENZHEN CORE MEDICAL TECH CO LTD

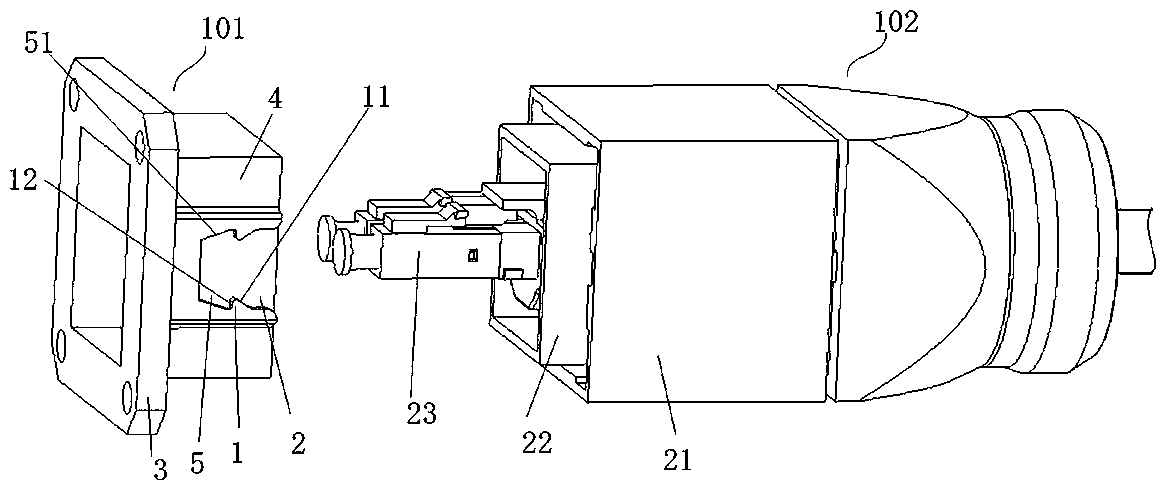

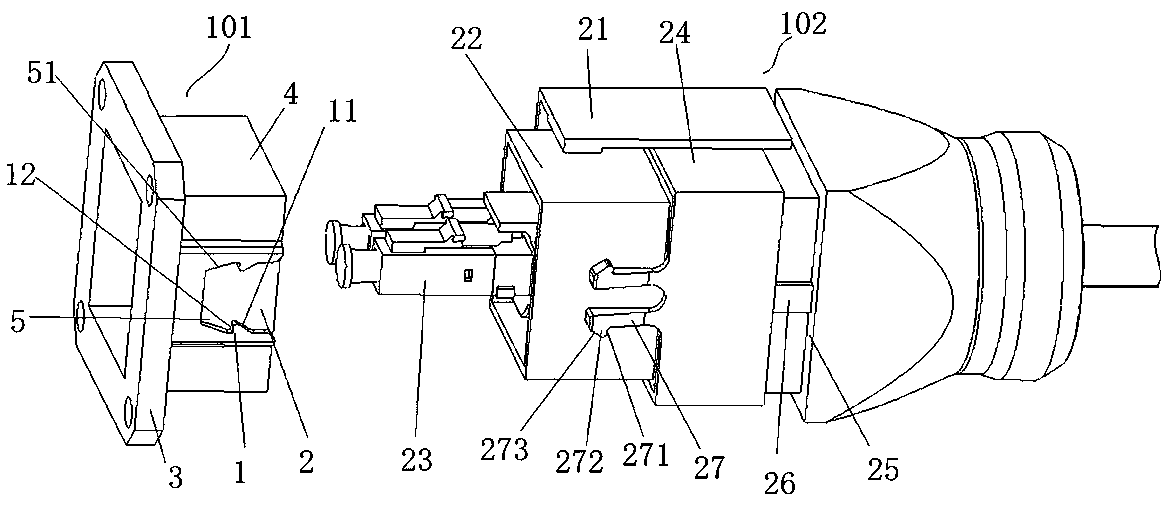

Connector and plug thereof

PendingCN111200214AIncrease radial sizeMiniaturizationCoupling device detailsTwo-part coupling devicesEngineeringMechanical engineering

The invention relates to a connector and a plug thereof. The plug comprises a plug shell, wherein the front end of plug shell is a plugging end. The plug comprises an elastic claw, wherein the elasticclaw is arranged on the plug shell, the elastic claw is provided with a hooking part, the hooking part is used for being matched with a hooking matching part on a socket shell in a hooking manner soas to lock and fix the plug and the socket which are assembled in a plugging manner, and the elastic claw is provided with a passive unlocking part. The plug further comprises an unlocking piece, wherein the unlocking piece is movably assembled on the plug shell in the front-back direction, the unlocking piece is provided with an active unlocking part, and when the unlocking piece moves in the front-back direction, the active unlocking part and the passive unlocking part are matched in a pushing mode to drive the hooking part to act in the circumferential direction of a connector shell, so that the hooking part is separated from the corresponding hooking matching part, and then unlocking of the plug and the socket is achieved; and at least one of the active unlocking part and the passive unlocking part is of an inclined plane structure. No auxiliary device is needed in the unlocking process, and the unlocking mode is simple.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

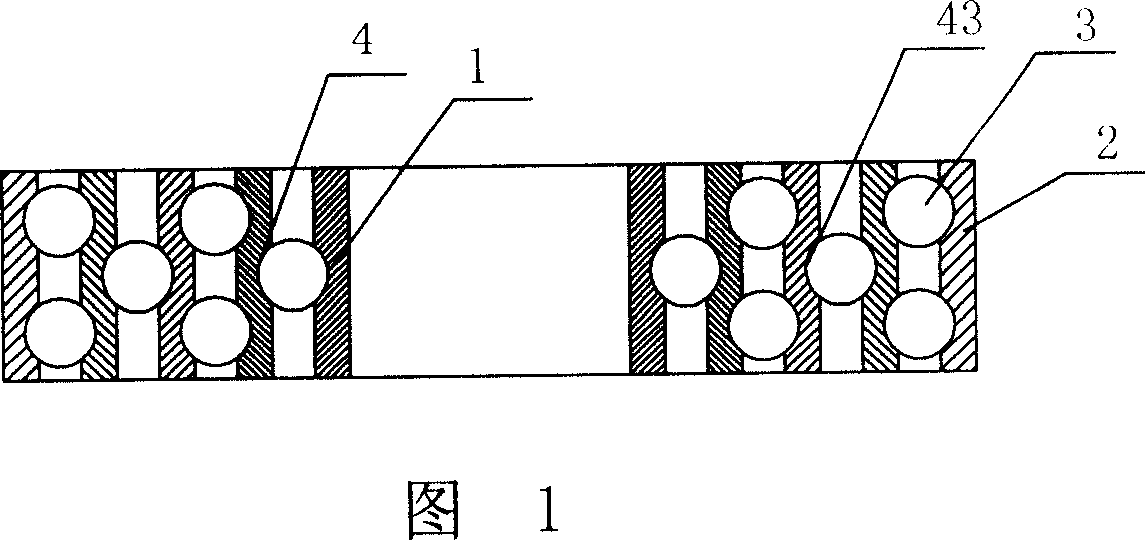

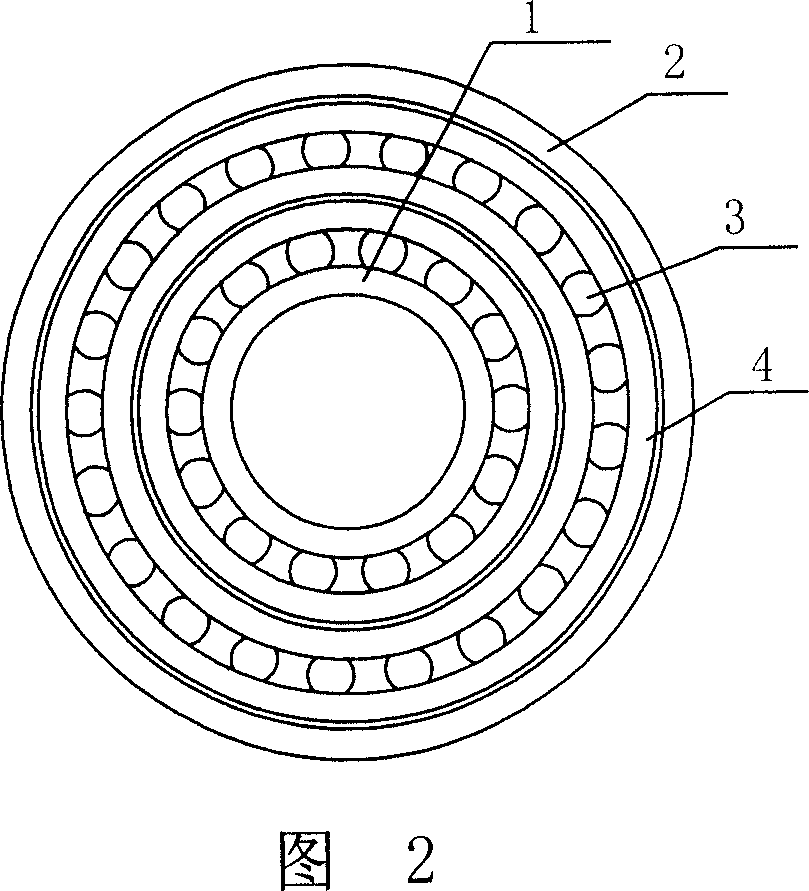

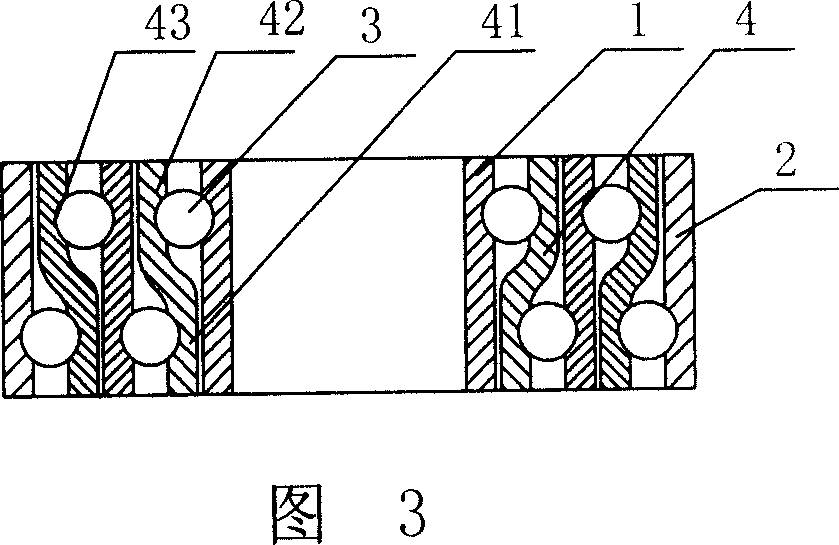

High speed bearing

InactiveCN1948772AImprove stabilityIncrease speedShaftsBall bearingsEngineeringMechanical engineering

Owner:陈兆红

Rotary insulator and isolating switch

InactiveCN103219189ACompact structureIncrease radial sizeAir-break switch detailsEngineeringTorque transmission

The invention relates to a rotary insulator and an isolating switch. The rotary insulator comprises an insulator which is a cake-shaped revolving body; connecting pieces are fixedly arranged at both ends of the insulator; one end, facing to the insulator, of each connecting piece is wrapped and fixedly arranged inside the insulator, and one end, extending out of the insulator, of each connecting piece is a transmission end; a transmission hole in which a connecting end corresponding to a rotating shaft is inserted so as to realize torque transmission connection is formed in the end surface of each transmission end; the transmission holes at both ends are arranged coaxially; and the minimum distance between the two connecting pieces inside the insulator is not less than the striking distance of the insulator. The distance between two adjacent phases or between an operating mechanism and a corresponding phase is shortened, so that the structure of the isolating switch is more compact, the boundary dimension of the isolating switch is shortened, the isolating switch can be installed and used in a smaller space, and simultaneously the manufacturing cost of the isolating switch is also reduced.

Owner:STATE GRID CORP OF CHINA +2

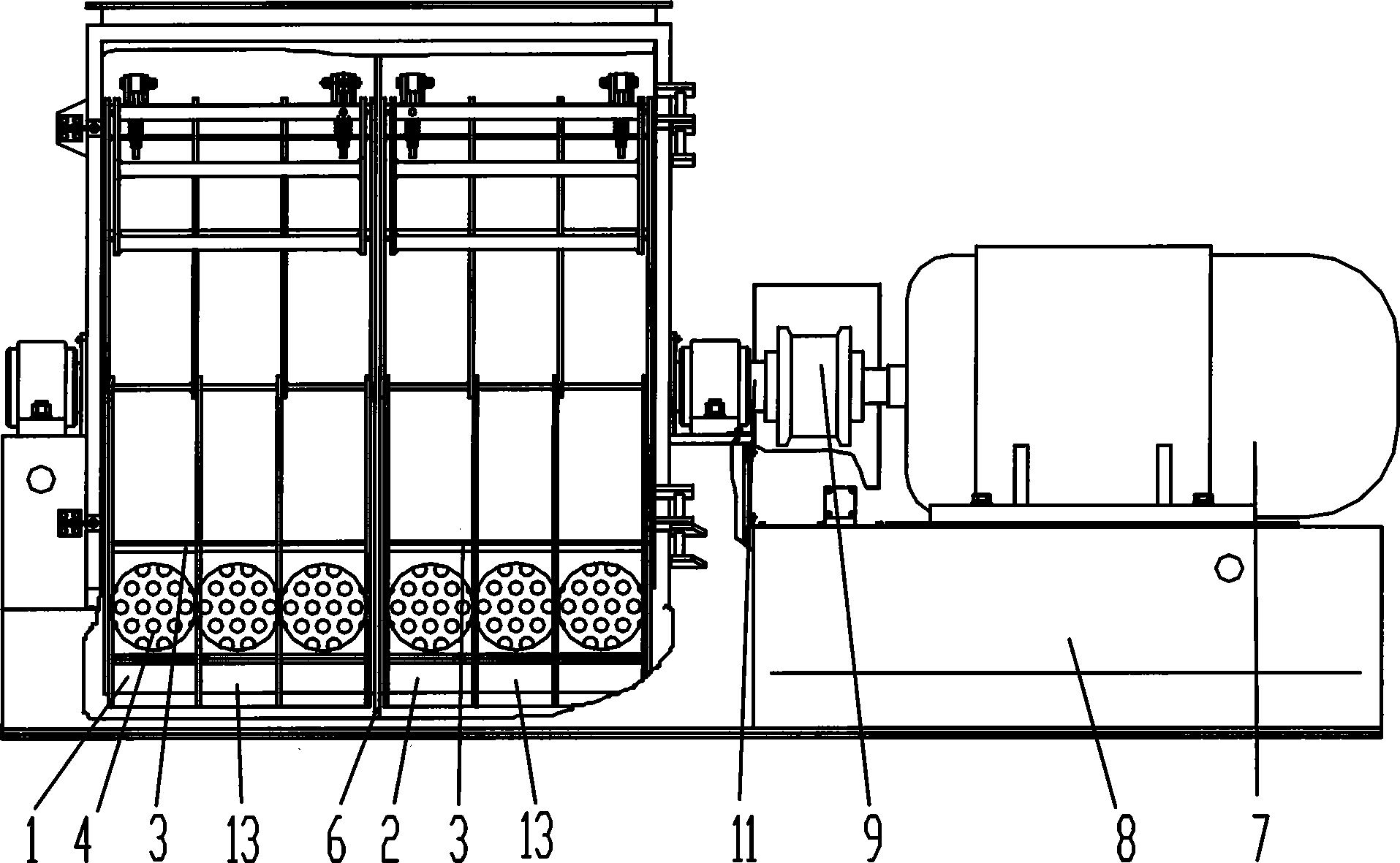

Beater disintegrating machine

The invention discloses a hammer plate type crushing machine, and belongs to the field of a hammer plate type crushing machine. The crushing machine comprises a pressing screen rack, a screen plate, a screen plate rack, a motor, a machine base, a junction box, a rotor, a rotor shaft and hammer plates, wherein the motor arranged on the machine base is connected with the rotor of the crushing machine by the junction box; the rotor, the screen plate and the screen plate rack jointly form a crushing room; the rotor shaft of the rotor is connected with the junction box, and the rotor is provided with a plurality of hammer plates; a big separation sleeve is arranged between two adjacent hammer stand plates of the rotor shaft, the big separation sleeve comprises an inner edge of the separation sleeve and an outer edge of the separation sleeve, both sides of the inner and the outer edges of the separation sleeve are closely and fixedly connected with the adjacent hammer stand plates respectively; the inner edge of the separation sleeve is arranged on the rotor shaft, and the outer edge of the separation sleeve is arranged on the inner side of the mounting position of the hammer plates, and is 1 to 60mm away from the moving track of the hammer plates. Compared with prior art, the crushing machine has the advantages of improving the parts of the rotor-big separation sleeve, enhancing the operational balance of the rotor and lowering the influence on operational balance of the rotor due to wearing of parts.

Owner:TSZJANSU CHZHEHNCHAN SIRIEHL OIL EHND FID MASHINERI KO

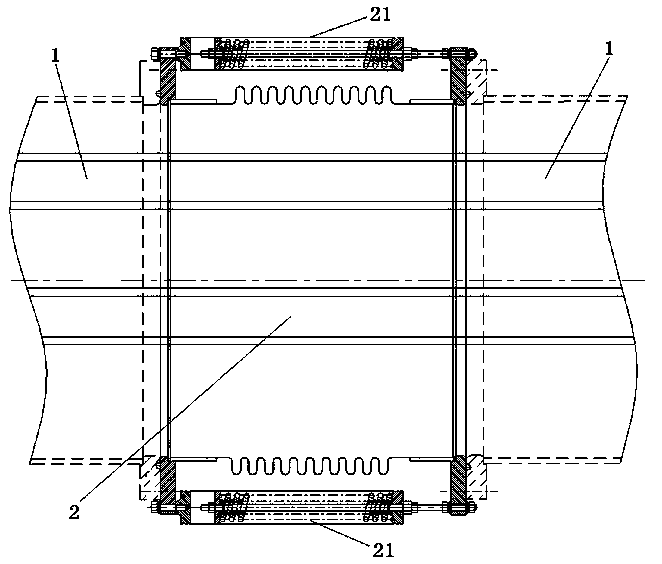

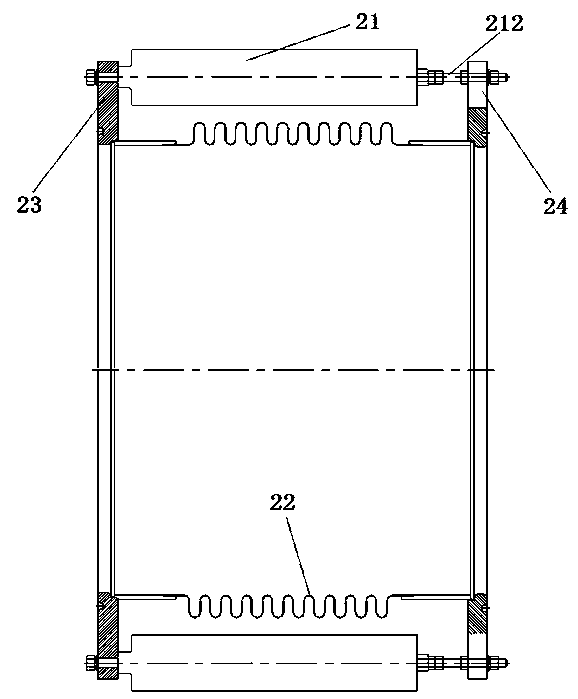

GIS busbar and busbar expansion joint thereof

ActiveCN109755908ALow costImprove deformation abilityTotally enclosed bus-bar installationsElastic componentBusbar

The invention relates to the technical field of power transmission and transformation engineering, in particular to a GIS busbar and a busbar expansion joint thereof. The busbar expansion joint in theGIS busbar comprises a front flange and a rear flange arranged along the axis of the busbar; a bellows is connected between the front flange and the rear flange; the busbar expansion joint also comprises an elastic component connected between the front flange and the rear flange; the elastic component includes a sleeve fixedly connected to the front flange and a force-transmitting rod fixedly connected to the rear flange; the force-transmitting rod extends into the sleeve, and a coil spring is arranged between the force-transmitting rod portion extending into the sleeve and the rear end of the sleeve; and when the busbar expansion joint is butted against the busbar cylinder and the bellows is not deformed by a force, the sum of the spacings of the adjacent loops of the coil spring is notgreater than the maximum allowable stretch quantity of the bellows. The busbar expansion joint can be used to solve the problem that the expansion joint has a small telescopic deformation range in theprior art, and can also be used to solve the problem that the structure of the busbar cylinder or the expansion joint itself is damaged due to the small deformation range of the expansion joint.

Owner:HENAN PINGGAO ELECTRIC +2

High-capacity classified-storage student desk

The invention discloses a high-capacity classified-storage student desk, which consists of a regular-prism drum type drawer box, wherein the regular-prism drum type drawer box can rotate around a central axis; the central axis of the drum type drawer box is horizontally arranged; an inner cavity of the drum type drawer box is divided into a plurality of storage cavities by axial baffle plates; each side surface, corresponding to a regular prism, of each storage cavity is provided with a drawer box opening; each drawer box opening is provided with a cover plate hinged to the corresponding baffle plate; the cover plates are provided with closure locking devices and open angle adjusting mechanisms; the cover plates are opened in an upward rotation manner, so that the drawer box openings are located below the opened cover plates; the opened cover plates and the unopened cover plates which are joined with the opened cover plates form a desktop of a desk. The higher storage capacity can be provided; the structure is simplified; the classified storage, the taking and the using of a book and information are convenient; the high-capacity classified-storage student desk is natural and convenient to use.

Owner:潘琦云

Hub driving assembly

InactiveCN105691104AIncrease radial sizeIncrease stiffnessHubsMotor depositionReduction driveEngineering

A hub driving assembly comprises a hub, a hub bearing, a motor, a speed reducer, a housing and a flexible connecting piece, wherein the hub bearing is positioned in the hub. The hub bearing comprises an outer ring, an inner ring and a rolling body; the housing encloses a motor chamber and a speed reducer chamber; an output end of the motor extends out of an opening of the motor chamber and is connected with an input end of the speed reducer; the motor, the speed reducer and the housing are all positioned on the internal side of the hub bearing in a radial direction; the outer ring is fixedly connected with the hub, or the hub is also used as the outer ring; the inner ring is fixedly connected with the housing; the flexible connecting piece is positioned on one side of the inner ring in an axial direction of the assembly; and the two ends of the flexible connecting piece in a radial direction of the assembly are fixedly connected with both the output end of the speed reducer and the hub, respectively. According to the technical scheme of the invention, problems that the rigidity of the hub bearing in the traditional hub driving assembly is not enough, hard matters may stop the rotation of the hub and damage the hub when the hard matters on a pavement are clamped into the internal circumferential surface of the hub in the vehicle running process, the speed reducer cannot obtain a large speed reduction ratio, and the speed reducer is prone to generate high noise and wear during the running of the wheel are solved.

Owner:SCHAEFFLER TECH AG & CO KG

Pin connection structure for metal shell of solid rocket engine

InactiveCN105626311AReduce axial sizeReduce structural massRocket engine plantsStructural reliabilityMass ratio

The invention relates to a pin connection structure for a metal shell of a solid rocket engine. The pin connection structure comprises shell connectors, a top cover, pins and a sealing ring. Each shell connector is provided with an axial locating face, a circumferential locating groove, a shell connector connection face, pin holes, a transition face and a sealing face. The top cover is provided with an axial locating boss, a circumferential locating boss, a top cover connection face, top cover pin holes and a sealing groove. Each pin is composed of a pin cap, a polished rod and a screw. The sealing ring is installed in the sealing groove in the top cover. According to the pin connection structure, assembly and disassembly are simple, and the structural reliability is high. The opening radial dimension of the front shell connector and the rear shell connector can be effectively increased, the structural mass of the shell of the solid rocket engine can be decreased, the structural mass of the top cover is decreased, the axial dimension of the engine is shortened, and the mass ratio of the solid rocket engine to a missile is effectively increased.

Owner:中国航天科工集团第六研究院四十一所

Tile sorting and stacking system

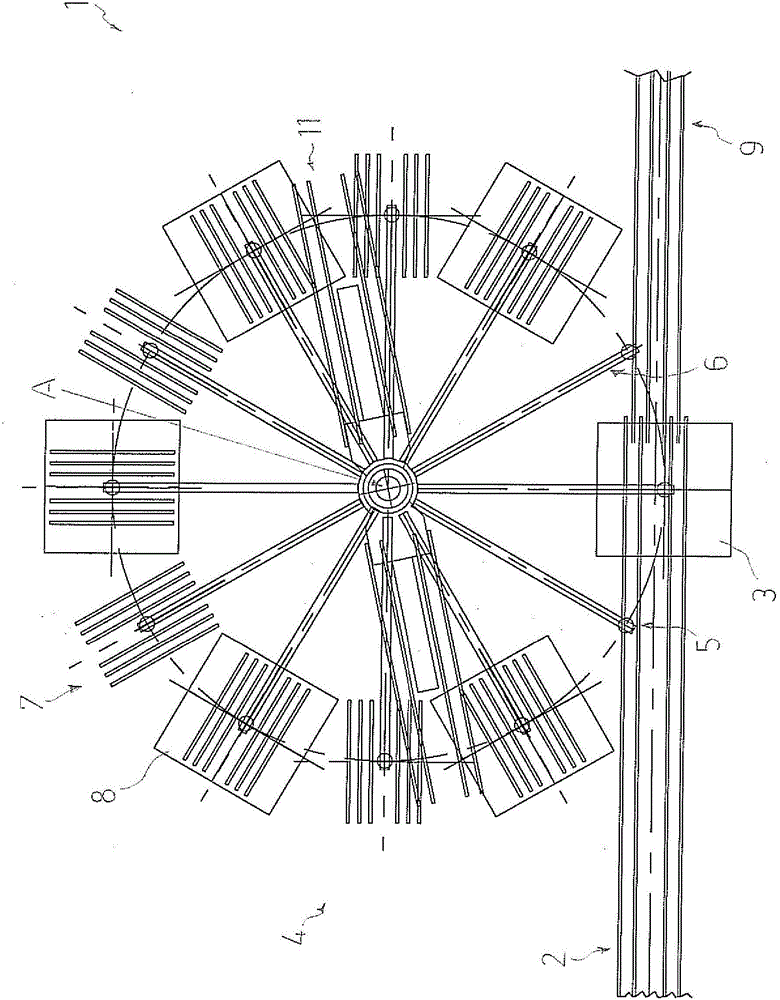

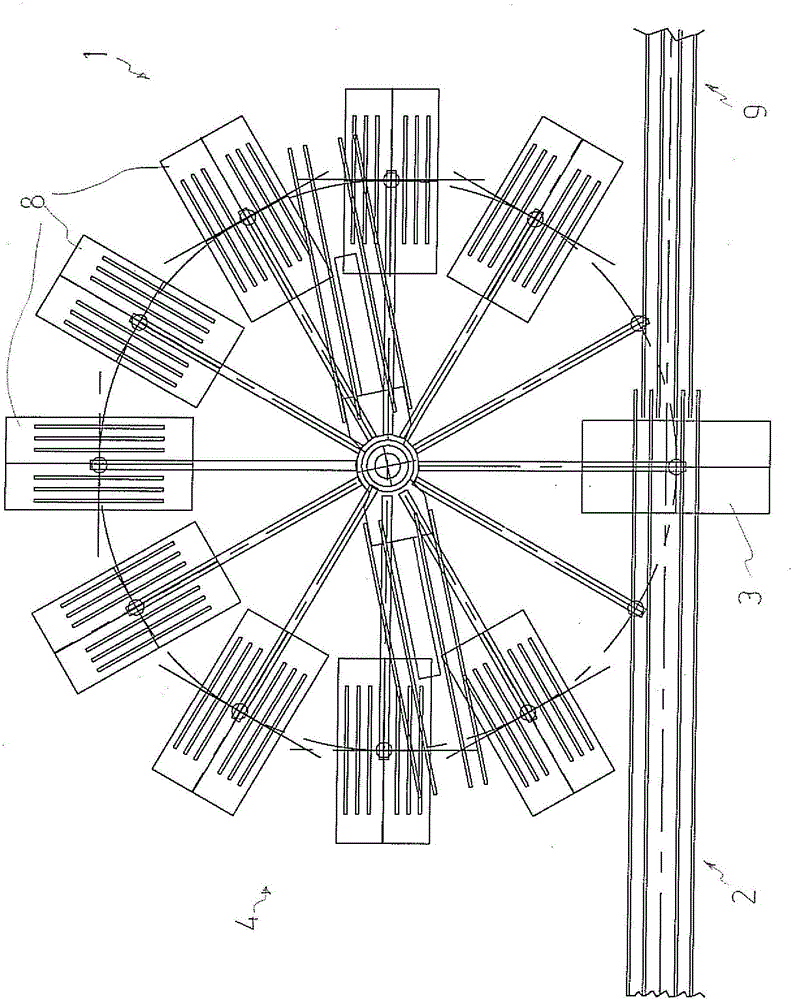

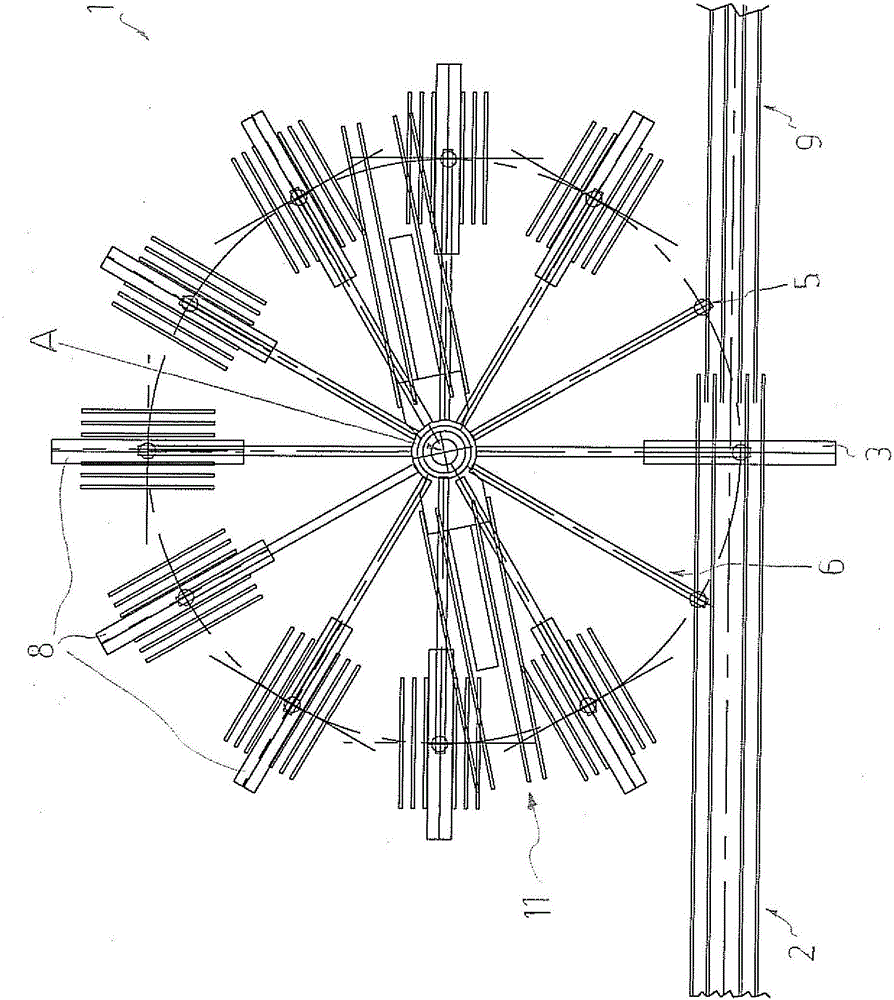

ActiveCN105793174AIncrease radial sizeSmall sizeDischarging arrangementStacking articlesEngineeringMechanical engineering

Disclosed is a tile sorting and stacking system (1), comprising: a sorting carousel (4) comprising carousel arms (6) with gripping means (18); seatings (7) for receiving the tiles; and an input line (2) and an output line (9) arranged radially or tangentially to the sorting carousel (4). The gripping means (18) are vertically mobile so as to collect a tile from the input line (2) and to release the tile onto a seating (7). Also included are a rotating transfer arm (11); loading means (10) for loading a stack of tiles (8) from a seating (7) onto the transfer arm (11); unloading means (12) for unloading a stack of tiles (8) from the transfer arm (11) onto the output line (9). The transfer arm (11), the loading means (10) and the unloading means (12) are arranged and operating in a region of space (13) delimited superiorly by the carousel arms (6) and delimited laterally by the seatings (7), the input line (2) and the output line (9).

Owner:NUOVA SIMA

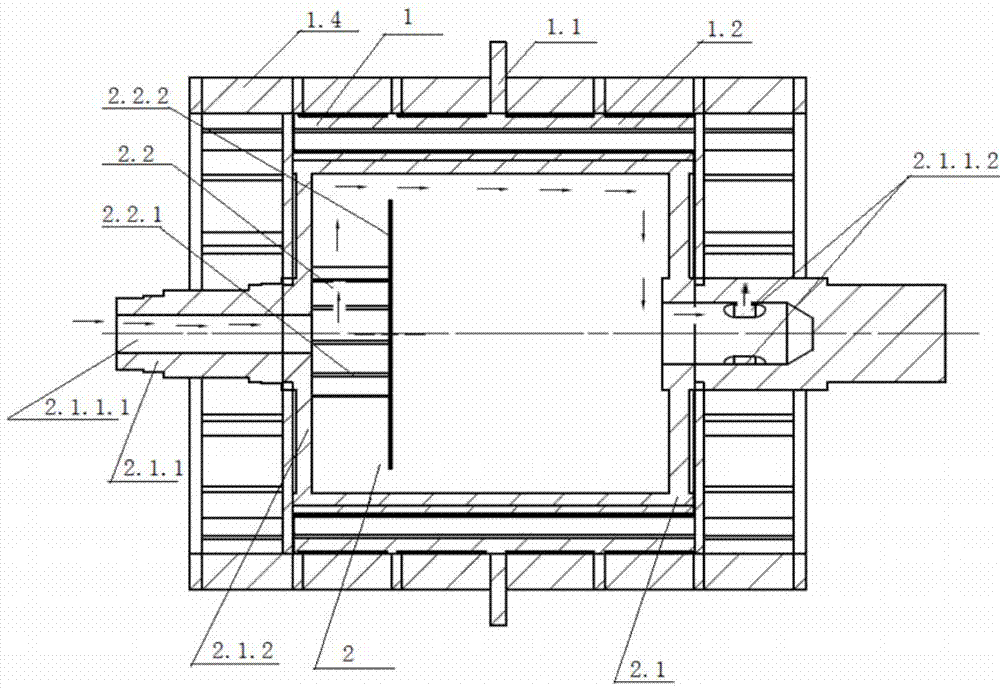

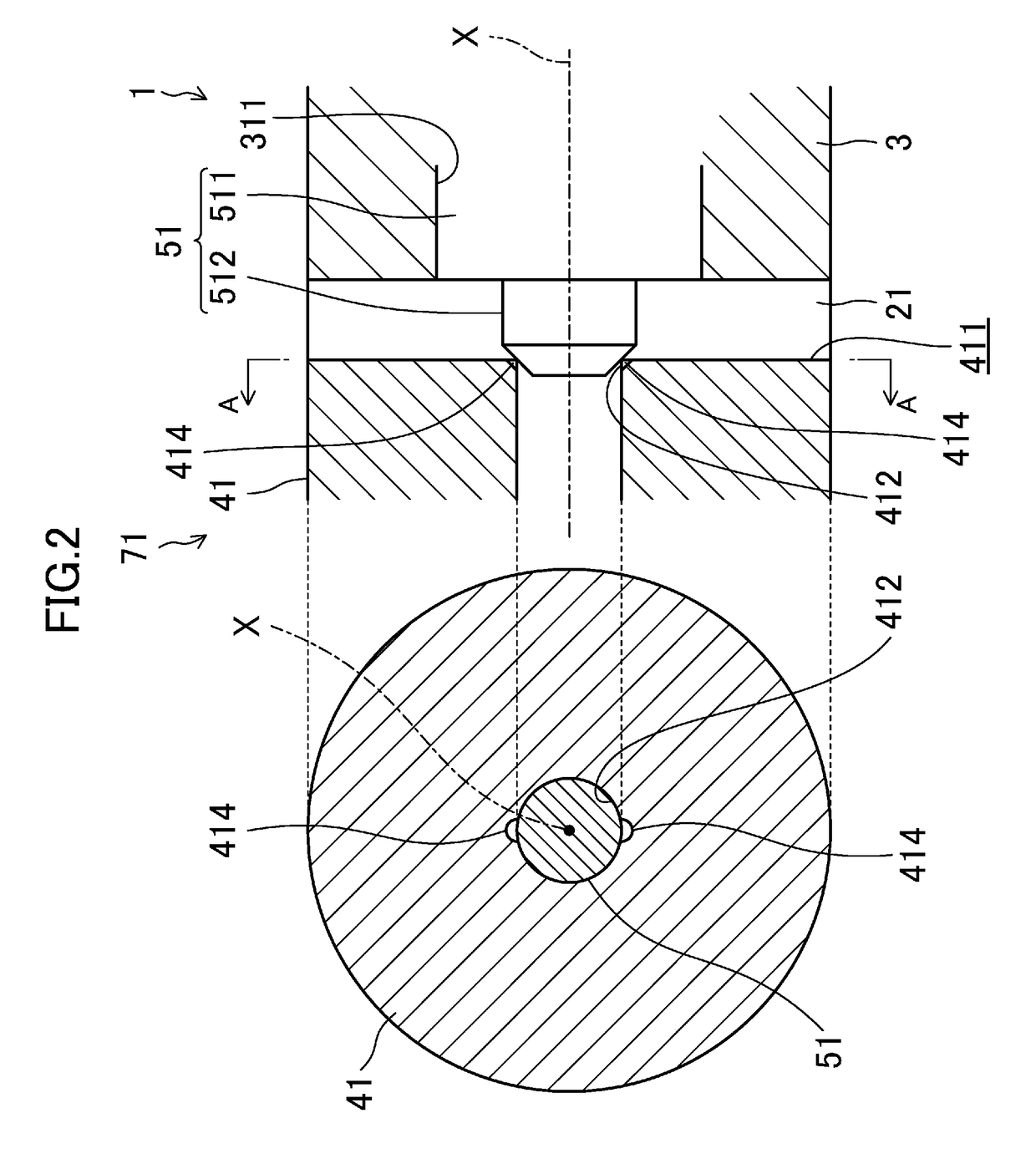

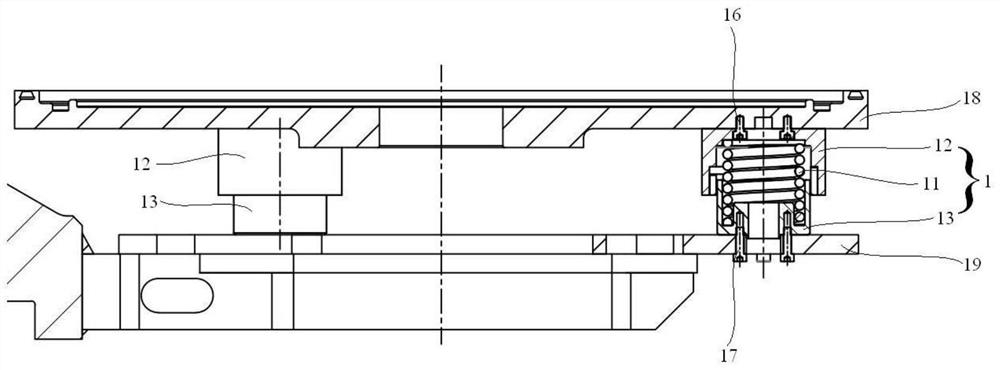

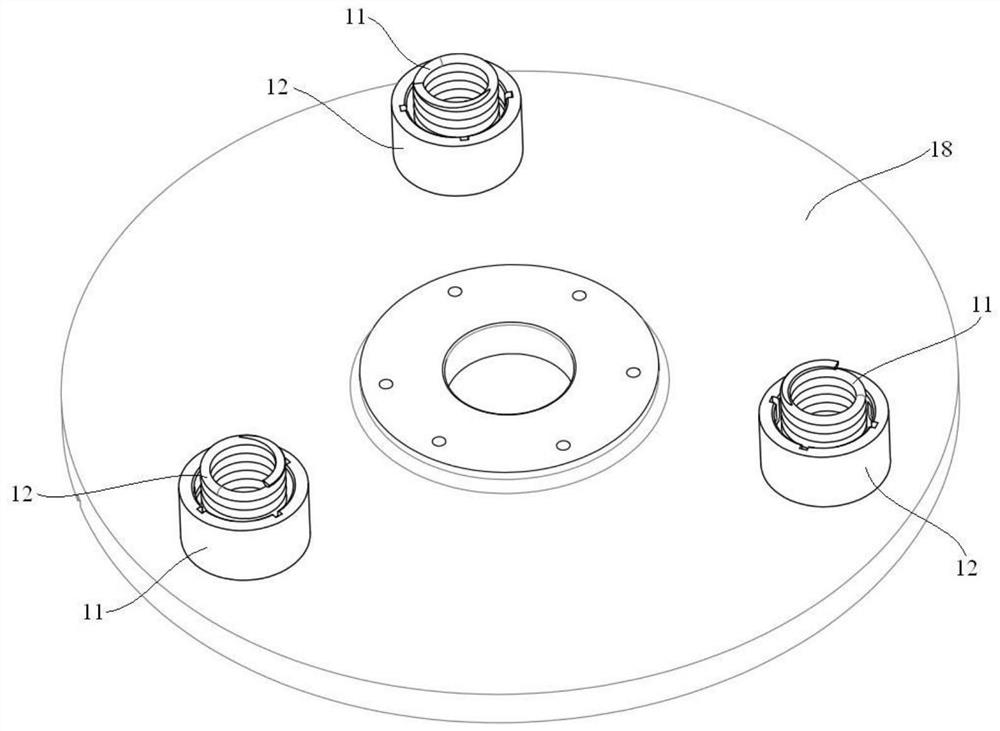

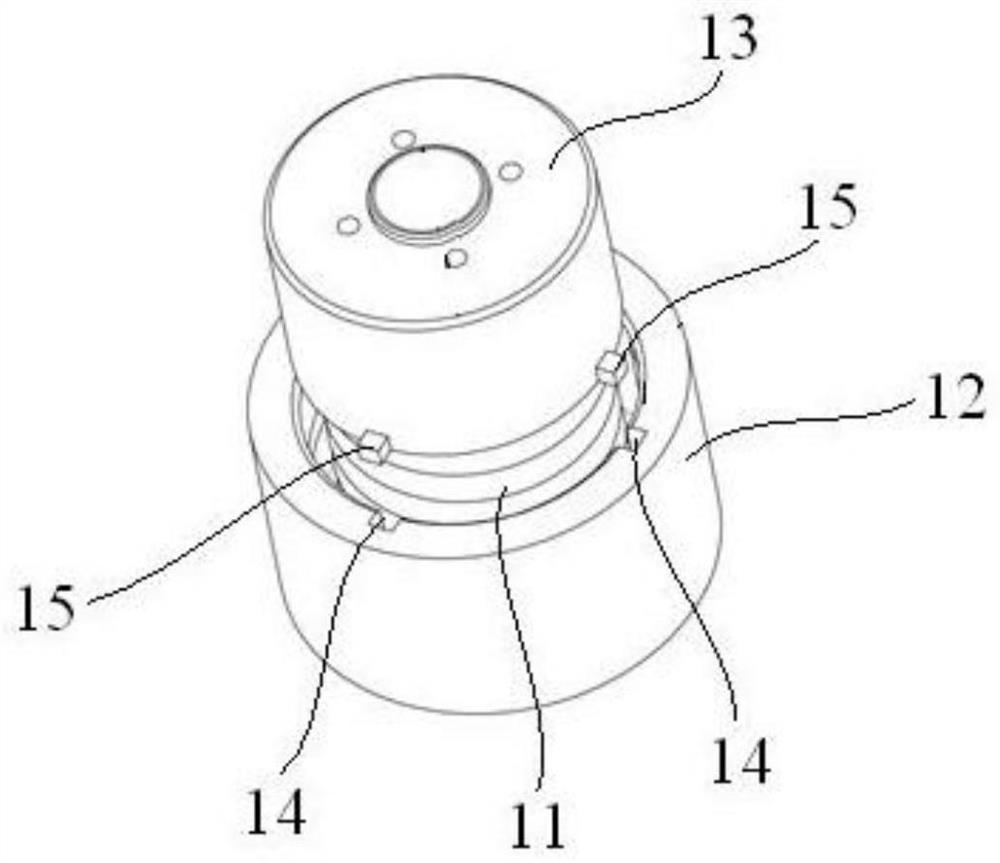

Leveling device in semiconductor heat treatment equipment and semiconductor heat treatment equipment

ActiveCN112325657AReduce installation difficultyReduce the probability of failureFurnace componentsSemiconductor/solid-state device manufacturingPhysicsEngineering

The invention provides a leveling device in semiconductor heat treatment equipment and the semiconductor heat treatment equipment. The leveling device comprises an elastic component, a first connecting part and a second connecting part; the first connecting part is connected with one of a sealing door and a supporting part, and a first accommodating groove is formed in the first connecting part; the second connecting part is connected with the other one of the sealing door and the supporting part; a second accommodating groove opposite to the first accommodating groove is formed in the secondconnecting part; the first connecting part and the second connecting part are connected in a clamped mode and can relatively move in the elastic deformation direction of the elastic component during clamping; and the elastic component is arranged in a containing space defined by the first containing groove and the second containing groove in a matched mode. According to the leveling device in thesemiconductor heat treatment equipment and the semiconductor heat treatment equipment provided, the mounting difficulty of the leveling device can be reduced, the failure probability of the leveling device is reduced, and the use stability of the leveling device is improved, so that the sealing stability of a process door assembly is improved, and the stability of a semiconductor heat treatment process is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com