Hub driving assembly

A hub drive and assembly technology, applied in the direction of hub, motion deposition, power unit, etc., can solve the problems of hub wear, hindering hub rotation, and the inability of the reducer to obtain the reduction ratio, etc., and achieve the effect of large rigidity and large reduction ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

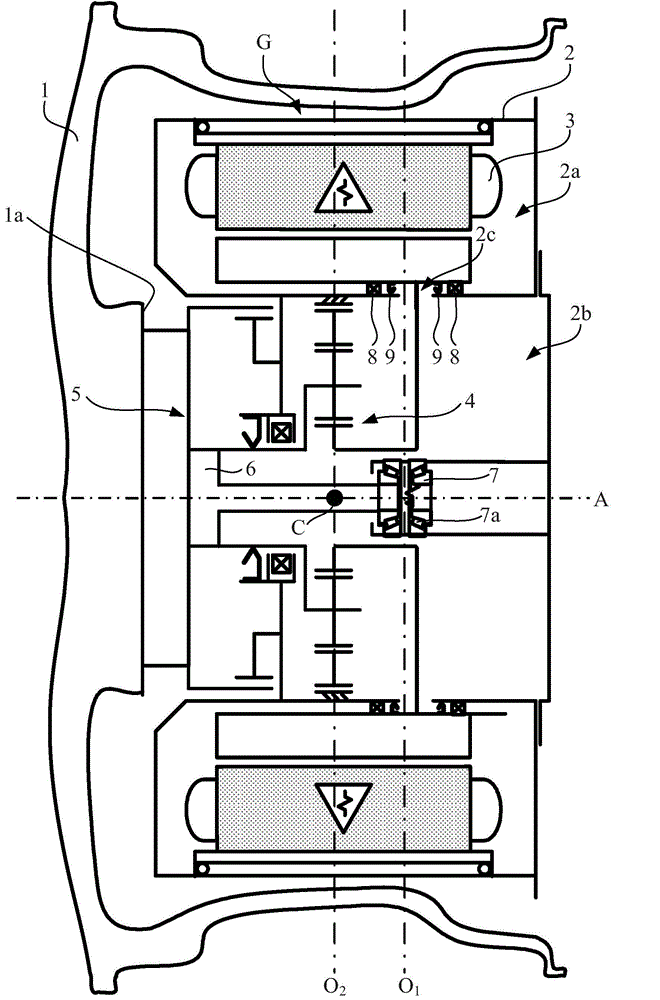

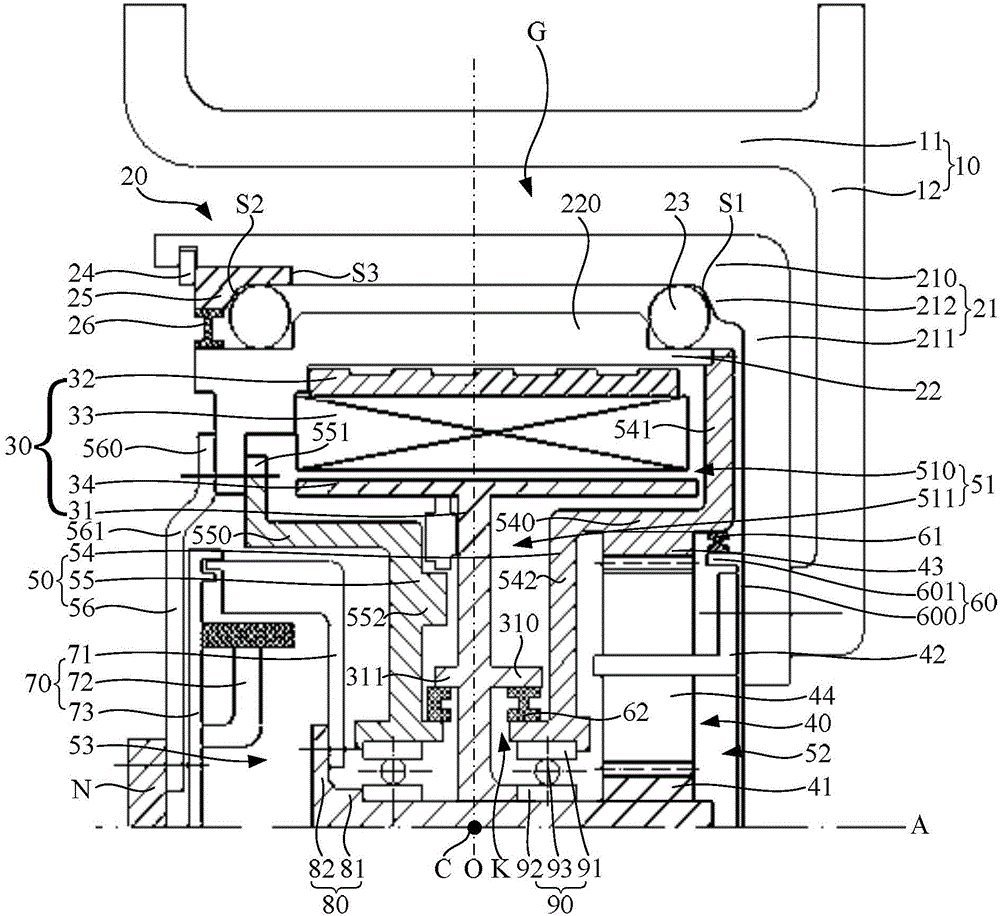

[0041] Such as figure 2 As shown, the hub drive assembly of this embodiment includes: a hub 10 , a hub bearing 20 located in the hub 10 , a motor 30 , a reducer 40 , and a housing 50 . Among them, the wheel hub 10 is used to accommodate the components other than the wheel hub 10 in the wheel hub drive assembly; the wheel hub bearing 20 is used to carry the load transmitted from the vehicle body to the wheel; the motor 30 is used to generate the driving torque that drives the wheel hub 10 to rotate; the speed reducer 40 Used to amplify the driving torque output by the motor 30 . The casing 50 is used to enclose a motor cavity 51 for accommodating the motor 30 and a reducer cavity 52 for accommodating the reducer 40 .

[0042] The motor 30, the speed reducer 40, and the casing 50 are all located on the radially inner side of the hub bearing 20, that is, the hub bearing 20 surrounds the motor 30, the speed reducer 40, and the casing 50, and plays a role in accommodating all par...

no. 2 example

[0103] The difference between the second embodiment and the first embodiment is that in the second embodiment, the wheel hub bearing is not provided with a special outer ring, but is used as the wheel hub, which simplifies the structure of the wheel hub drive assembly. In the second embodiment, the rolling elements in the hub bearing may directly contact the inner peripheral surface of the hub.

[0104] In the second embodiment, since the hub doubles as the outer ring of the hub bearing, when the vehicle is running, hard objects on the road will not enter the radial inner side of the hub, so no hard objects will be stuck into the inner peripheral surface of the hub , and hinder the rotation of the hub and cause wear and tear on the hub.

[0105] In addition, compared with the first embodiment, the technical solution of the second embodiment also has the following advantages: all the space in the hub can be used to accommodate components other than the hub in the hub drive asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com