Patents

Literature

64results about How to "Axial dimensions are compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

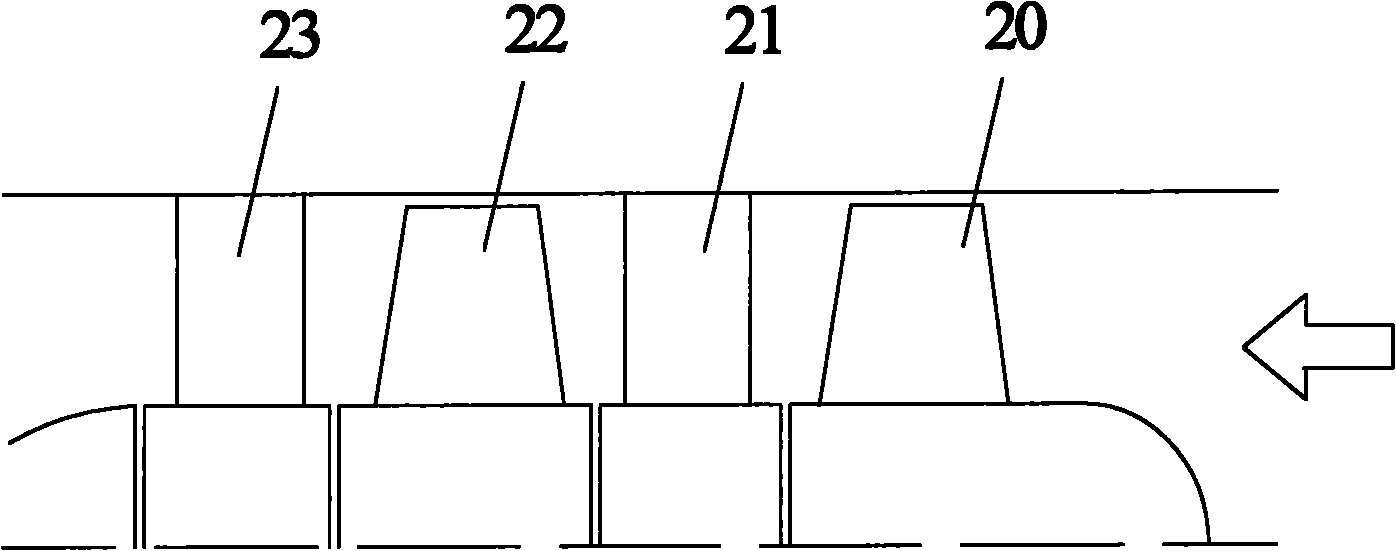

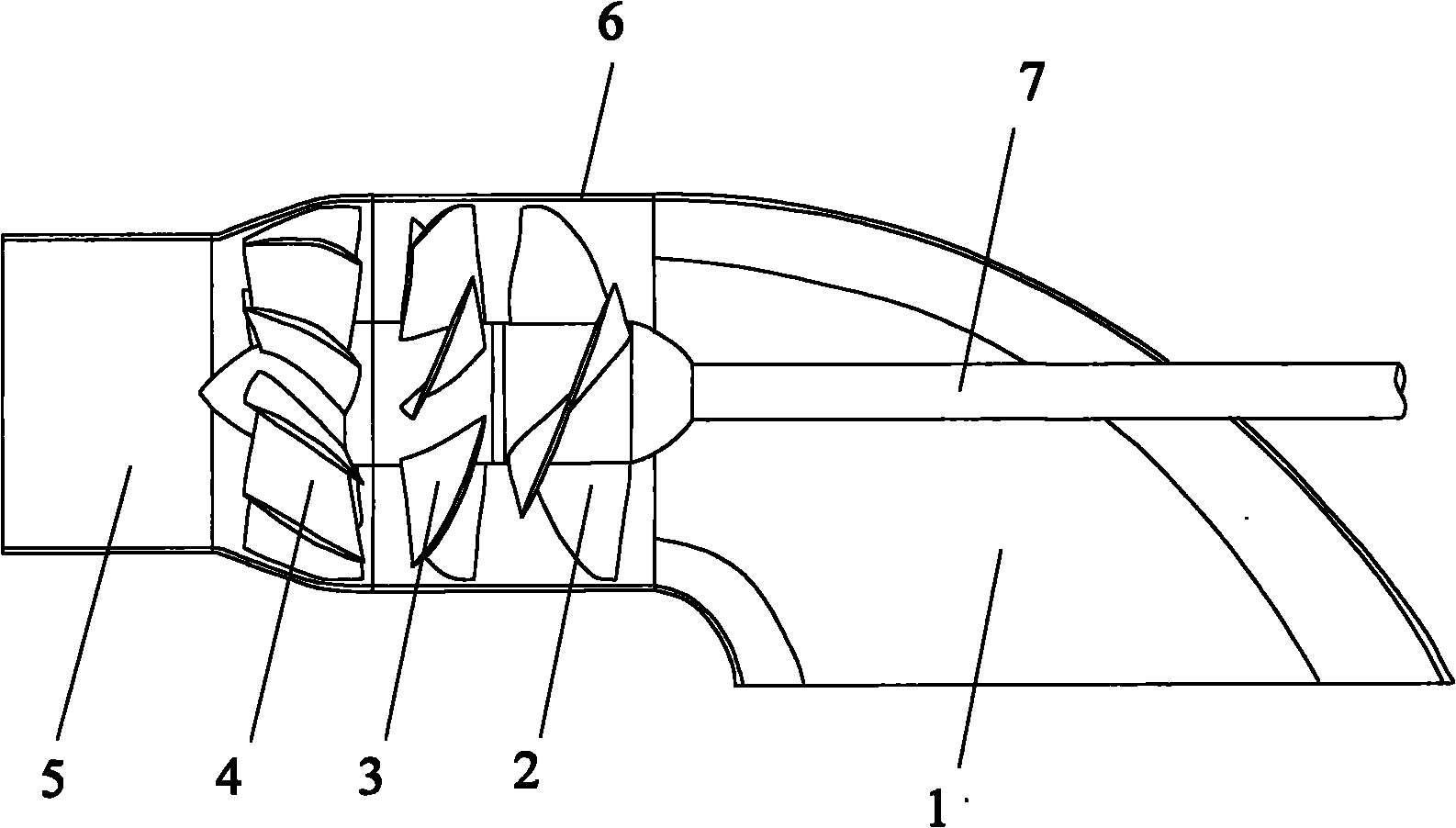

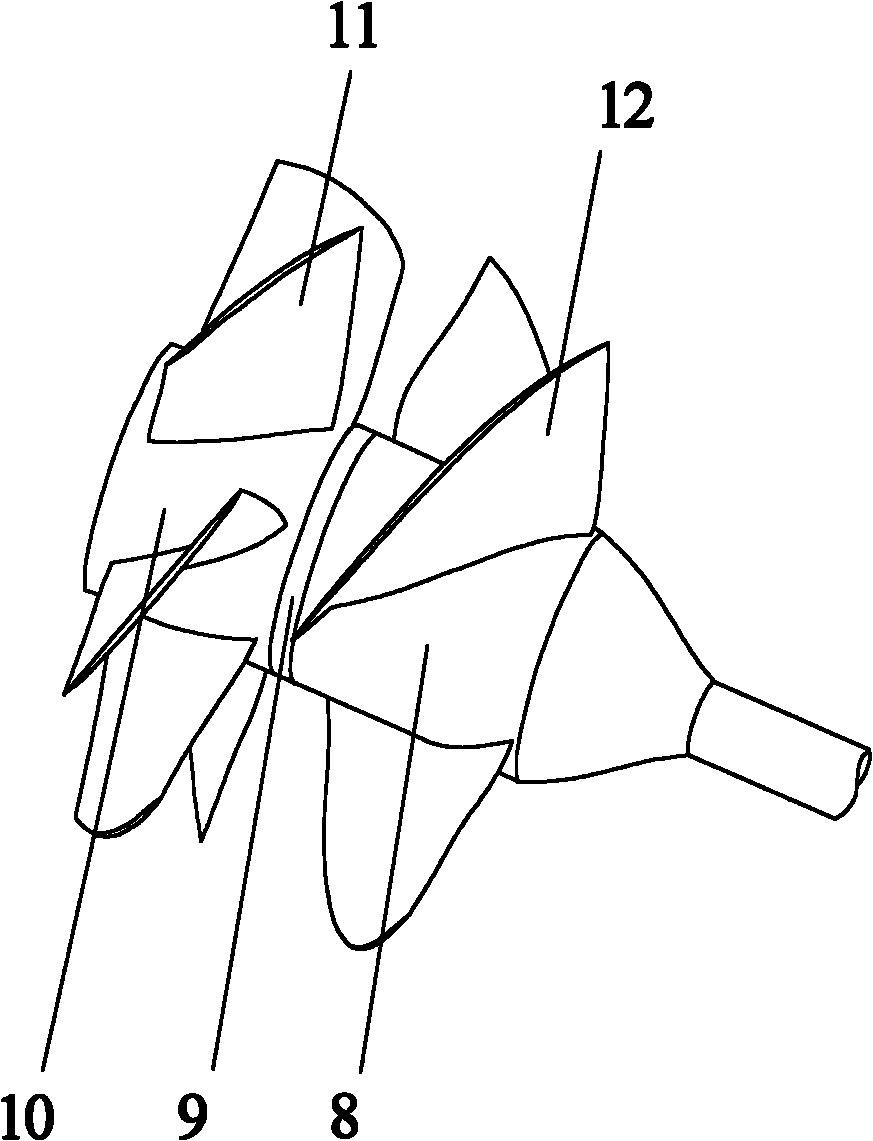

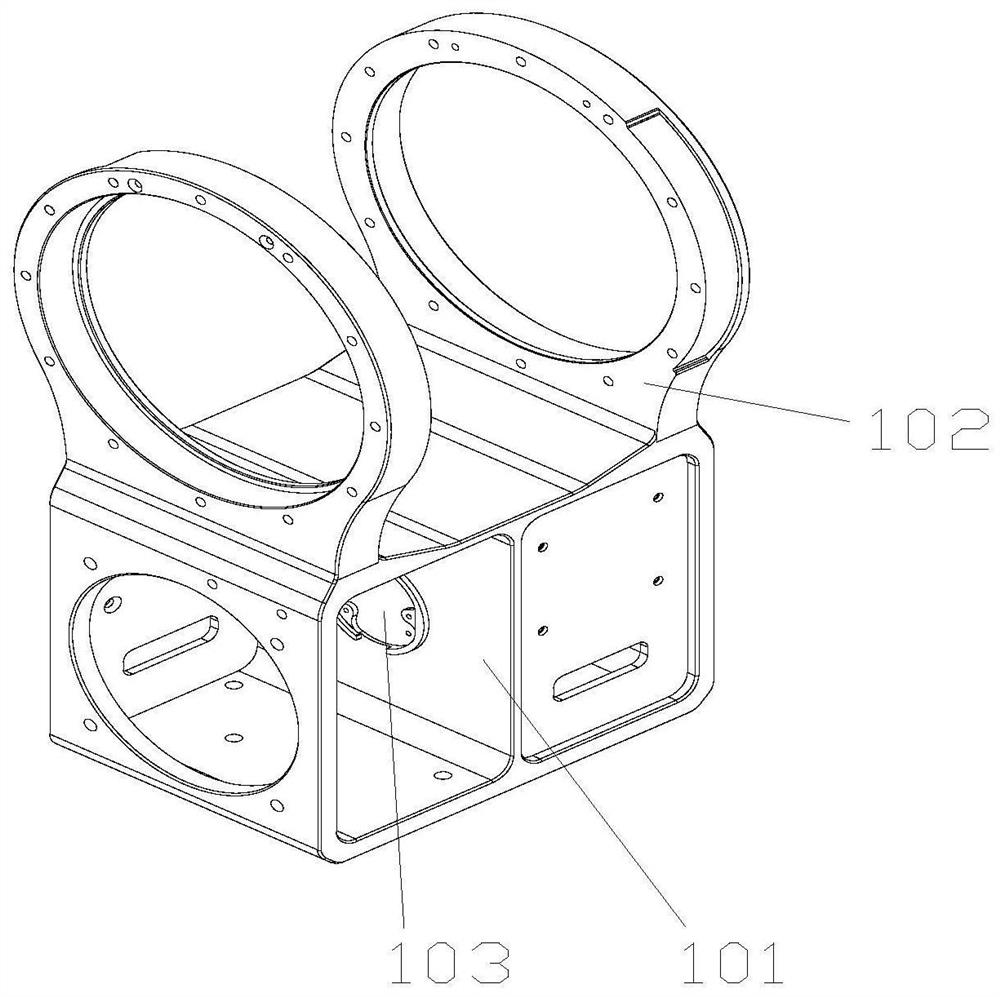

Serial axial-flow water jet propulsion pump

InactiveCN101830278AAvoid internal cavitationAvoid cavitationPump componentsPropulsive elementsImpellerCavitation

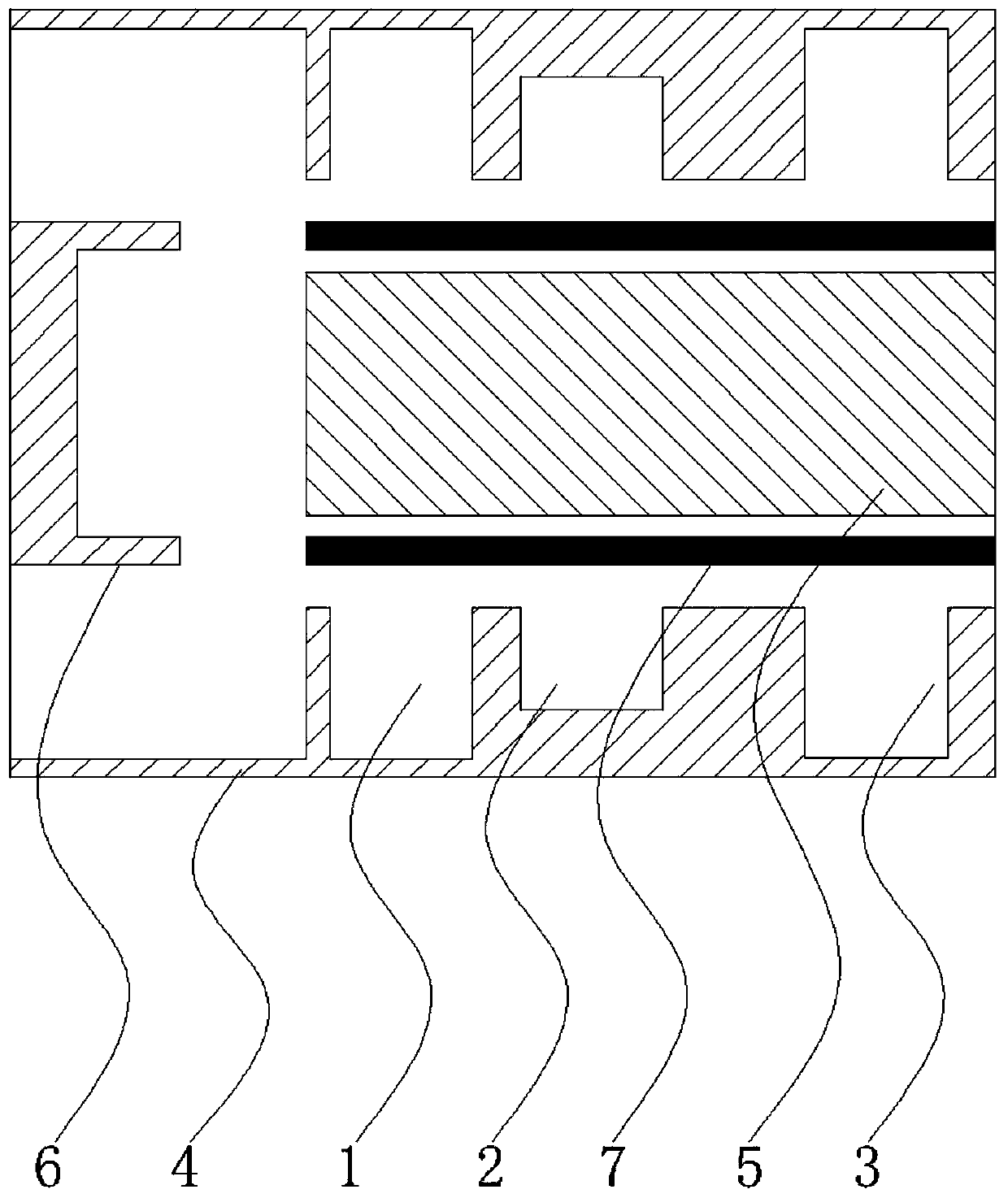

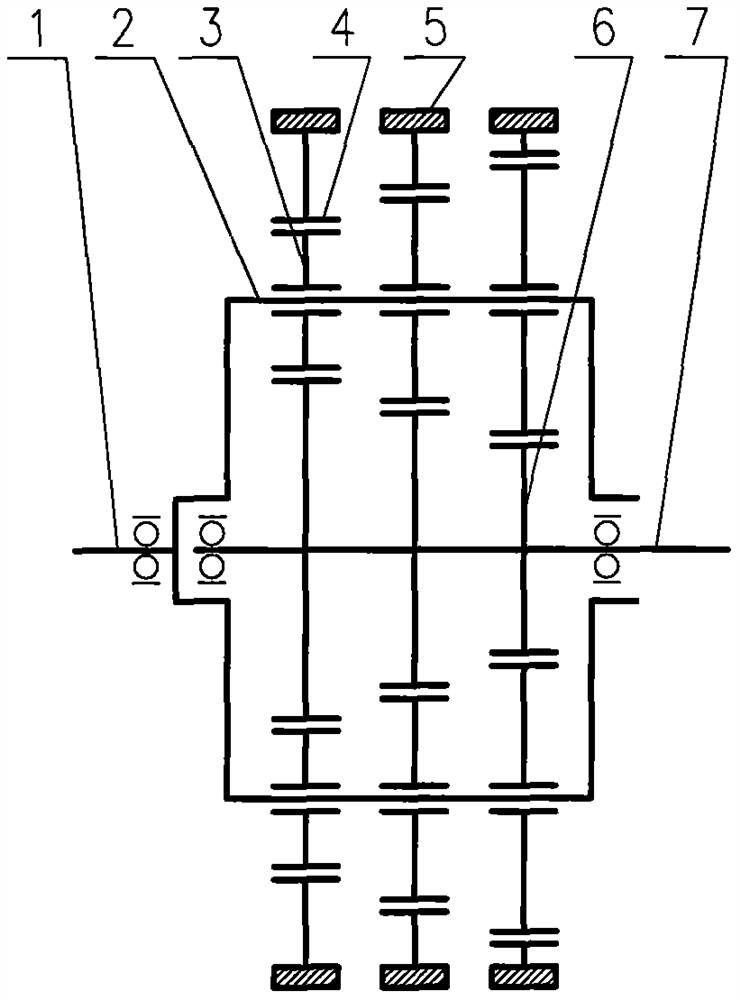

The invention discloses a serial axial-flow water jet propulsion pump which comprises a water suction elbow (1), a pump shaft (7), an impeller chamber (6), an inducer (2) and a main impeller (3), wherein the inducer (2) and the main impeller (3) are positioned in the impeller chamber (6); the pump shaft (7) is horizontally arranged; the inducer (2) and the main impeller (3) are fixed on the pump shaft (7) through keys; the outlet of the water suction elbow (1) is connected with the inlet of the inducer (2); the outlet of the main impeller (3) is orderly connected with a rectifier (4) and a jet pipe (5); and the area of the overflowing cross section gradually reduces along the central line of the flow channel to form a contracting flow channel. The invention avoids cavitation in the main impeller, solves the problems of cavitation under the operating conditions of large thrust and high speed of the water jet propulsion pump and reduces the axial size of the propulsion pump.

Owner:CHINA AGRI UNIV

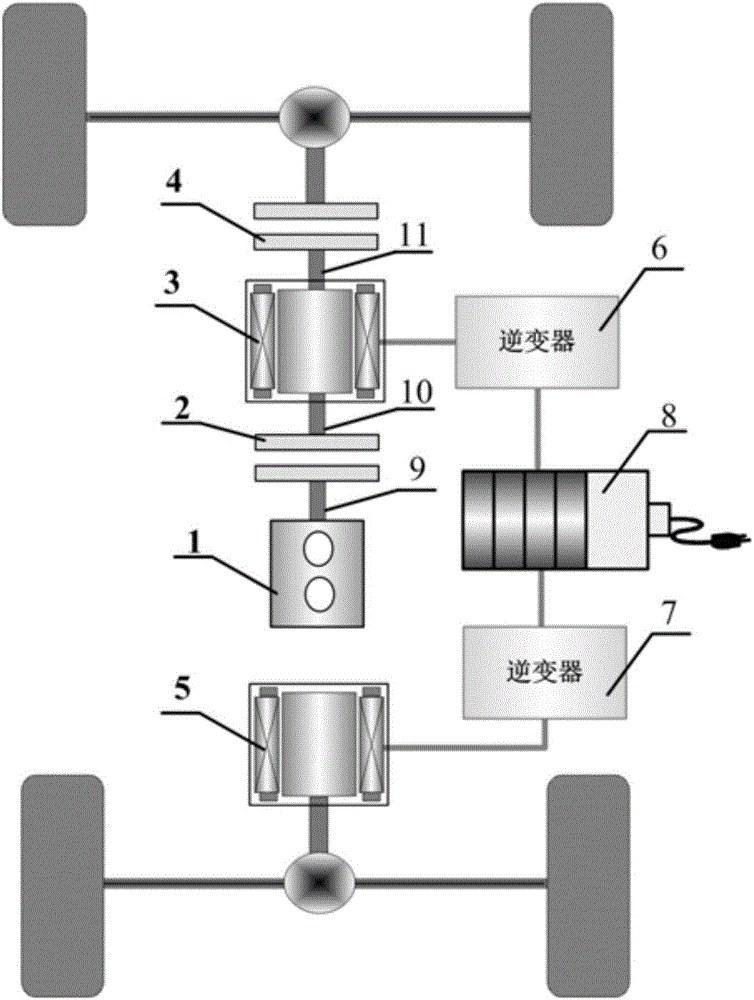

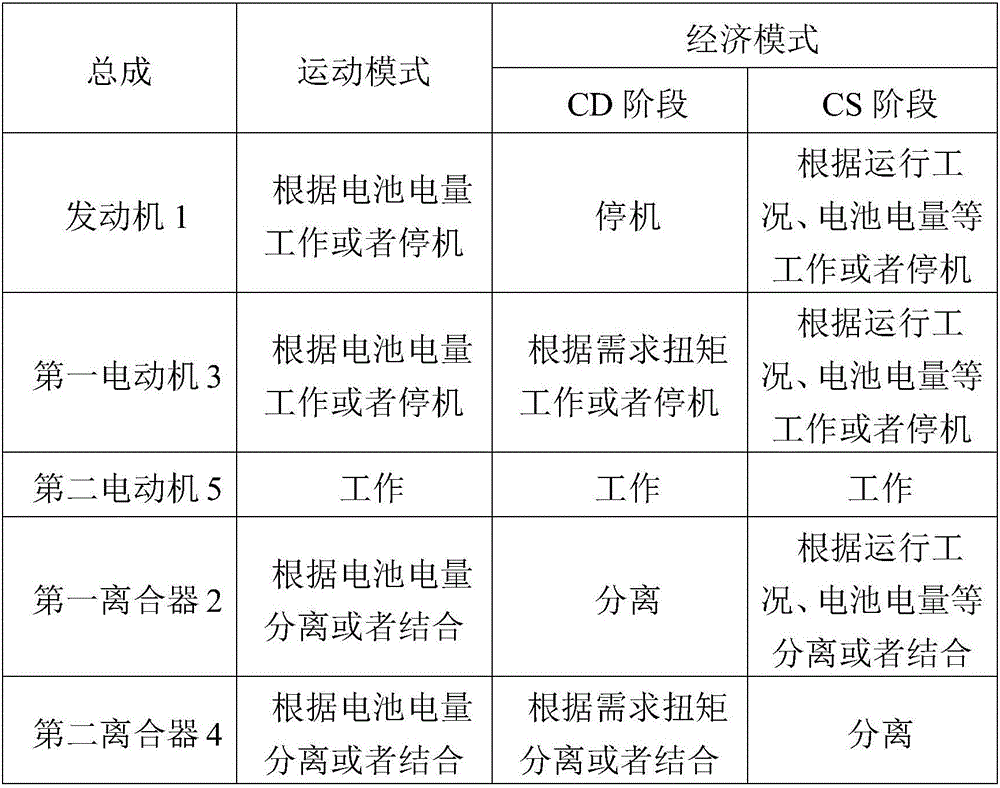

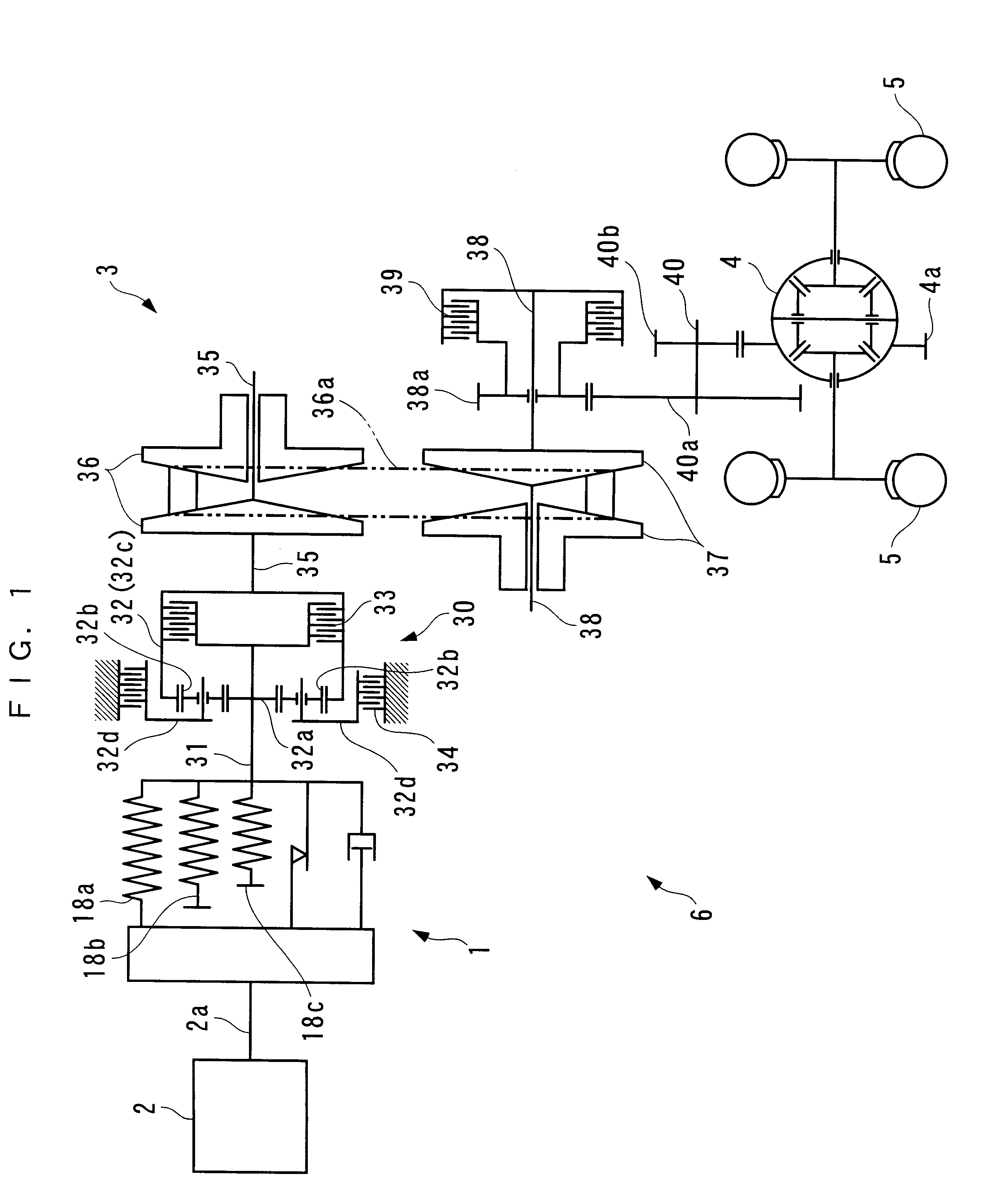

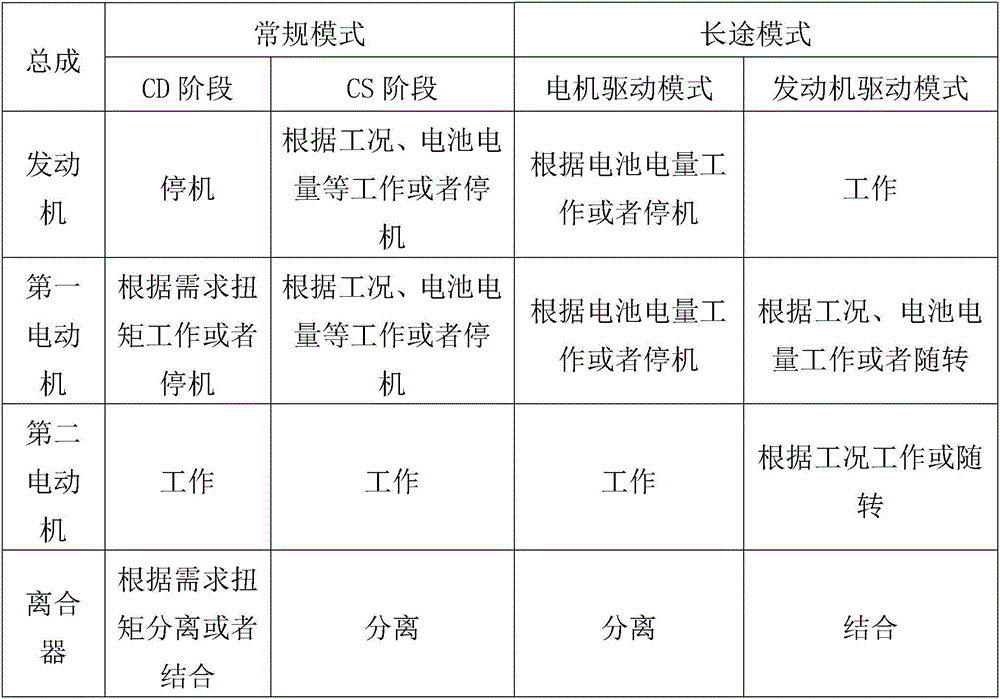

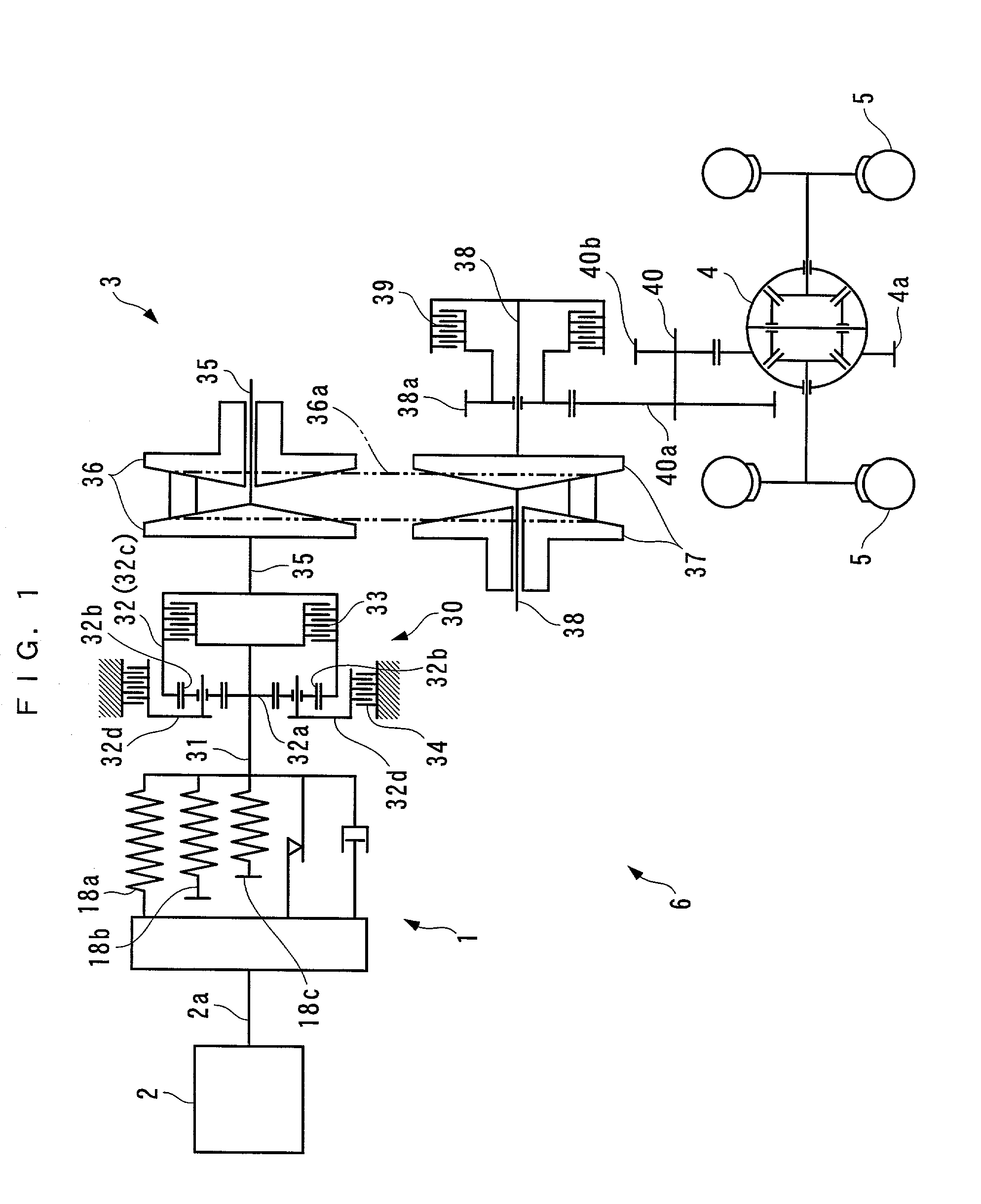

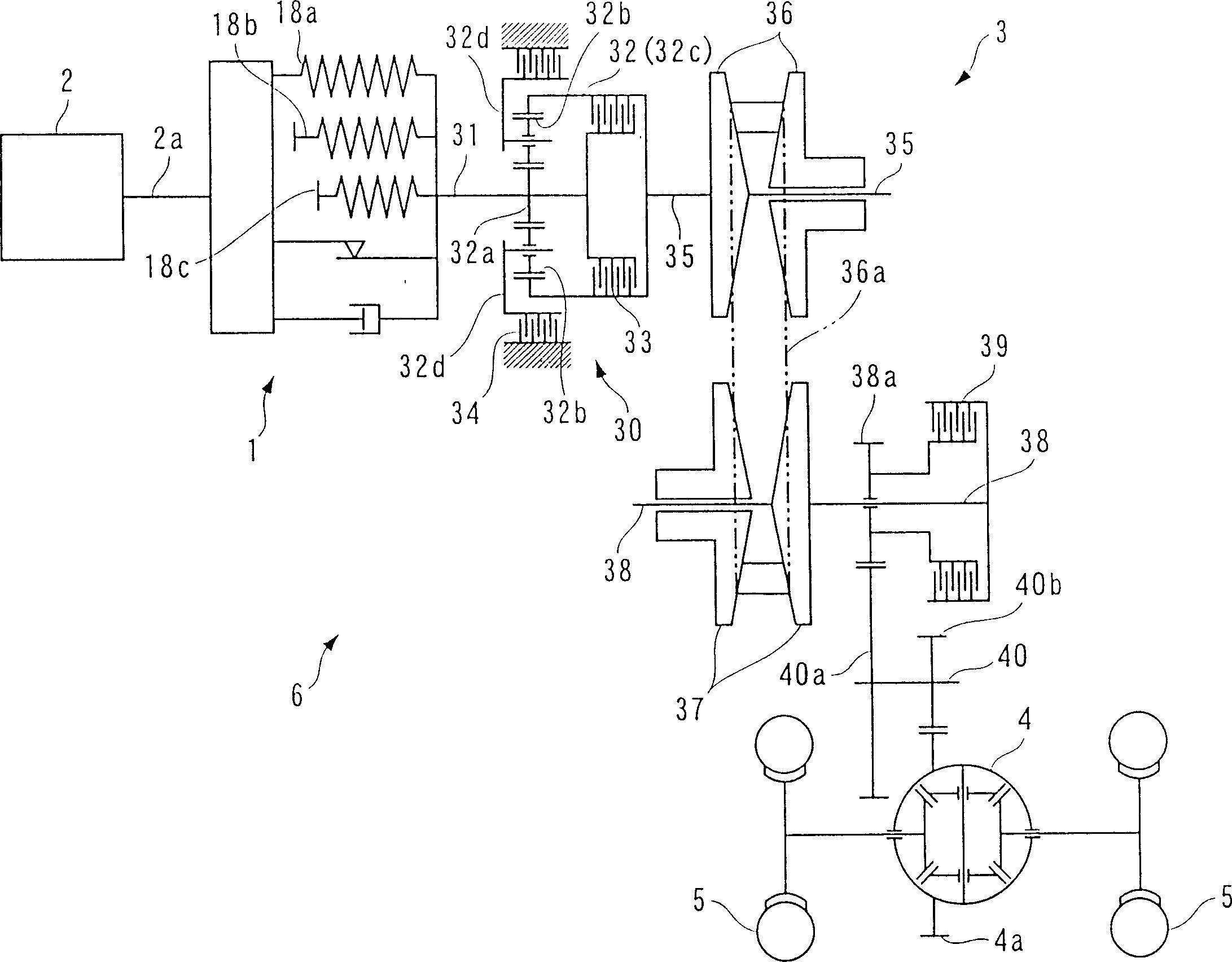

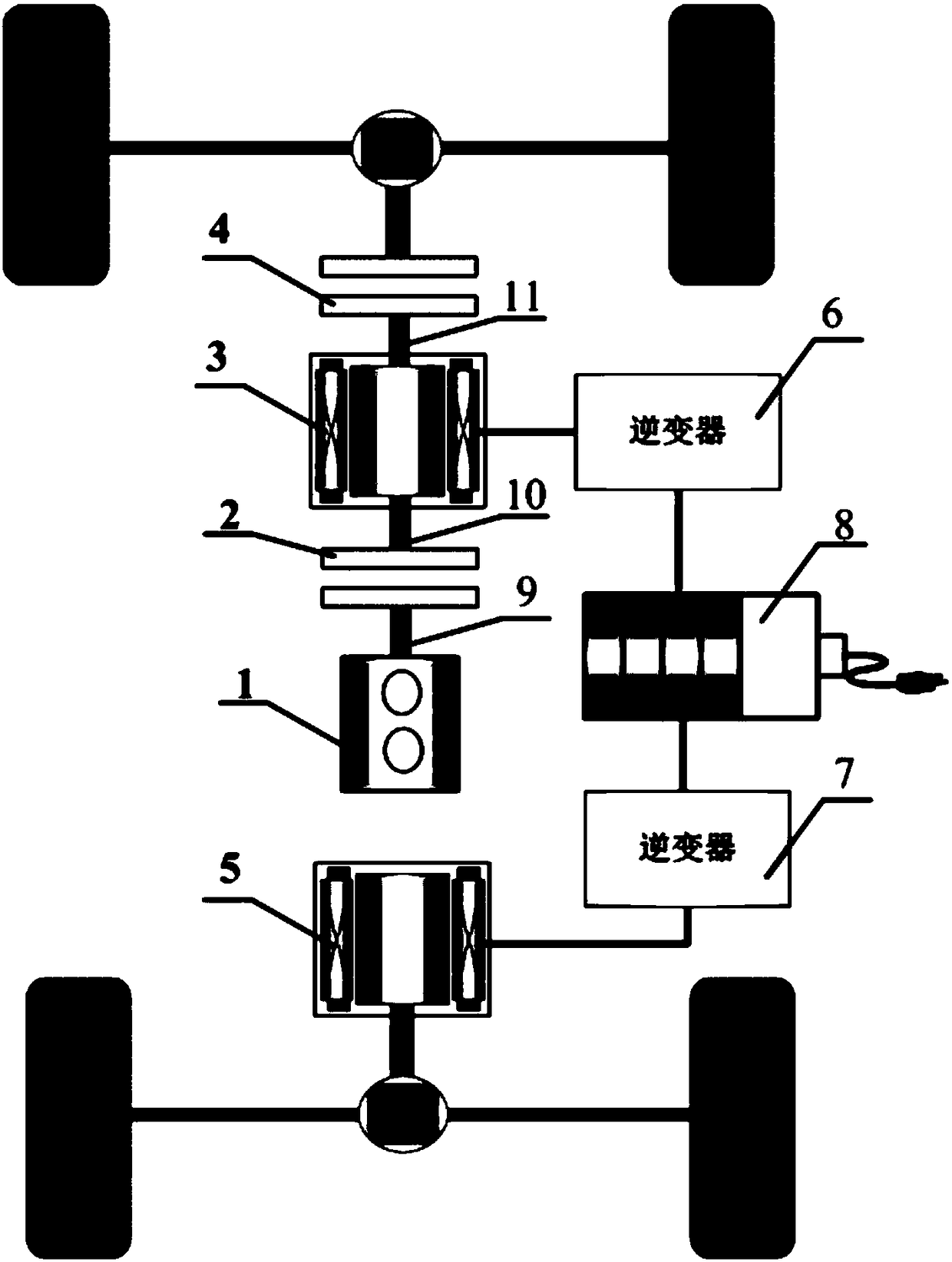

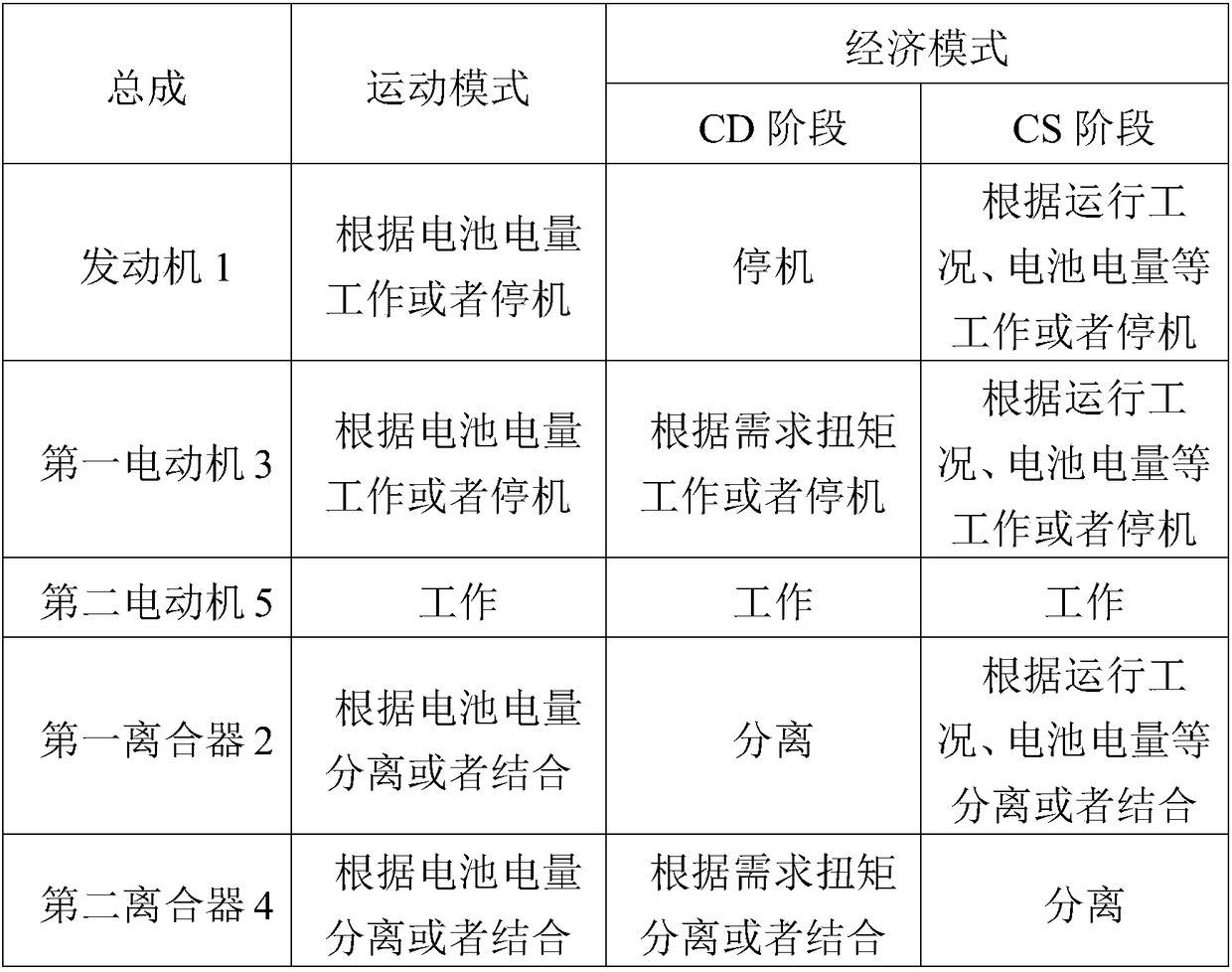

Series connection range extending type electric automobile power system and control method thereof

ActiveCN105946600ABattery does not dropPrevent slippingHybrid vehiclesInternal combustion piston enginesPower batteryReduction drive

The invention provides a series connection range extending type electric automobile power system. The system is characterized by comprising an engine, a first motor, a second motor, a first clutch, a second clutch, a first inverter, a second inverter and a power battery; the engine is connected with the first clutch through a first transmission shaft; the first clutch is connected with the first motor through a second transmission shaft; the first motor is connected with the second clutch through a third transmission shaft; the second clutch outputs power to front wheels of an automobile through a main speed reducer and a differential mechanism of a front axle of the automobile; the second motor outputs power to rear wheels of the automobile through a main speed reducer and a differential mechanism of a rear axle of the automobile; and the power battery is connected with the first motor through the first inverter and connected with the second motor through the second inverter.

Owner:CHINA FIRST AUTOMOBILE

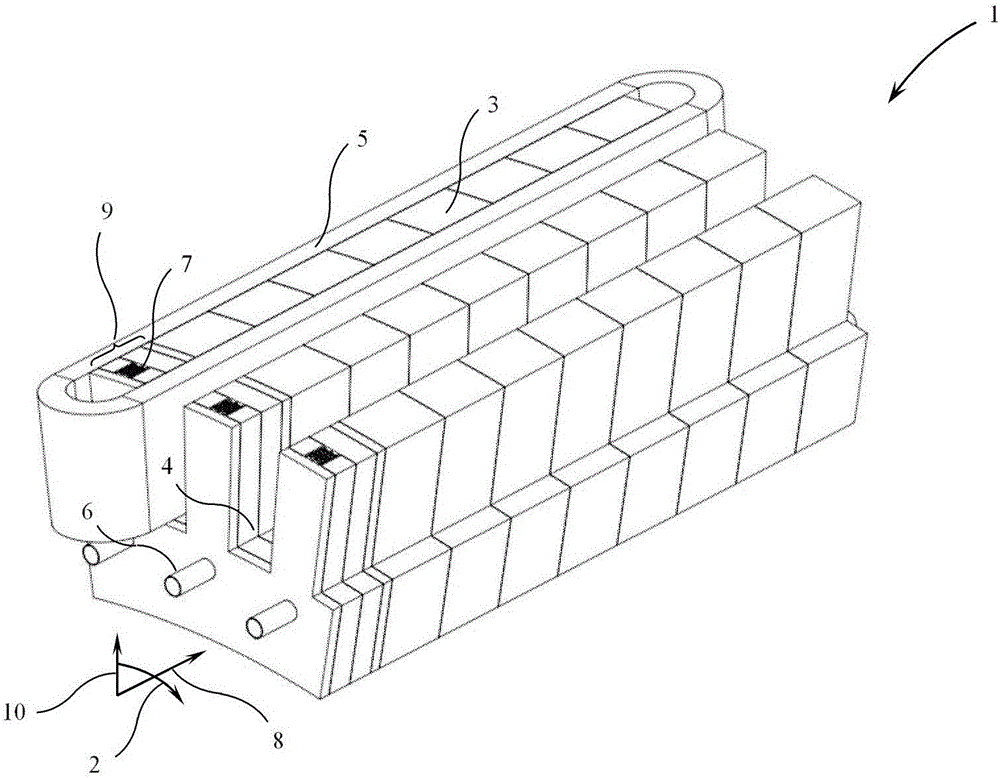

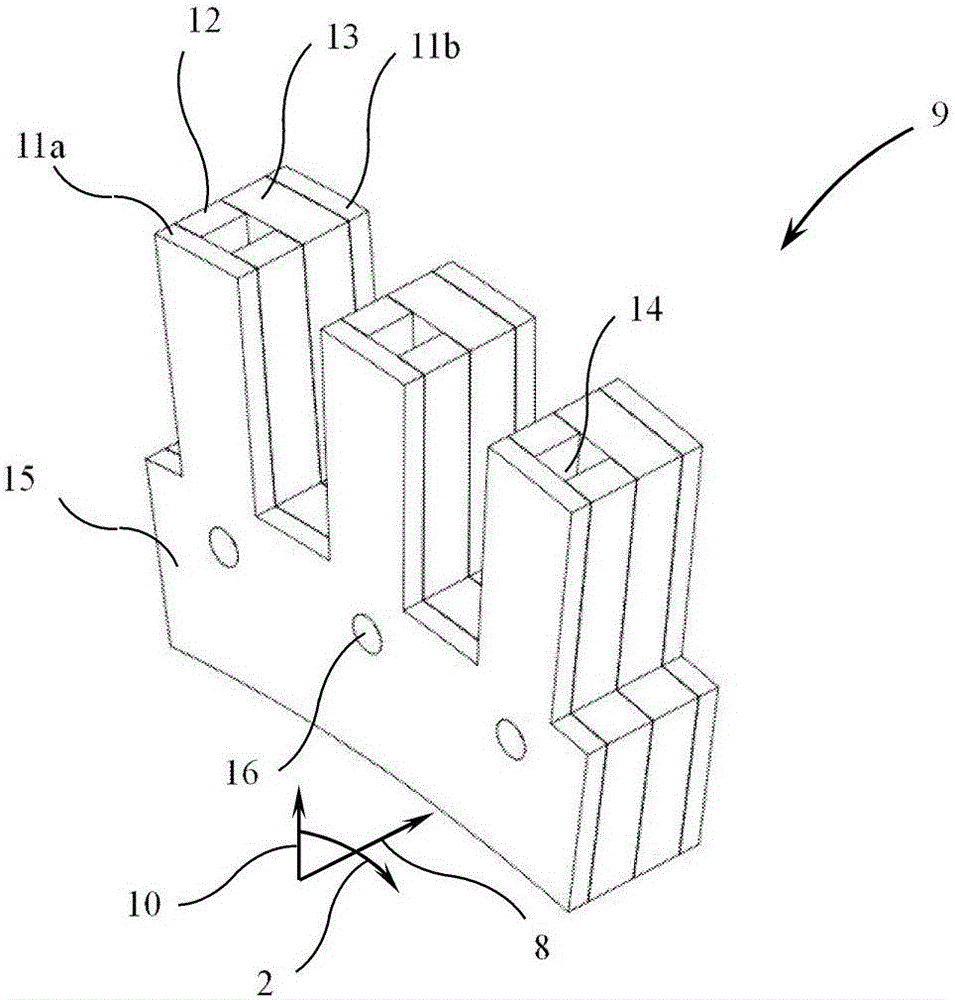

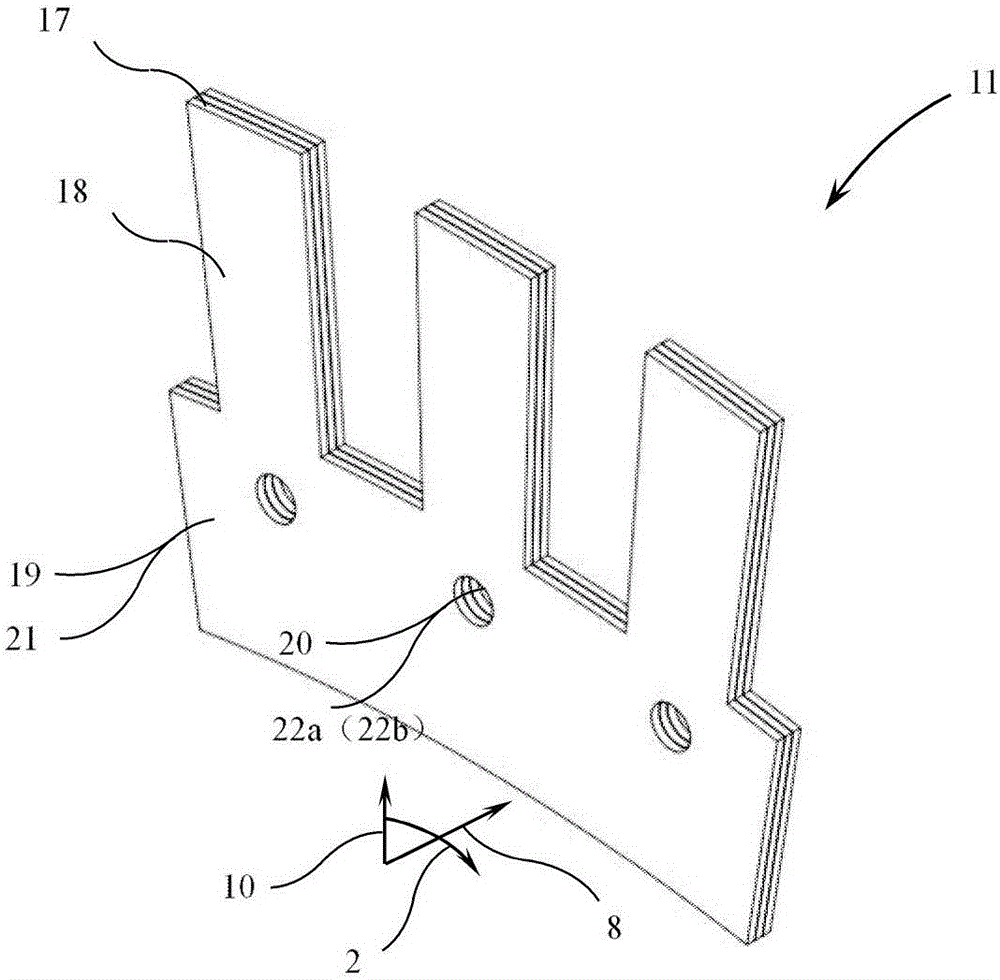

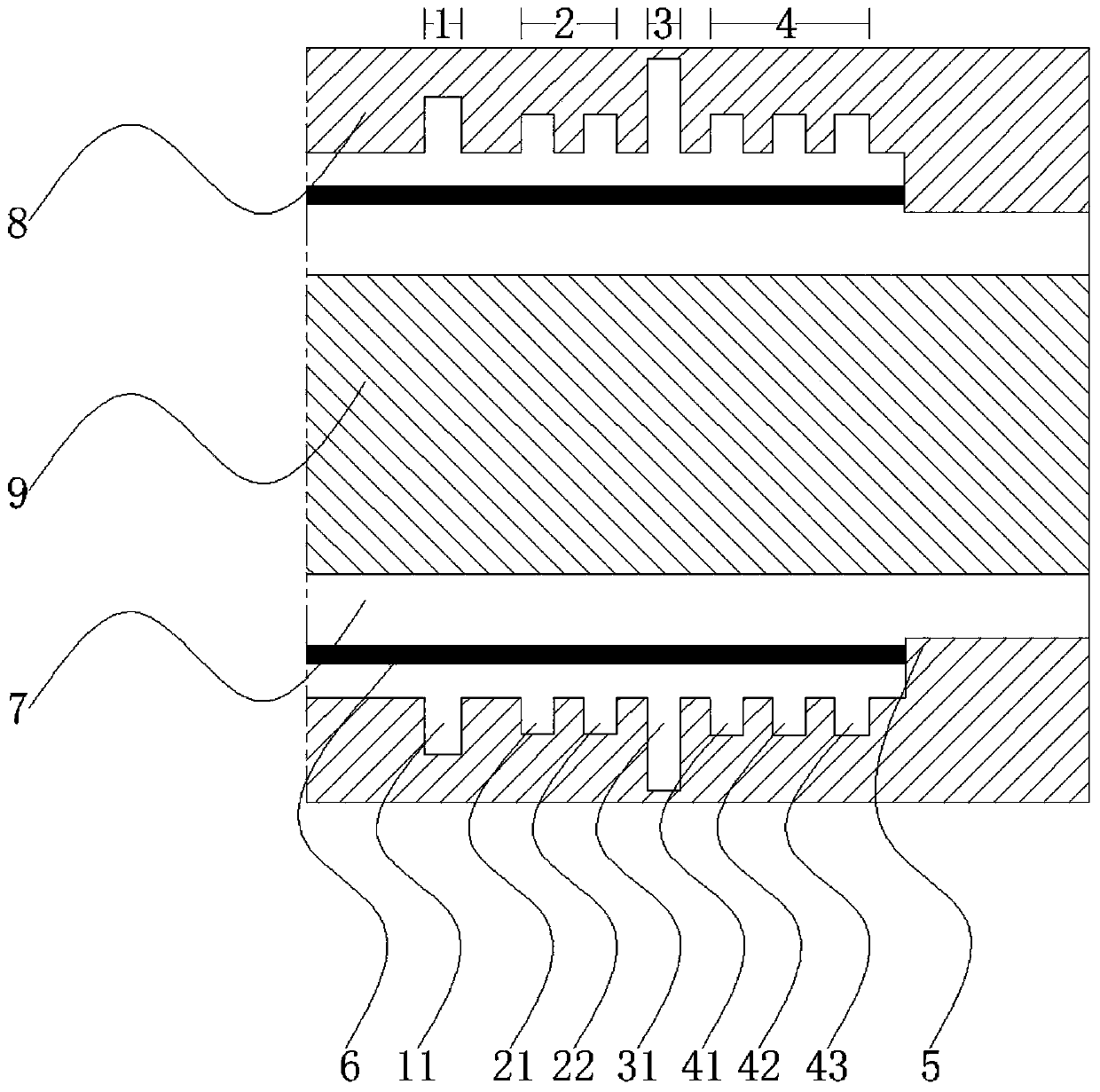

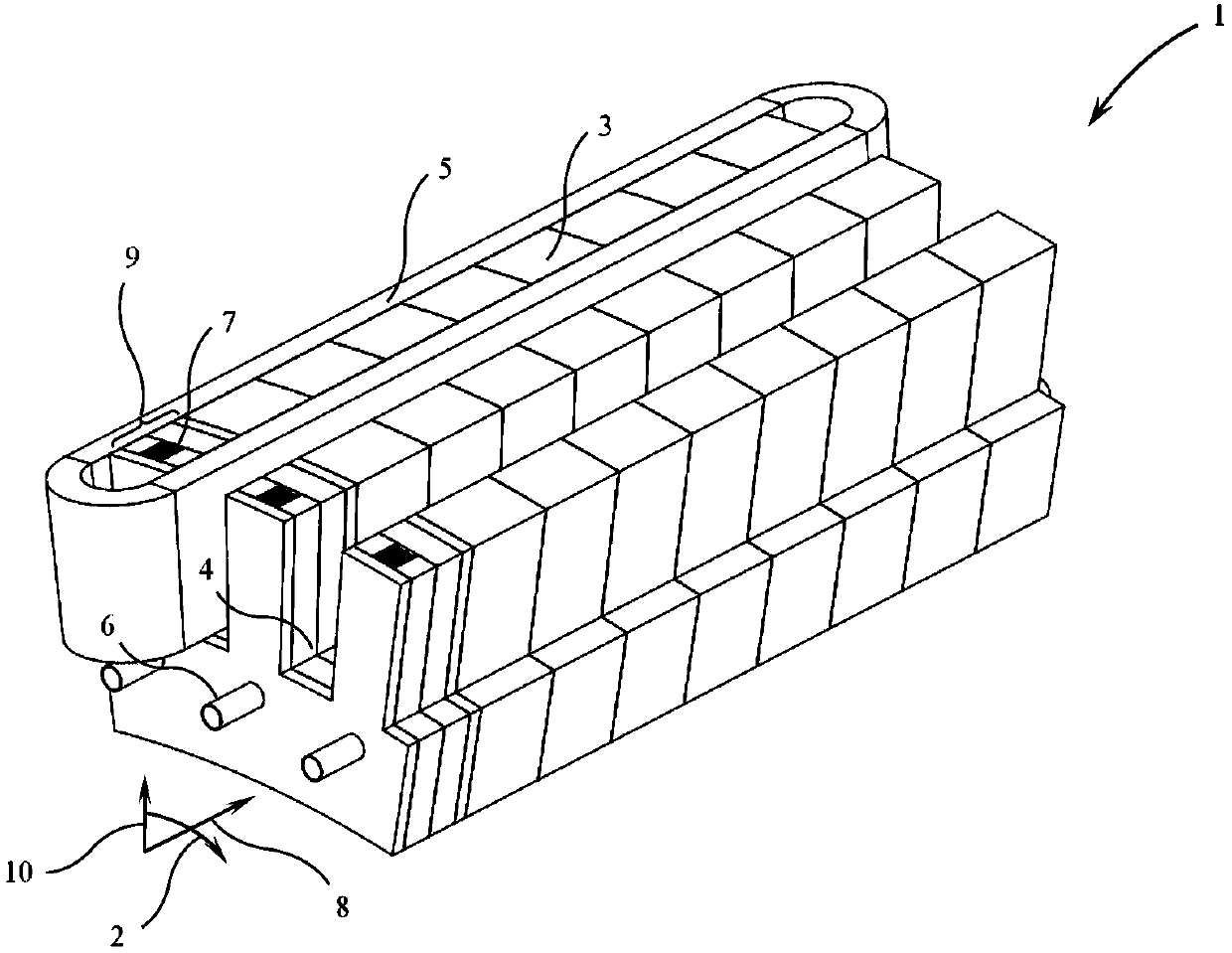

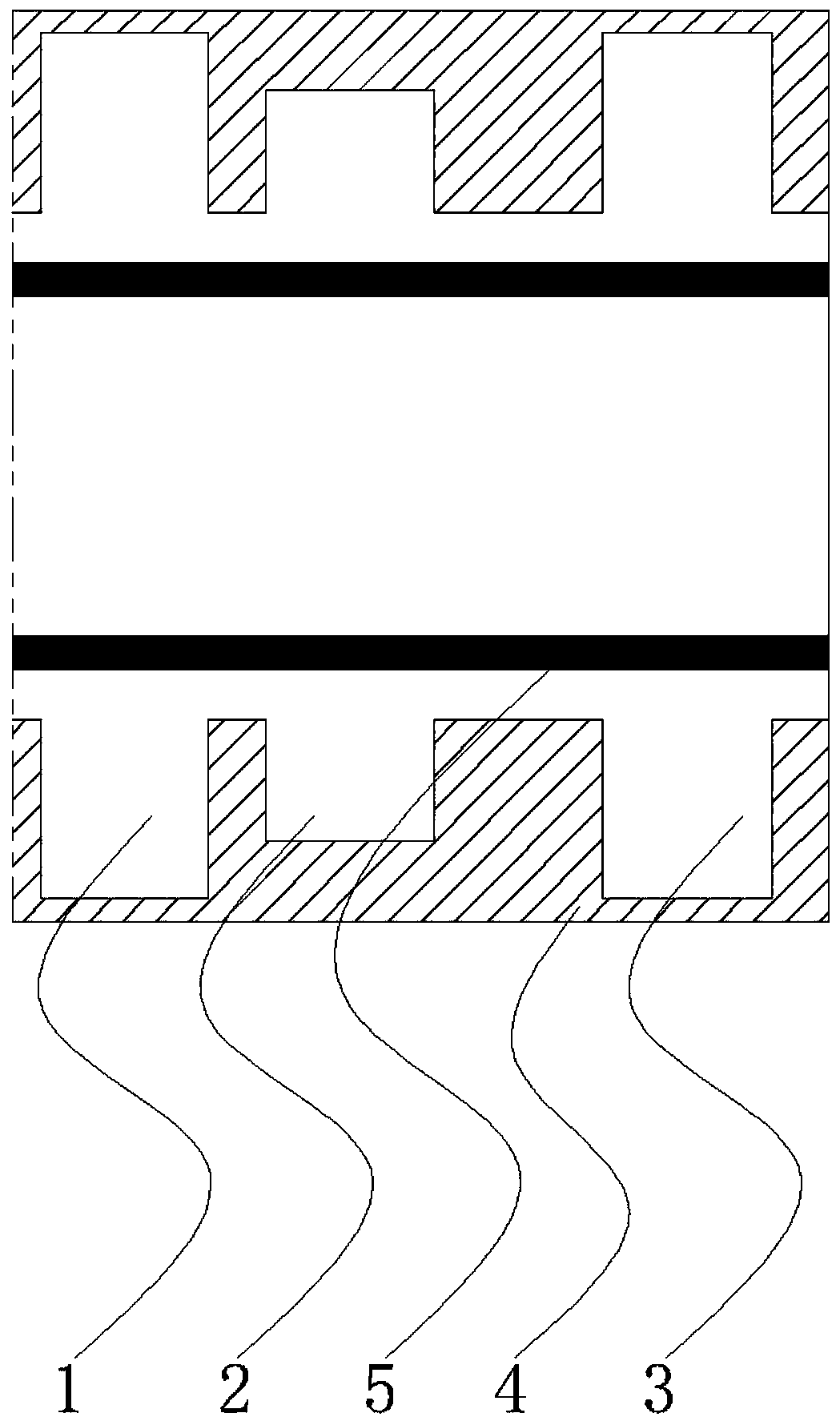

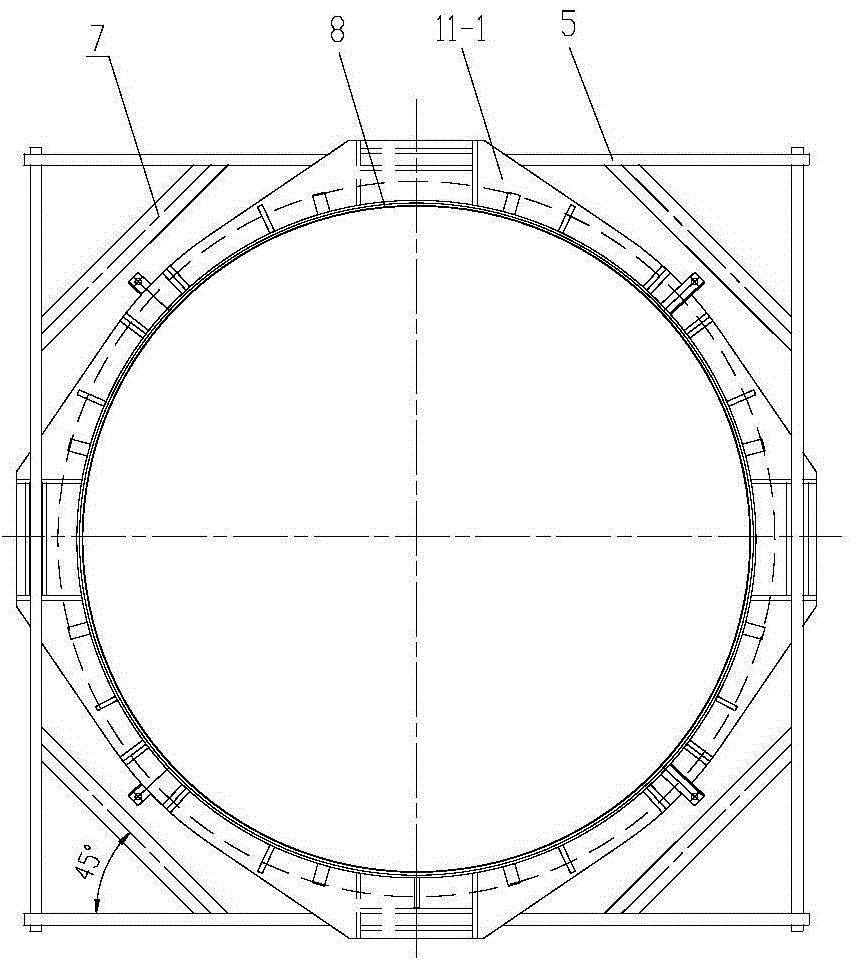

Stator core unit, stator, motor and wind generator unit

ActiveCN106655564AAxial dimensions are compactImprove cohesionEngine fuctionsMagnetic circuit stationary partsEngineeringWind force

The invention relates to a stator core unit for a stator of a motor. The stator core unit comprises first lamination stacks, second lamination stacks, first intermediate lamination stacks, second intermediate lamination stacks, first cooling liquid channels and second cooling liquid conveyer pipes, wherein various lamination stacks are adjacently engaged along the axial direction of the motor, and the first intermediate lamination stacks and the second intermediate lamination stacks are arranged between the corresponding first lamination stacks and second lamination stacks; the first intermediate lamination stacks and the second intermediate lamination stacks are provided with first cutting grooves and second cutting grooves separately, and the first cutting grooves correspondingly communicate with the second cutting grooves to form the first cooling liquid channels, so that a first cooling liquid can flow through the first cooling liquid channels; and the second cooling liquid conveyer pipes pass through the first lamination stacks, the first intermediate lamination stacks, the second intermediate lamination stacks and the second lamination stacks and a second cooling liquid flowing through the second cooling liquid conveyer pipes can carry out heat exchange with the first cooling liquid. The invention further relates to the stator for the motor, the motor and a wind generator set.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

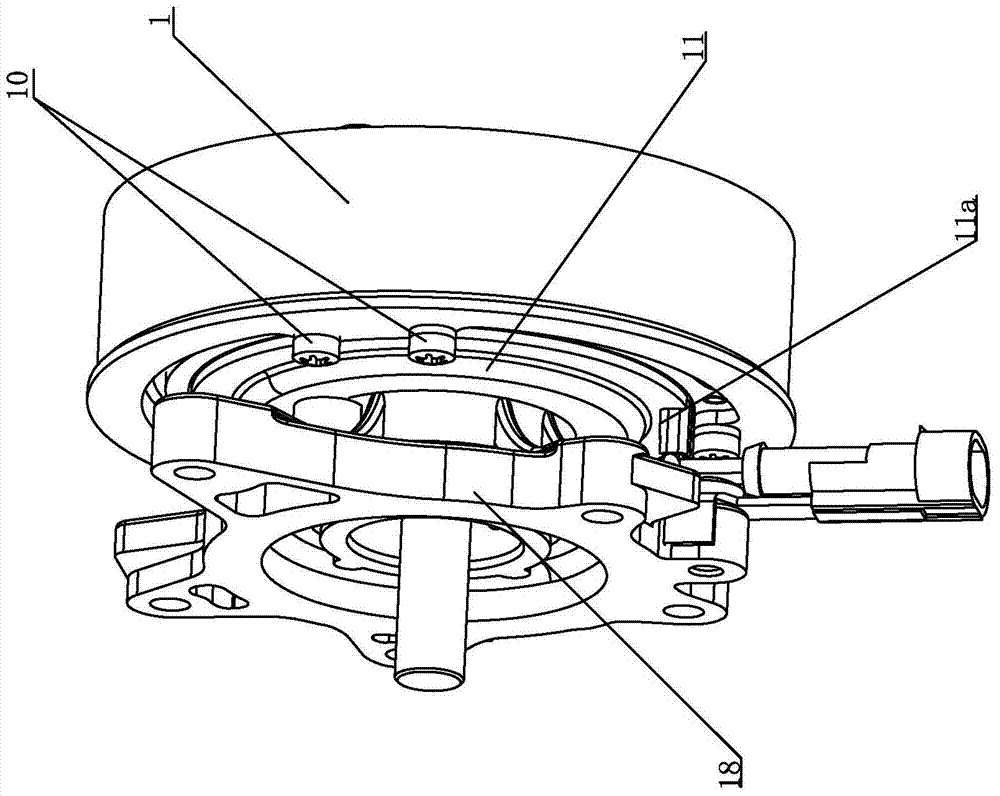

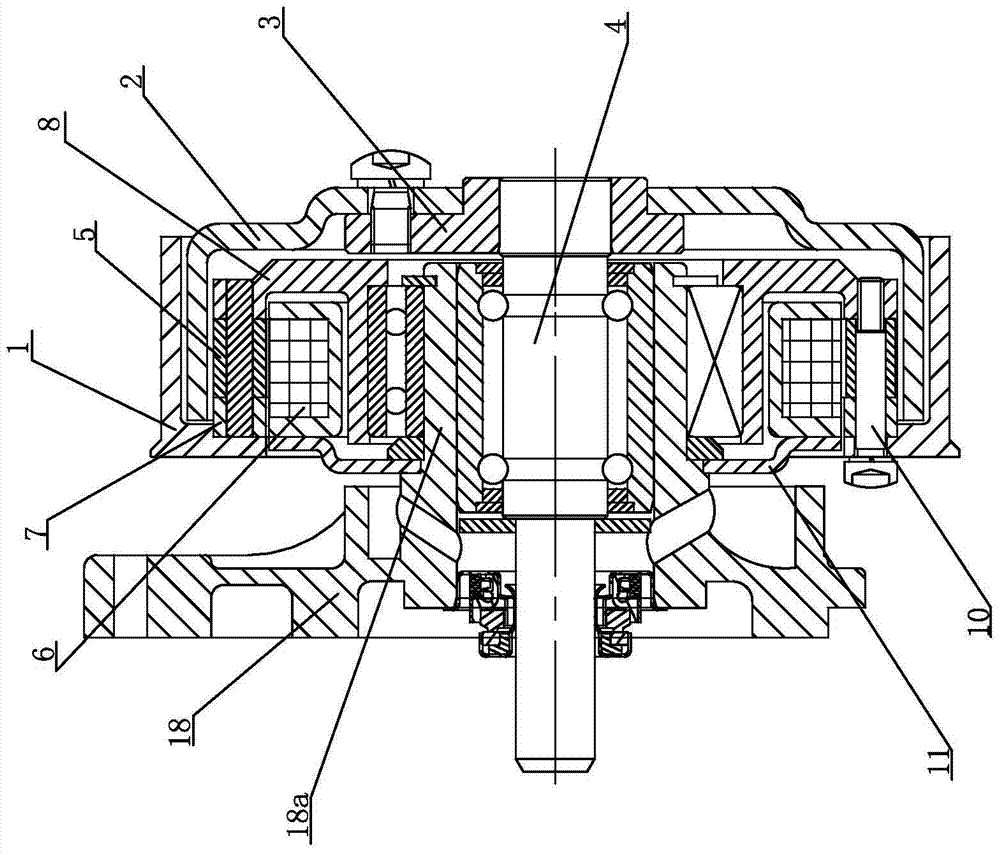

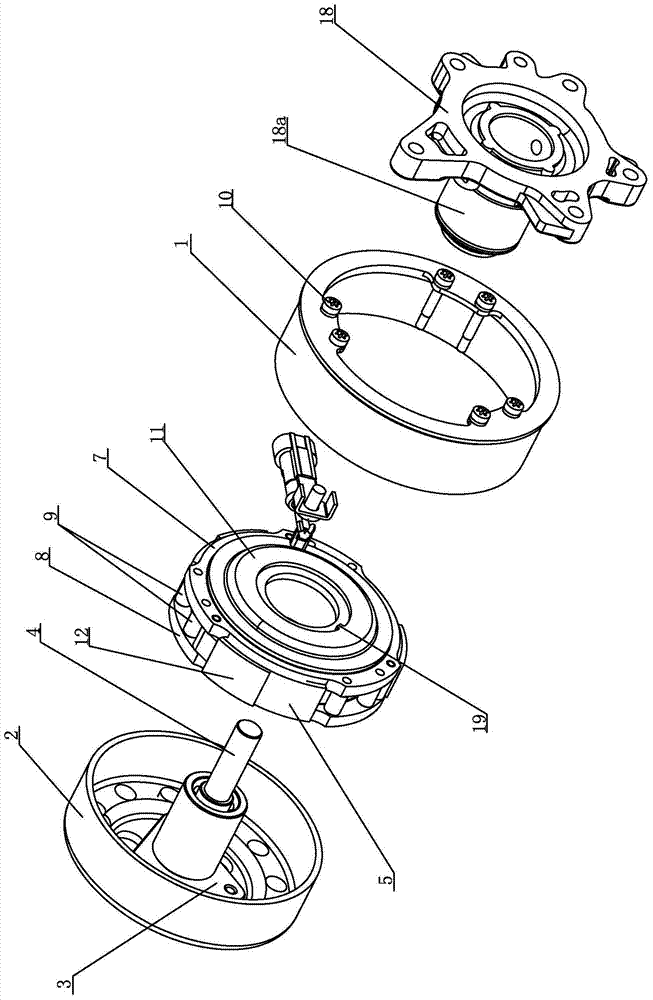

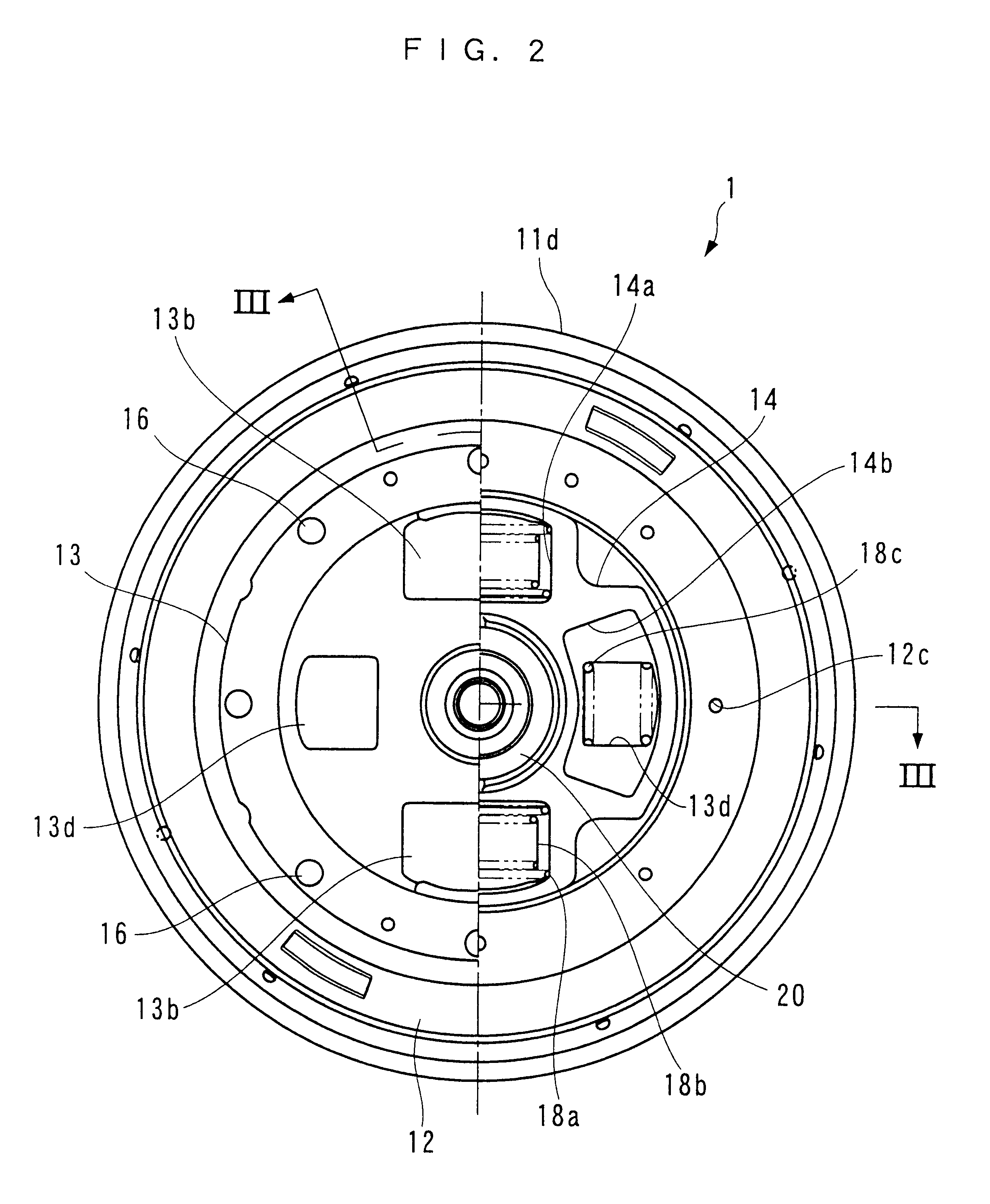

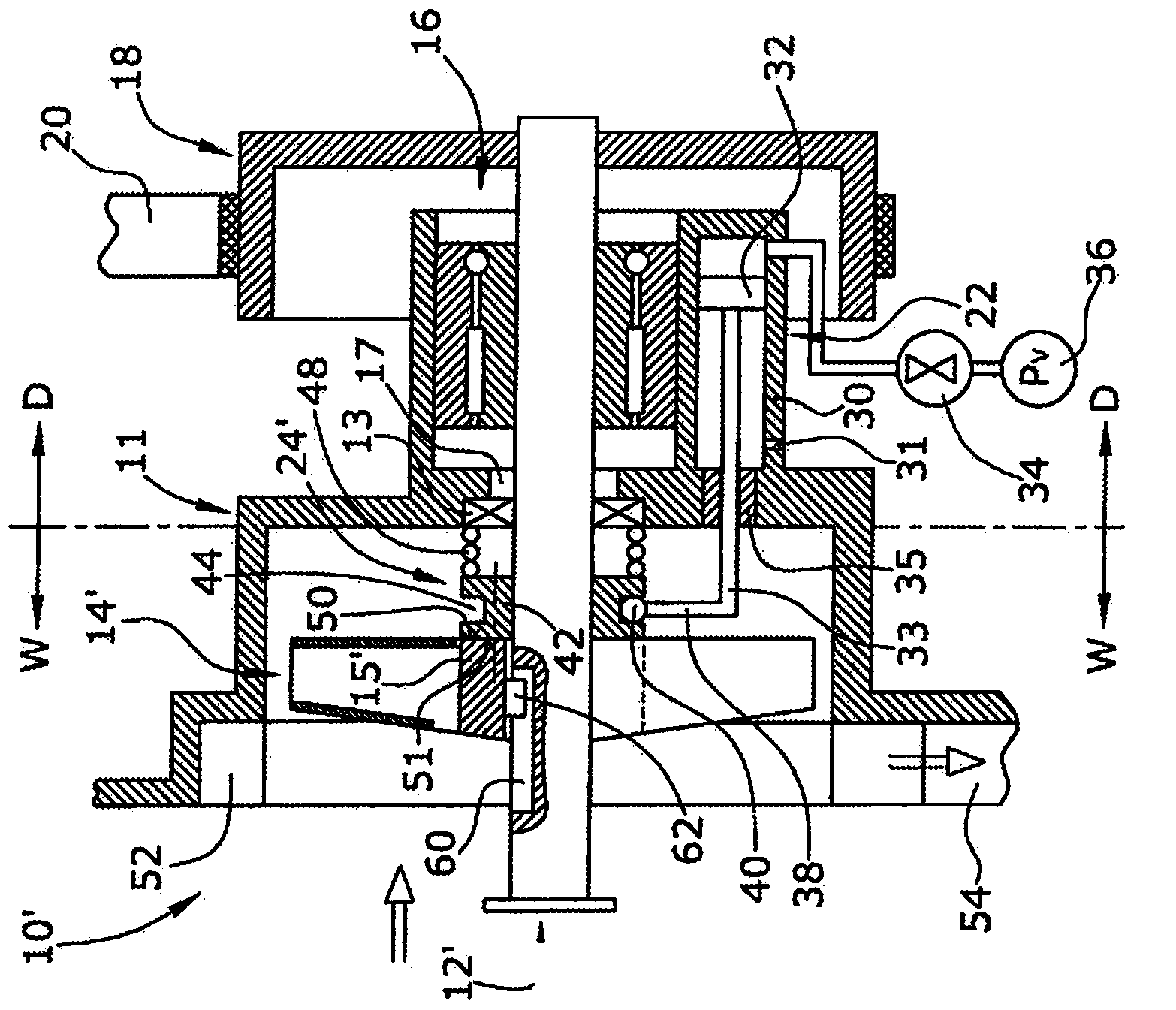

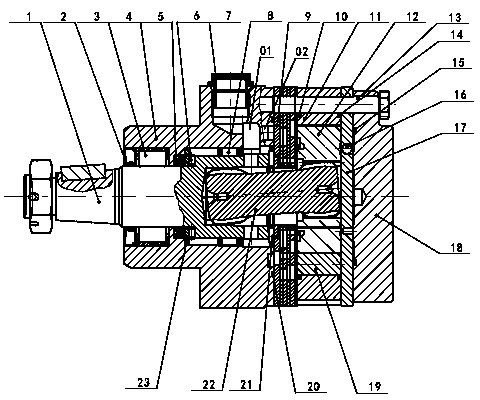

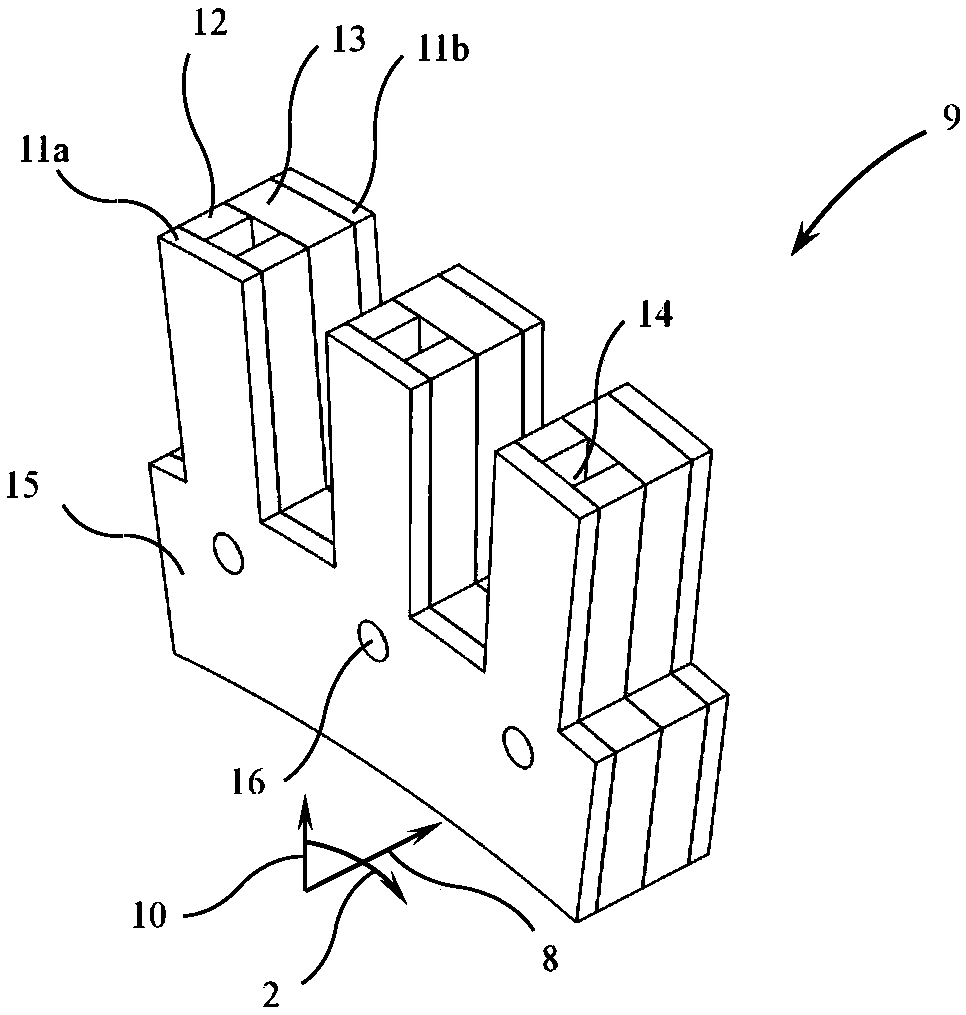

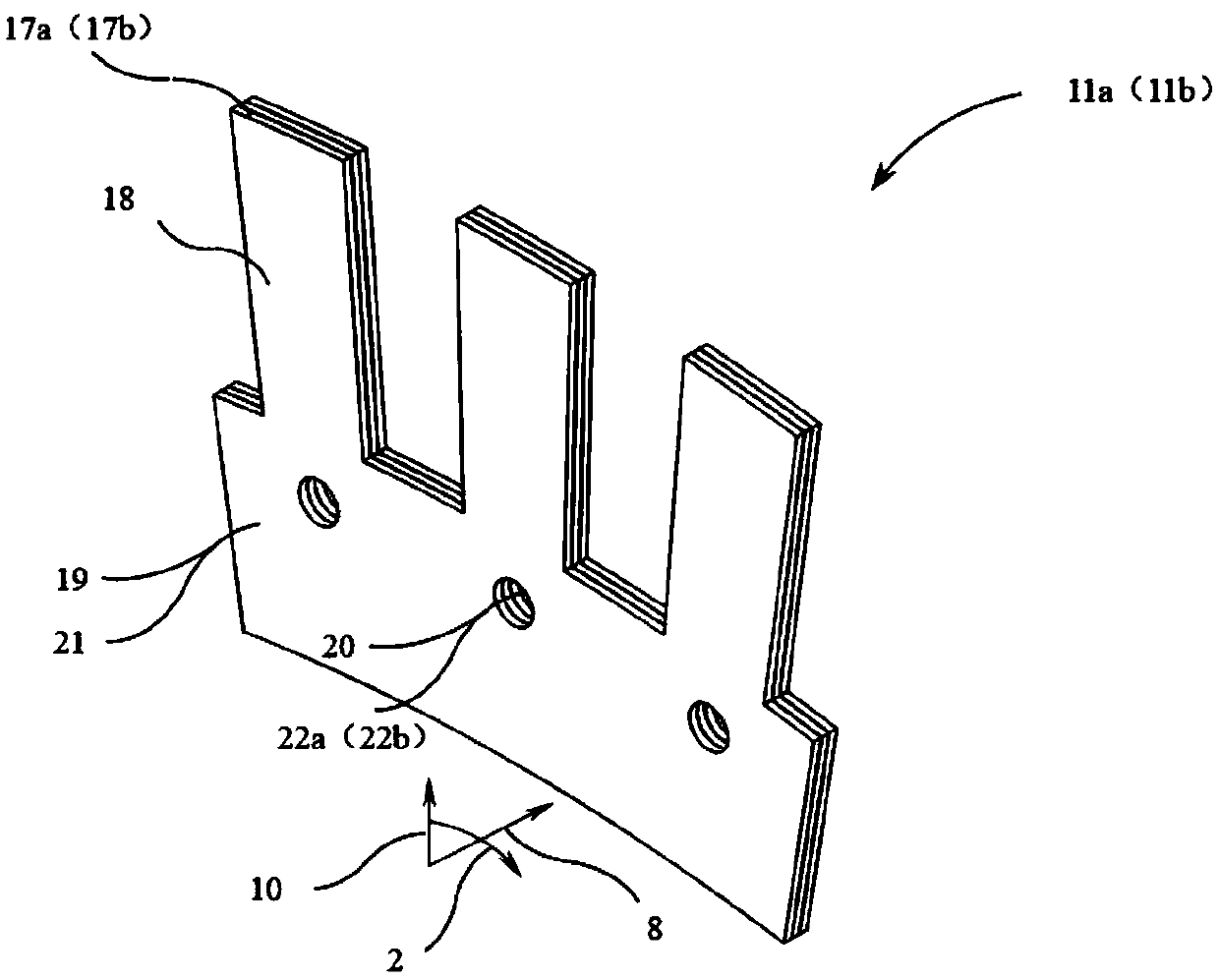

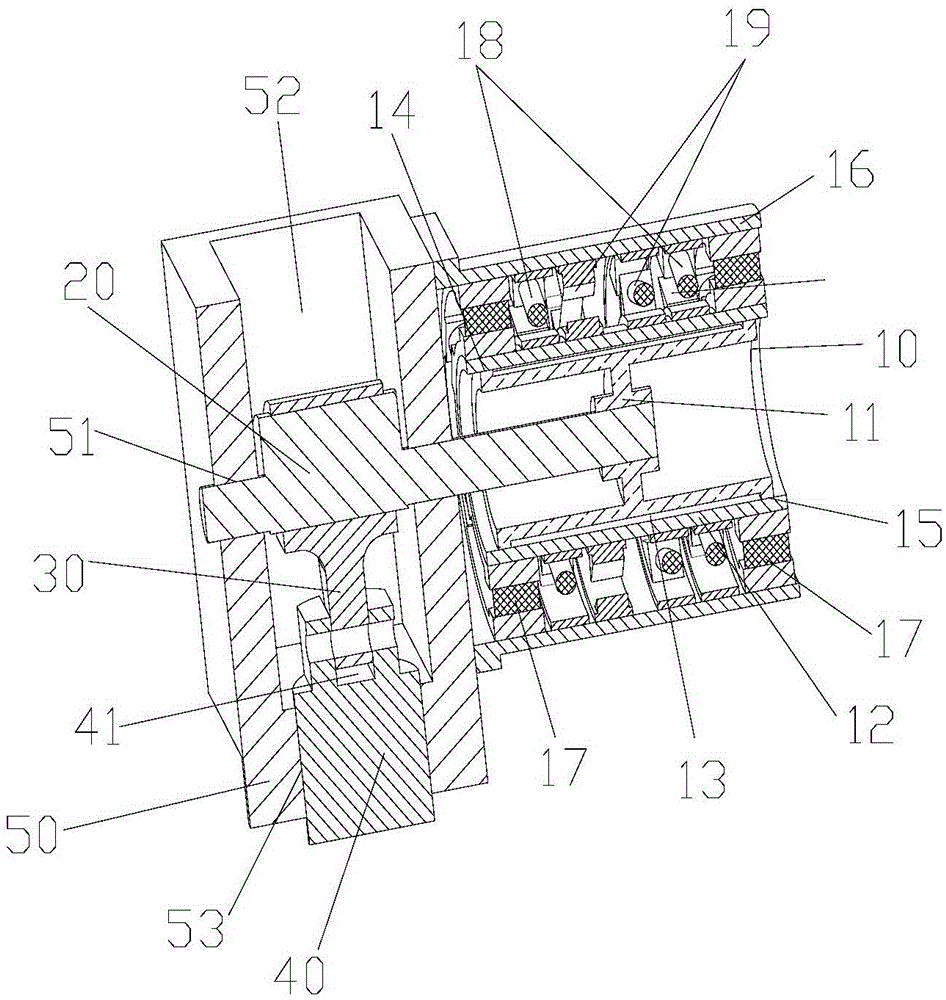

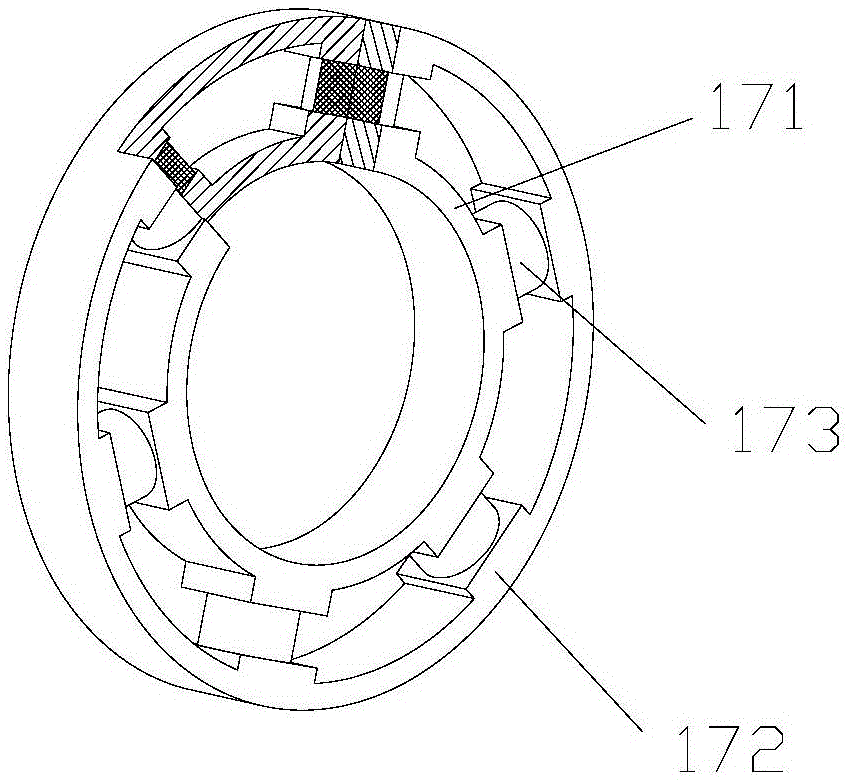

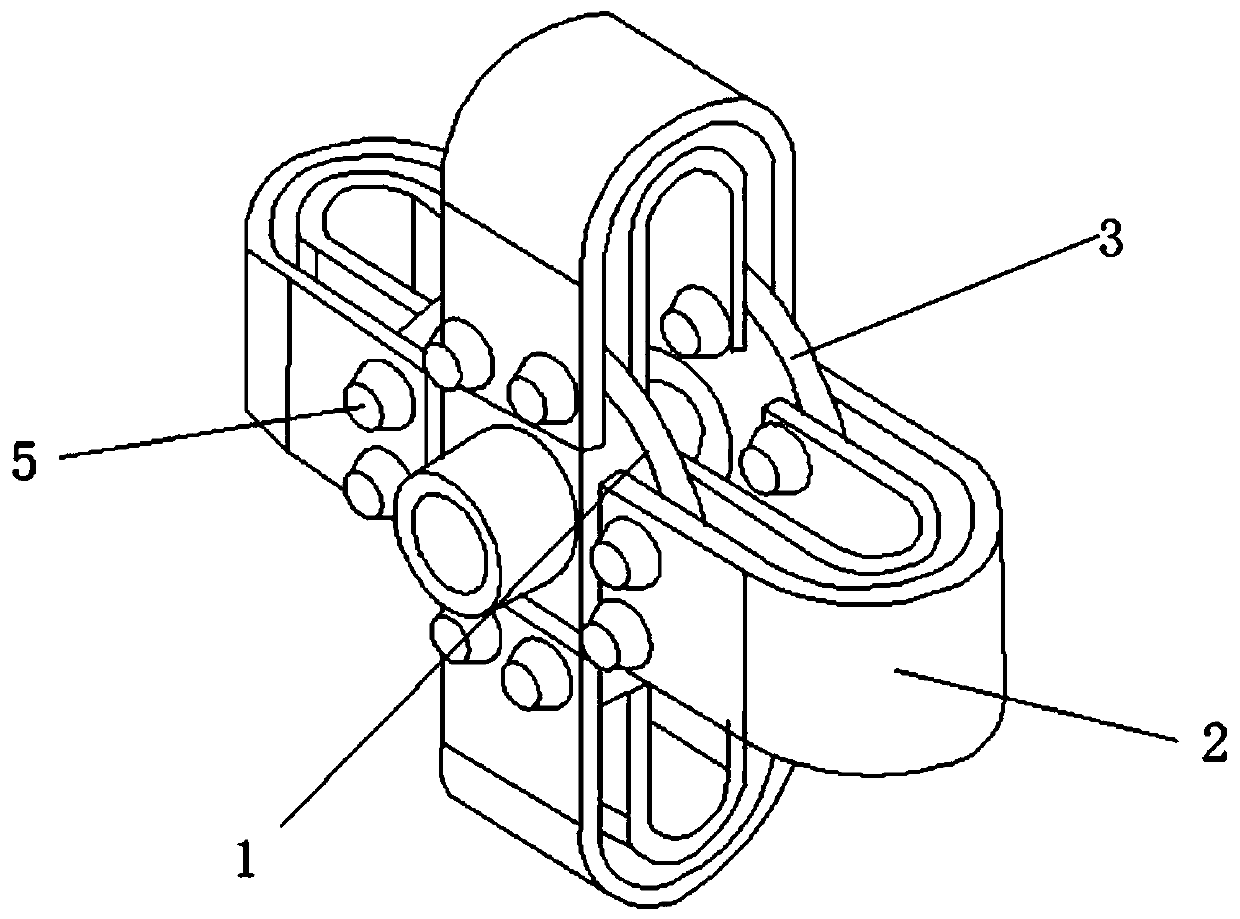

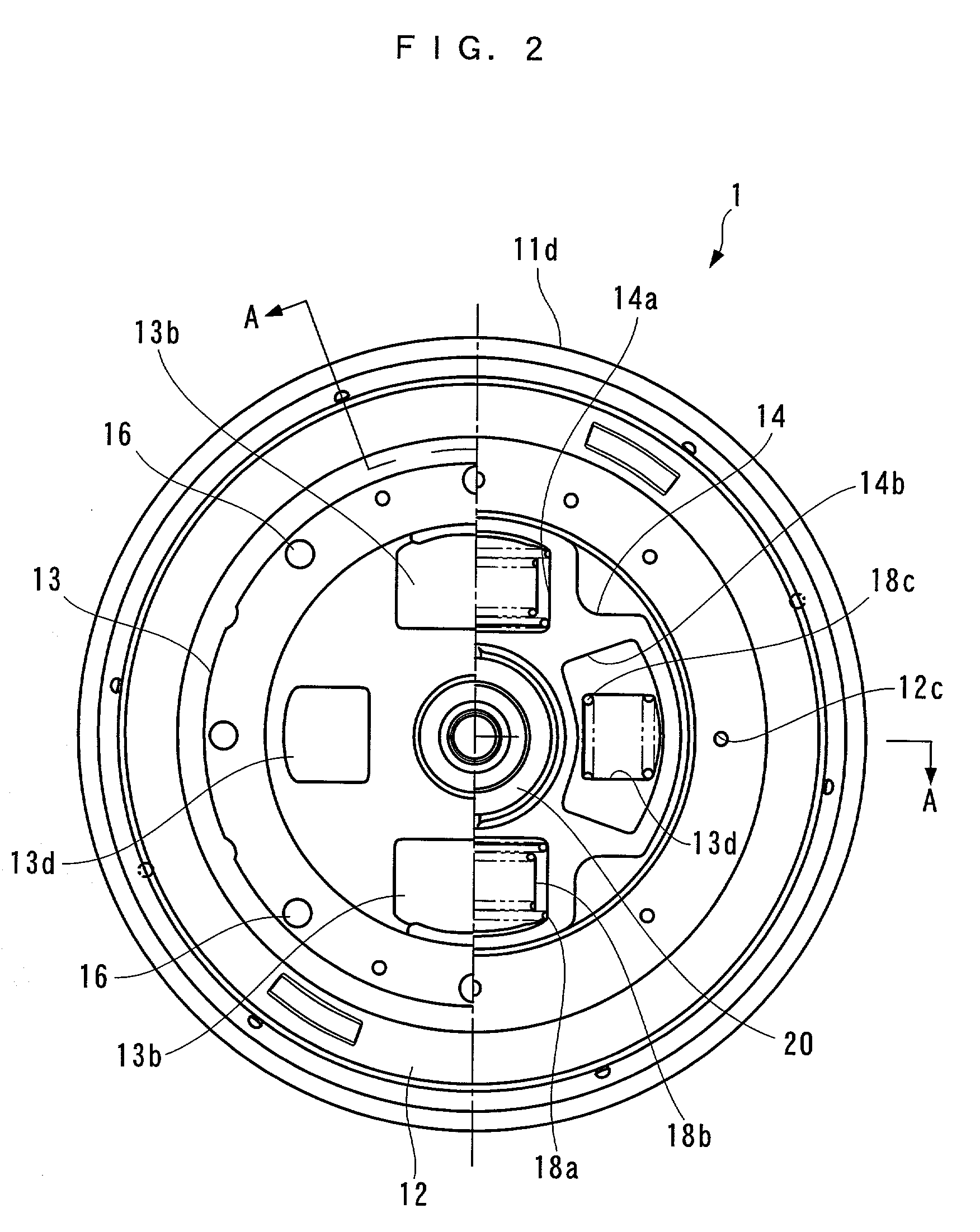

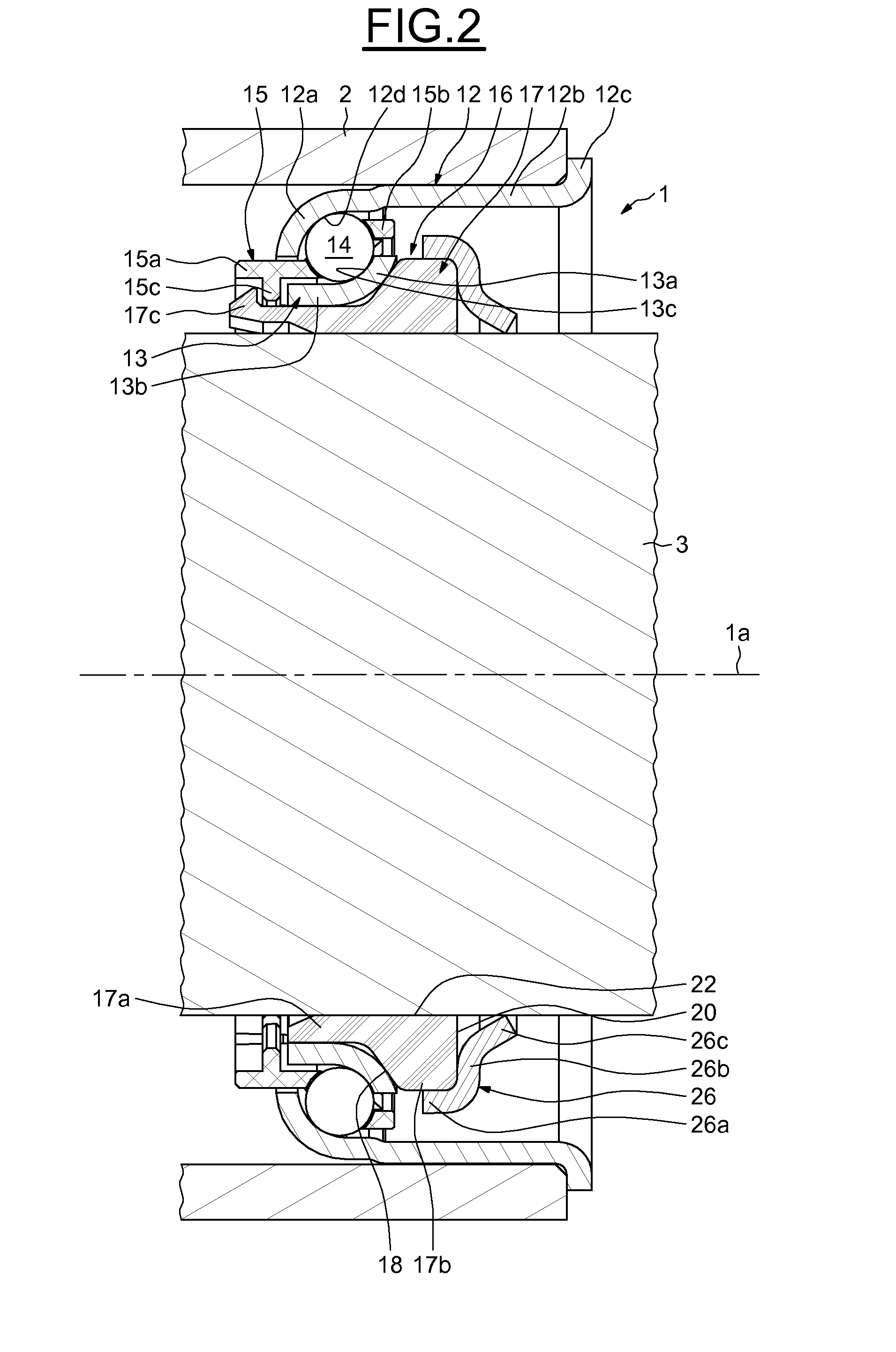

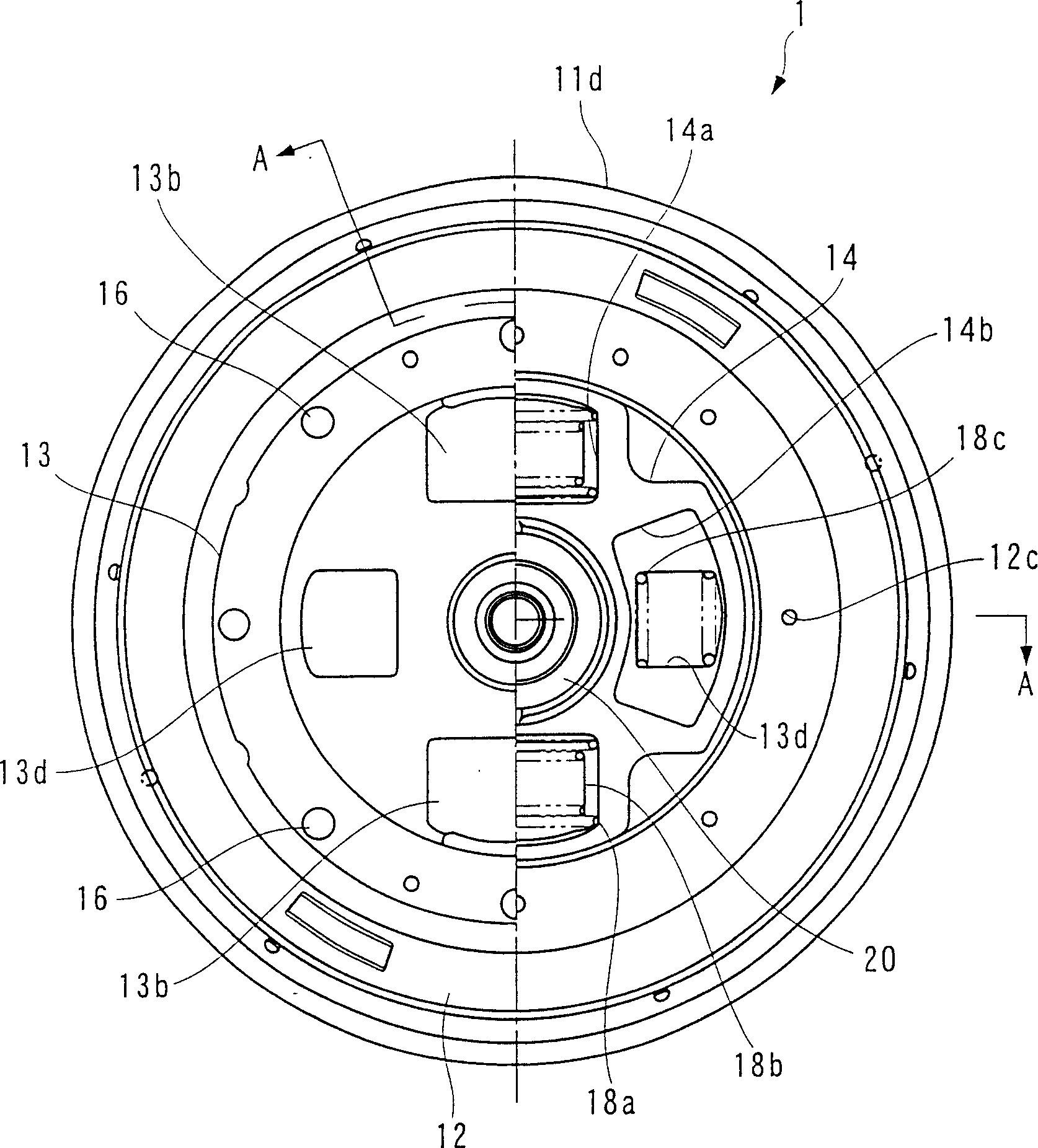

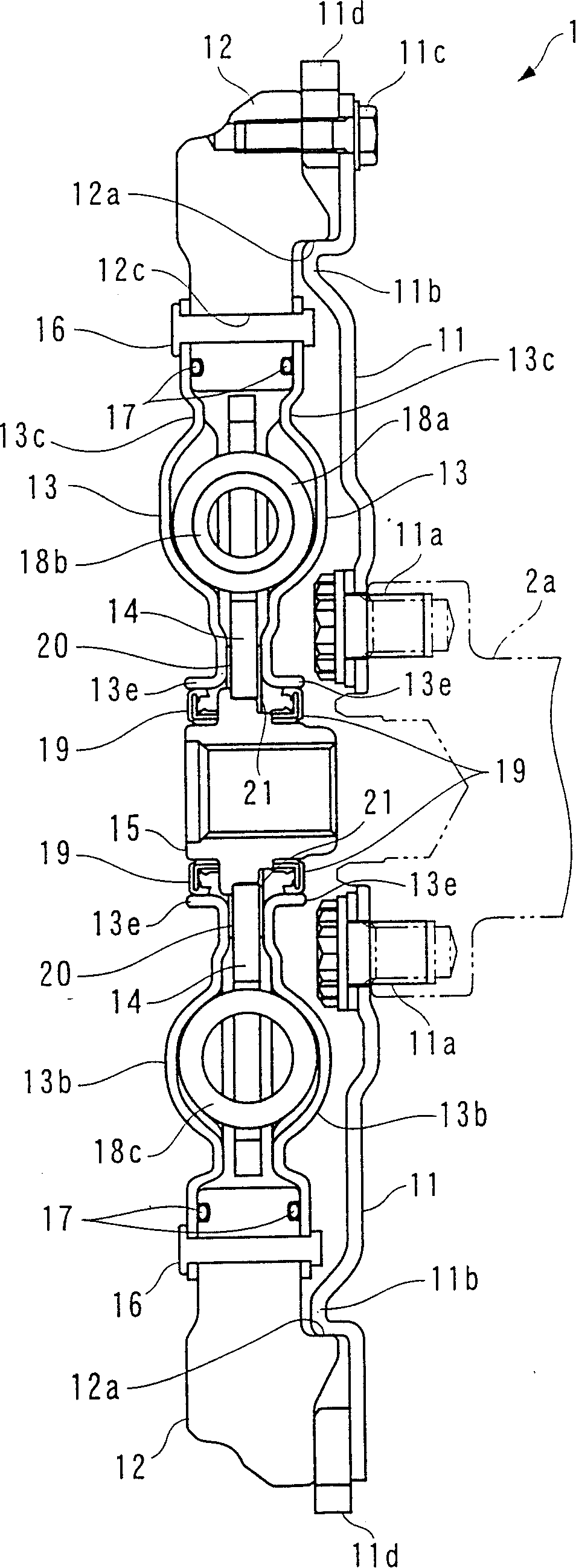

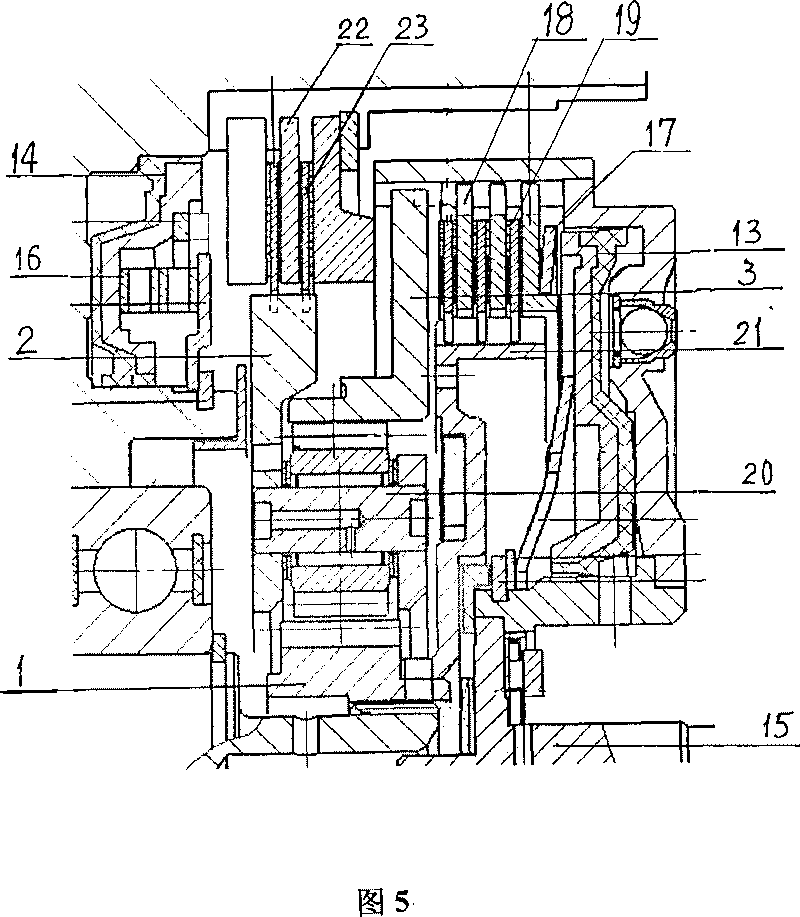

Centrifugal electromagnetic clutch and water pump with centrifugal electromagnetic clutch

ActiveCN103615477AAxial dimensions are compactReduce volumeMagnetically actuated clutchesPump controlElectromagnetic clutchDrive shaft

Provided is a centrifugal electromagnetic clutch. The centrifugal electromagnetic clutch comprises a first rotating body, a second rotating body and a transmission shaft, wherein the second rotating body can rotate along with the first rotating body, power of the second rotating body is transmitted out through the transmission shaft, the second rotating body is arranged inside the first rotating body in a radial mode, and a centrifugal clutch device is axially arranged between the first rotation body and the second rotating body, and is arranged inside the second rotating body in a radial mode. The centrifugal clutch device comprises a plurality of magnetism-conductive centrifugal pieces, an electromagnetic coil, a magnetism-conductive connecting body and a magnetism-conductive supporting body, wherein the magnetism-conductive connecting body is fixed to the inner side of the first rotating body, and is arranged outside the electromagnetic coil in a radial mode, the magnetism-conductive supporting body is installed on the transmission shaft, the first rotating body is fixed to the magnetism-conductive supporting body, the magnetism-conductive centrifugal pieces are distributed along the outer circumference of the electromagnetic coil, one end of each magnetism-conductive centrifugal piece is hinged to the position between the magnetism-conductive connecting body and the magnetism-conductive supporting body, friction plates are arranged on the outer surfaces of the magnetism-conductive centrifugal pieces, wear-resistant layers are arranged on the inner wall face, opposite to the friction plates, of the second rotating body, when the electromagnetic coil is deenergized, the friction plates are attached to the wear-resistant layers of the second rotating body, and when the electromagnetic coil is energized, the friction plates are separated from the wear-resistant layers of the second rotating body.

Owner:LONGKOU ZHONGYU MACHINERY

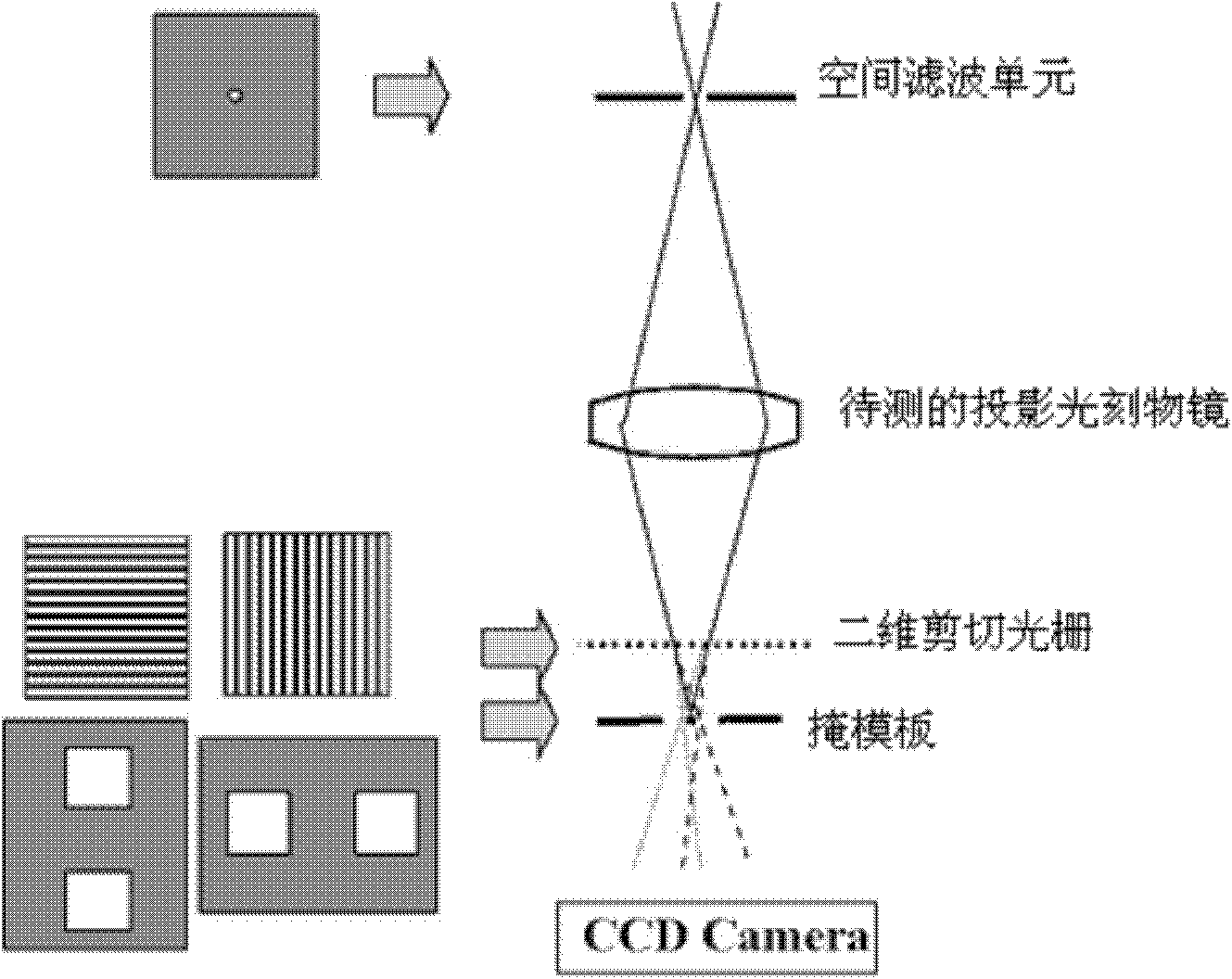

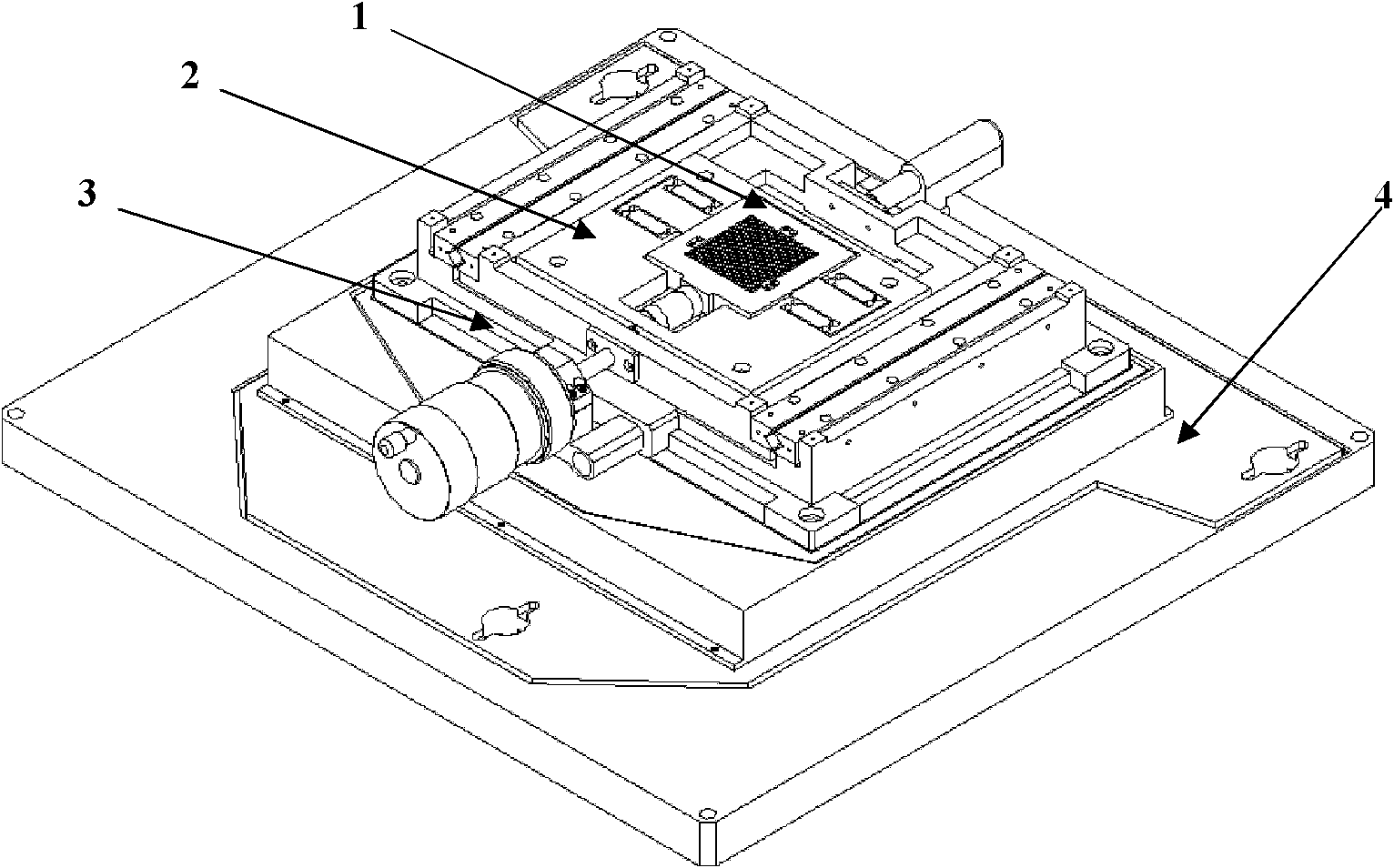

High-precision phase shift device of lateral shear interferometer

InactiveCN102519610AHigh motion resolutionFast dynamic responseOptical measurementsPhase shiftedGrating

The invention relates to a high-precision phase shift device of a lateral shear interferometer, which comprises a shear grating, a mask assembly, a base, a one-dimensional small travel high resolution displacement assembly, a one-dimensional big travel high resolution displacement assembly and a phase shifter leveling assembly. The shear grating is located in and fixed on the one-dimensional small travel high resolution displacement assembly, the mask assembly is fixed at the bottom of the one-dimensional small travel high resolution displacement assembly and keeps to be relative static with the one-dimensional small travel high resolution displacement assembly fixed on the one-dimensional big travel high resolution displacement assembly which is fixed on the base, and the phase shifter leveling assembly is connected with the bottom of the base. The high-precision phase shift device has the advantages of being ultrahigh in movement resolution, big in movement travel, high in dynamic response, capable of conducting high-precision fine tuning position in a relative large travel range, and compact in axial size simultaneously.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

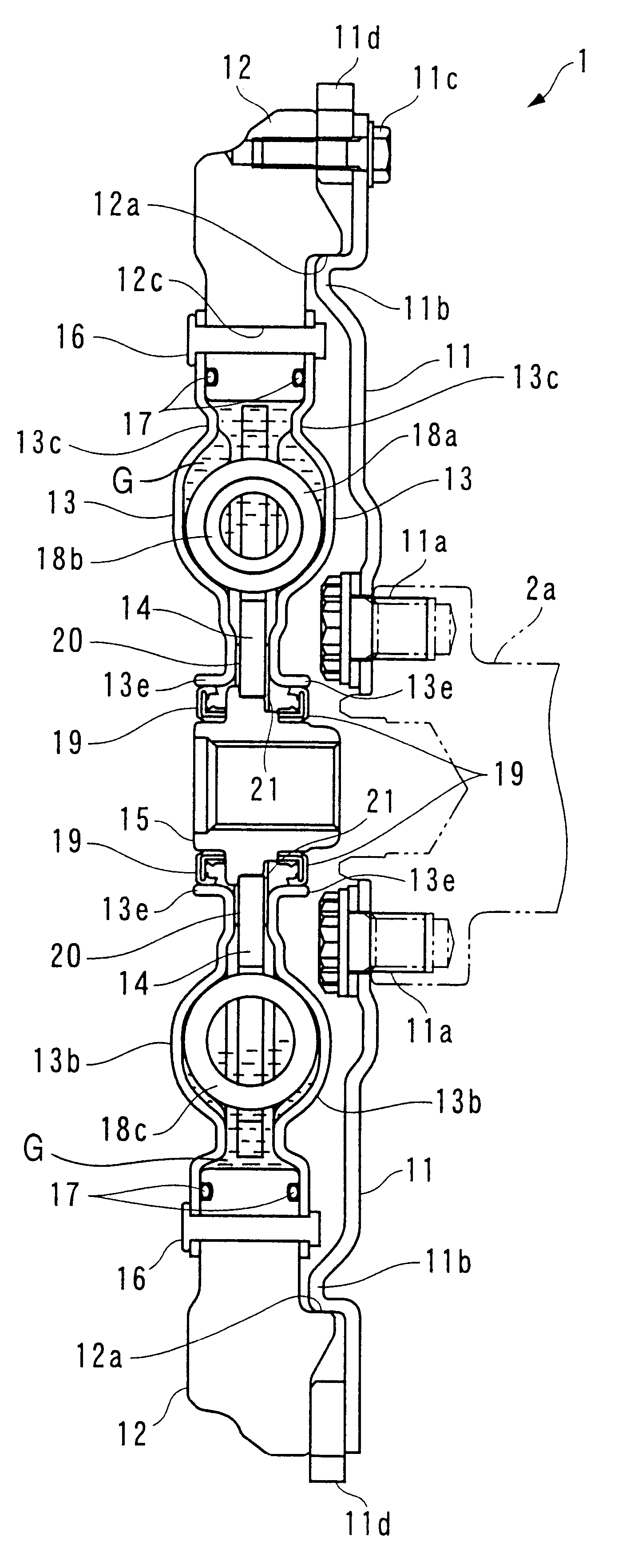

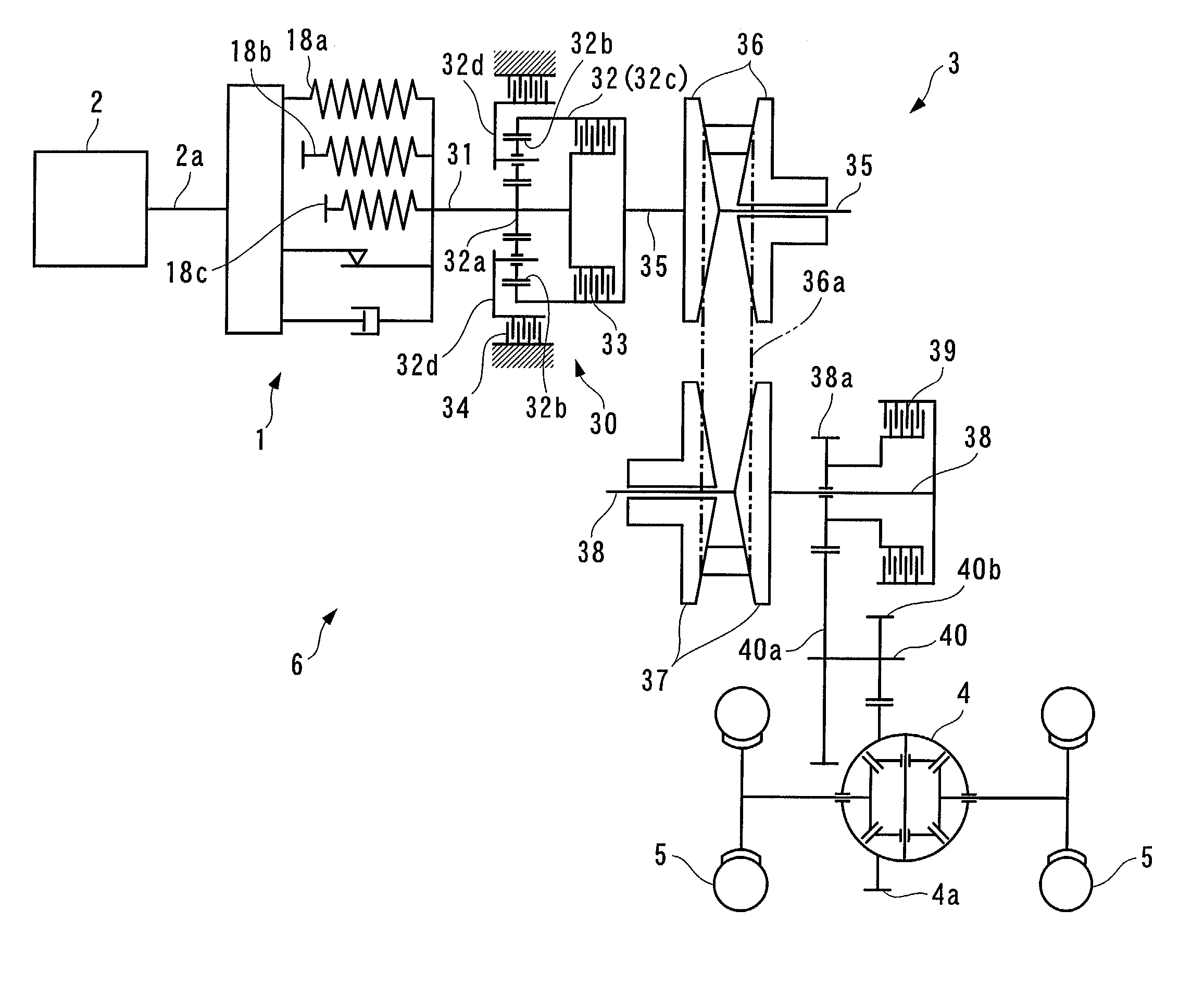

Flywheel device for prime mover

InactiveUS6763743B2Reduce variationQuality improvementControlling membersRotating vibration suppressionInertial massAutomatic transmission

A flywheel device for a prime mover can be made compact in axial size and has an effectively increased inertial mass. The flywheel device includes a drive plate and a mass ring. The drive plate has an annular projection and is attached to a crankshaft concentric with the crankshaft. The mass ring has an annular recess and is concentrically attached to the drive plate by the annular recess being fitted on the annular projection of the drive plate. The flywheel device transmits torque from an engine as the prime mover to the input shaft of an automatic transmission while reducing variation in the torque.

Owner:HONDA MOTOR CO LTD

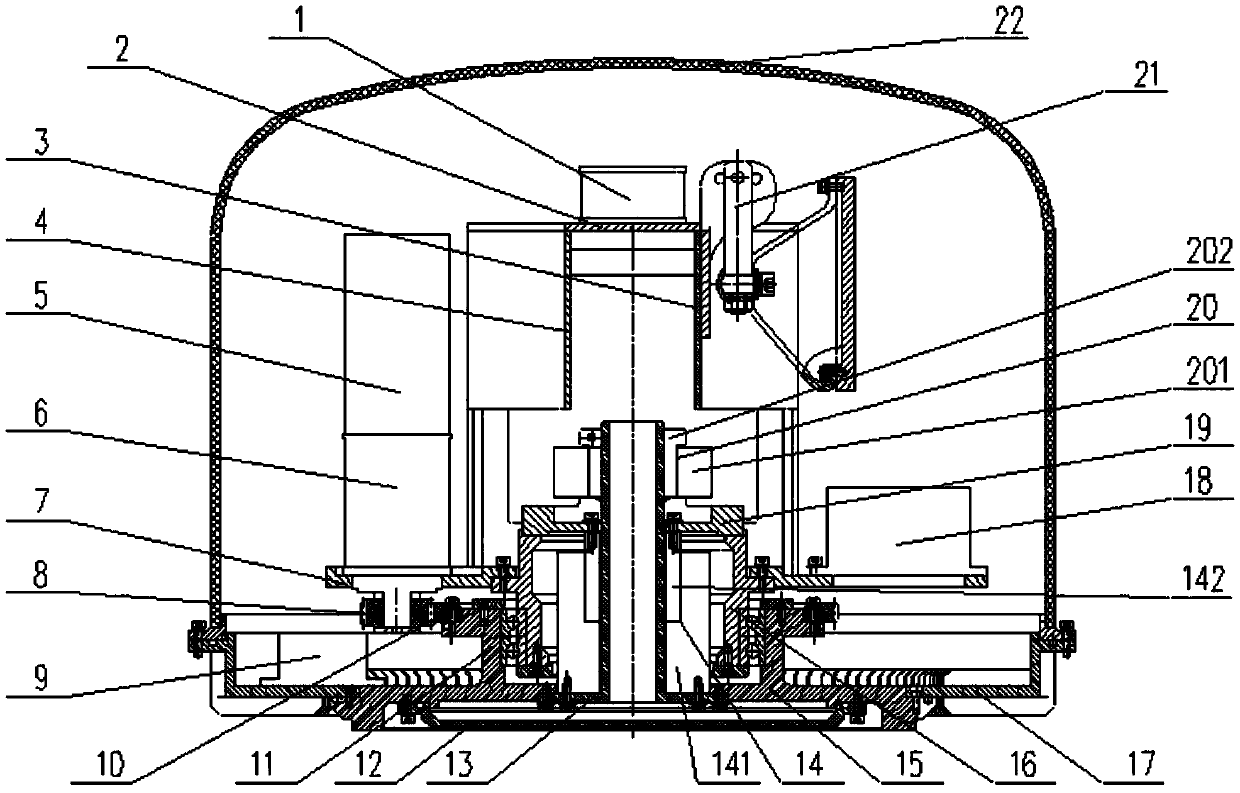

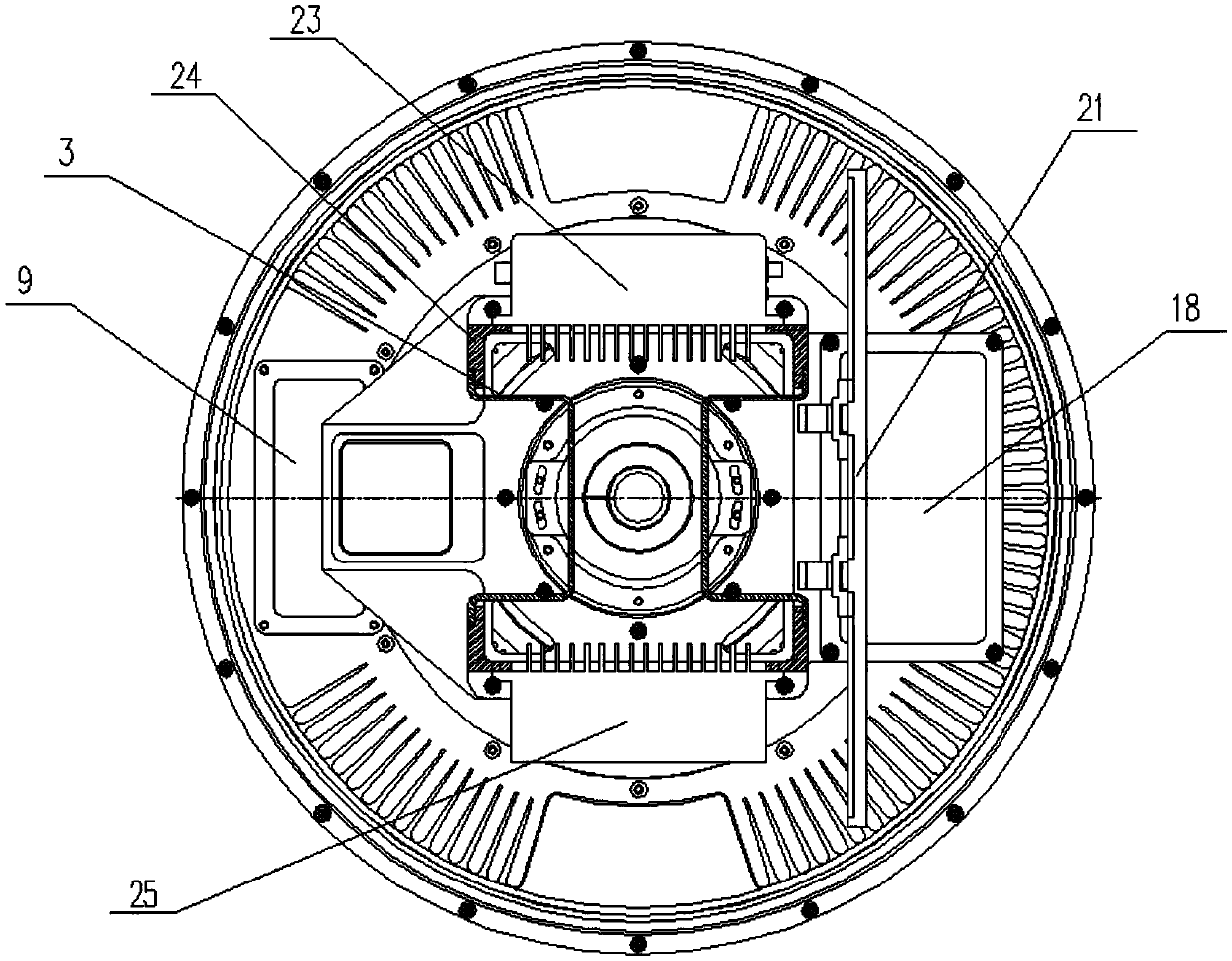

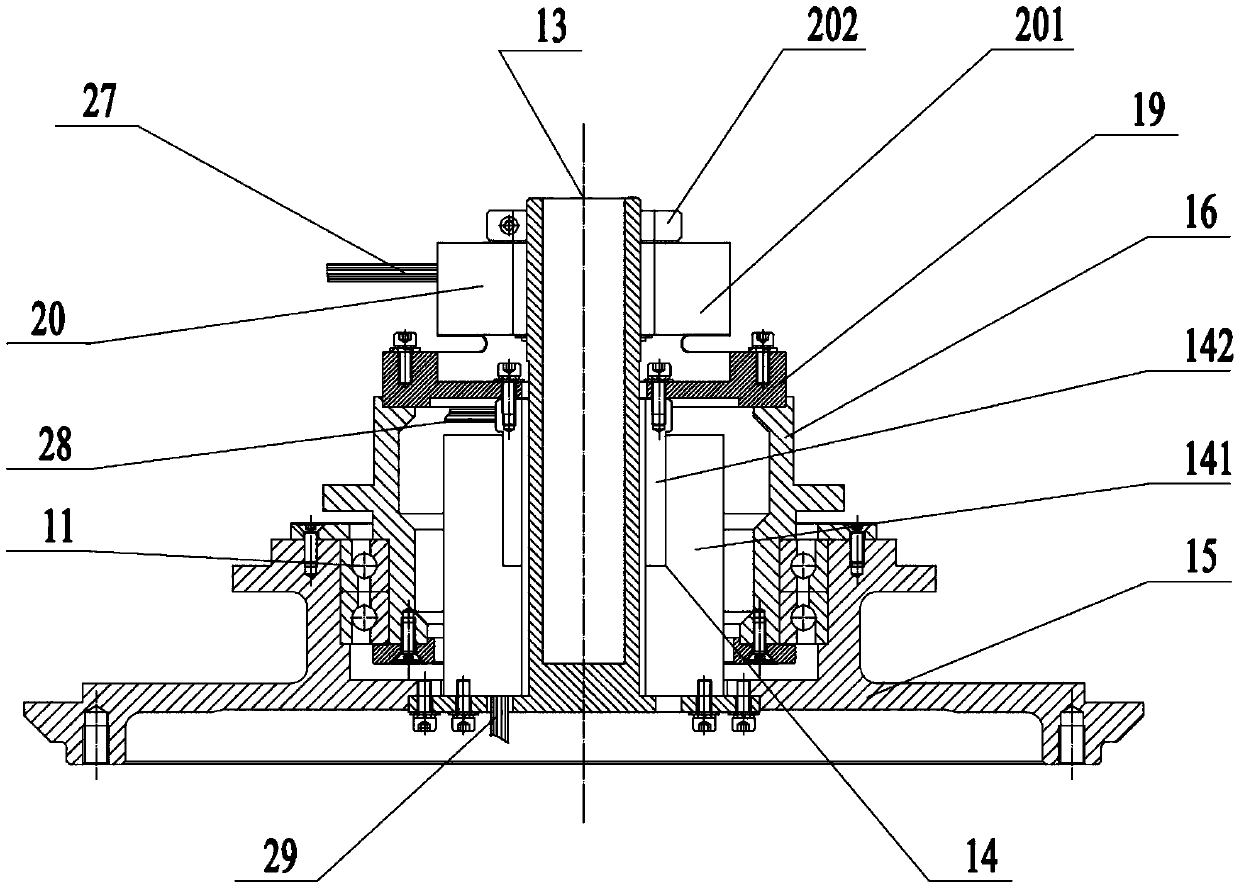

Lightweight fully sealed security surveillance radar structure

The present invention relates to a lightweight fully sealed security surveillance radar structure which comprises a radome, a heat radiation bottom cover, a fixed part, a rotating part, a collector ring and a photoelectric encoder. The collector ring comprises collector ring stator and a collector ring rotor. The photoelectric encoder comprises an encoder stator and an encoder rotor. The lightweight fully sealed security surveillance radar structure has the advantages of good heat radiation performance, strong environmental adaptability, and a strong cost advantage.

Owner:咸阳赛德橡塑科技有限公司

Hydraulic double moving stretcher oil cylinder

InactiveCN1492154AAppropriate distanceLarge adjustment rangeFluid-pressure actuatorsCylinder blockScrew thread

The present invention belongs to the field of rolling equipment technology. The upper oil cylinder for hydraulic double-moving stretcher has a cylinder with oil holes in upper and lower end and piston in the middle part, and the piston is connected to the piston rod in one end and stretching beyond the lower end of the cylinder and fitted to the cylinder in sealing mode. The present invention has improved piston rod, which is hollow and has counter bore with fixed guide key, inserted central screw with guide slot, external screw thread with locking screw nut, adjusting screw nut on the central screw and limited by the locking screw nut. Loosening the locking screw nut and regulating the adjusting screw makes the central screw move linearly for regulating structure precisely. The upper oil cylinder has relatively great regulation range, compact axial size and small height.

Owner:SUZHOU YUEHAI STRETCHING MACHINERY

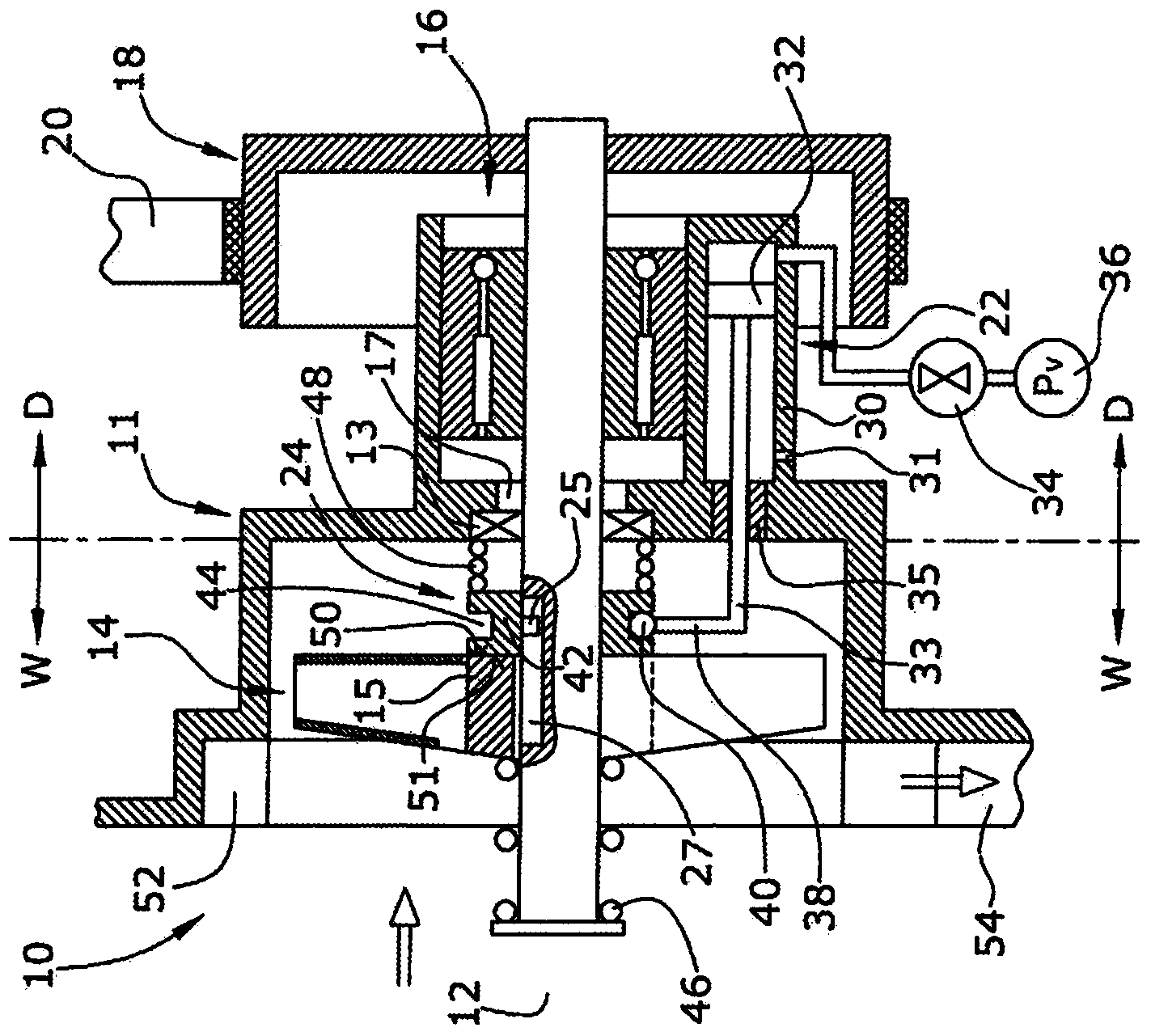

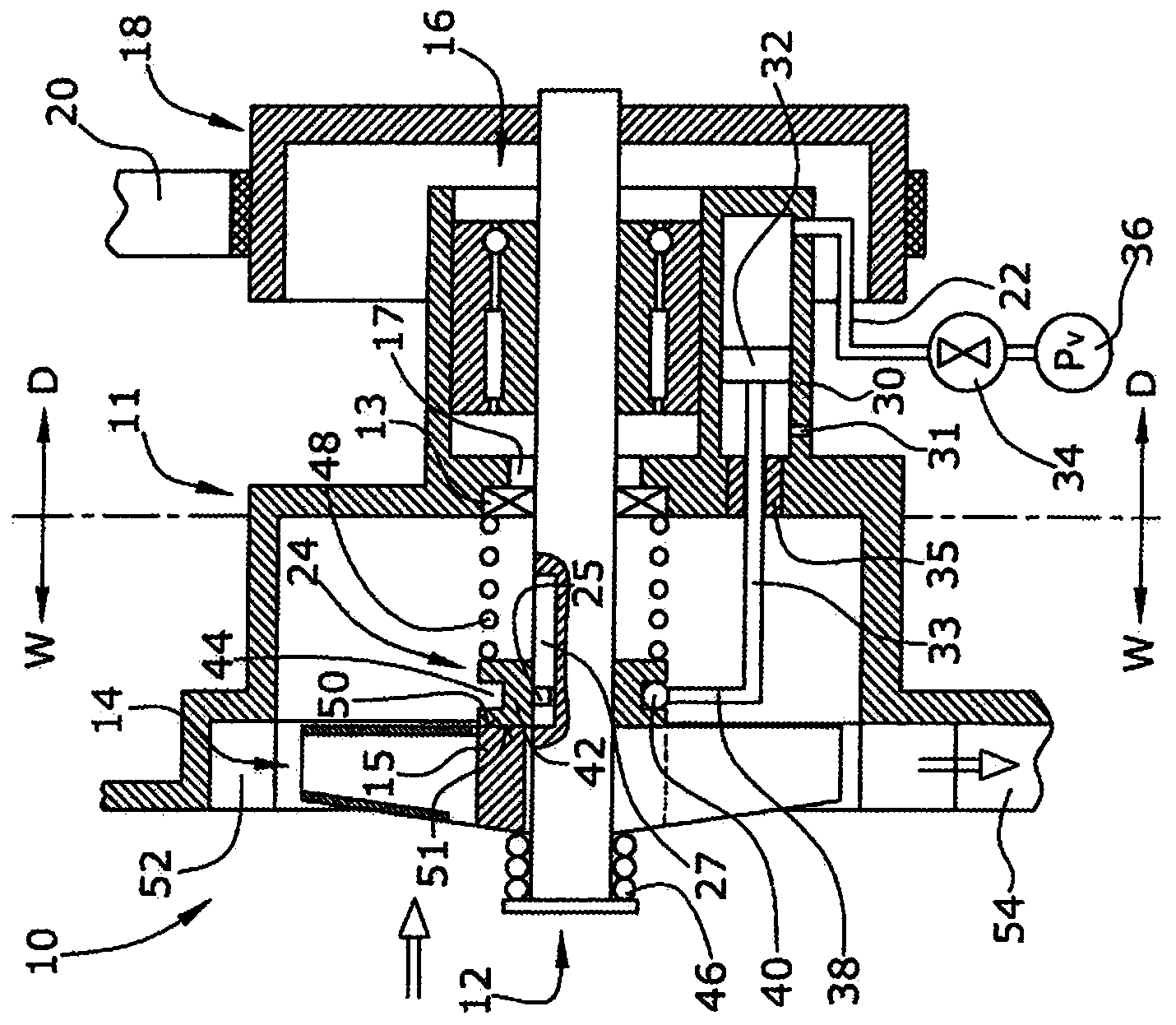

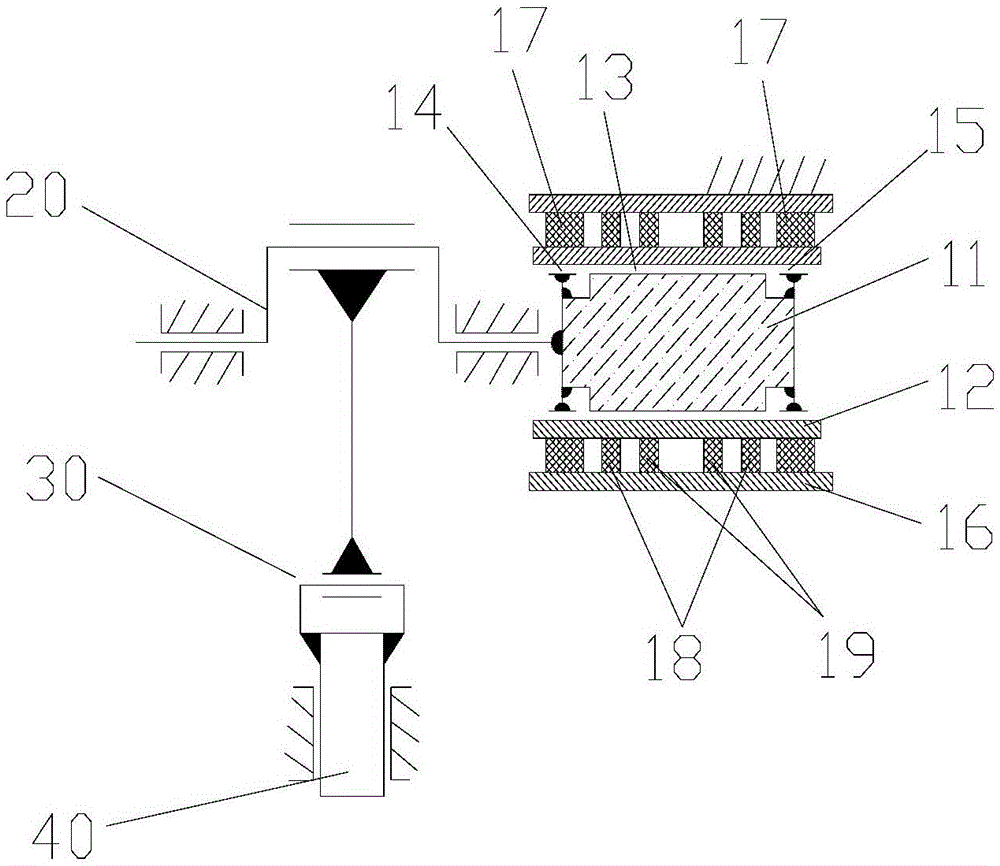

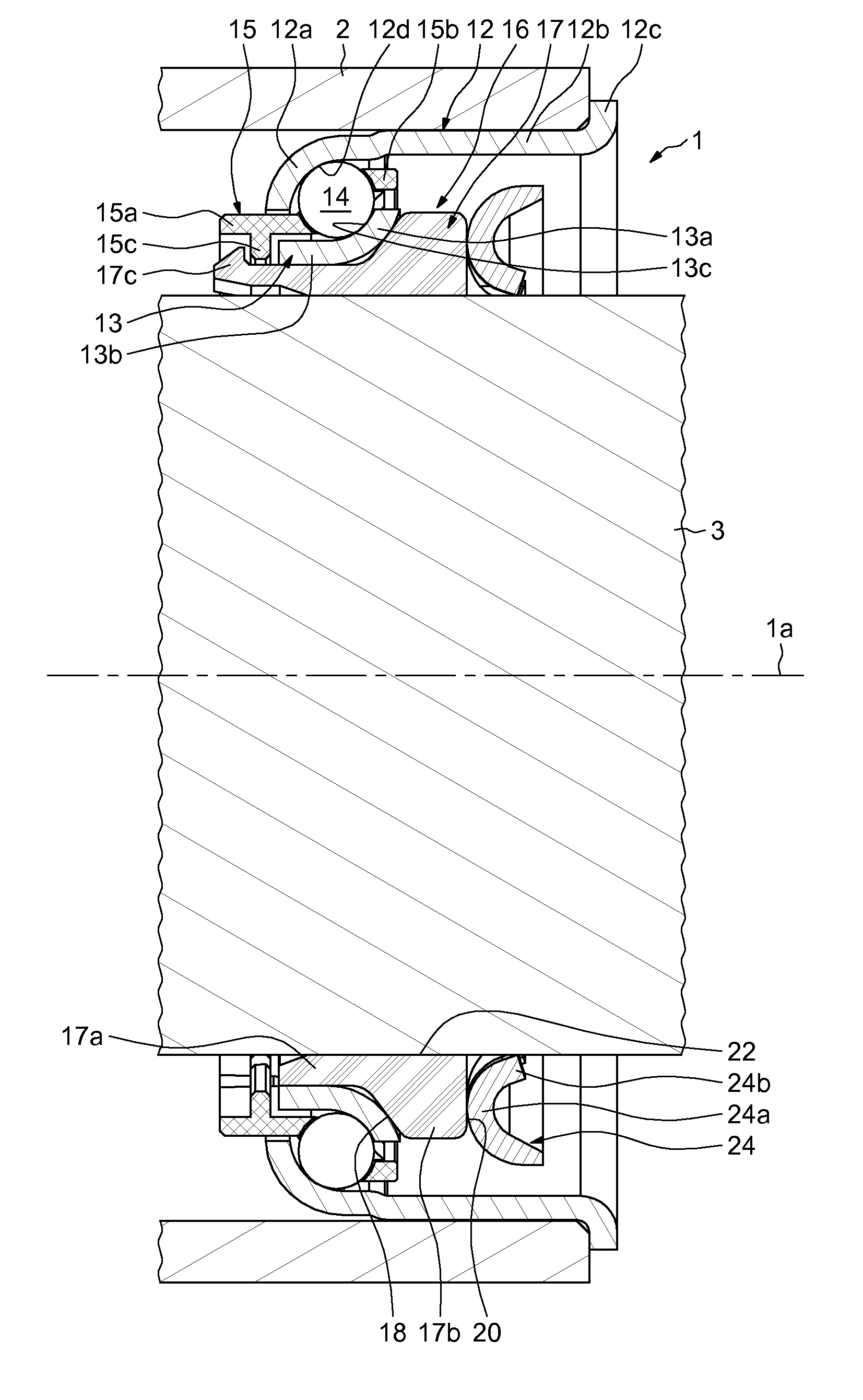

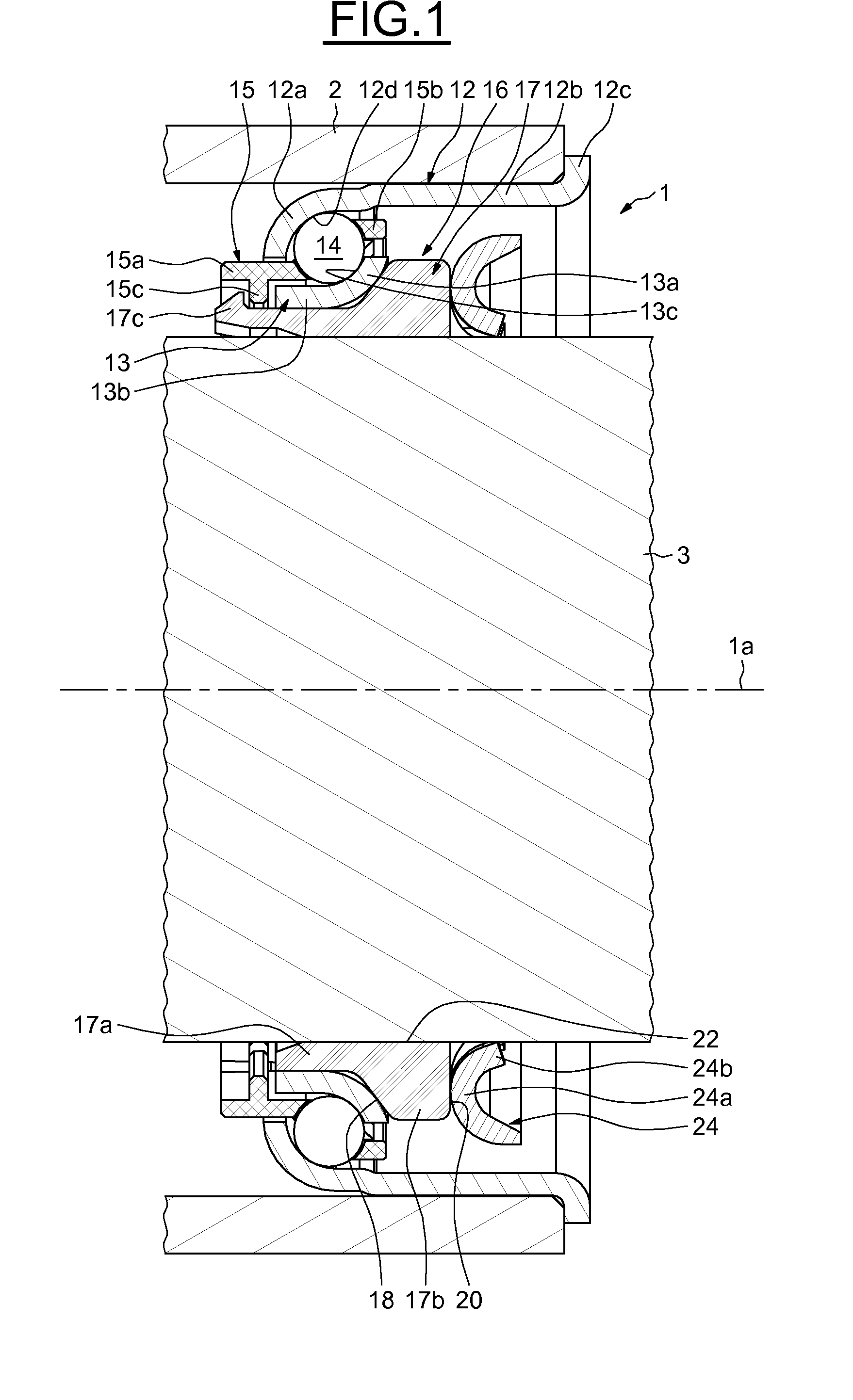

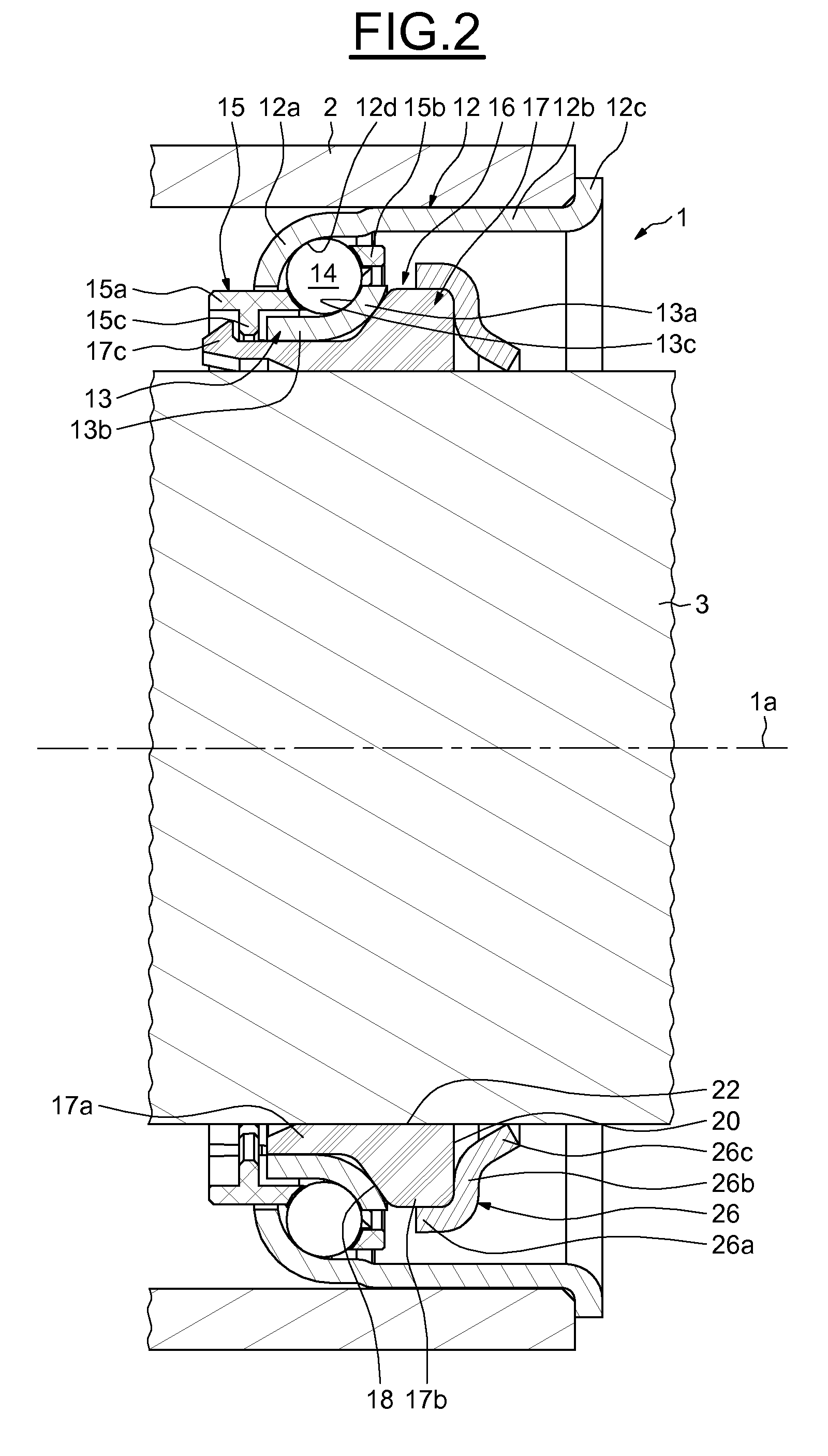

Switchable automotive coolant pump

InactiveCN103764968AReduced pumpabilityAxial dimensions are compactCoolant flow controlPump componentsEngineeringLinear actuator

The invention refers to a switchable automotive coolant pump (10; 10') with a pulley wheel (18) fixedly supported by a rotor shaft (12; 12'), a shaft sealing (13) separating the a dry section (D) from a wet section (W) with respect to the rotor shaft (12; 12), a pump wheel (14; 14') which is supported in the wet section (W) by the rotor shaft (12; 12') and which is arranged axially slidable between a pumping position and a non-pumping position, a linear actuator rod (33) being arranged in parallel to and eccentrically with respect to the rotor shaft (12; 12'), a rod sealing (35) separating the wet section and the dry section of the actuator rod (33), the actuator rod (33) being actuated by an actuator (22) arranged in the dry pump section (D), and a shift ring (24; 24') being arranged axially shiftable and rotatably fixed at the rotor shaft (12; 12') in the wet pump section (W), whereby the shift ring (24; 24') is axially moved by the actuator rod (33) and is axially moving the pump wheel (14).

Owner:PIERBURG PUMP TECH

High-frequency high-power microwave device

ActiveCN110718426AAffect outputHigh energyTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses a high-frequency high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. An electron beam transmission channel with an inner diameter of 8mm and an outer diameter of 14.6mm is formed between the inner conductor and the circular waveguide sleeve. A high-frequency structure is sequentially provided with a reflection region, a beam current pre-modulation region, a phase modulation region and a beam wave conversion region which are coaxial in the electron beam transmission direction. An annular collector protruding inwards in the radial direction is arranged behind the beam wave conversion region. An annular electron beam with the inner diameter of 12mm, the outer diameter of 12.6mm, thevoltage of 400kV and the beam intensity of 7.3kA is transmitted in the high-frequency structure under the guidance of an axial magnetic field with the magnetic field intensity of 1.5T, and high-frequency high-power microwaves with the frequency of 67.4GHz are generated. The high-frequency high-power microwave device is simple in structural size, and has the advantages of being small, light and easy to assemble.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

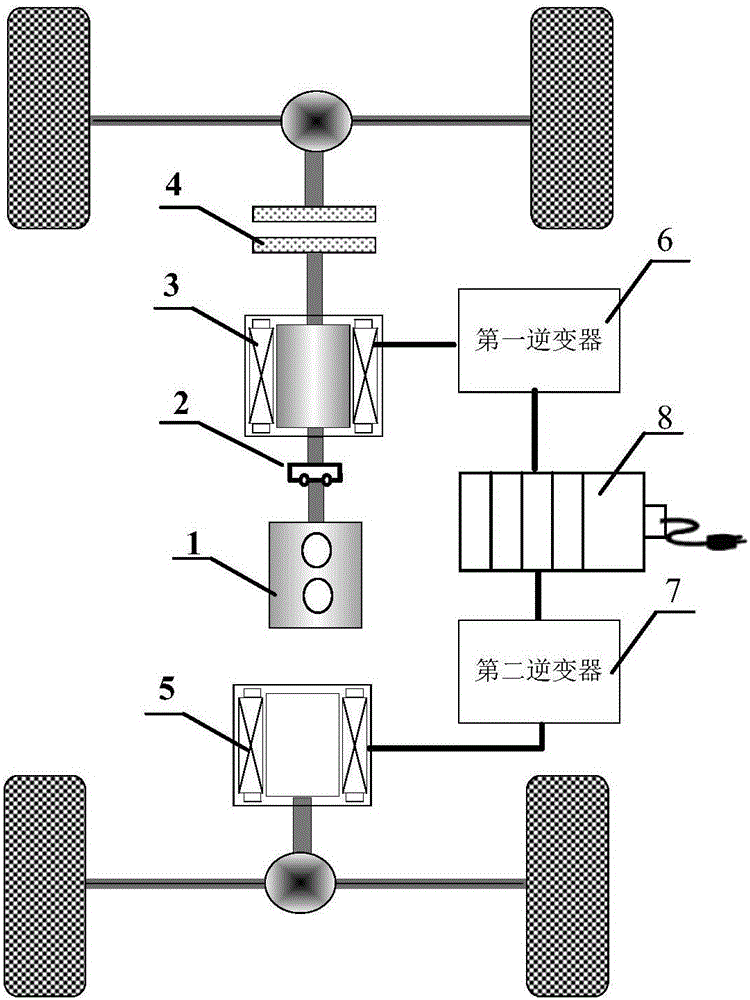

Power system of four-wheel-drive electric vehicle and control method

ActiveCN106004413ALow costSave layout spaceHybrid vehiclesGas pressure propulsion mountingPower batteryElectrical battery

The invention discloses a power system of a four-wheel-drive electric vehicle. The power system comprises an engine, a shock absorber, a first motor, a clutch, a second motor, a first inverter, a second inverter and a power battery, wherein the engine is connected with the shock absorber, and the shock absorber is connected with the first motor which is connected with the clutch; the power battery is connected with a first motor circuit through the first inverter and is connected with a second motor circuit through the second inverter. A transmission is omitted for the power system of the four-wheel-drive electric vehicle, a drive system is simplified greatly, compartment arrangement space is saved, the number of parts is reduced, and the cost of the power system of the four-wheel-drive electric vehicle is reduced; four-wheel drive is realized through a bridge, driving torque of a front axle and a rear axle of the vehicle can be distributed reasonably according to the ground adhesive force and vehicle demanded torque, and the power performance of the whole vehicle is guaranteed. The invention further discloses a control method of the power system of the four-wheel-drive electric vehicle.

Owner:CHINA FIRST AUTOMOBILE

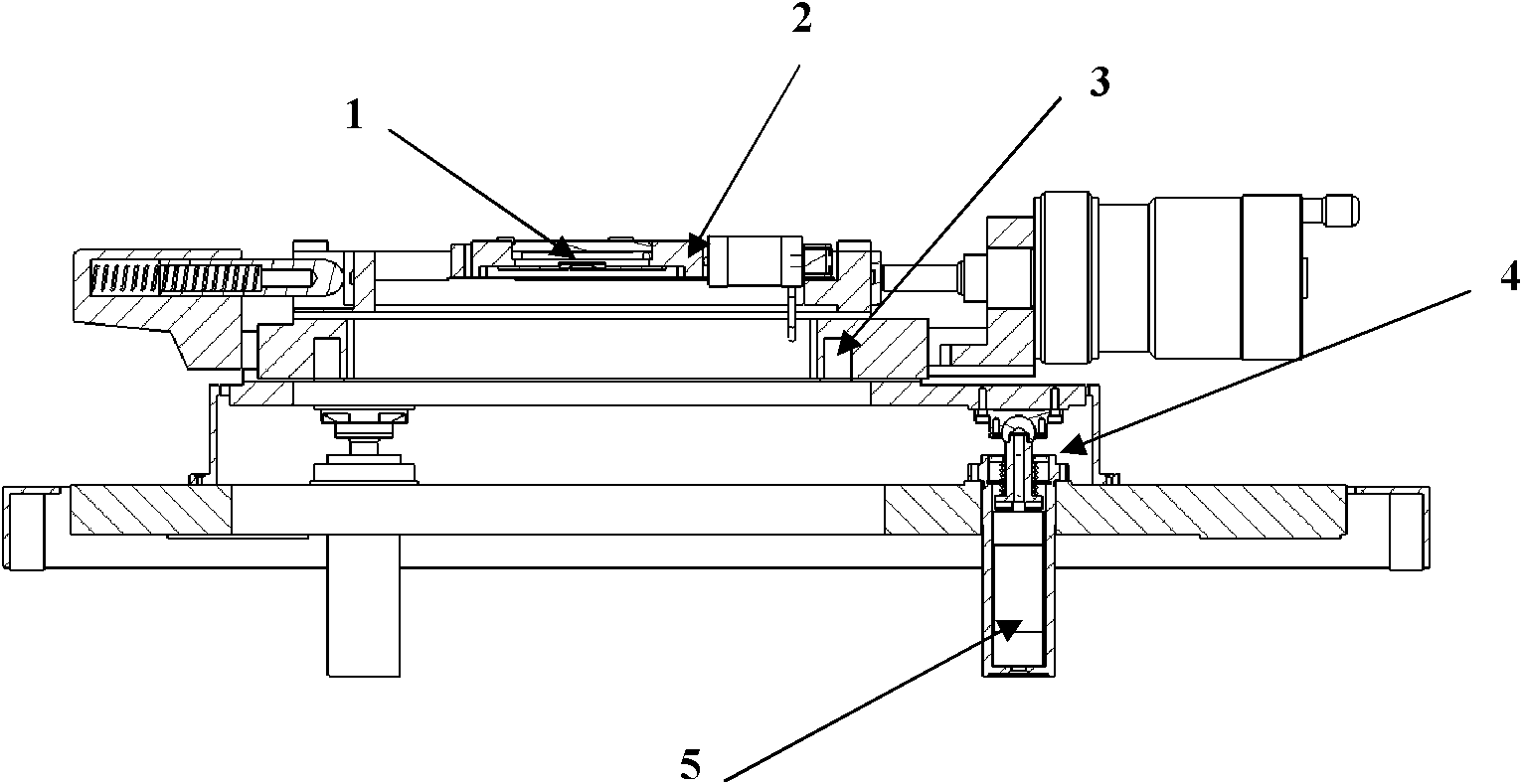

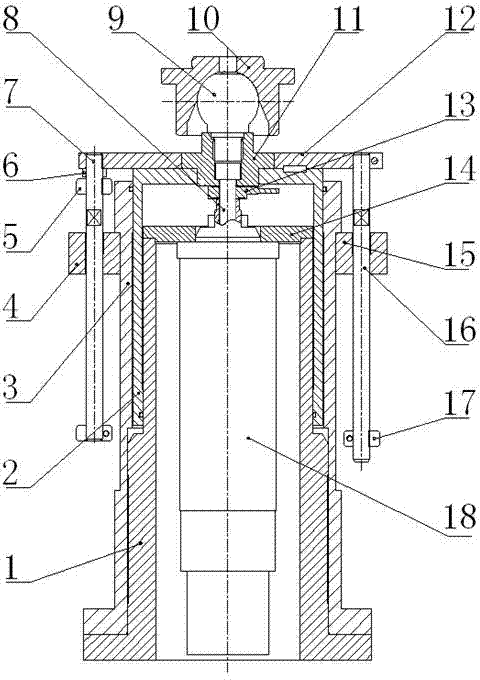

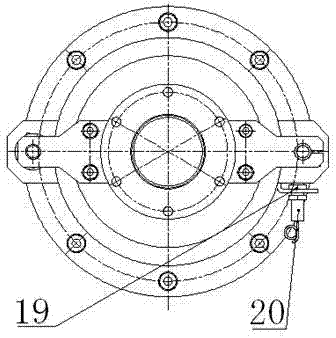

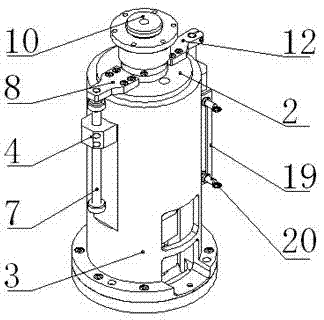

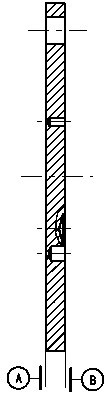

Vertical supporting device driven through servo electric cylinder

ActiveCN104723134APrecise positioningGood orientationPositioning apparatusMetal-working holdersClassical mechanicsCylinder block

The invention relates to a vertical supporting device driven through a servo electric cylinder. The vertical supporting device driven through the servo electric cylinder is mainly composed of an inner guiding base (1), an outer guiding base (3), a sliding sleeve (2), the servo electric cylinder (18) and an anti-rotation device, wherein the sliding sleeve (2) is arranged between the inner guiding base (1) and the outer guiding base (3), the cylinder body of the servo electric cylinder (18) is arranged in the inner guiding base (1), and the inner guiding base (1), the outer guiding base (3), the sliding sleeve (2) and the servo electric cylinder (18) are arranged in a stacked and overlapped mode; a cylinder rod (8) is further connected with a force measuring sensor (13) and the anti-rotation device in series, and the anti-rotation device is provided with travel dead stop iron (5), a travel adjusting nut (6), switch stop iron (17) and an approach switch (20); the rod end of the cylinder rod (8) is provided with a bulb (9) and a bulb socket base (10) capable of installing a machined workpiece. The vertical supporting device has the advantages that the axial size is small, supporting rigidity is good, and three protection of servo soft limiting, a travel switch and the mechanical stop iron can be achieved.

Owner:JIANGSU HENGLI MACHINE TOOL

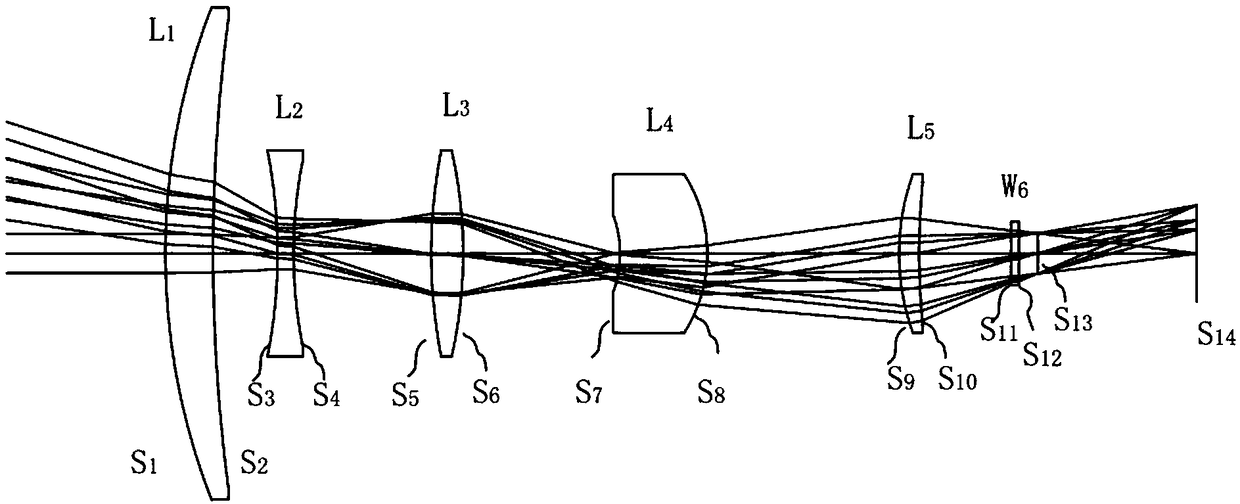

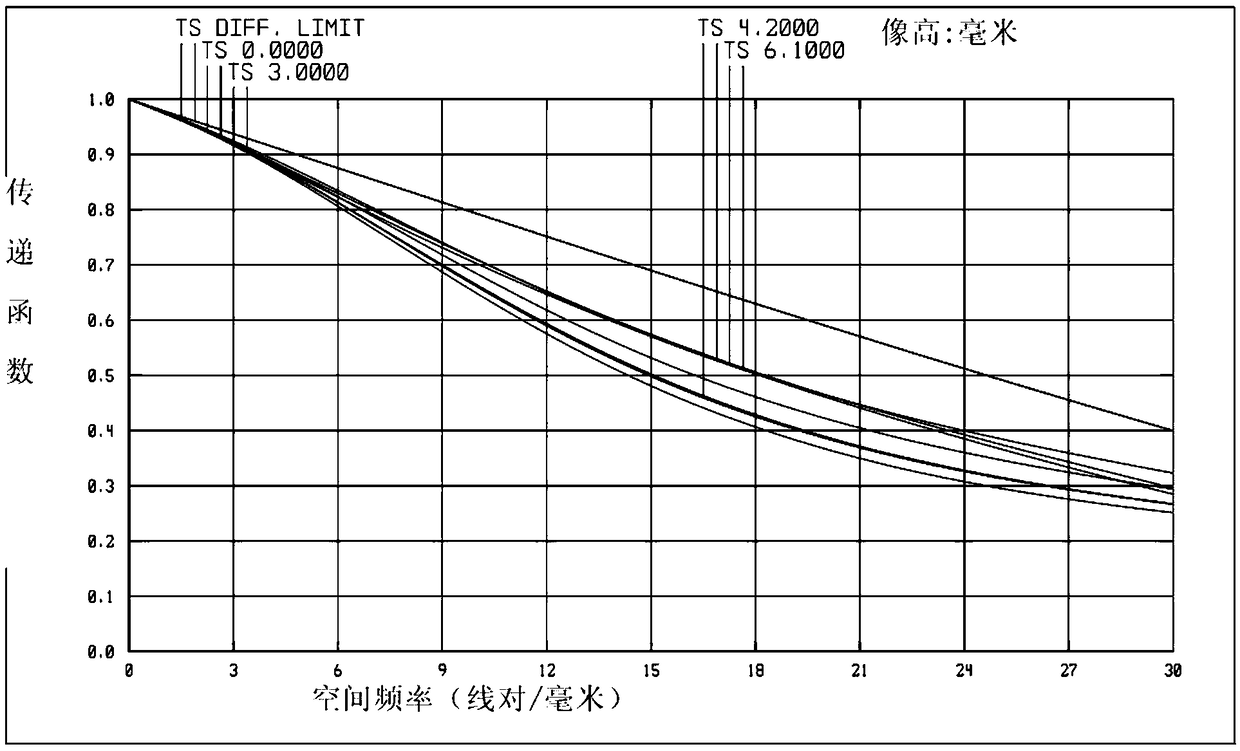

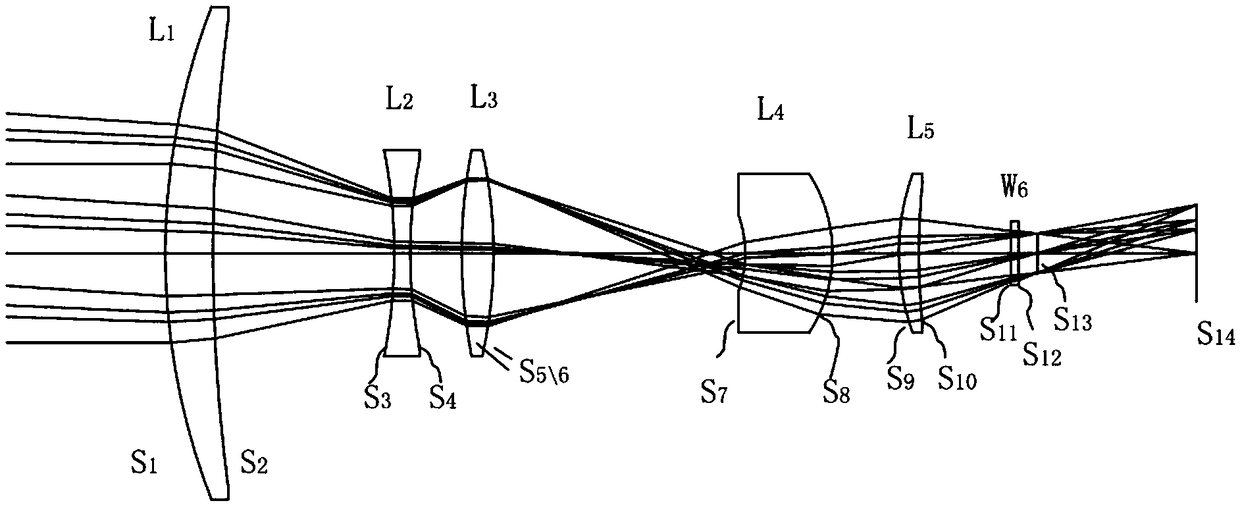

Five-piece compact medium-wave refrigeration continuous zoom lens

The invention discloses a five-piece compact medium-wave refrigeration continuous zoom lens which comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens which are arrangedin order from an object side to a target surface. Three groups of lenses (including the second lens, the third lens and the fourth lens) move in the optical system. Besides a zoom group (the second lens) and a compensation group (the third lens) in the conventional sense, the fourth lens in a secondary imaging group also participates in a zoom process. The optical system is compact in axial dimension, avoids installation and adjustment difficulty caused by using a reflector to change the optical path, has high optical axis precision and optical transmittance, is suitable for 3-5[mu]m medium-wave refrigerating movement, has a focal length range from 20mm to 200mm, and an optical total length not more than 130mm, can be used in applications which require small optical load sizes and light weight, such as UAVs, pods, forest fire monitoring and the like.

Owner:NANJING WAVELENGTH OPTO ELECTRONICS SCI & TECH CO LTD +1

L-band three-cavity high-power microwave device

ActiveCN110718431ASimple structureAxial dimensions are compactTransit-tube circuit elementsTransit-tube coupling devicesResonant cavityElectrical conductor

The invention discloses an L-band three-cavity high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. A cathode coaxial with the circular waveguide sleeve is arranged at one end in the circular waveguide sleeve. The opening of the cathode is annular, the inner diameter of the cathode is 60mm, and the outer diameter of the cathode is 69mm. The circular waveguide sleeve is sequentially provided with a reflection cavity, a resonant cavity and an extraction cavity with the same inner diameter in the electron beamtransmission direction, and the reflection cavity, the resonant cavity and the extraction cavity are annular grooves formed in the circular waveguide sleeve. The axial length of the microwave device is 130mm, the maximum diameter of the microwave device is 150mm, and the diameter of the inner conductor is 40mm. The cathode emits an annular electron beam with the beam intensity of 7.0kA, the innerdiameter of 60mm and the outer diameter of 69mm under a 400KV voltage, the annular electron beam is transmitted in the microwave device under the guidance of a 0.4T axial magnetic field, and L-band high-power microwaves with the frequency of 1.92GHz are generated through radiation within one pulse time. The L-band three-cavity high-power microwave device has the advantages of being small in size,light and easy to adjust.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

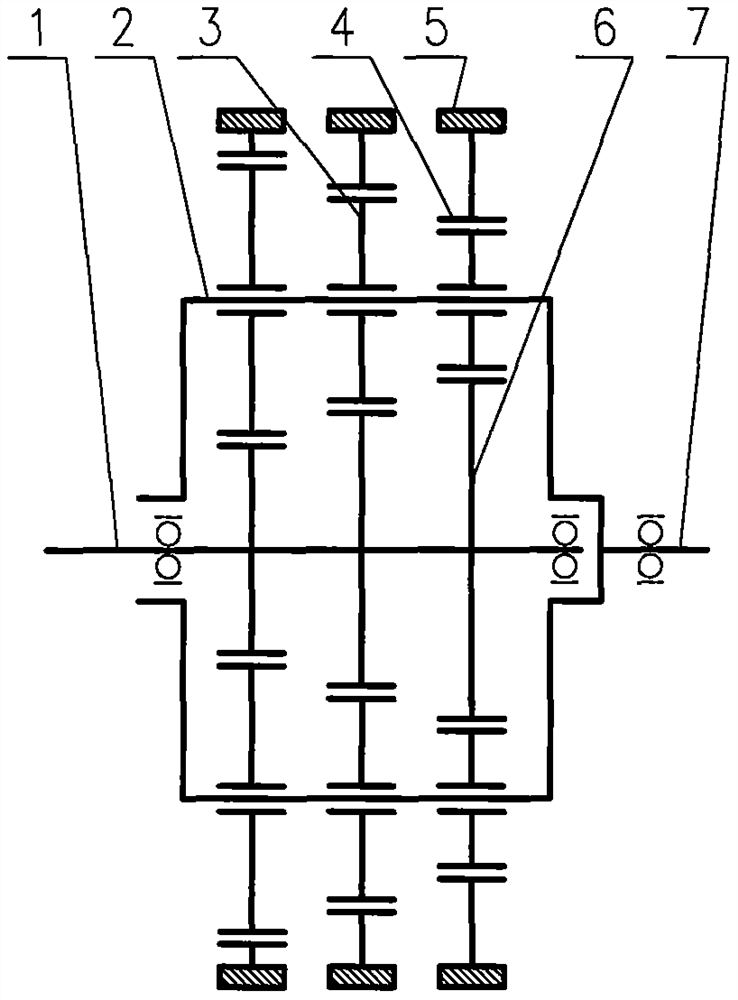

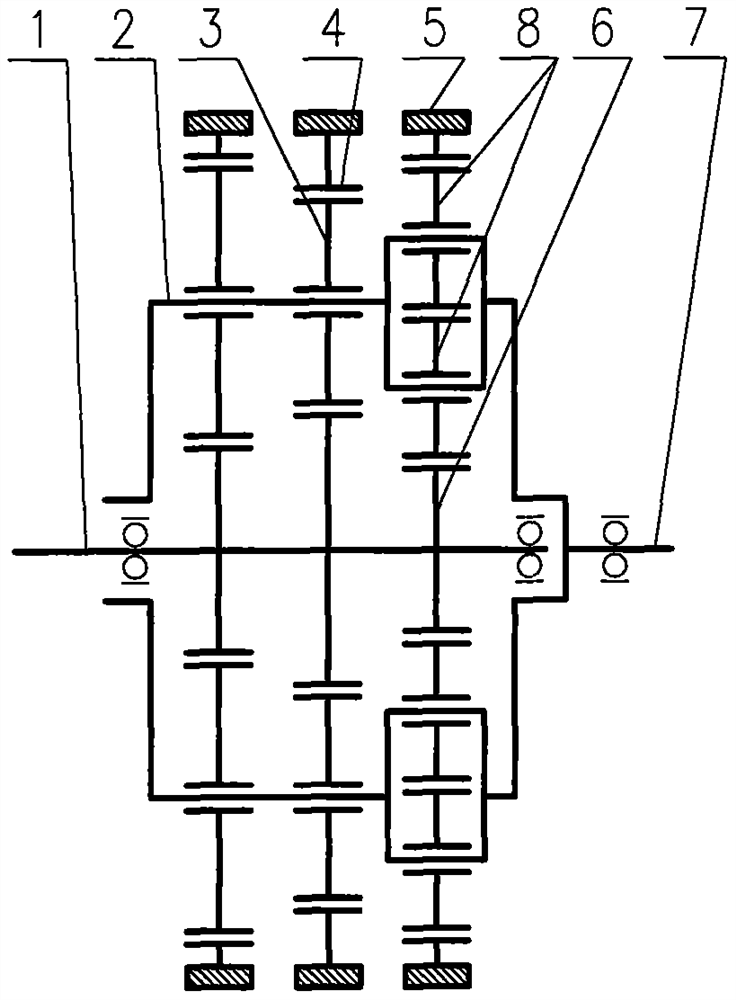

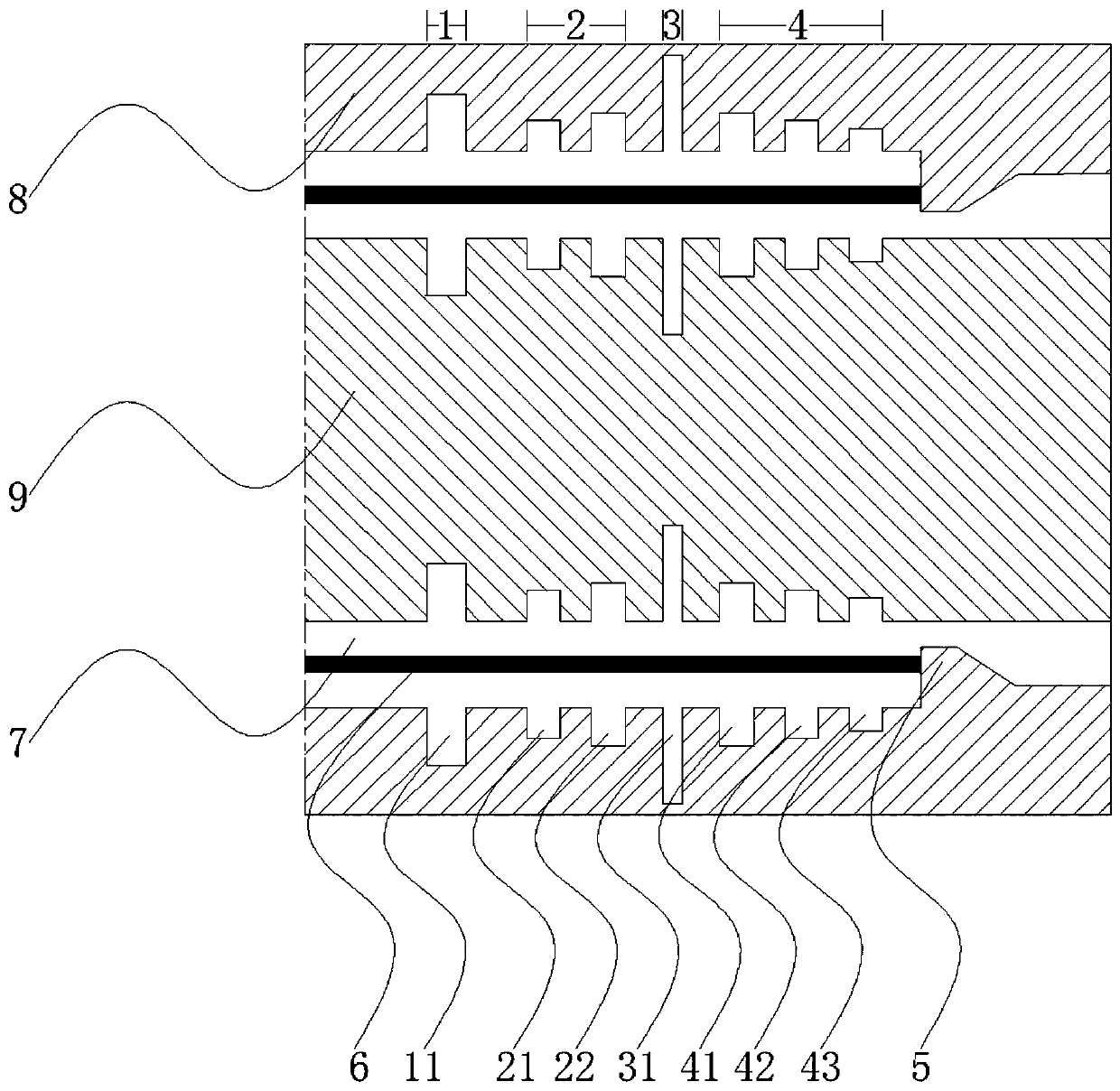

Compact type constraint number shifting planetary gear train transmission

PendingCN114076183AAxial dimensions are compactCompact layoutToothed gearingsMechanical driveGear train

The invention discloses a compact type constraint number gear shifting planetary gear train transmission, and belongs to the technical field of mechanical transmission and transmission design and manufacturing. The compact type constraint number gear shifting planetary gear train transmission comprises an input shaft, an output shaft and a plurality of planetary gear trains, and is characterized in that: a state that the degree of freedom is equal to or larger than 1 is constructed by changing the constraint number of the planetary gear trains, so that a fixed-transmission-ratio output gear or a neutral gear is obtained, when the degree of freedom of the planetary gear trains is equal to 1, a fixed speed ratio is output and corresponding gear output is formed, and when the degree of freedom is greater than 1, power cannot be output, thereby being equivalent to a neutral gear; and through parallel connection or series connection combination of the plurality of groups of planetary gear trains, gear output of different transmission ratios can be obtained. Gear shifting of the compact type constraint number gear shifting planetary gear train transmission is completed by controlling a brake, the clutch starting function is achieved, the types of parts are greatly simplified, and the gear train transmission has the advantages of being compact in structure, small in size, low in internal friction, light in weight, low in cost and the like.

Owner:王国斌

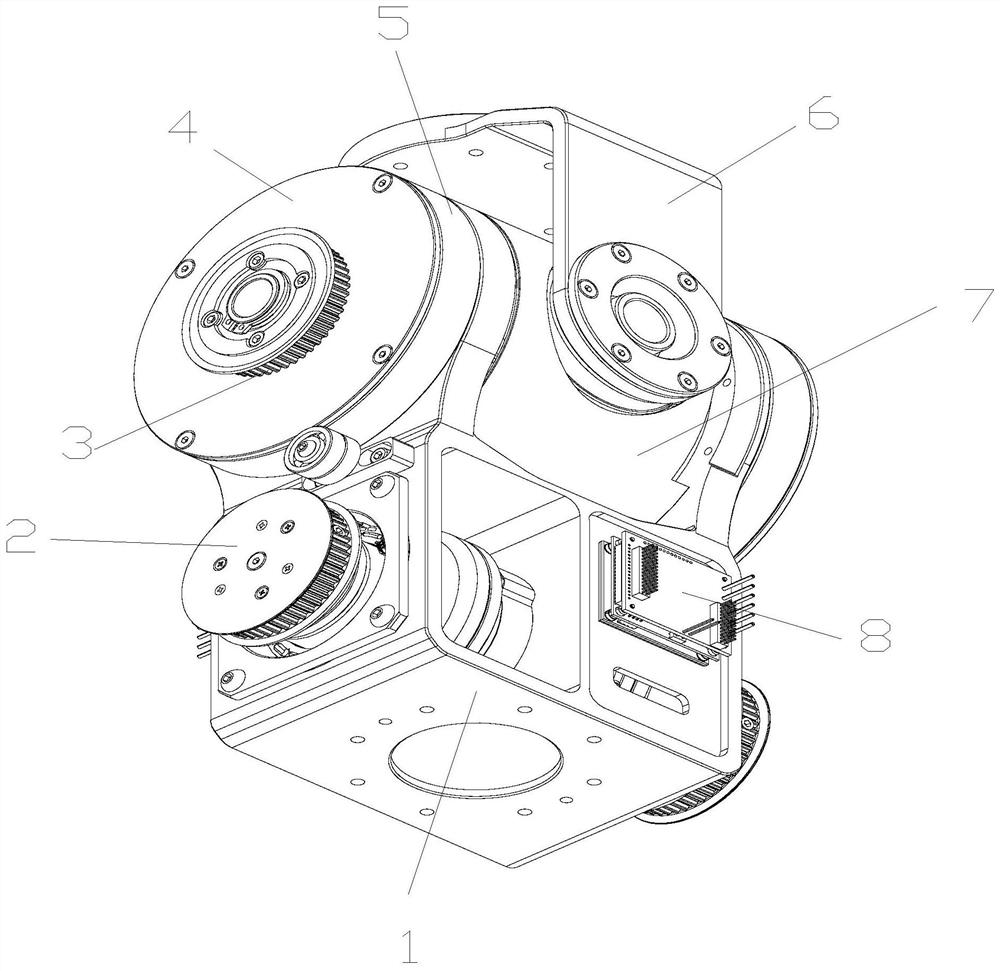

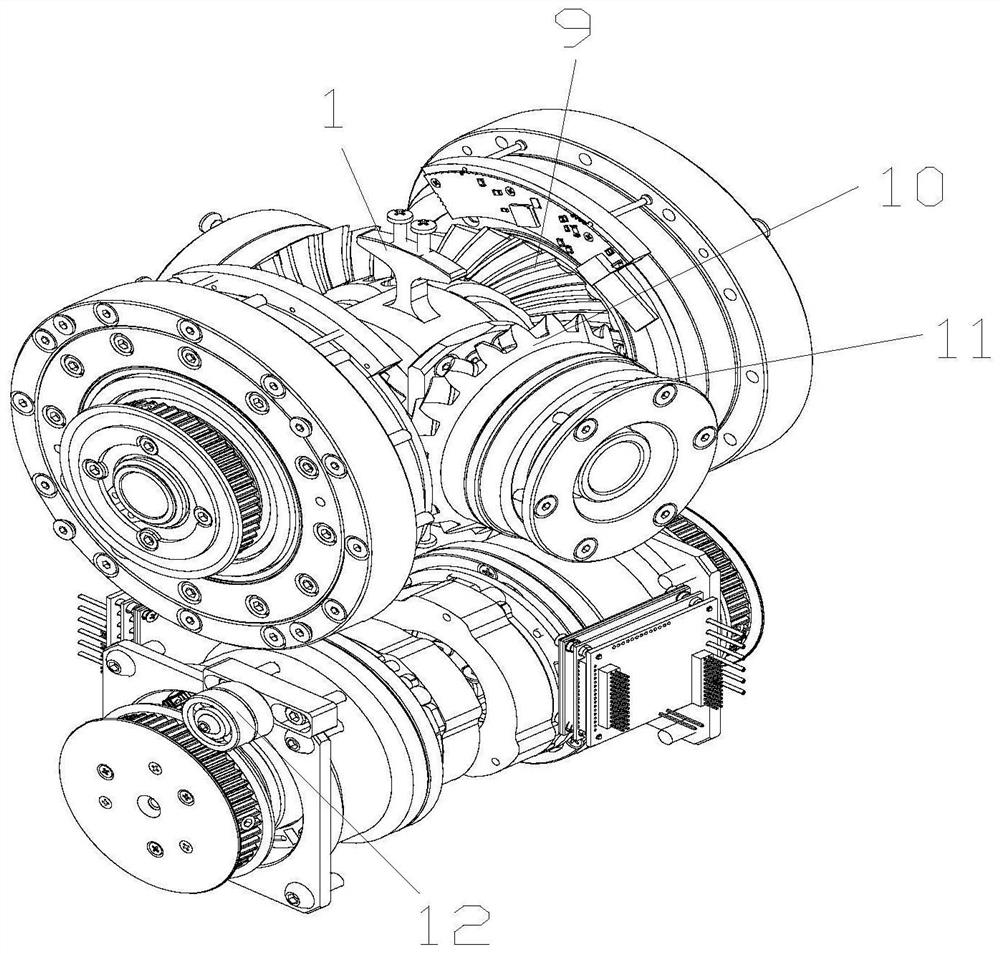

Two-degree-of-freedom differential type mechanical arm joint module

InactiveCN112894783AEasy to disassembleEasy maintenanceProgramme-controlled manipulatorJointsReduction driveControl engineering

The invention discloses a two-degree-of-freedom differential type mechanical arm joint module. The joint module comprises a first power source and a second power source, the first power source and the second power source are installed on a support and connected with a first small synchronous belt wheel and a second small synchronous belt wheel respectively, and a differential transmission mechanism is further installed on the support. A differential transmission structure comprises a driving bevel gear set, a driven bevel gear set and a cross shaft, a first large synchronizing wheel, a second large synchronizing wheel, a speed reducer and two driving bevel gears are installed on a first supporting shaft, two driven bevel gears are installed on a second supporting shaft, and the driven bevel gears are fixedly connected with connecting discs. One connecting disc is fixedly connected with one end of an output connecting rod, the other end of the output connecting rod is connected with a flange plate, and the flange plate sleeves the second supporting shaft and is tightly attached to the connecting discs. According to the scheme of a synchronous belt, the synchronous belt can eliminate gaps and is placed in front of the speed reducer, and errors can be reduced.

Owner:SHENZHEN TECH UNIV

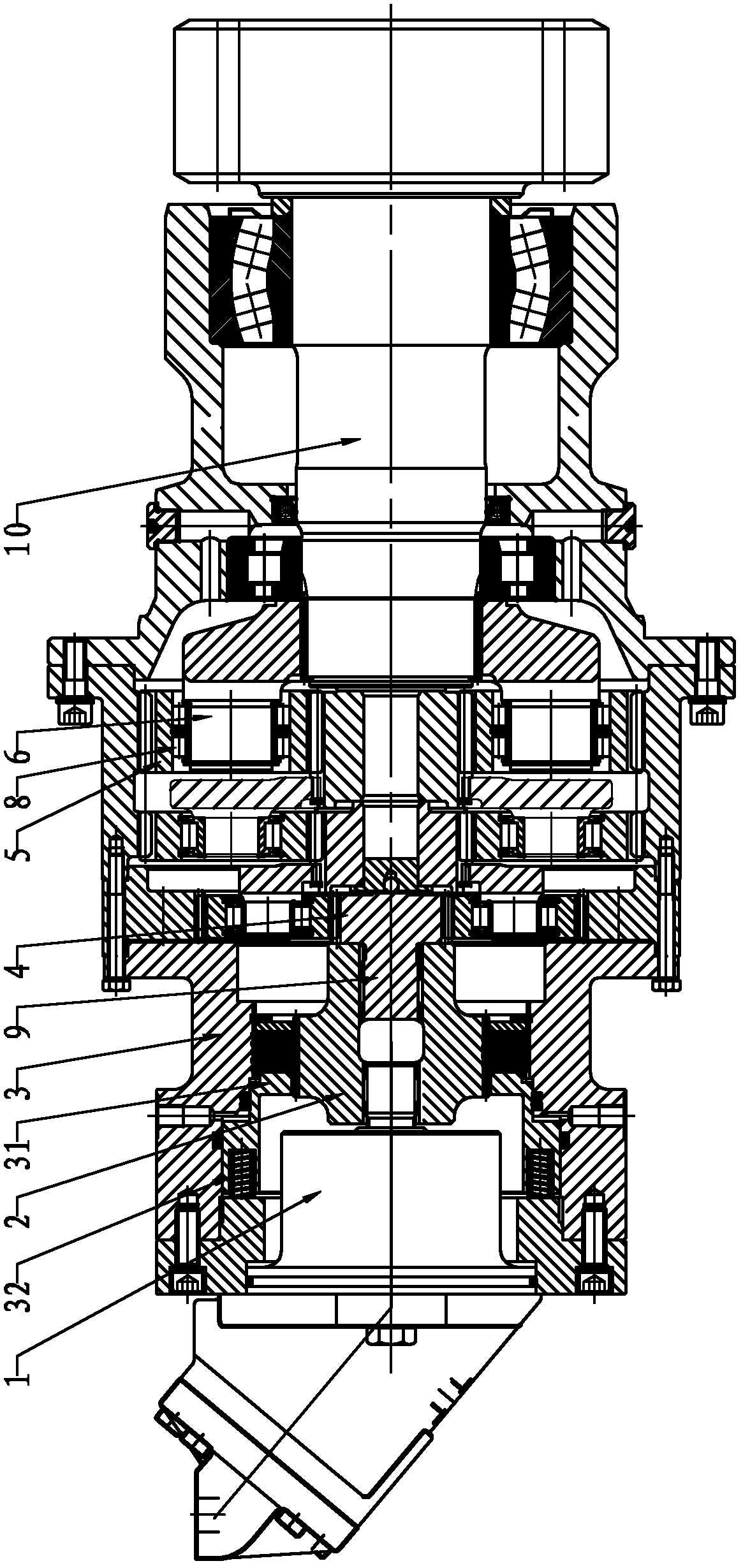

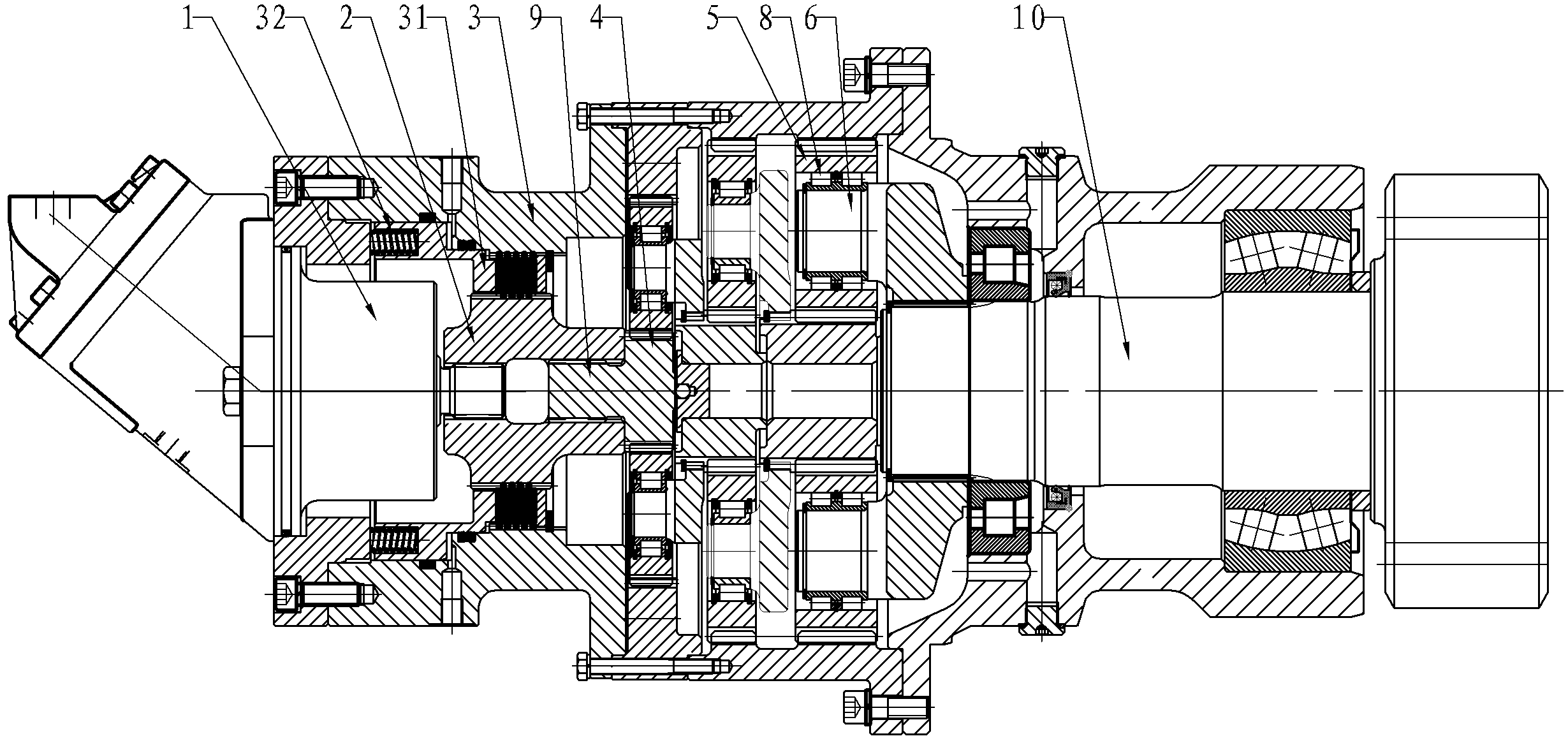

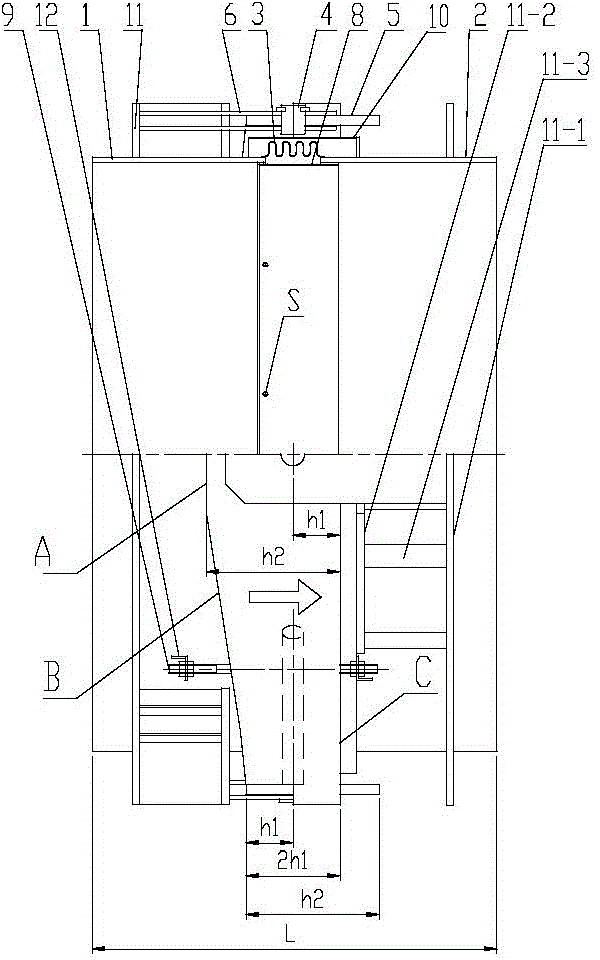

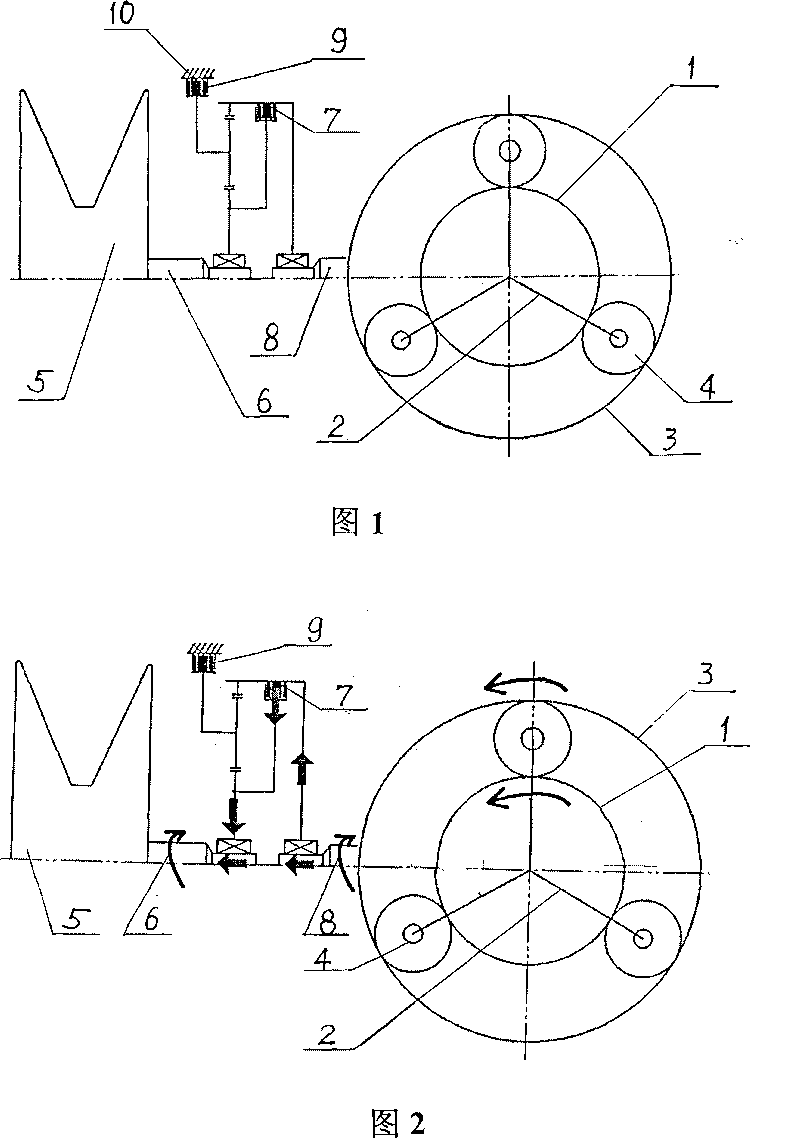

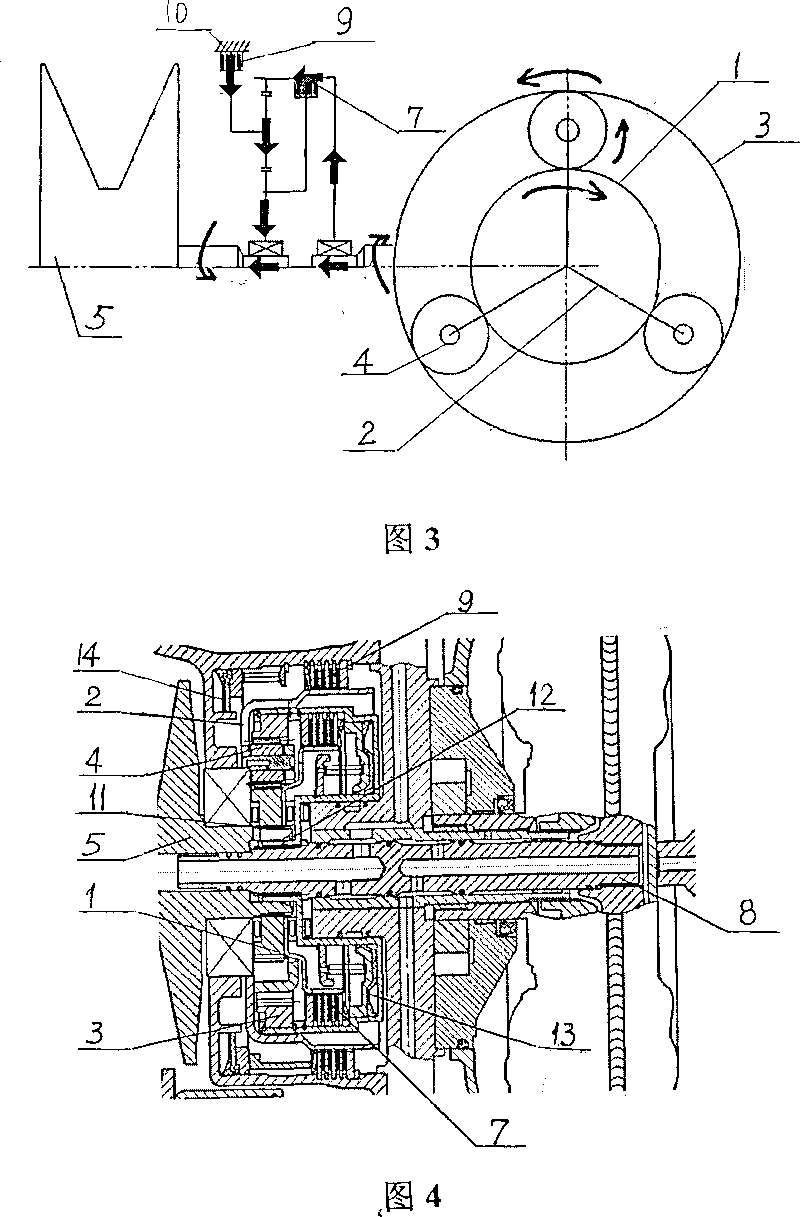

Short-shell axially compact high-speed flow distribution cycloid hydraulic motor

ActiveCN103696907AAxial dimensions are compactWork reliablyRotary piston enginesHydraulic motorEngineering

The invention relates to a short-shell axially compact high-speed flow distribution cycloid hydraulic motor, and belongs to the technical field of hydraulic transmission. The cycloid hydraulic motor comprises a shell and a flow distribution mechanism, wherein the shell is provided with a liquid inlet and a reflux inlet; a rotor of a cycloid-pin wheel set and a composite hydraulic passageway of a flow distribution support plate form the flow distribution mechanism; the rotor contacts a compensation plate; the two planes of the compensation plate form slightly concave surface structures or convex surface structures; a front bearing of an output shaft is supported by a full complement roller bearing; the axial length of the shell is short. The axial size of the motor is compact, high pressure can be born by the motor, and the motor can bear strong radial force.

Owner:ZHENJIANG DALI HYDRAULIC MOTOR

Stator core unit, stator, motor and wind turbine

ActiveCN106655564BAxial dimensions are compactImprove cohesionEngine fuctionsMagnetic circuit stationary partsEngineeringTurbine

The invention relates to a stator core unit for a stator of a motor. The stator core unit comprises first lamination stacks, second lamination stacks, first intermediate lamination stacks, second intermediate lamination stacks, first cooling liquid channels and second cooling liquid conveyer pipes, wherein various lamination stacks are adjacently engaged along the axial direction of the motor, and the first intermediate lamination stacks and the second intermediate lamination stacks are arranged between the corresponding first lamination stacks and second lamination stacks; the first intermediate lamination stacks and the second intermediate lamination stacks are provided with first cutting grooves and second cutting grooves separately, and the first cutting grooves correspondingly communicate with the second cutting grooves to form the first cooling liquid channels, so that a first cooling liquid can flow through the first cooling liquid channels; and the second cooling liquid conveyer pipes pass through the first lamination stacks, the first intermediate lamination stacks, the second intermediate lamination stacks and the second lamination stacks and a second cooling liquid flowing through the second cooling liquid conveyer pipes can carry out heat exchange with the first cooling liquid. The invention further relates to the stator for the motor, the motor and a wind generator set.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

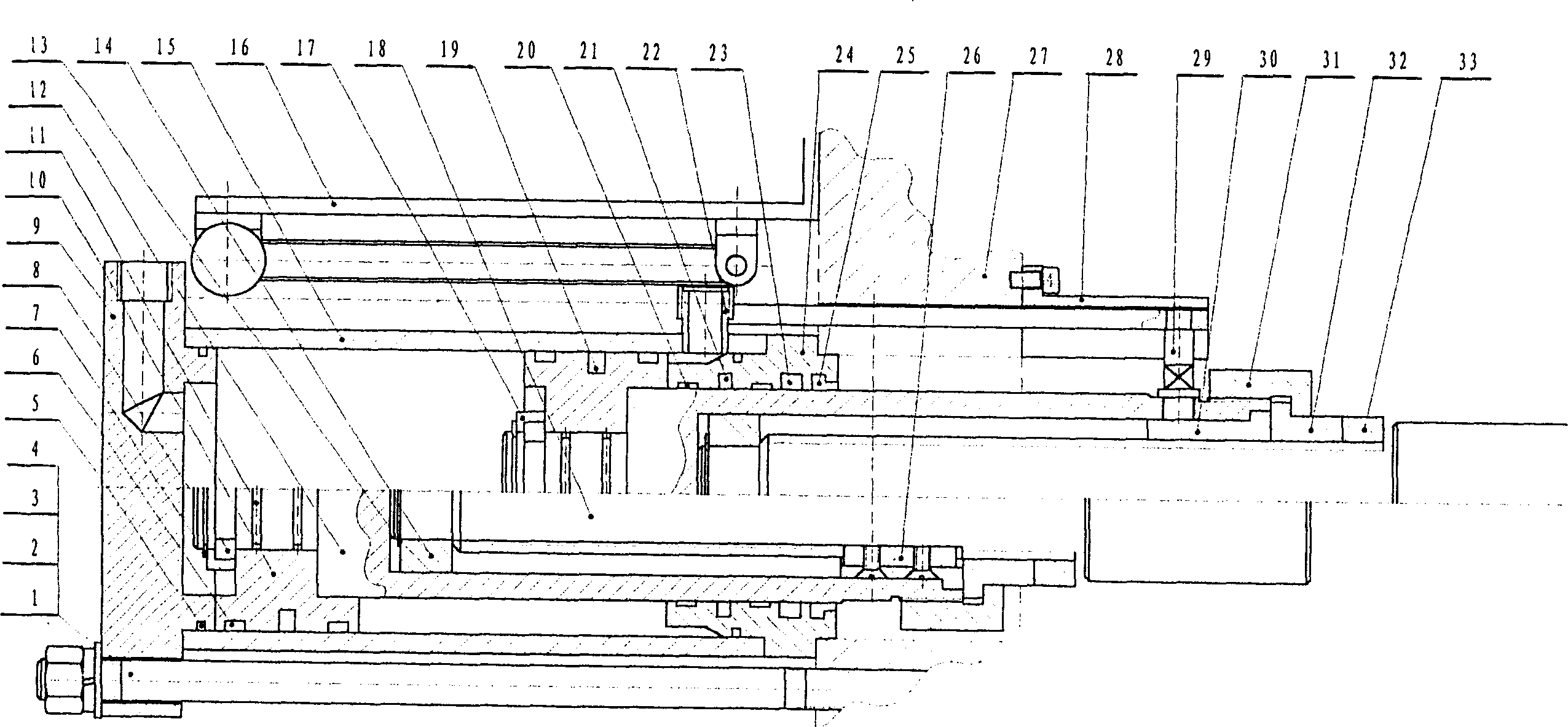

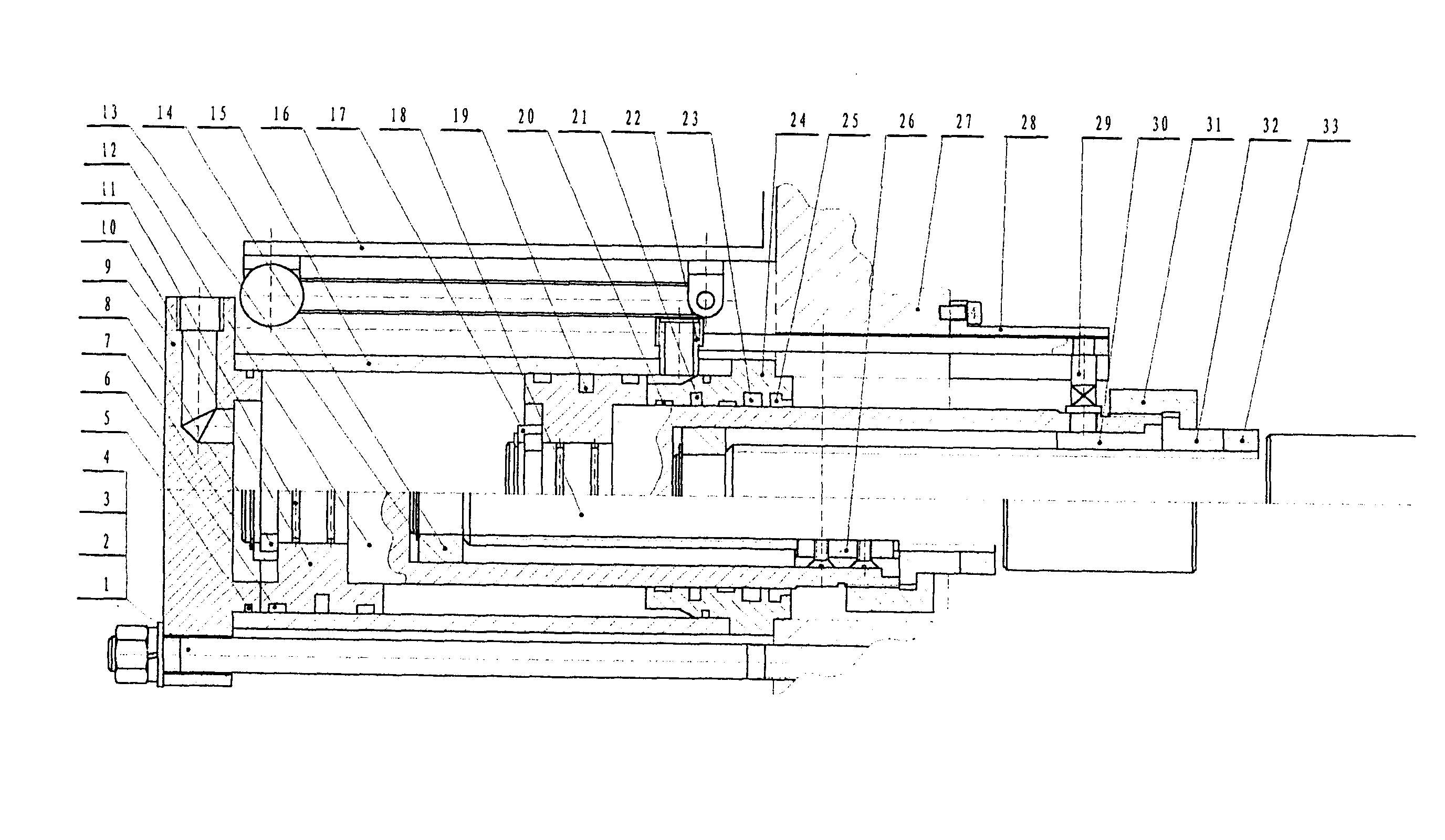

Main transmission mechanism of all-electric servo numerical control turret punch press

The invention discloses a main transmission mechanism of an all-electric servo numerical control turret punch press. The main transmission mechanism comprises a servo motor, a crankshaft, a connection rod, a sliding block, a frame and a fixing frame. The crankshaft is connected with the sliding block. The input end of the crankshaft penetrates through the frame and is fixedly connected with a motor rotor in a rigid mode. The motor rotor and a motor stator are hinged through a front bearing and a rear bearing. The motor stator is coaxially sleeved with the fixing frame, and at least one elastic assembly is arranged between the motor stator and the fixing frame. Each elastic assembly comprises multiple suspension components, first torsion components and second torsion components, wherein the first torsion components and the second torsion components are distributed in symmetry. By means of the structure, the servo motor is flexibly connected with the frame, the axial size is compact, and the load inertia of the mechanism is small. Radial deformation in any direction can happen and is not large in rigidity. When the radial deformation in any direction happens, the suspension components have an energy consumption effect. Torsion deformation around the axial direction is avoided, torsion rigidity is infinite, and the main transmission mechanism can be applied to occasions of high speed and heavy loads.

Owner:NANJING UNIV OF POSTS & TELECOMM

S-band three-cavity high-power microwave device

ActiveCN110718430ASimple structureAxial dimensions are compactTransit-tube circuit elementsTransit-tube coupling devicesResonant cavityMicrowave

The invention discloses an S-band three-cavity high-power microwave device, which comprises a circular waveguide sleeve. The circular waveguide sleeve is sequentially provided with a reflection cavity, a resonant cavity and an extraction cavity with the same inner diameter in the electron beam transmission direction, and the reflection cavity, the resonant cavity and the extraction cavity are annular grooves formed in the circular waveguide sleeve. An annular electron beam with the voltage of 400kV and the beam intensity of 7.0kA is transmitted in the microwave device under the guidance of a 0.4T axial magnetic field, and S-band high-power microwaves with the frequency of 2.4GHz are generated through radiation within one pulse time. The S-waveband three-cavity high-power microwave device has the advantages of being small in size, light and easy to adjust.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Planetary transmission swinging mechanism

The invention relates to a planetary transmission swinging mechanism which comprises a motor. The mechanism is characterized by also comprising a coupler, a multi-plate-type friction brake, a multi-stage planetary speed reducing mechanism and an output gear shaft; the motor is connected with a main shaft through the coupler; the multi-plate-type friction brake is assembled on the coupler; the main shaft is provided with a sun wheel of the multi-stage planetary speed reducing mechanism; the output end of the multi-stage planetary speed reducing mechanism is a planetary frame; the planetary frame is connected with an output gear shaft through a spline; the planetary frame of the multi-stage planetary speed reducing mechanism is provided with a suspending arm; and the suspending arm is provided with a planetary wheel through an outer-ring-free bearing. The brake of a walking mechanism is reliable by adopting the multi-plate-type friction brake; a full-floating structure is adopted for the sun wheel and the planetary wheel, thus the loadings of the two wheels are uniform; the suspending arm structure is adopted for the planetary frame, thus the axial size of the swing mechanism is compact; and the outer-ring-free structure is adopted for the planetary wheel bearing, thus the radial size of the swinging mechanism is smaller.

Owner:康少松

Coaxial high-frequency high-power microwave device

ActiveCN110718425AAffect outputIncrease beam energyTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses a coaxial high-frequency high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. A high-frequency structure is arranged in the circular waveguide sleeve. The high-frequency structure is sequentially provided with a reflection region, a beam current pre-modulation region, a phase modulation region and a beam wave conversion region which are coaxial in the electron beam transmission direction. The reflection region, the beam pre-modulation region, the phase modulation region and the beam-wave conversion region are respectively provided with annular groove-shaped cavities at the corresponding positions of the sleeve wall of the circular waveguide sleeve and the inner conductor, and thecavities at the corresponding positions of the sleeve wall of the circular waveguide sleeve and the inner conductor form a reflection cavity, beam pre-modulation cavities a phase modulation cavity andbeam-wave conversion cavities. An annular collector protruding inwards in the radial direction is arranged behind the beam wave conversion region. An annular electron beam with the voltage of 400kV and the current of 9.0kA is transmitted in the microwave device under the guidance of an axial magnetic field with the magnetic field intensity of 1.2T, and 70GHz high-frequency high-power microwaves are generated. By adopting the coaxial high-frequency high-power microwave device, high-frequency high-power microwaves can be generated, and the microwave generation efficiency can be improved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Flexible transmission connecting device

PendingCN110410427ADoes not affect normal useAvoid shock and vibrationYielding couplingWorking environmentLubrication

The invention discloses a flexible transmission connecting device comprising a first connecting disk, a second connecting disk and connecting pieces; the first connecting disk and the second connecting disk are arranged oppositely, and the connecting pieces are flexible connecting pieces; the first ends of the connecting pieces are fixedly installed on the first connecting disk, and the second ends of the connecting pieces are fixedly installed on the second connecting disk. According to the flexible transmission connecting device, the deviation of two axes between a prime mover and load equipment can be compensated effectively, and the maximum deviation can be 10 mm; meanwhile, the problem of vibration impact generated by transmission can be further solved, and the device has the advantages of compact axial dimensions, no need of lubrication, no noise, large transmitted torque, low manufacturing cost and simple installation and maintenance; the working procedures of correction, regulation and the like during installation of a rigid transmission connecting device are avoided, and the flexible transmission connecting device is especially suitable for transmission connecting betweentwo shafts which are not concentric under the condition that the prime mover and the load equipment are installed in a floating mode or one ends of the prime mover and the load equipment are installedin the floating mode and the other ends of the prime mover and the load equipment are installed fixedly; and the use of the transmission connecting device is not affected in bad working environment.

Owner:ZHAOYUAN HUAFENG MACHINERY

Flywheel device for prime mover

InactiveUS20020170380A1Reduce variationQuality improvementRotating vibration suppressionFriction clutchesInertial massAutomatic transmission

There is provided a flywheel device for a prime mover, which can be made compact in the axial size thereof and have an effectively increased inertial mass. The flywheel device is comprised of a drive plate and a mass ring. The drive plate has an annular projection and is attached to a crankshaft in a manner concentric with the crankshaft. The mass ring has an annular recess and is concentrically attached to the drive plate by the annular recess being fitted on the annular projection of the drive plate. The flywheel device transmits torque from an engine as the prime mover to the input shaft of an automatic transmission while reducing variation in the torque.

Owner:HONDA MOTOR CO LTD

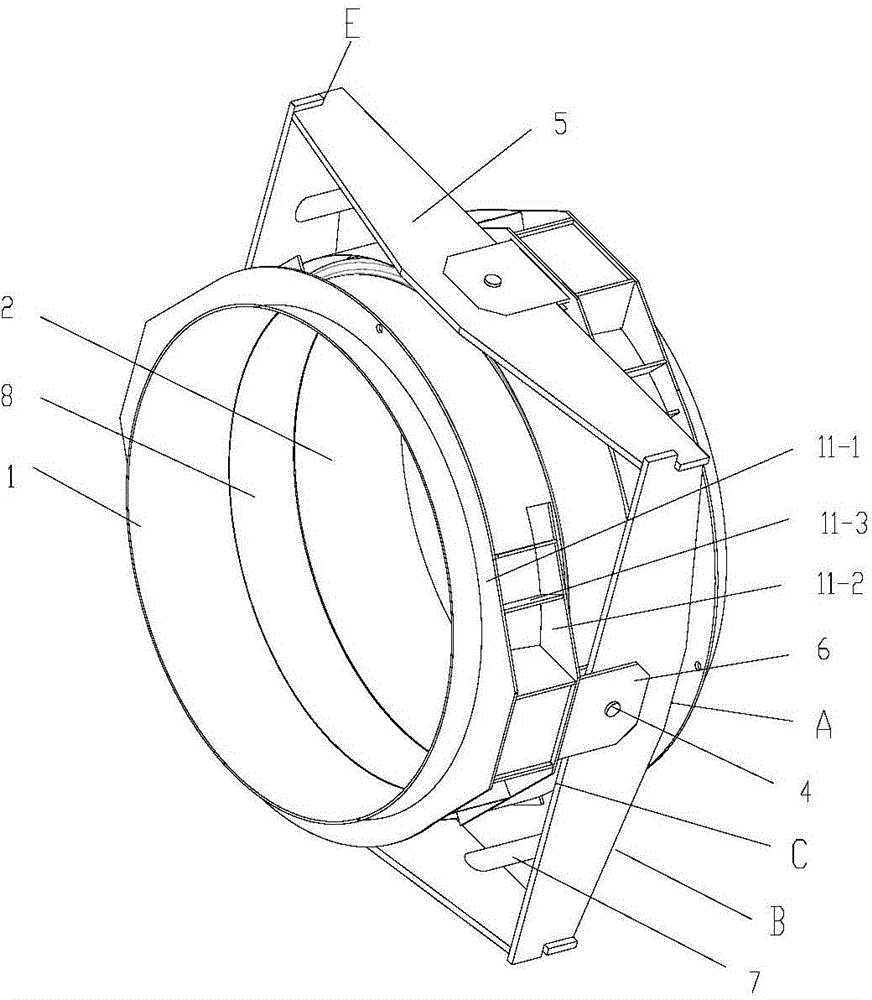

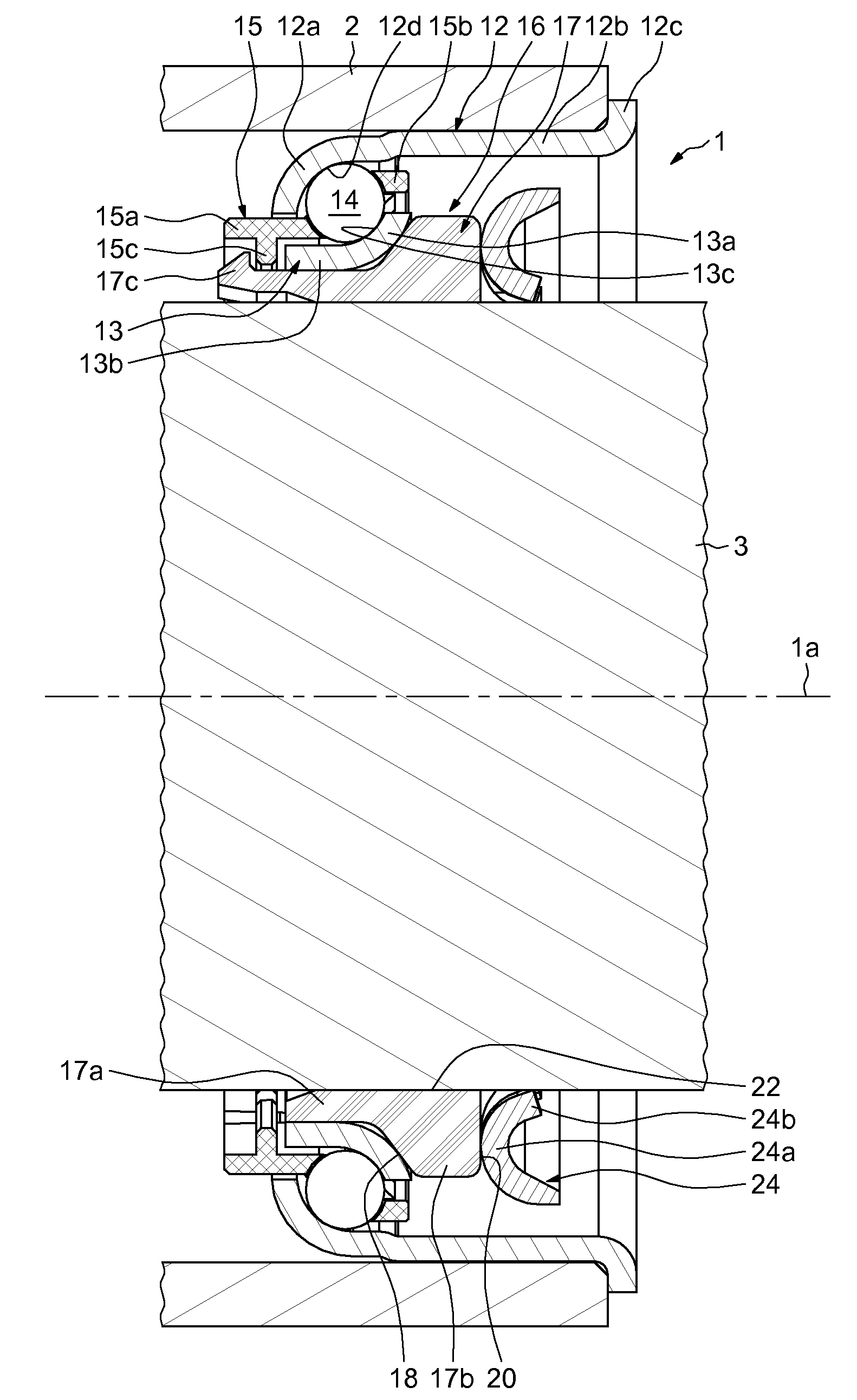

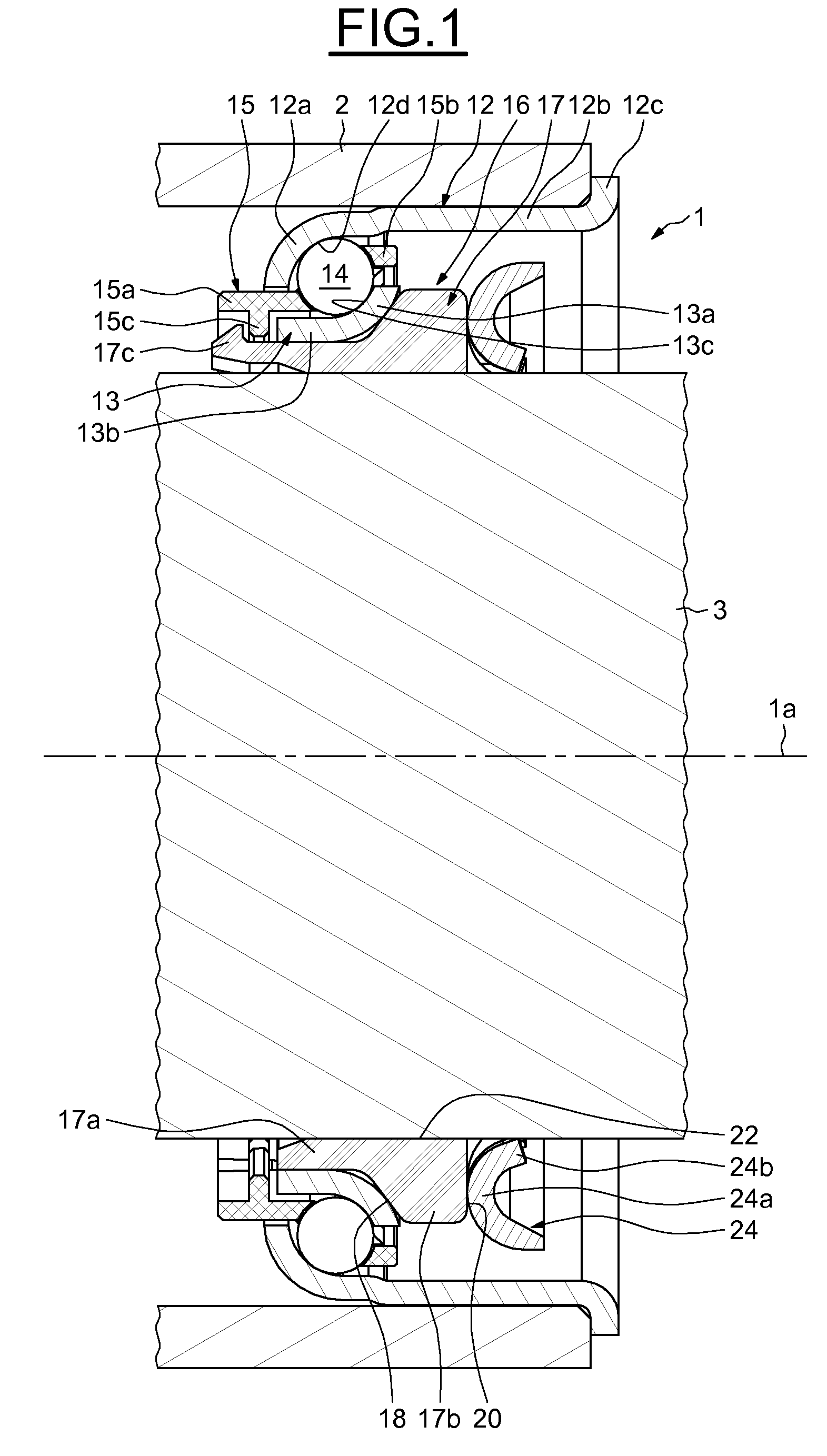

Rolling bearing device, in particular for a steering column

ActiveUS20150010259A1Easy to manufactureEasy to mountMetal-working apparatusBall bearingsElastomerSteering column

A rolling bearing device for a steering column having an outer ring, an inner ring, at least one row of rolling elements arranged between the rings, a sleeve mounted in the bore of the inner ring and coming to bear axially against the ring is provided. The sleeve provides a bore designed to come into radial contact with a shaft, and a member for the axial retention of the sleeve including retention means designed to engage with the shaft. The sleeve having at least one elastic body at least partially delimiting the bore. The axial retention member mounted to bear axially directly against the sleeve on the opposite side from the inner ring.

Owner:AB SKF

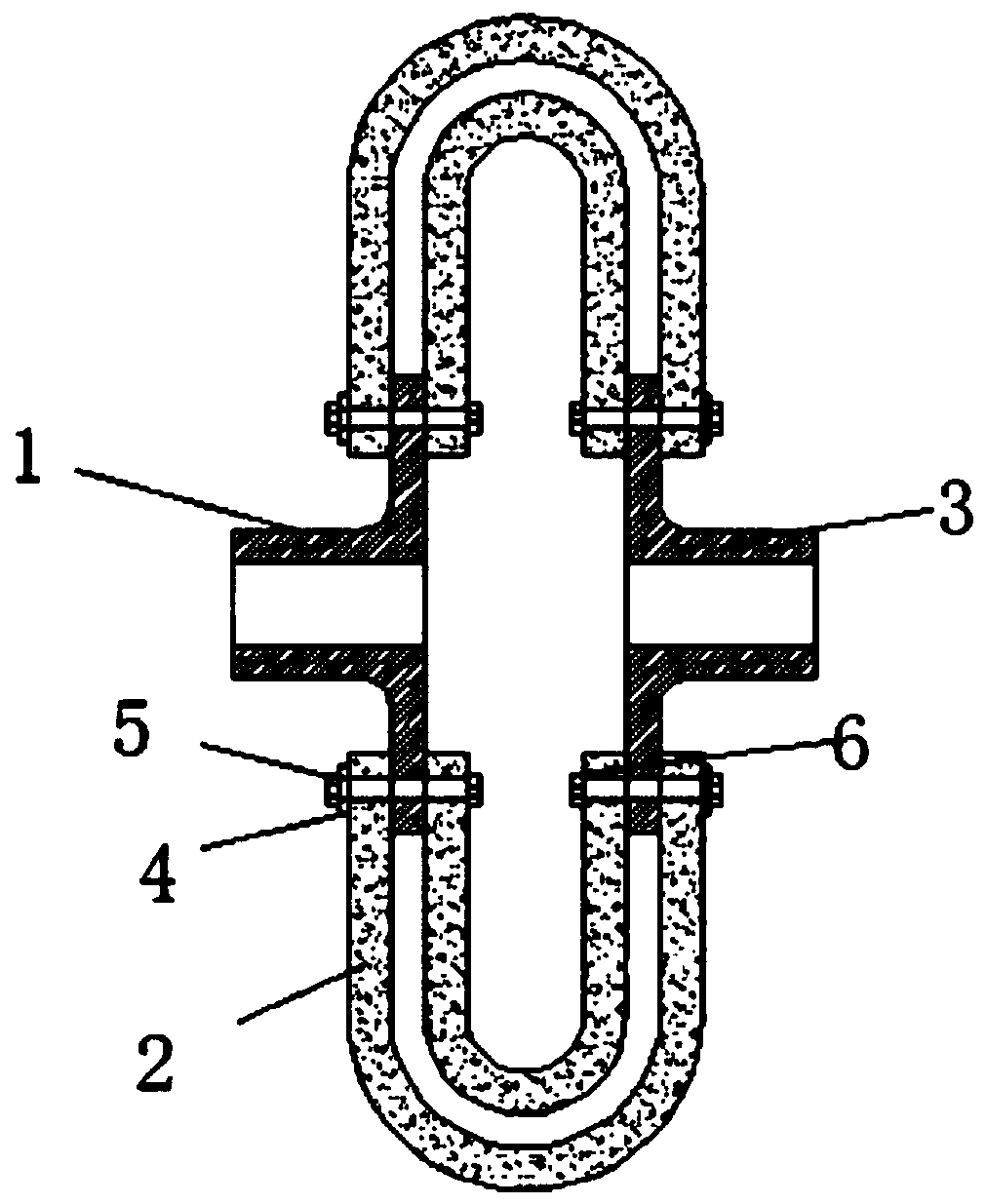

Universal hinge-type expansion joint

ActiveCN104089138AShorten the axial lengthAxial dimensions are compactPipeline expansion-compensationAdjustable jointsHinge angleEngineering

The invention belongs to the technical field of fluid delivery pipelines and relates to a universal hinge-type expansion joint which comprises a first connecting pipe, a second connecting pipe and a rectangular universal ring. The first connecting pipe and the second connecting pipe are in abutted connection through a corrugated pipe, each of the first connecting pipe and the second connecting pipe is provided with a pair of hinge seats formed by radial extending of an outer circle, and the hinge seats axially extend towards the direction of the connecting pipe adjacent to the hinge seats to form hinge plates; the rectangular universal ring is formed by surrounding of four polygonal plates with hinge holes in the middle, each polygonal plate has a long straight edge, a short straight edge, end portions positioned at two ends of the long straight edge, and a gradually-narrowing bevel edge transiting from the short straight edge to the end portions, the hinge holes are positioned in middle sections of the end portions in the width direction, and the end portions of adjacent polygonal plates are welded at positions opposite to the short straight edges; the hinge seats of the first connecting pipe and the second connecting pipe are angularly staggered by 90 degrees respectively and are close to the long straight edges of the corresponding polygonal plates, and the hinge plates are hinged to the hinge holes of the corresponding polygonal plates. The universal hinge-type expansion joint has the outstanding advantages of high load-bearing capacity in each direction, flexibility in rotating, long fatigue life, controllability in angular displacement and compact structure.

Owner:AEROSUN CORP

Rolling bearing device, in particular for a steering column

ActiveUS9194423B2Easy to manufactureEasy to mountBall bearingsSteering columnsElastomerSteering column

A rolling bearing device for a steering column includes an outer ring, an inner ring, at least one row of rolling elements arranged between the rings, and a sleeve mounted in the bore of the inner ring and coming to bear axially against the ring. The sleeve provides a bore designed to come into radial contact with a shaft, and a member for the axial retention of the sleeve that is designed to engage with the shaft. The sleeve has at least one elastic body at least partially delimiting the bore. The axial retention member is mounted to bear axially directly against the sleeve on the opposite side from the inner ring.

Owner:AB SKF

Flywheel unit of prime motor

InactiveCN1226541CIncrease configuration freedomReduce weightRotating vibration suppressionFlywheelsInertial massAutomatic transmission

There is provided a flywheel device for a prime mover, which can be made compact in the axial size thereof and have an effectively increased inertial mass. The flywheel device is comprised of a drive plate and a mass ring. The drive plate has an annular projection and is attached to a crankshaft in a manner concentric with the crankshaft. The mass ring has an annular recess and is concentrically attached to the drive plate by the annular recess being fitted on the annular projection of the drive plate. The flywheel device transmits torque from an engine as the prime mover to the input shaft of an automatic transmission while reducing variation in the torque.

Owner:HONDA MOTOR CO LTD

Series extended-range electric vehicle power system and its control method

ActiveCN105946600BBattery does not dropPrevent slippingHybrid vehiclesInternal combustion piston enginesPower batteryReduction drive

The invention provides a series connection range extending type electric automobile power system. The system is characterized by comprising an engine, a first motor, a second motor, a first clutch, a second clutch, a first inverter, a second inverter and a power battery; the engine is connected with the first clutch through a first transmission shaft; the first clutch is connected with the first motor through a second transmission shaft; the first motor is connected with the second clutch through a third transmission shaft; the second clutch outputs power to front wheels of an automobile through a main speed reducer and a differential mechanism of a front axle of the automobile; the second motor outputs power to rear wheels of the automobile through a main speed reducer and a differential mechanism of a rear axle of the automobile; and the power battery is connected with the first motor through the first inverter and connected with the second motor through the second inverter.

Owner:CHINA FIRST AUTOMOBILE

Single planet wheel reversing mechanism

ActiveCN101245832BAxial dimensions are compactAvoid dangerToothed gearingsAutomatic transmissionEngineering

The invention provides a single planetary wheel type steering mechanism. The planetary mechanism is compsed of a sun wheel, a planetary frame, a gear ring and three planetary wheel groups. The sun wheel is fixedly connected with a stepless automatic transmission drive belt pulley shaft. The sun wheel is connected with an advance clutch internal tooth friction sheet. An advance clutch external tooth friction sheet is fixedly connected with an input shaft and a gear ring. The planetary frame is connected with the internal tooth friction sheet of a backing brake. The external tooth friction sheet of the backing brake is fixedly connected with the stepless automatic transmission shell. The dual planetary wheel type steering mechanism has compact structure and flexible and convenient operation, realizes automation easily, avoids the gear-strike phenomenon, works stably, and runs reliably.

Owner:HUNAN JIANGLU & RONGDA VEHICLE TRANSMISSION LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com